API 5L GR B Pipe

Table of Content

- API 5L GR B Pipe Manufacturer

- What Is API 5L Grade B Pipe?

- Types of API 5L Gr B Pipe

- API 5L Grade B Pipe Specification

- API 5L Grade B Material

- API 5L Grade B Chemical Composition

- API 5L Grade B Mechanical Properties

- API 5L Grade B PSL2 Pipe Thickness

- API 5l Grade B Pipe Equivalent Material

- API 5L Grade B Welded Pipe Yield Strength

API 5L GR B Pipe, API 5L Pipe, API 5L GR B Carbon Steel Pipe, API 5L GR B Carbon Steel Pipes Suppliers, API 5L Gr B Seamless Pipe Supplier, Carbon Steel API 5L Gr B PSL2 High Yield Pipe Supplier In India, API 5L Gr B Seamless Pipe in India, API 5L Grade B ERW Pipe Manufacturer in India, API 5L Grade b Carbon Steel Welded Pipe, API 5L Grade B PSL2 Weight, Schedule 40 Api 5l Grade B Carbon Steel Pipe suppliers, Schedule 80 Api 5l Grade B Carbon Steel Pipe suppliers.

API 5L GR B material, API 5L GR B chemical composition, API 5L GR B specification, API 5L GR B mechanical properties, API 5L GR B equivalent material

API 5L GR B Pipe Manufacturer

Kalpataru Piping Solution is known as a top manufacturer and supplier of API 5L Grade B seamless pipes. These pipes are produced from high-quality carbon steel, with a significant addition of manganese, which enhances their mechanical properties. The manganese acts as a microalloying agent, improving the pipes’ strength, hardness, and durability.API 5L Grade B pipes are commonly subjected to carburizing or nitriding processes to enhance their surface hardness. Nitriding involves heat treatment combined with nitrogen diffusion, resulting in increased hardness and wear resistance.

Our API 5L Grade B seamless pipes are available in sizes ranging from 1/2″ NB to 60″ NB, These pipes are widely used in oil and gas refineries, petrochemical plants, and other sectors requiring robust and reliable piping solutions. The API 5L Grade B pipes are manufactured under two product specification levels, PSL1 and PSL2, each catering to specific requirements. The PSL1 grade provides standard quality for line pipes, while PSL2 pipes come with additional requirements for chemical composition, mechanical properties, notch toughness, and non-destructive testing. This ensures that PSL2 pipes offer superior performance and durability, making them ideal for demanding applications.

API 5L Grade B pipes are resistant to cracking caused by sulfur, making them ideal for harsh environments. They have a minimum yield strength of 245 MPa (about 35,500 psi), making them affordable and dependable for many industrial uses.For more information or to discuss your specific requirements, please contact us. We are committed to delivering the best piping solutions to meet your needs.

What Is API 5L Grade B Pipe?

API 5L Grade B pipes, made primarily from carbon steel with trace elements, are known for their strength, dimensions, and resistance to cracking. Ideal for long pipelines, especially in environments with hydrogen sulfide, they prevent brittleness and have a long lifespan, making them cost-effective. Commonly used in the petroleum, petrochemical, and natural gas industries, these pipes are reliable for transporting fluids and gasses due to their sturdy design and ability to withstand pressure.

Types of API 5L Gr B Pipe

- PSL1 & PSL2 Types

- PSL1: This specification is commonly used and is equivalent to ASTM A106 B and A53 B.

- PSL2: A higher specification level than PSL1, PSL2 pipes have stricter chemical composition and mechanical strength requirements. They also undergo additional testing methods such as Non-Destructive Testing (NDT), Charpy V-Notch (CVN) Impact Test, and Drop Weight Tear (DWT) Test. API 5L B PSL2 is denoted as API 5L BN/Q/R/M.

- Seamless and Welded Pipe Types

- Seamless Type: Includes hot rolled seamless pipes for diameters above 3 inches and cold rolled seamless pipes for diameters below 3 inches.

- ERW Welded Type: Electric Resistance Welded pipes are suitable for diameters below 24 inches.

- LSAW Type: Longitudinal Submerged Arc Welding pipes are used for outer diameters ranging from 20 inches to 48 inches. This type is also known as JCOE, referring to the pipe manufacturing process shapes (J-shape, C-shape, O-shape) followed by cold expansion.

