What is Extruded Aluminum?

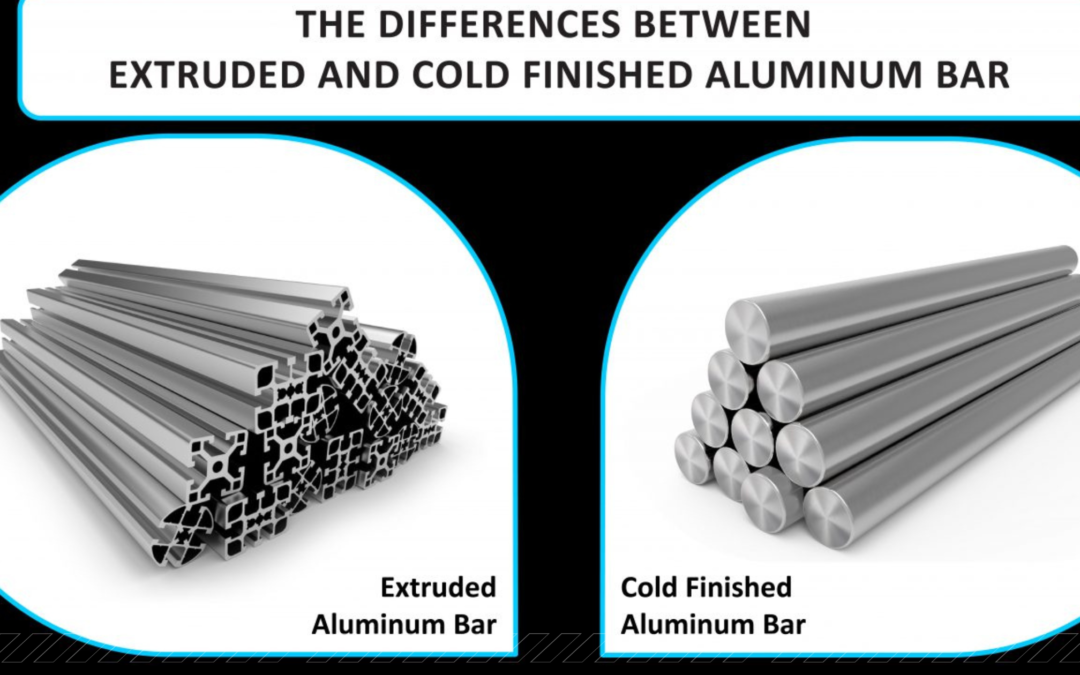

Extrusion is the technique of driving a material through a die to create a cross-sectional bar, whether it be aluminium or another material. Despite having a number of steps, the method is rather straightforward. The final exterior dimension of the extruded bar must first be produced by a manufacturer or designer using a die.

The finished die is put into an extrusion press where a billet of the desired alloy of aluminium is heated to the necessary temperature, making it malleable. The press then pushes the aluminium through the die, causing a lineal length of regularly formed aluminium to emerge from the other side.

The extruded piece is tension relieved and then cut to the required length after cooling. Now that the metal has undergone post-production processes, it can be heat treated. Less pressure is needed to push the metal through the die since the process occurs at a high temperature, up to 75% of the melting point of aluminium. This indicates that it is quicker than cold forming techniques.

What Is Cold-Finished Aluminum?

Since aluminium is simpler to form at higher temperatures, extrusion is frequently done there as opposed to cold finishing, which is done at ambient temperature. Extremely tight tolerances for the outer diameter are produced by cold finishing. The most typical kind of cold finishing is drawing.

Since aluminium is simpler to form at higher temperatures, extrusion is frequently done there as opposed to cold finishing, which is done at ambient temperature. Extremely tight tolerances for the outer diameter are produced by cold finishing. The most typical kind of cold finishing is drawing.

What is the Difference between Extruded and Cold Finished Aluminum?

Standard aluminium extrusions have the main benefit of being significantly simpler to work with at higher temperatures. An extruded bar often costs less than a cold finished product since this corresponds to faster production rates. Faster production leads to shorter lead times to market.

The tighter dimensional tolerances produced by cold finished production are helpful for using the close-fitting collets present in modern high-speed precision CNC machining machines. Additionally, it enhances the material’s mechanical and physical qualities, boosting machinability and resulting in smaller, quicker-elimination chips during milling.

Extruded and Cold Finished Aluminum are Used in What Applications?

Although extruded aluminium is frequently used in many different applications, it is not appropriate for all of them. The use of the cold finished product as a raw material may result from any requirement for improved properties. Cold polished bar is often used in automotive applications as well as aerospace and defense products that need high strength. In cold finished applications, alloys including 2011, 2024, 6061, and 7075 are employed. Extrusions frequently use the aluminium alloys 1100, 3003, 6061, 6063, and 6101. Probably the most popular is 6061, which is prized for its advantageous characteristics.

Read More :

Different Type of Steel Reinforcement Bars : There are different kinds of steel bars that can be used for building. You should know which one you should choose and why.

Some of the Best Uses of Inconel 600 Round Bars : INCONEL (nickel-chromium-iron) alloy 600 Round bars (UNS N06600/W.Nr. 2.4816) is a technological material that is heat and corrosion resistant. Excellent mechanical properties of the alloy combine high strength with ease of production.