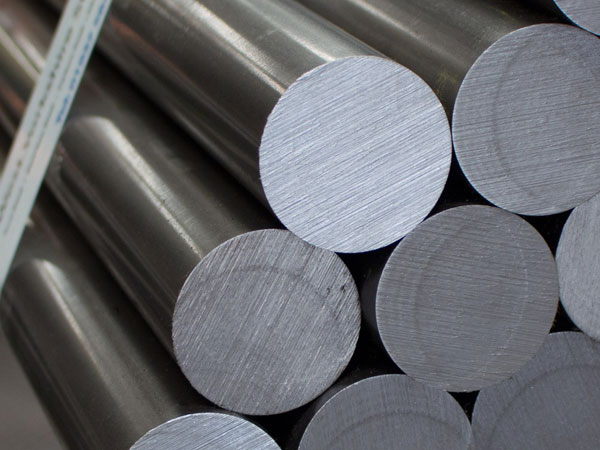

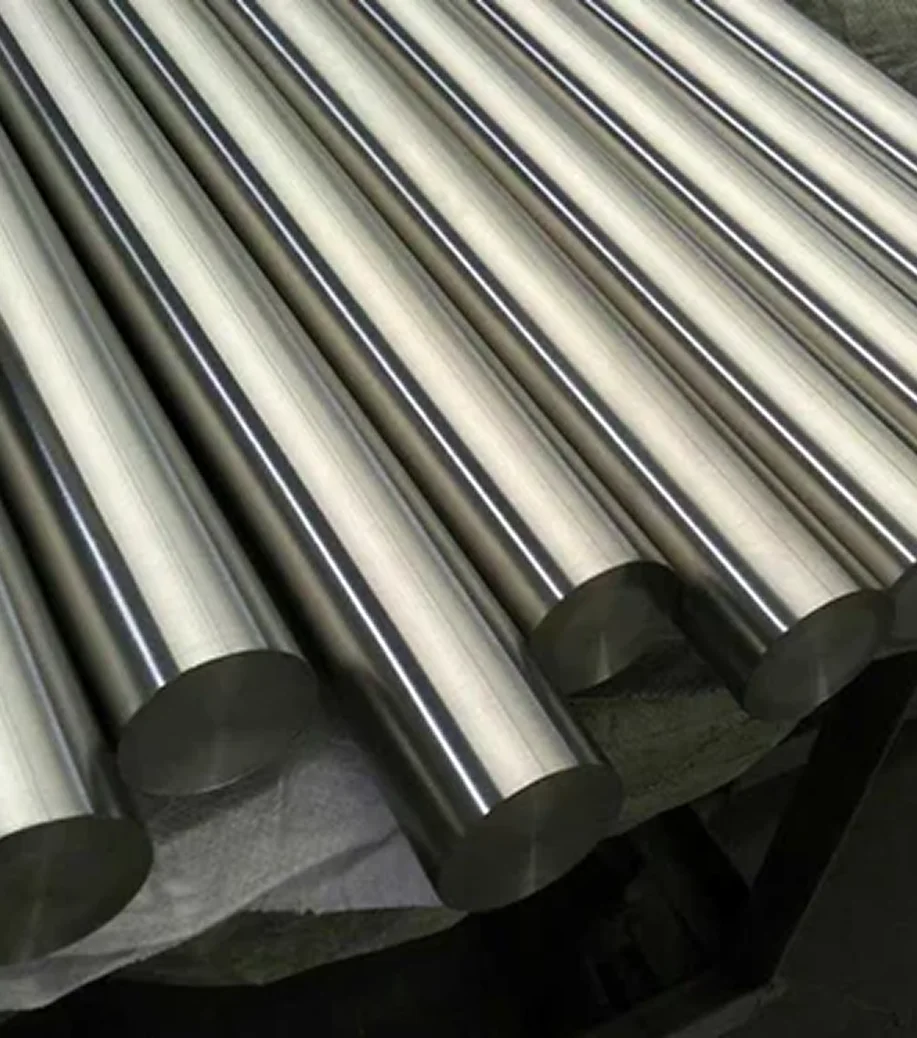

Inconel Round Bar

Alloy Welding Rod Suppliers in India, check latest price, Inconel Alloy Rod Manufacturer, Leading Supplier of Inconel Alloy Rod, Alloy 600 Hex Bar & UNS N06600 Rod Stock, Check Price List of Inconel 600 Round Bar, Inconel Bar Stock, Inconel UNS N06600 / N06625 / N07718 Round Bars, Inconel Rods Supplier.