- SSAW/HSAW Type: Spiral Submerged Arc Welding or Helical Submerged Arc Welding pipes can have outer diameters up to 100 inches.

API 5L Grade B Pipe Specification

| Standard | API 5L standard Grade B steel grade seamless steel pipe/tube |

| Sizes |

Nominal Pipe Size 1/2″ to 60″ O.D. Wall Thickness – Schedule 10 through 160, STD, XS, XXS. |

| Product Specification Level (PSL) |

API 5L GrB PSL 2 API 5L GrB PSL 1 |

| Origin | Indian Origin, Japanese Origin, Korean Origin, European Origin, US Origin, Ukraine Origin, Russian Origin |

| Thickness | SCH 40, SCH 80, SCH 160, SCH XS, SCH XXS, All Schedules |

| Pipe End | Plain, Bevel, Screwed, Threaded |

| API 5L GrB Pipes Type | Seamless / ERW / Welded / Fabricated / CDW |

| API Grade B Line Pipe Length | Single Random, Double Random & Required Length, Custom Size – 12 Meter lengths |

| Technique | Hot rolling; cold drawing; NDT test; UT test; Hydrostatic Tester |

| Testing and Inspection Reports | EN 10204 3.1, PMI Test Reports, Visual Inspection Reports, Third Party Inspection Reports, Destructive Test Report, Non Destructive Test Reports, Mill TC EN 10204 3.1, NABL Approved Lab, Chemical and Mechanical Reports, India Boiler Regulations (IBR) Test Certificate |

| Range of Length: SRL, DRL, 20FT, 40FT, 5 – 12 meter | Range of Length: SRL, DRL, 20FT, 40FT, 5 – 12 meter |

| Coatings: FBE, 3PE/3LPE, Black Painting, Varnished | Coatings: FBE, 3PE/3LPE, Black Painting, Varnished |

