Introduction

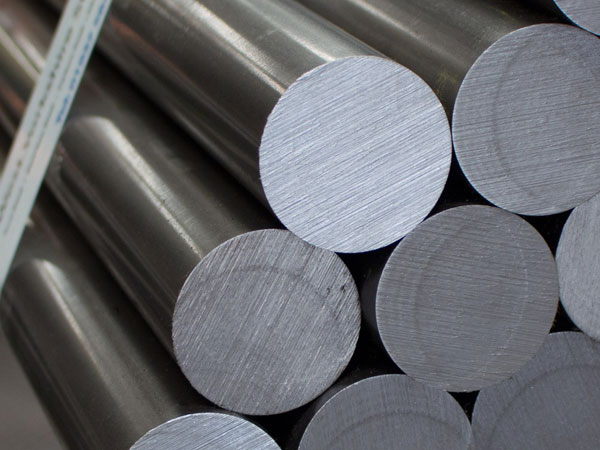

INCONEL (nickel-chromium-iron) alloy 600 Round bars (UNS N06600/W.Nr. 2.4816) is a technological material that is heat and corrosion resistant. Excellent mechanical properties of the alloy combine high strength with ease of production.

An Inconel fastener, often known as a fastening, is a piece of hardware that mechanically connects or fastens two or more things. Inconel round bars are often used to create non-permanent connections, which may be disassembled and rebuilt without causing damage to the connecting components. For their weight, Inconel 600 round bars are very robust. Round Inconel 600 bars have a melting point of 1413 degrees Celsius and a density of 8.47 grammes per centimetre (2580 degrees Fahrenheit).

- Cylindrical Inconel 600 bar characteristics

In Inconel 600 round bars, you can find nickel 72.0, chromium 14.0–17.0, iron 6.00–10.00, carbon 0.15, manganese 1.00, sulphur 0.015, silicon 0.50, and copper 0.50. It also exhibits tensile strengths of 95,000 Psi and 655 MPa as well as yield strengths of 45,000 Psi and 310 MPa.

- Round Inconel 600 Bars’ features

Inconel 600 round bars were extremely powerful and have great corrosion resistance. The presence of sulfuric and hydrochloric acids is advantageous for this material. Amazing Mechanical Capabilities at High Temperatures The resistance to stress corrosion cracking is good.

- Application of Round Inconel 600 Bars

Round Inconel 600 bars are applied throughout a wide range of industries. They execute their jobs in an environment where they must be able to handle the extreme pressure and do well under stress. Some of the industries that use these round bars are trains, petrochemicals, pulp and paper, oil and gas, and pulp and paper. Based on nickel, Inconel 600 is an alloy. Round bars have been utilised in a wide variety of applications, including the heaters, stills, bubble towers, and condensers used in the processing of fatty acids; the same evaporator tubes, tube sheets, and flaking trays used in the production of sodium sulphide; and the machinery used to handle biogenic acid in the manufacturing of paper pulp.

Read More :

Monel or Inconel? Which Alloy Is Best for You? : Inconel is a nickel-chromium alloy with iron and molybdenum that comprises 50-72 per cent nickel and 14-21 per cent chromium.

Inconel vs Hastelloy: Inconel is a corrosion-resistant, oxidation-resistant alloy that performs well in high-temperature, high-pressure conditions, Hastelloy is a nickel-molybdenum alloy with a high melting point. It is available in a variety of grades, the bulk of which are nickel chromium molybdenum alloys.