The power of modern industry often depends on its components among these seamless pipes are primarily important. They are valued for their great strength, long life and crucially their natural waterproof design. For those in oil and gas, construction, power generation, or chemical processing, understanding what a seamless pipe is, how it’s made and who makes it in India is important for smart buying and use.

This detailed seamless pipe guide for 2025 aims to explain the seamless pipe meaning, list its types, detail the seamless pipe manufacturing process, show seamless pipe size charts and name leading Indian makers. It also points to tools like seamless pipe weight calculators to help choose these key products well.

What is a Seamless Pipe?

So, what is a seamless pipe really? A seamless pipe is best seen as a round steel tube made in one continuous piece, with no welded seams running along its length or around it. This main feature sets the basic seamless pipe meaning. Not like welded pipes that are made by rolling and then welding a steel plate or coil seamless pipes start as a solid steel block (a billet). This starting method gives them better structural strength and consistent quality throughout—a key difference.

This lack of seams makes them a very good fit for uses involving:

- Exposure to high internal or external pressures

- Operation at high temperatures

- Carrying corrosive or dangerous materials

- Jobs needing very precise engineering

Why Seamless Pipes? Key Benefits

Using seamless pipes offers several clear pluses compared to welded types:

Top Strength: Their solid build, without welds that could be weak spots, makes them naturally more reliable for tough high-pressure systems.

Better Corrosion Resistance: They resist corrosive things well, a feature very clear in stainless steel seamless pipe (often called ss seamless pipe), giving better material life in harsh places.

High Dimensional Accuracy: How they are made allows for tight size control, making them great for uses where exact size is vital for performance and fit.

Smooth Inner Surface: A steady inside bore helps fluids or gases flow better by cutting down on drag and the chance of blockages.

Longer Service Life: Because they are made the same all through and stress is spread evenly, seamless pipes usually last a lot longer.

Seamless Pipe Manufacturing Process

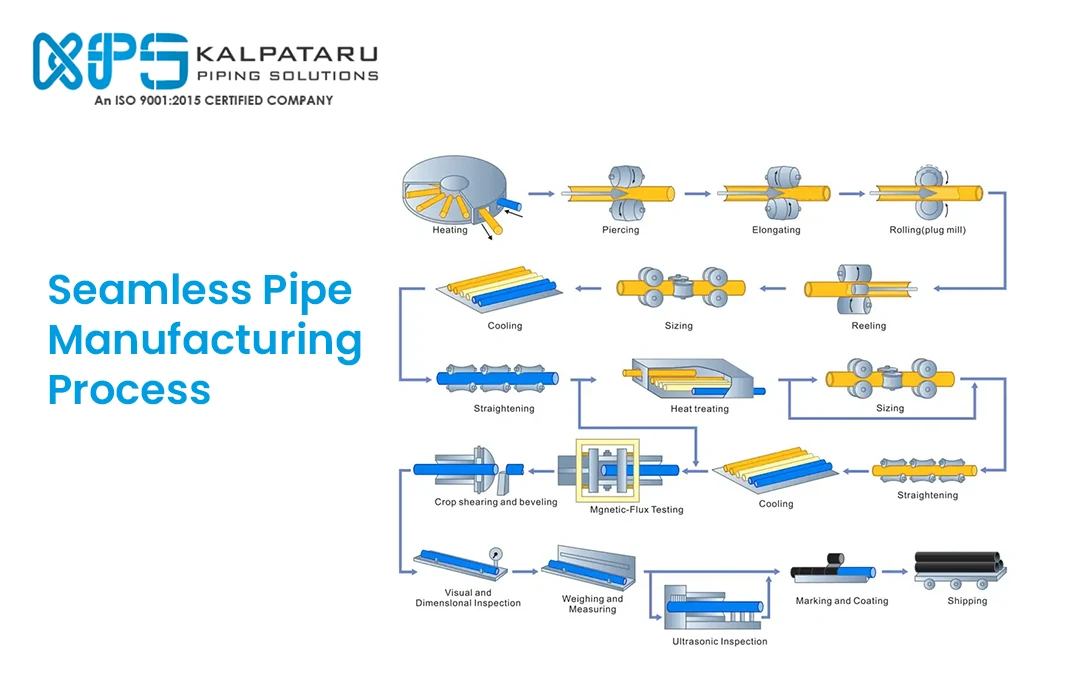

Knowing the seamless pipe manufacturing process is key to seeing why they are so reliable and strong. The usual steps in seamless pipe manufacturing are:

Billet Preparation: The process starts by carefully picking a solid, round steel billet. This billet is then heated to high temperatures to make it soft enough for the next shaping steps.

Piercing: Once hot enough, the billet goes through a vital piercing step. This is usually done with machines like a rotary piercer or mandrel mill, which cleverly turn the solid billet into a hollow tube—importantly, without any welding.

Elongation: After piercing, the new hollow billet is rolled and stretched. This step is key for getting the final length and diameter, and crucially, it sets the pipe’s wall thickness and inside diameter.

Sizing: The pipes then go through a careful sizing step. This ensures each pipe has the exact same size and shape along its whole length, an important feature for how they will be used and fit with other parts.

Heat Treatment: Next, the seamless pipe gets specific heat treatments. Things like annealing are used to modify and elevate its mechanical characteristics like tensile strength, hardness and ability to bend without breaking making it tougher and perform better.