Table of Content

- Inconel Round Bar Supplier

- Available Types of Inconel Round Bars

- Specification of Inconel Round Bars

- ASTM B166 Inconel Alloy Round Bar/ Rod Chemical Composition

- Inconel Rods Mechanical Properties

- Inconel Round Bars Equivalent Grades

- ASTM B166 Inconel Round Bar Grades Chart

- Inconel Round Bar Weight Chart

- Exporter of Alloy 600 Hex Bar in Variety of Sizes as Per ASME SB166 Standards

- Inconel Round Bar Inventory

Inconel round bars are metal rods that are cylindrical in shape and are produced using a chromium-nickel alloy that is highly resistant to corrosion, oxidation and high temperatures. It is made of carbon, manganese, silicon, sulfur, chromium, nickel, copper and ferrous elements that increase its strength and durability. These bars are much sought after in industrial and commercial applications that have high strength at extreme temperatures and pressures like gas turbines and heat exchangers. The tensile strength of inconel rods is 655 Mpa and the yield strength is 310 Mpa. They can be machined readily and are capable of being extended by up to 40%. The Inconel hex bars, which are used in nuts, bolts and fasteners, are welded to create a hexagonal cross-section, which is available in sizes between 2mm to 100mm. The hollow bars are made of Inconel, which is lighter and less expensive since it has a thicker wall, and these are as strong as round bars. Inconel square bars are famous due to their high creep-rupture characteristics and are widely applied in the industry systems. The Inconel Round Bar is applicable in both cryogenic temperatures and in other applications where the temperature is up to 2000 degrees F.

Looking to Buy Inconel Round Bar?

Inconel Round Bar Supplier

Kalpataru Piping Solutions is a reliable manufacturer, exporter and supplier of a full spectrum of Inconel bars, rods, wires. Inconel 600, Incoloy 800, Incoloy 825, Inconel 625 and Inconel 718 are our Inconel products that are very resistant to oxidation and corrosion. We offer Inconel bars in different sizes, 15 NB to 150 NB length up to 3000mm and customization to suit a particular project. We produce our products under the international standards including ASTM, ASME and API standards, which guarantee high quality, durability and performance. Inconel alloys are resistant to further degradation in severe conditions due to the high-temperature and pressure resistance coupled with the fact that they can create a stable oxide layer. We use the latest technology and high quality raw materials to manufacture products that meet the national and global safety and quality requirements at Kalpataru Piping Solutions.

You may call us to have all your industrial requirements or to get a quote.

Available Types of Inconel Round Bars

We are a leading exporter of both hot and cold rolled Inconel bars, available in various shapes including hexagonal, flat, square, and rectangular.

Inconel Rods

Versatile and widely used, these solid rods are ideal for machining and fabrication in aerospace, chemical, and power industries.

Inconel Hollow Bars

Featuring a hollow center, these bars reduce weight while maintaining strength, perfect for heat exchangers and structural components.

Inconel Bright Bars

Precision-rolled and polished for smooth finishes, bright bars are suitable for applications requiring tight tolerances and excellent surface quality.

Inconel Half-Round Bars

Semi-circular bars often used in custom fabrications and architectural applications, offering unique design flexibility.

Inconel Threaded Bars

Designed with precise threading, these bars are used for high-strength fastening in demanding environments.

Inconel Precision Ground Bars

Manufactured with exacting dimensional control and surface finish, these bars are essential in precision engineering and high-performance machinery.