API 5L Grade B Pipes Tolerance Specifications

| Tolerance on dimension | |||||

| OD Tolerance | WT Tolerance | ||||

| A, B | X42 ~ X70 | ||||

| D<60.3mm | +0.41/-0.40mm | D<73mm | +20%/-12.5% | D<73mm | +15%/-12.5% |

| D>=60.3mm | +0.75/-0.40mm | D>=73mm | +15%/-12.5% | D>=73mm | +15%/-12.5% |

API 5L Grade B Material

| Grade L175 / A25 |

175 MPa (25.4 ksi) YS 310 MPa (45.0 ksi) UTS |

| Grade L210 / A |

210 MPa (30.5 ksi) YS 335 MPa (48.6 ksi) UTS |

| Grade L245 / B |

245 MPa (35.5 ksi) YS 415 MPa (60.2 ksi) UTS |

| Grade L290 / X42 |

290 MPa (42.1 ksi) YS 415 MPa (60.2 ksi) UTS |

| Grade L320 / X46 |

320 MPa (46.4 ksi) YS 435 MPa (63.1 ksi) UTS |

| Grade L360 / X52 |

360 MPa (52.2 ksi) YS 460 MPa (66.7 ksi) UTS |

| Grade L390 / X56 |

390 MPa (56.6 ksi) YS 490 MPa (71.1 ksi) UTS |

| Grade L415 / X60 |

415 MPa (60.2 ksi) YS 520 MPa (75.4 ksi) UTS |

| Grade L450 / X65 |

450 MPa (65.3 ksi) YS 535 MPa (77.6 ksi) UTS |

| Grade L485 / X70 |

485 MPa (70.3 ksi) YS 570 MPa (82.7 ksi) UTS |

API 5L Grade B Chemical Composition

| Material |

Max, % |

|||||||||

| C | Mn | Ph | Su | Si | Co | Ni | Cr | Mo | V | |

| Seamless Type | ||||||||||

| API 5L Gr B | 0.28 | 1.20 | 0.030 | 0.030 | – | 0.50 | 0.50 | 0.50 | 0.15 | – |

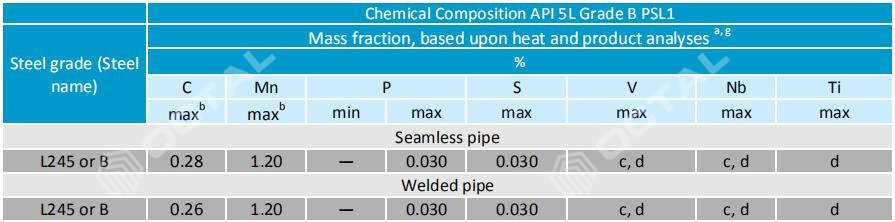

API 5L Grade B Pipe PSL1 Chemical Composition

API 5L Grade B Pipe PSL2 Chemical Composition

API 5L Grade B Mechanical Properties

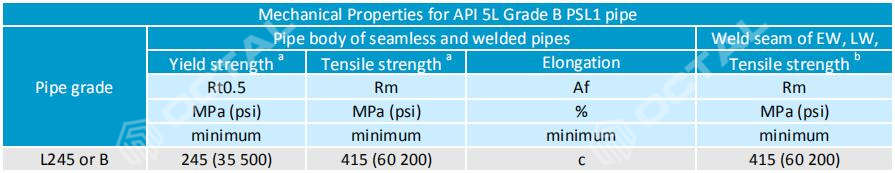

API 5L Grade B Pipe PSL1 Mechanical Properties

API 5L Grade B Pipe PSL2 Mechanical Properties

API 5L Grade B PSL2 Pipe Thickness

We stock and supply HIC tested API 5L Grade B Carbon Steel Pipe, API 5L Grb HIC Pipeline and 3LPE/ Galvanized/ Epoxy Coated L245 Pipes

| NPS

(in) |

Outside Diameter

(in) |

API 5L Grade B Pipe Schedule | ||||||||||||

| SCH 10 | SCH 20 | SCH 30 | SCH STD | SCH 40 | SCH 60 | SCH XS | SCH 80 | SCH 100 | SCH 120 | SCH 140 | SCH 160 | SCH XXS | ||

| PSL 2 Pipe Wall Thickness (in) | ||||||||||||||

| 1/8 | 0.405 | 0.068 | 0.068 | 0.095 | 0.095 | |||||||||

| 1/4 | 0.540 | 0.088 | 0.088 | 0.119 | 0.119 | |||||||||

| 3/8 | 0.675 | 0.091 | 0.091 | 0.126 | 0.126 | |||||||||

| 1/2 | 0.840 | 0.109 | 0.109 | 0.147 | 0.147 | 0.187 | 0.294 | |||||||

| 3/4 | 1.050 | 0.113 | 0.113 | 0.154 | 0.154 | 0.219 | 0.308 | |||||||

| 1 | 1.315 | 0.133 | 0.133 | 0.179 | 0.179 | 0.250 | 0.358 | |||||||

| 1 1/4 | 1.660 | 0.140 | 0.140 | 0.191 | 0.191 | 0.250 | 0.382 | |||||||

| 1 1/2 | 1.900 | 0.145 | 0.145 | 0.200 | 0.200 | 0.281 | 0.400 | |||||||

| 2 | 2.375 | 0.154 | 0.154 | 0.218 | 0.218 | 0.344 | 0.436 | |||||||

| 2 1/2 | 2.875 | 0.203 | 0.203 | 0.276 | 0.276 | 0.375 | 0.552 | |||||||

| 3 | 3.500 | 0.216 | 0.216 | 0.300 | 0.300 | 0.438 | 0.600 | |||||||

| 3 1/2 | 4.000 | 0.226 | 0.226 | 0.318 | 0.318 | |||||||||

| 4 | 4.500 | 0.237 | 0.237 | 0.337 | 0.337 | 0.438 | 0.531 | 0.674 | ||||||

| 5 | 5.563 | 0.258 | 0.258 | 0.375 | 0.375 | 0.500 | 0.625 | 0.750 | ||||||

| 6 | 6.625 | 0.280 | 0.280 | 0.432 | 0.432 | 0.562 | 0.719 | 0.864 | ||||||

| 8 | 8.625 | 0.250 | 0.277 | 0.322 | 0.322 | 0.406 | 0.500 | 0.500 | 0.594 | 0.719 | 0.812 | 0.906 | 0.875 | |

