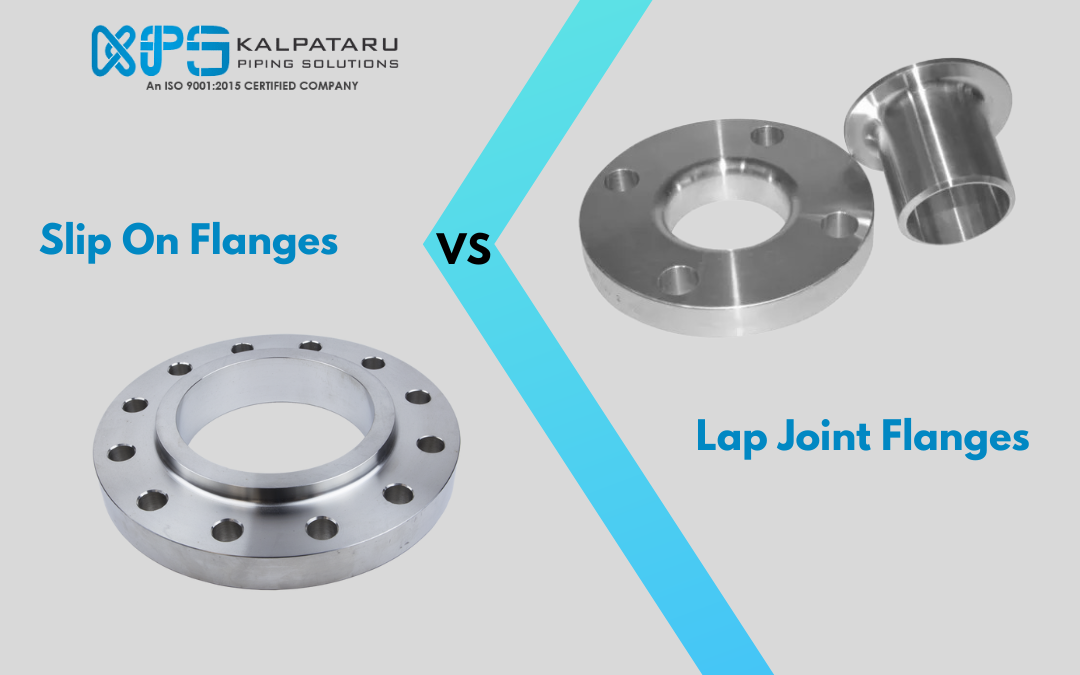

At Kalpataru Piping Solutions, we manufacture high-quality slip on flanges & lap joint flanges by using stainless steel, carbon steel & alloy steel material. Our products are designed to meet international standards to use in a wide range of industrial applications. Contact us today to get the right flange solution for your project.

What is Slip On Flanges?

Key Advantages of Slip-On Flanges:

Discover the benefits of Slip-On Flanges for low-pressure piping systems. Ideal for diverse industrial applications.

- Easy Installation: Simplifies pipe alignment and reduces welding time.

- Cost-Effective: An economical option, especially for systems under moderate pressure.

- Versatile Use: Adaptable to a variety of industries and compatible with different pipe sizes.

- Efficient Flow: Offers minimal turbulence and pressure loss within the piping system.

What is a Lap Joint Flange?

Advantages of Lap Joint Flanges:

Lap Joint Flanges offer easy alignment, reduced bolt stress, and cost-effective maintenance ideal for systems requiring frequent disassembly or inspection.

- Alignment Flexibility: The rotatable backing flange allows easy alignment of bolt holes, even in systems with slight misalignments.

- Ease of Maintenance: Its design enables quick access for maintenance & inspection without removing the entire flange assembly.

- Cost Effective: Used for large diameter piping systems or where frequent disassembly is required to reduce long term maintenance costs.

- Leak Prevention: The stub end is welded to the pipe for ensuring a secure seal & minimizing the risk of leakage around the joint.

Lap Joint Flange vs Slip-On Flange: Key Differences

Understand the key differences in flexibility, pressure handling, welding requirements & sealing performance. Make informed decisions when selecting the right flange type for efficient, safe & cost-effective piping installations.

| Feature | Lap Joint Flange | Slip On Flange |

| Flexibility and Maintenance | Allows rotation of the flange around the stub end for easy bolt hole alignment and simple disassembly. | Fixed in place once welded, offering limited flexibility and not ideal for frequent removal. |

| Pressure Rating | Typically used in medium-pressure applications; not recommended for very high pressures due to design limits | Suitable for low to medium pressures; welding limits may restrict use in high-pressure systems. |

| Size and Variety | Available in larger sizes, often preferred for big-diameter pipes needing flexible installation options. | Available in standard sizes, mostly used with small to medium diameter pipes. |

| Installation & Welding | Lap joint flanges use a stub end that is welded to the pipe while the backing flange remains unwelded. It requires more precise welding on the stub end & more complex installation process. | Slip-on flanges slide over the pipe and are welded on both the inside & outside for making alignment easier & allowing for quicker installation without the need for highly specialized welding. |

| Cost & Leak Prevention | Slip-on flanges tend to be more cost effective due to fewer welds & easier fabrication. Due to their flange lip sticking out past the pipe, they don’t support leakage. | Lap joint flanges are more expensive due to the welding of the stub end but offer a better seal because the flange stays flush with the pipe to prevent leaks. |

Lap Joint Flange vs Slip-On Flange: Applications

Lap joint flanges are ideal for systems requiring frequent disassembly, alignment adjustments, or corrosive environments, while slip-on flanges are perfect for low-pressure applications needing easy & cost effective installation. Understand where each fits best in industrial piping setups:

|

Industry |

Lap Joint Flange |

Slip On Flange |

|

Oil and Gas |

Best for low-pressure pipeline connections (Class ≤600). |

Ideal for systems handling corrosive media that need frequent cleaning or replacement. |

|

Water Treatment |

Water TreatmentCommonly used for transporting clean water in low-cost, stable setups. |

Preferred in wastewater treatment where high corrosion resistance is required. |

|

Chemical Industry |

Suitable for non-corrosive fluids like cooling water systems. |

Excellent choice for handling strong acids or alkalis; stub ends can be made from special alloys like Hastelloy. |

|

Construction |

Used in HVAC low-pressure pipelines and building water supply systems. |

Less common, as these systems typically don’t require frequent maintenance. |