Specification of Inconel Round Bars

Explore detailed specifications of Inconel bars, including grades, standard sizes for round, angle, square, flat, hex bars, billets, and rectangles. We offers various finishes, tight tolerances, surface conditions, and fabrication techniques to meet diverse industrial requirements with precision and reliability.

| Grade | Inconel – UNS |

| Specification | ASTM B166 |

| Inconel Round bar size | Diameter: 3mm~800mm |

| Inconel Angle bar size | 3mm*20mm*20mm~12mm*100mm*100mm |

| Inconel Square bar size | 4mm*4mm~100mm*100mm |

| Inconel Flat bar size | Thickness: 2mm~100mm |

| Width: 10mm~500mm | |

| Inconel Hex Bar size | 2mm~100mm |

| Inconel Billet Size | 1/2″ to 495mm Diameter |

| Inconel Rectangles Size | 33mm x 30mm to 295mm x 1066mm |

| Finish | Bright, Polish, Bright, Rough Turned, Grinding, Centreless Ground & Black |

| Tolerance | H8, H9, H10, H11, H12, H13K9, K10, K11, K12 or as per clients’ requirements |

| Surface | Hot Rolled Pickled or Sand Blasting Finished, Cold Drawn, Bright, Polished, Hairline |

| Condition | Cold Drawnd Pulished Cold Drawn Centreless Ground & Polished, Annealed round bar |

| Technique | Inconel Hot Rolled, Cold Rolled, Cold Drawn, Forged Round Bar, Rod |

| Inconel Bar Type | Drawn Bar, Rolled Bar, Forged Bar, GFM Forged Bar, Open Die Bar, Forged Stepped Shafts, Forged Flat Bar, Forged Square Bar |

| Form | Round, Rod, Precision Ground Bar, Square, Round Rod, Hollow, Hex (A/F), Triangle, Rectangle, Threaded, T-Bar, Half Round Bar, Flat Bar, Rings, Blocks, Billet, Ingot, I/H Bar, Angle, Channel Bar, Profiles, Forging Etc. |

ASTM B166 Inconel Alloy Round Bar/ Rod Chemical Composition

Explore the detailed chemical composition of Inconel round bars and rods, featuring key elements like nickel, chromium, molybdenum, and iron. This precise alloy blend ensures superior corrosion resistance, high-temperature strength, and durability, making Inconel rods and bars ideal for demanding industrial applications.

| Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr |

| Inconel 600 | 0.15 max | 1.00 max | 0.50 max | 0.015max | 0.50 max | 6.00 – 10.00 | 72.00 min | 14.00 – 17.00 |

| Inconel 601 | 0.10 max | 1.0 max | 0.5 max | 0.015 max | 1.0 max | Balance | 58.0 – 63.0 | 21.0 – 25.0 |

| Inconel 625 | 0.10 max | 0.50 max | 0.50 max | 0.015 max | – | 5.0 max | 58.0 min | 20.0 – 23.0 |

| Inconel 718 | 0.08 max | 0.35 max | 0.35 max | 0.015 max | 0.30 max | – | 50.00 – 55.00 | 17.00 – 21.00 |

Inconel Rods Mechanical Properties

| Inconel 600 | Inconel 601 | Inconel 625 | Inconel | |

| Density | 8.4 g/cm³ | 8.1g/cm³ | 8.4 g/cm³ | 8.2 g/cm³ |

| Melting Range,℃ | 1370-1425 ℃ | 1320-1370℃ | 1290-1350℃ | 1260-1340 ℃ |

| Elongation % | 30min. | 30 min. | 30 min. | 30 min. |

| Tensile strength – Mpa | 550min. | 650min. | 760min. | 965min |

| Yield strength – Mpa | 240min. | 300min. | 345min. | 550 min. |

| Brinell hardness (HB) | ≤195 | ≤220 | ≤220 | ≤363 |

Inconel Round Bars Equivalent Grades

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| Inconel 600 | 2.4816 | N06600 | NCF 600 | NA 13 | МНЖМц 28-2,5-1,5 | NC15FE11M | NiCr15Fe |

| Inconel 601 | 2.4851 | N06601 | NCF 601 | NA 49 | XH60BT | NC23FeA | NiCr23Fe |

| Inconel 625 | 2.4856 | N06625 | NCF 625 | NA 21 | ХН75МБТЮ | NC22DNB4M | NiCr22Mo9Nb |

| Inconel 718 | 2.4668 | N07718 | – | – | – | – | – |

ASTM B166 Inconel Round Bar Grades Chart

Inconel round bars come in a variety of grades, each designed for specific performance requirements and applications. Each grades including Inconel 600, 601, 625, 718, 800 & 825 has distinct chemical composition and mechanical properties.