| 10 | 10.750 | 0.250 | 0.307 | 0.365 | 0.365 | 0.500 | 0.500 | 0.594 | 0.719 | 0.844 | 1.000 | 1.125 | 1.000 | |

| 12 | 12.750 | 0.250 | 0.330 | 0.375 | 0.406 | 0.562 | 0.500 | 0.688 | 0.844 | 1.000 | 1.125 | 1.312 | 1.000 | |

| 14 | 14.000 | 0.250 | 0.312 | 0.375 | 0.375 | 0.438 | 0.594 | 0.500 | 0.750 | 0.938 | 1.094 | 1.250 | 1.406 | |

| 16 | 16.000 | 0.250 | 0.312 | 0.375 | 0.375 | 0.500 | 0.656 | 0.500 | 0.844 | 1.031 | 1.219 | 1.438 | 1.594 | |

| 18 | 18.000 | 0.250 | 0.312 | 0.438 | 0.375 | 0.562 | 0.750 | 0.500 | 0.938 | 1.156 | 1.375 | 1.562 | 1.781 | |

| 20 | 20.000 | 0.250 | 0.375 | 0.500 | 0.375 | 0.594 | 0.812 | 0.500 | 1.031 | 1.281 | 1.500 | 1.750 | 1.969 | |

| 22 | 22.000 | 0.250 | 0.375 | 0.500 | 0.375 | 0.875 | 0.500 | 1.125 | 1.375 | 1.625 | 1.875 | 2.125 | ||

| 24 | 24.000 | 0.250 | 0.375 | 0.562 | 0.375 | 0.688 | 0.969 | 0.500 | 1.219 | 1.531 | 1.812 | 2.062 | 2.344 | |

| 30 | 30.000 | 0.312 | 0.500 | 0.625 | 0.375 | 0.500 | ||||||||

| 32 | 32.000 | 0.312 | 0.500 | 0.625 | 0.375 | 0.688 | ||||||||

| 34 | 34.000 | 0.312 | 0.500 | 0.625 | 0.375 | 0.688 | ||||||||

| 36 | 36.000 | 0.312 | 0.500 | 0.625 | 0.375 | 0.750 | ||||||||

| 42 | 42.000 | 0.500 | 0.625 | 0.375 | 0.750 | |||||||||

API 5l Grade B Pipe Equivalent Material

| Welded | Seamless | Standard | Other standards |

| EN 10217-1 P265 | EN 10216-1 P265 | API 5L Grade B PSL2 Equivalent | BS 3601 430 |

| EN 10217-1 P265 | EN 10216-1 P265 | API 5L Gr B PSL1 Equivalent | BS 3601 430 |

API 5L Grade B Welded Pipe Yield Strength

| Tolerance on dimension | |||||

| Outside Diameter Tolerance | Wall thickness Tolerance | ||||

| A, B | X42 ~ X70 | ||||

| +0.41/-0.40 milimeter | D<60.3 milimeter | D<73 milimeter | +20%/-12.5% | D<73 milimeter | +15%/-12.5% |

| +0.75/-0.40 milimeter | D>=60.3 milimeter | D>=73 milimeter | +15%/-12.5% | D>=73 milimeter | +15%/-12.5% |