Finishing and Inspection: After sizing and heat treatment, the pipe is cut to the needed lengths. It then gets a full check-up, which might include surface treatments (like pickling or polishing, if needed for the job), and tough tests to find and get rid of any flaws, making sure it meets strict quality rules.

Kalpataru Piping is serious about making top-quality seamless pipes. Our seamless pipe manufacturing way includes strict quality checks at every point, ensuring each pipe meets, and often beats, tough global standards.

Types of Seamless Pipes

Carbon Steel Seamless Pipe

Stainless Steel Seamless Pipe (SS Seamless Pipe)

Alloy Steel Seamless Pipe

Mild Steel Seamless Pipe

Nickel Alloy Seamless Pipe

Copper Seamless Pipe

Seamless Pipe Size Chart

Getting the size right is a must when picking the best seamless pipe for any project.For a quick look, here’s a simple seamless pipe size chart. Don’t forget, special sizes can often be made if your project has unique needs:

Instructions for Developer: This goes in a table

Nominal Pipe Size (NPS) Outer Diameter (OD) Wall Thickness (SCH 40) Approx. Weight ( kg/m )

1/2 inch 21.3 mm 2.77 mm 1.27 kg

1 inch 33.4 mm 3.38 mm 2.75 kg

2 inch 60.3 mm 3.91 mm 5.44 kg

4 inch 114.3 mm 6.02 mm 15.54 kg

6 inch 168.3 mm 7.11 mm 28.26 kg

For exact figures, especially when planning shipping, moving or checking loads, our seamless pipe weight calculator is a very helpful tool. It helps users find correct weights based on specific materials and detailed sizes.

Applications of Seamless Pipes

The many uses of seamless pipes let them do vital, often crucial, jobs across lots of industries and tasks:

Oil & Gas Industry: In this tough field, seamless pipes are vital for drilling rigs, pipelines and refineries. Their natural high strength and good rust resistance are key in these often harsh places.

Power Generation Plants: They are perfect for key parts like high-power boiler tubes, superheaters and heat exchangers, where being totally reliable under great heat and pressure is a must for safe, good running.

Automotive Sector: In car making, seamless pipes are used in important engine parts, hydraulic systems, and exhaust lines, adding a lot to both how well cars run and their safety.

Chemical & Petrochemical Operations: Stainless steel seamless pipes are especially liked here for being very good at resisting acids and harsh chemicals, making them the best pick for complex chemical plants.

Construction & Infrastructure Projects: They give needed structural strength for building frames, foundations, scaffolds and important water systems that are key for city and industry growth.

How to Choose the Right Seamless Pipe?

Picking the best seamless pipe for your job needs careful thought about several key things to make sure it works well and lasts long:

Material Type: Your pick here should be based on where it will be used, thinking about things like contact with corrosive stuff or long times at high heat.

Size & Wall Thickness: Using a good seamless pipe size chart or an exact seamless pipe weight calculator is a smart move for getting sizes right.

Industry Standards: Making sure the pipe meets the right industry rules (like ASTM, ASME, DIN) is very important. This ensures quality, safety, and that it will work with your system.

Specific Application: Don’t forget, different kinds and types of seamless pipes are made for different jobs, from safely moving high-pressure liquids to giving key structural support in heavy-load spots.

Supplier Reputation: Always get your seamless pipes from known, trusted makers or sellers who have a good history of quality products and dependable service.

Top Seamless Pipe Manufacturer in India (2025)

India has some of the world’s top makers of seamless pipes. When looking at who to buy from in 2025, these well-known makers should be looked at closely:

Kalpataru Piping Solutions is known as one of India’s fastest-growing sellers and exporters, focusing on stainless steel seamless pipes, alloy pipes and carbon steel pipes.Our company’s good name is built on always providing quality, being flexible with custom orders, and sticking to on-time delivery.

Key Products:

- SS seamless pipe (including common grades like 304, 316, 310, and others).

- A full selection of Alloy & carbon steel seamless pipes.

- Special Nickel alloy seamless pipes for tough jobs.

- Precisely made Heat exchanger tubes.

- All custom lengths & a wide range of wall thicknesses are available to fit specific project needs.

Future of Seamless Pipes in India

Looking to 2025 and after, India’s building, energy, and industrial areas are set for big growth. This growth means the need for top-quality seamless pipes will naturally go up. Government plans like ‘Make in India’, ‘Digital India’, and ‘Smart Cities’ also help local seamless pipe manufacturing, while selling to other countries also looks good.

New ideas in metals, better thermal treatment and very exact engineering are making seamless pipes work better, last longer, and cost less than before.

Conclusion

A good grasp of what a seamless pipe, its kinds, sizes, and the seamless pipe manufacturing process, helps industries pick the best product. This smart choice makes sure work is safe and runs well. Seamless pipes are more than just parts; they are the strong backbone of key modern systems, ensuring long life, safety, and top performance, especially in tough spots.

So, if your project needs top-quality, certified, and custom-sized seamless pipes, please think of Kalpataru Piping. We try to be India’s most trusted partner for your many industrial piping needs.

Get in Touch

For any questions, to ask for prices, or to get expert advice about your specific seamless pipe needs, please feel free to check our website at Kalpataru Piping or call our expert sales team directly.