Explore each grade below for detailed specifications and composition:

Inconel Round Bar Weight Chart

| Size | 10mm | 1/8″ | 16mm | 5/32″ | 15mm | 5mm | 3/16″ | 17mm | 6mm | 7/32″ | 14mm | 7mm | 1/2″ | 5/8″ |

| kg/mtr | 0.62 | 0.062 | 1.578 | 0.095 | 1.391 | 0.154 | 0.141 | 1.791 | 0.223 | 0.19 | 1.207 | 0.298 | 0.994 | 1.551 |

| kg/ft | 0.189 | 0.019 | 0.481 | 0.029 | 0.424 | 0.047 | 0.043 | 0.543 | 0.068 | 0.058 | 0.368 | 0.091 | 0.303 | 0.473 |

| Size | 36mm | 22mm | 2″ | 7/8″ | 48mm | 1″ | 25mm | 2-1/8″ | 27mm | 26mm | 45mm | 30mm | 1-5/8″ | 50mm |

| kg/mtr | 7.999 | 2.979 | 15.906 | 3.038 | 14.205 | 3.97 | 3.871 | 17.963 | 4.49 | 4.17 | 12.555 | 5.548 | 10.449 | 15.414 |

| kg/ft | 2.438 | 0.908 | 4.848 | 0.926 | 4.33 | 1.21 | 1.18 | 5.475 | 1.368 | 1.271 | 3.807 | 1.691 | 3.2 | 4.698 |

| Size | 8″ | 3-1/4″ | 3-1/2″ | 4-1/4″ | 4″ | 4-3/4″ | 4-1/2″ | 5-1/2″ | ||||||

| kg/mtr | 254.55 | 41.996 | 48.772 | 72.249 | 63.34 | 90.249 | 80.34 | 121 | ||||||

| kg/ft | 77.586 | 12.8 | 14.85 | 21.908 | 19.306 | 27.366 | 24.4487 | 36.69 | ||||||

| Size | 8mm | 11/16″ | 18mm | 5/16″ | 13mm | 3/8″ | 12mm | 9mm | 9/16″ | 11mm | 3/4″ | 1/4″ | ||

| kg/mtr | 0.398 | 1.88 | 2.001 | 0.387 | 1.043 | 0.557 | 0.889 | 0.498 | 1.256 | 0.748 | 2.237 | 0.249 | ||

| kg/ft | 0.12 | 0.573 | 0.61 | 0.118 | 0.318 | 0.17 | 0.271 | 0.152 | 0.383 | 0.228 | 0.682 | 0.076 | ||

| Size | 32mm | 2-1/4″ | 60mm | 1-1/4″ | 1-3/4″ | 35mm | 40mm | 1-3/8″ | 1-7/8″ | 38mm | 2-3/8″ | 1-1/8″ | 2-1/2″ | 2-5/8″ |

| kg/mtr | 6.314 | 20.128 | 22.205 | 6.349 | 12.179 | 7.553 | 9.872 | 7.55 | 13.977 | 8.903 | 22.435 | 5.033 | 24.856 | 27.409 |

| kg/ft | 1.894 | 6.135 | 6.768 | 1.924 | 3.712 | 2.39 | 3.009 | 2.303 | 4.26 | 2.792 | 6.838 | 1.534 | 7.576 | 8.354 |

| Size | 6-1/2″ | 6″ | 7-1/2″ | 7″ | 10″ | 5″ | ||||||||

| kg/mtr | 167.63 | 143.9 | 225 | 196 | 397.14 | 99.94 | ||||||||

| kg/ft | 51.093 | 43.86 | 68.226 | 59.432 | 121.048 | 30.461 |

Exporter of Alloy 600 Hex Bar in Variety of Sizes as Per ASME SB166 Standards

| Size (inches) | 3/16″ | 5/16″ | 5/8″ | 3/4″ | 1/4″ | 7/8″ | 1-1/16″ | 3/8″ | 1″ | 1-5/8″ | 15/16″ | 7/16″ | 1/2″ | 1-3/4″ | 1-7/16″ |

| Wt per Ft | 0.104 | 0.29 | 1.15 | 1.66 | 0.18 | 2.3 | 3.3 | 0.625 | 2.9 | 7.8 | 2.625 | 0.56 | 0.74 | 9.03 | 6.1 |

| Wt per 12′ | 1.248 | 3.48 | 13.8 | 19.92 | 2.16 | 27.6 | 39.6 | 4.92 | 34.8 | 93.6 | 31.2 | 6.72 | 8.88 | 108.36 | 73.2 |