|

Pipes Grade |

Seam of Welded Pipes |

Tensile Properties – B Pipes Body of SMLS and Welded Pipes PSL 1 |

||

|

Tensile Strength b |

Tensile Strength a |

Yield Strength a |

Elongation |

|

|

A |

48,600 |

48,600 |

30,500 |

c |

|

B |

60,200 |

60,200 |

35,500 |

c |

|

X42 |

60,200 |

60,200 |

42,100 |

c |

|

X46 |

63,100 |

63,100 |

46,400 |

c |

|

X52 |

66,700 |

66,700 |

52,200 |

c |

|

X56 |

71,100 |

71,100 |

56,600 |

c |

|

X60 |

75,400 |

75,400 |

60,200 |

c |

|

X65 |

77,500 |

77,500 |

65,300 |

c |

|

X70 |

82,700 |

82,700 |

70,300 |

c |

API 5L Grade B Pipe Weight, Pressure And Temperature Rating

| D | NPS | SCH | WT (mm) | Temperature Range (°C) | ||

| 204 | 260 | |||||

| Allowable Stress (MPa) | ||||||

| 137.9 | 130.3 | |||||

| Maximum Allowable Stress (MPa) | ||||||

| 21.3 | 1/2 | STD | 40 | 2.77 | 34.5 | 32.6 |

| 26.7 | 3/4 | STD | 40 | 2.87 | 28.1 | 26.5 |

| XS | 80 | 3.91 | 39.4 | 37.2 | ||

| 33.4 | 1 | STD | 40 | 3.38 | 26.3 | 24.8 |

| XS | 80 | 4.55 | 36.3 | 34.3 | ||

| 42.2 | 1.1/4 | STD | 40 | 3.56 | 21.6 | 20.4 |

| XS | 80 | 4.85 | 30.2 | 28.5 | ||

| 160 | 6.35 | 40.6 | 38.4 | |||

| 48.3 | 1.1/2 | STD | 40 | 3.68 | 19.4 | 18.4 |

| XS | 80 | 5.08 | 27.4 | 25.9 | ||

| 160 | 7.14 | 39.8 | 37.6 | |||

| 60.3 | 2 | STD | 40 | 3.91 | 16.4 | 15.5 |

| XS | 80 | 5.54 | 23.7 | 22.4 | ||

| 160 | 8.74 | 38.9 | 36.8 | |||

| 73 | 2.1/2 | STD | 40 | 5.16 | 17.9 | 17 |

| XS | 80 | 7.01 | 24.8 | 23.5 | ||

| 160 | 9.53 | 34.7 | 32.8 | |||

| 88.9 | 3 | STD | 40 | 5.49 | 15.6 | 14.7 |

| XS | 80 | 7.62 | 22 | 20.8 | ||

| 160 | 11.13 | 33.1 | 31.3 | |||

| 114.3 | 4 | STD | 40 | 6.02 | 13.2 | 12.5 |

| XS | 80 | 8.56 | 19.1 | 18 | ||

| 120 | 11.13 | 25.2 | 23.8 | |||

| 160 | 13.49 | 31 | 29.3 | |||

| XXS | 17.12 | 40.4 | 38.2 | |||

| 141.3 | 5 | STD | 40 | 6.55 | 11.6 | 10.9 |

| XS | 80 | 9.53 | 17.1 | 16.1 | ||

| 120 | 12.7 | 23.1 | 21.9 | |||

| 160 | 15.88 | 29.4 | 27.8 | |||

| XXS | 19.05 | 35.9 | 33.9 | |||

| 168.3 | 6 | STD | 40 | 7.11 | 10.5 | 9.9 |

| XS | 80 | 10.97 | 16.5 | 15.6 | ||

| 120 | 14.27 | 21.8 | 20.6 | |||

| XXS | 160 | 18.26 | 28.3 | 26.8 | ||

| 219.1 | 8 | 20 | 6.35 | 7.1 | 6.7 | |

| 30 | 7.04 | 7.9 | 7.5 | |||

| STD | 40 | 8.18 | 9.3 | 8.7 | ||

| 60 | 10.31 | 11.7 | 11.1 | |||

| XS | 80 | 12.7 | 14.6 | 13.8 | ||

| 100 | 15.09 | 17.5 | 16.5 | |||

| 120 | 18.26 | 21.4 | 20.2 | |||

| 140 | 20.62 | 24.3 | 23 | |||

| XXS | 22.23 | 26.4 | 24.9 | |||

| 160 | 23.01 | 27.4 | 25.8 | |||

