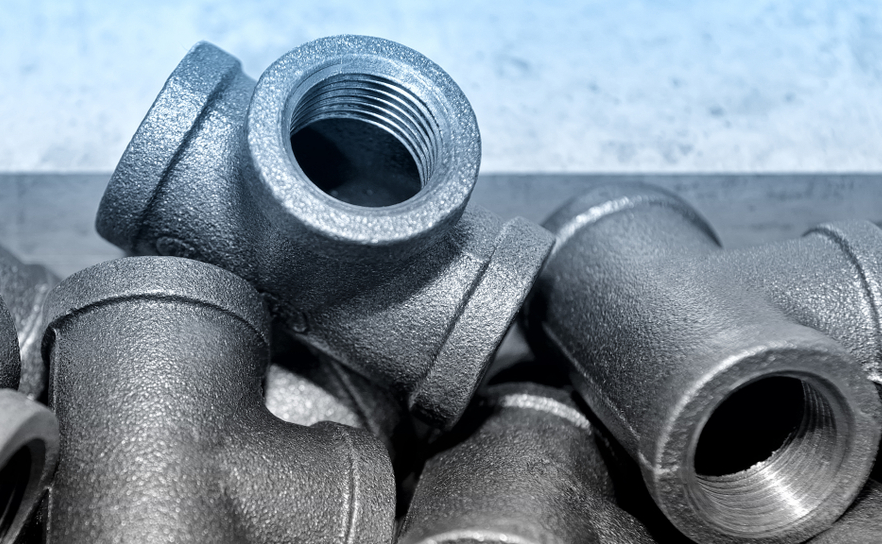

What is a threaded joint fitting that has been forged?

Forged Threaded 45-degree Elbows are said to be one of the oldest types of forged fittings that have been used for a long time. When pipes have a smaller bore and diameter, threaded fittings are used to connect them. A pipe with a threaded fitting should have a nominal diameter of around 2 NPS or less.

Why would you want to use threaded forged fittings?

When a Forged Threaded 45-degree Elbow is used, the number of equipment types can be cut down.

By using threaded fittings, the number of joints can be cut down.

A male or female thread makes it easy to connect many different kinds of equipment.

A threaded fitting doesn’t need any special tools to be put in place.

Here are a few important things to remember when putting in forged threaded fittings:

Use a male PVC thread in a female PVC thread at all times. If you did this process backward, the pipe might break.

The thread tape should always be wound in the same direction as the thread. This ensures a safe and durable seal.

Don’t make threads out of hemp. When hemp is put in water, it grows bigger. The pipe could break if this keeps happening.

How forged threaded fittings are used

Always keep in mind that forged threaded fittings can’t be used in high-pressure situations.

So, here are some of the most common ways that Forged threaded fittings are used:

Cooling system for water distribution

Fire hydrants and fire safety, among other things.

Let’s look at a few different kinds of threaded fittings:

There are two main types of elbow fittings: threaded and plain.

90-degree elbow with threads

45-degree elbow with threads

Pipes that change direction by 90 degrees use threaded 90-degree elbows.

Pipes that change direction by 45 degrees need threaded 45-degree elbows.

Threaded Tee Connection Fitting: This fitting turns the main pipe into a 90-degree branch.

There are two kinds of tee fittings.

Equal tee: Both the Branch pipe and the Main pipe are the same size.

Reducing tee: The branch pipe is smaller than the main pipe.

A threaded cross fitting is a joint that connects in four different ways. This fitting has one entry point and three exit points. The flow of things goes in three different directions. Most cross fittings have female threads that make sure connections are secure.

Threaded Coupling Fittings: There are both full and half couplings for these fittings.

Caps with threads: Caps with threads are used to seal the ends of pipes.

Threaded Plug: A threaded plug is used to seal a joint or block it from being seen.

There are three kinds of plugs with threads:

Square plugs with threads

Plugs with a hexagonal head

Plugs with round tops

Threaded Bushing: These fittings have a head in the shape of a hex or hexagon, and they are used to connect different-sized threaded pipes.

Threaded Union: A threaded union is made up of three parts that are all connected to each other. There are mainly two kinds of threaded unions:

Male to Female

Female to Female

A lug nut holds the pieces of equipment together.

Read More :

Differences Between Copper and Beryllium Copper : Copper is a fragile metal, and beryllium copper is used for its superior quality. Beryllium copper gets the highest quality rating out of any copper compound.

What Can The SS 904L Tube Do To Reduce Air Pollution? : This high-alloy austenitic stainless steel tube is a popular choice because it works well in our climate and can also be used in harsh environments.