| Size (inches) | 9/16″ | 1-7/8″ | 11/16″ | 13/16″ | 2″ | 1-1/2″ | 1-1/8″ | 2-1/4″ | 2-3/8″ | 2-1/2″ | 1-1/4″ | 1-5/16″ | 1-3/8″ | 3″ | |

| Wt per Ft | 0.93 | 10.4 | 1.39 | 1.95 | 11.8 | 6.625 | 3.7 | 14.92 | 16.92 | 18.42 | 4.625 | 5.1 | 5.625 | 26.53 | |

| Wt per 12′ | 11.16 | 124.8 | 16.68 | 23.4 | 141.6 | 79.2 | 44.4 | 179.04 | 203.04 | 221.04 | 55.2 | 61.2 | 67.2 | 318.36 |

Inconel Round Bar Inventory

| Inconel Round Bars | Inconel 600 ASTM B166 Hex Bars |

| Alloy 600 Round Bars | ASTM B166 Inconel Round Bars |

| Inconel 600 Bars | Inconel Square Bars |

| Alloy 600 Bars | ASTM B166 N06600 Inconel 600 Flat Bars |

| Alloy 600 Rod | Inconel Bar Material |

| ASTM B166 UNS N06600 Bars | ASTM B166 600 Inconel Rod |

| Alloy 6600 Hot rolled bars | Inconel 600 AMS 5665 Flat Bars |

| Alloy 600 Hex Bars | Nickel Alloy 600 Rod |

| Alloy 600 Round Bars | ASME SB 166 N06600 Inconel Cold Drawn Bars |

| DIN 2.4816 Flat Bars | Alloy 600 ASTM B166 Round Rod |

| Alloy 600 Forged Bars | ASME SB166 Inconel 600 Bars |

| Nickel Alloy 600 Square Bar | Alloy 600 Hex Bar |

| Inconel 600 Flat Bar | ASME SB 166 N06600 Hot Rolled Square Bar |

| 600 Alloy Square Bar | Inconel 600 Forged Round Bar |

| Alloy 600 Rod | ASTM B166 UNS N06600 Hex Bar |

| Alloy Flat Bar | Inconel Tig Rod |

| UNS N06600 hex bar | DIN 2.4816 Cold Drawn Bars |

| Inconel Welding Rod | Alloy Hex Bar |

| AMS 5665 Rod | ASME SB166 Inconel 600 Rod |

| 600 Inconel cold drawn bar | AMS 5665 Bar |

| Alloy Rods | Inconel Hollow Bar |

Inconel Bar Stock Hardness

| Grade | Hardness (Rockwell B) | Hardness (Brinell) |

| 718 | 35 – 45 | 250 – 300 |

| 625 | 85 – 90 | 170 – 200 |

| 600 | 90 – 95 | 170 – 210 |

| 601 | 90 – 95 | 180 – 220 |

Surface Finishes of Inconel Forged Bar

| P | Polished | CD | Cold drawn |

| SRE | Slit rolled edge | BD | Bright drawn |

| HF | Hot finished | CG | Centreless ground |

| PR | Peeled and reeled | ST | Smooth turned |

| RT | Rough turned/peeled | P&T | Peeled and turned |

| HRAP | Hot rolled annealed and pickled | CF | Cold finished |

Inconel Round Bar Sizes

Explore the wide range of Inconel round bar sizes available in both inches and millimeters. Kalpataru Piping Solutions offers precise Inconel bars in various diameters to meet diverse industrial requirements, ensuring the right fit for applications.

| Diam. (Inch) | Bar Size | Diameter (mm) | Bar Size | Diam. (mm) | Bar Size | Diameter (mm2) | Bar Size |