| 273.1 | 10 | 20 | 6.35 | 5.7 | 5.4 | |

| 30 | 7.8 | 7 | 6.6 | |||

| STD | 40 | 9.27 | 8.4 | 7.9 | ||

| XS | 60 | 12.7 | 11.6 | 11 | ||

| 80 | 15.09 | 13.9 | 13.1 | |||

| 100 | 18.26 | 16.9 | 16 | |||

| 120 | 21.44 | 20 | 18.9 | |||

| XXS | 140 | 25.4 | 24 | 22.7 | ||

| 160 | 28.58 | 27.3 | 25.8 | |||

| 323.9 | 12 | 20 | 6.35 | 4.8 | 4.5 | |

| 30 | 8.38 | 6.4 | 6 | |||

| STD | 9.53 | 7.2 | 6.9 | |||

| 40 | 10.31 | 7.9 | 7.4 | |||

| XS | 12.7 | 9.7 | 9.2 | |||

| 60 | 14.27 | 11 | 10.4 | |||

| 80 | 17.48 | 13.5 | 12.8 | |||

| 100 | 21.44 | 16.8 | 15.8 | |||

| XXS | 120 | 25.4 | 20 | 18.9 | ||

| 140 | 28.58 | 22.7 | 21.4 | |||

| 160 | 33.32 | 26.8 | 25.3 | |||

| 355.6 | 14 | 10 | 6.35 | 4.4 | 4.1 | |

| 20 | 7.92 | 5.5 | 5.2 | |||

| STD | 30 | 9.53 | 6.6 | 6.2 | ||

| 40 | 11.13 | 7.7 | 7.3 | |||

| XS | 12.7 | 8.8 | 8.4 | |||

| 60 | 15.09 | 10.6 | 10 | |||

| 80 | 19.05 | 13.4 | 12.7 | |||

| 100 | 23.83 | 17 | 16 | |||

| 120 | 27.79 | 20 | 18.9 | |||

| 140 | 31.75 | 23 | 21.7 | |||

| 160 | 35.71 | 26.1 | 24.6 | |||

| 406.4 | 16 | 10 | 6.35 | 3.8 | 3.6 | |

| 20 | 7.92 | 4.8 | 4.5 | |||

| STD | 30 | 9.53 | 5.8 | 5.4 | ||

| XS | 40 | 12.7 | 7.7 | 7.3 | ||

| 60 | 16.66 | 10.2 | 9.6 | |||

| 80 | 21.44 | 13.2 | 12.5 | |||

| 100 | 26.19 | 16.3 | 15.4 | |||

| 120 | 30.96 | 19.4 | 18.4 | |||

| 140 | 36.53 | 23.1 | 21.9 | |||

| 160 | 40.49 | 25.8 | 24.4 | |||

| 457 | 18 | 10 | 6.35 | 3.4 | 3.2 | |

| 20 | 7.92 | 4.2 | 4 | |||

| STD | 9.53 | 5.1 | 4.8 | |||

| XS | 30 | 11.13 | 6 | 5.7 | ||

| 12.7 | 6.8 | 6.5 | ||||

| 40 | 14.27 | 7.7 | 7.3 | |||

| 60 | 19.05 | 10.4 | 9.8 | |||

| 80 | 23.83 | 13.1 | 12.3 | |||

| 100 | 29.36 | 16.2 | 15.3 | |||

| 120 | 34.93 | 19.5 | 18.4 | |||

| 140 | 39.67 | 22.3 | 21.1 | |||

| 160 | 45.24 | 25.7 | 24.3 | |||

| 508 | 20 | 10 | 6.35 | 3 | 2.9 | |

| STD | 20 | 9.53 | 4.6 | 4.3 | ||

| XS | 30 | 12.7 | 6.1 | 5.8 | ||

| 40 | 15.09 | 7.3 | 6.9 | |||

| 60 | 20.62 | 10.1 | 9.5 | |||

| 80 | 26.19 | 12.9 | 12.2 | |||

| 100 | 32.54 | 16.2 | 15.3 | |||

| 120 | 38.1 | 19.1 | 18.1 | |||

| 140 | 44.45 | 22.5 | 21.3 | |||

| 160 | 50.01 | 25.5 | 24.1 | |||

| 610 | 24 | 10 | 6.35 | 2.5 | 2.4 | |

| STD | 20 | 9.53 | 3.8 | 3.6 | ||

| XS | 12.7 | 5.1 | 4.8 | |||

| 30 | 14.27 | 5.7 | 5.4 | |||

| 40 | 17.48 | 7.1 | 6.7 | |||

| 60 | 24.61 | 10 | 9.5 | |||

| 80 | 30.96 | 12.7 | 12 | |||

| 100 | 38.89 | 16.1 | 15.2 | |||

| 120 | 46.02 | 19.2 | 18.2 | |||

| 140 | 52.37 | 22 | 20.8 | |||

| 160 | 59.54 | 25.3 | 23.9 | |||