| 1.875 | #15 | 48 | 48 | 22 | 22 | ||

| 0.250 | #2 | 6 | 6 | 5 | 5 | 100 | 10M |

| 2.000 | #16 | 51 | 51 | 25 | 25 | ||

| 0.375 | #3 | 10 | 10 | 5.5 | 5.5 | 200 | 15M |

| 0.750 | #6 | 19 | 19 | 8 | 8 | 700 | 30M |

| 0.500 | #4 | 13 | 13 | 6 | 6 | 300 | 20M |

| 2.250 | #18 | 57 | 57 | 28 | 28 | ||

| 0.625 | #5 | 16 | 16 | 7 | 7 | 500 | 25M |

| 1.625 | #13 | 41 | 41 | 18 | 18 | ||

| 0.875 | #7 | 22 | 22 | 9 | 9 | 1000 | 35M |

| 1.500 | #12 | 38 | 38 | 16 | 16 | ||

| 1.000 | #8 | 25 | 25 | 10 | 10 | 1500 | 45M |

| 1.375 | #11 | 35 | 35 | 14 | 14 | ||

| 1.125 | #9 | 29 | 29 | 11 | 11 | 2500 | 55M |

| 1.750 | #14 | 44 | 44 | 20 | 20 | ||

| 1.250 | #10 | 32 | 32 | 12 | 12 |

Inconel Bar Density

Understand the density of Inconel bars and Inconel rods across different grades to ensure accurate material selection and weight calculations. We provides detailed density data in lb/in³ and g/cm³ helping engineers optimize designs for strength, durability & performance in high-temperature applications.

| Inconel Grade | Density (lb/in³) | Density (g/cm³) |

| Inconel 600 | 0.306 | 8.47 |

| Inconel 601 | 0.293 | 8.11 |

| Inconel 625 | 0.305 | 8.44 |

| Inconel 718 | 0.296 | 8.19 |

Temperature Range for Inconel Rods

Discover the temperature ranges for various grades of Inconel rods and Inconel bars, designed to maintain strength and corrosion resistance under extreme heat. We provides reliable data to help select the right alloy for high-temperature industrial applications.

| Inconel Grade | Temperature Range (°F) | Temperature Range (°C) |

| Inconel 600 | -328 to 1796 | -200 to 980 |

| Inconel 601 | -328 to 2282 | -200 to 1250 |

| Inconel 625 | -328 to 1500 | -200 to 815 |

| Inconel 718 | -418 to 1292 | -250 to 700 |

Application of Inconel Round Bars

Inconel bars and rods are widely used in industries requiring exceptional heat and corrosion resistance. From aerospace components and chemical processing to power generation and marine engineering, these alloys provide strength and durability in extreme environments. Kalpataru Piping Solutions supports your needs with high-quality Inconel rods and bars

- Construction and Architecture

- Chemical and Petrochemical Industry

- Food and Beverage Industry

- Pharmaceutical Industry

- Automotive Industry

- Power Generation

- Water Treatment and Desalination

- Oil and Gas Industry

Frequently Asked Questions About Inconel Round Bar/Rod

What is the difference between Inconel & monel bar?

Inconel is a nickel-chromium alloy known for its exceptional heat resistance and strength at high temperatures, making it ideal for extreme environments. Monel, primarily a nickel-copper alloy, offers excellent corrosion resistance in seawater and acidic environments but has lower high-temperature strength compared to Inconel.

How to ensure the quality of Inconel round bars?

Quality assurance involves verifying chemical composition per standards like ASTM, conducting mechanical tests (tensile strength, hardness), non-destructive testing (NDT) & inspecting dimensions & surface finish.

What are the common grades of Inconel round bars and their applications?

Common grades include Inconel 600, 601, 625, 718, 800, and 825.

- 600 & 601: Used in heat treatment, furnace components, and chemical processing.

- 625: Ideal for marine, chemical, and aerospace due to corrosion resistance.

- 718: High strength for aerospace, gas turbines, and power plants.

- 800 & 825: Used in petrochemical, nuclear, and high-temperature industrial applications.

How is Inconel round bar heat treated to enhance performance?

Heat treatment processes like annealing, solution treatment, and aging are applied to improve strength, ductility, and corrosion resistance. For example, Inconel 718 undergoes solution annealing and aging to achieve high tensile strength and creep resistance. Proper heat treatment refines grain structure and relieves internal stresses.

What are the welding techniques used for Inconel bars and rods?

Common welding methods include TIG (GTAW), MIG (GMAW) & resistance welding. Proper pre-welding cleaning, controlled heat input & post-weld heat treatment are essential to prevent cracking and preserve mechanical properties.

What is the temperature range for Inconel alloy round bars?

Inconel alloy round bars are designed to withstand extreme temperatures. They can perform efficiently in environments ranging from cryogenic temperatures up to 2000°F (1093°C), making them ideal for high-temperature applications like gas turbines, reactors, and heat exchangers.

What are the density values for different grades of Inconel square bars?

The density of Inconel square bars varies based on the grade:

- Inconel 600: 8.47 g/cm³

- Inconel 625: 8.44 g/cm³

- Inconel 718: 8.19 g/cm³

These densities reflect the material’s excellent strength and durability at elevated temperatures.

How are Inconel rods manufactured?

Inconel rods are produced through various processes such as forging, rolling, and extrusion. These rods are shaped and cut to required sizes, followed by heat treatment to enhance their strength and resistance properties. The rods are then finished to meet specific dimensional and surface quality standards based on industry requirements.

Explorer Other Inconel Products We Offer

- Inconel 600 Perforated Sheets

- Inconel 600 Forged Fittings

- Inconel 600 Olets

- Inconel 600 Fasteners

- Inconel 600 Compression Tube Fittings

- Inconel 600 Pipes & Tubes

- Inconel 600 Flanges

- Inconel 600 Round Bars & Wires

- Inconel 600 Plates & Sheets

- Inconel 600 Buttweld Fittings

- Inconel 600 Instrumentation Valves

- Inconel 600 Filler Wire

- Inconel 600 Long Radius Bends

- Inconel 600 Pipes Spools

- Inconel 600 Shims

- Inconel 600 Wiremesh

Cities We deliver

Bhopal, Lahore, Milan, Hyderabad, Pune, Vadodara, Pimpri-Chinchwad, Aberdeen, Howrah, Jeddah, Riyadh, Bogota, Petaling Jaya, Dallas, Lagos, Nagpur, Houston, Brisbane, Busan, Karachi, Coimbatore, Seoul, Caracas, Atyrau, Perth, Haryana, Bengaluru, Jaipur, Al Jubail, Kuwait City, Al Khobar, Sydney, Ranchi, Chiyoda, Noida, Chandigarh, Secunderabad, Ahvaz, Port-of-Spain, Singapore, Gurgaon, Rajkot, Rio de Janeiro, Abu Dhabi, Hong Kong, Surat, Sharjah, Hanoi, London, Muscat, Jakarta, Navi Mumbai, Istanbul, Kolkata, Cairo, Mumbai, Santiago, Montreal, Faridabad, Vung Tau, Bangkok, Ankara, Ahmedabad, Granada, Melbourne, Tehran, Visakhapatnam, New Delhi, Los Angeles, Ho Chi Minh City, Edmonton, La Victoria, Baroda, Thane, Nashik, Kuala Lumpur, Moscow, Ernakulam, Courbevoie, Calgary, Geoje-si, Indore, New York, Mexico City, Gimhae-si, Ludhiana, Kanpur, Ulsan, Thiruvananthapuram, Manama, Doha, Chennai, Madrid, Jamshedpur, Algiers, Dammam

Countries We Deliver

Iran, Venezuela, Saudi Arabia, Slovakia, Romania, Zimbabwe, Spain, Kazakhstan, Canada, Nigeria, Bulgaria, Afghanistan, Thailand, Bangladesh, Poland, United Kingdom, Bahrain, Jordan, Lithuania, Malaysia, France, Nigeria, Japan, Oman, Lebanon, Germany, Croatia, Australia, Puerto Rico, South Korea, Hungary, United States, Bhutan, Mexico, Mexico, Yemen, Singapore, New Zealand, Ecuador, Gabon, Qatar, Denmark, Iran, Netherlands, Norway, Sri Lanka, Belgium, Libya, Kuwait, Pakistan, Gambia, Sweden, Azerbaijan, Argentina, Chile, Ghana, United Arab Emirates, Finland, Nepal, Trinidad andamp; Tobago,Tunisia, Kenya, Peru, Austria, Russia, Ukraine, Italy, Belarus, Bolivia, Serbia, Poland, Mongolia, Turkey, Czech Republic, South Africa, Angola, India, Vietnam, Indonesia, Tibet, Ireland, Costa Rica, Greece, Colombia, Namibia, Iraq, Estonia, Israel, Macau, Philippines, Brazil, Switzerland, Algeria, Morocco, Chile, Portugal, Egypt, Taiwan, China, Hong Kong.