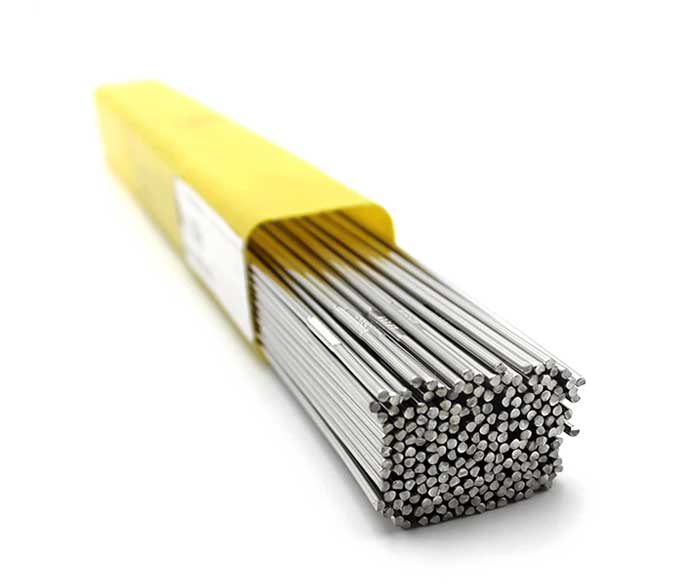

Super Duplex Steel UNS S32750 Filler Wire

Table of Content

- Super Duplex Steel UNS S32750 Filler Wire Supplier

- Super Duplex Steel Uns S32750 Filler Wire Equivalent Grades

- Super Duplex Steel Uns S32750 Filler Wire Chemical Composition

- Super Duplex Steel Uns S32750 Filler Wire Mechanical And Physical Properties

- Super Duplex Steel S32750 Wire Surface Finishes

- Availability of ASME SA 276 Super Duplex Steel S32750 Wire

- Types of Astm A276 Super Duplex Steel Wire

- Super Duplex Steel S32750 Wire Standard

- Price List of Super Duplex Steel S32750 Wire

- Super Duplex Steel UNS S32750 Filler Wire Application

Super Duplex Steel UNS S32750 Wire is known for its high yield strength, increased tensile strength, and excellent corrosion resistance. It also boasts perfect dimensional accuracy, smooth surface finish, full purity, long functional life, anti-corrosiveness, and rust-free properties. These characteristics make our Super Duplex Stainless Steel Filler Wire highly suitable for use in complex applications across various industries.

Similarly, Super Duplex Steel UNS S32760 Filler Wire is highly effective for components that need to resist oxidation and high temperatures. It is commonly used for turbine rotors, shafts, flanges, blades, and bolts that must endure temperatures up to 2200°F and maintain strength around 1500°F. This Duplex Stainless Steel Filler Wire is specifically designed to withstand high-stress, high-temperature environments in moderate to highly corrosive conditions where conventional iron-based alloys would fail.

Super Duplex Steel UNS S32760 Wire is a superalloy, it can experience degradation during fabrication and handling. Nonetheless, its excellent corrosion resistance and high-temperature strength make it a popular choice for applications exposed to extreme conditions.

Super Duplex Steel UNS S32750 Filler Wire Supplier

Kalpataru Piping Solutions is one of the leading manufacturers, suppliers, and exporters of high-quality Super Duplex Steel UNS S32750 Filler Wire. We provide a wide range of Super Duplex Filler Wires, available in different dimensions and grades, offered in various sizes and shapes as per customer needs. These filler wires are extensively used in diverse industries and are manufactured using advanced technology and superior-grade raw materials. Super Duplex Filler Wires are utilized in various applications, including welding ferritic-austenitic steels.

Super Duplex Steel Uns S32750 Filler Wire Equivalent Grades

| STANDARD | WERKSTOFF NR. | UNS |

| Super Duplex 2750 | 1.4410 | S32750 |

Super Duplex Steel Uns S32750 Filler Wire Chemical Composition

| Element | C | Mn | Si | P | S | Cr | Mo | Ni | N | Fe |

| UNS S32750 | 0.05 max | 1.00 max | 1.00 max | 0.030 max | 0.010 max | 24.00 – 26.00 | 3.00 – 4.00 | 6.00 – 8.00 | 0.20 – 0.30 | 57.61 min |

Super Duplex Steel Uns S32750 Filler Wire Mechanical And Physical Properties

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Super Duplex Steel UNS S32750 | 7.8 g/cm3 | 1350 °C (2460 °F) | Psi – 116000 , MPa – 800 | Psi – 80000 , MPa – 550 | 15 % |

Super Duplex Steel S32750 Wire Surface Finishes

- Tin and Lead Coated

- Heat Treated and Tempered

- Bright Polished

Availability of ASME SA 276 Super Duplex Steel S32750 Wire

| Preview | Products | UNS | DIN |

|

Super Duplex S32750 Wire | UNS S32750 Wires | 1.4410 Wires |

|

Super Duplex S32750 Wire Coil | UNS S32750 Wire Coils | 1.4410 Wire Coils |

|

Super Duplex S32750 Filler Wire | UNS S32750 Filler Wires | 1.4410 Filler Wires |

|

Super Duplex S32750 Spring Wire | UNS S32750 Spring Wires | 1.4410 Spring Wire |

|

Super Duplex S32750 Bright Wire | UNS S32750 Bright Wire | 1.4410 Bright Wire |

Types of Astm A276 Super Duplex Steel Wire

- Super Duplex S32750 Wire

- Super Duplex Steel S32750 Wire

- Super Duplex UNS S32750 Wire

- Super Duplex A276 Steel Wire

- Super Duplex S32750 Filler Wire

- Super Duplex S32750 Coil

- Super Duplex UNS S32750 Wire Bobbin

- Super Duplex UNS S32750 Wire

Super Duplex Steel S32750 Wire Standard

| Standard | Description |

| ASTM A276 | Standard Specification for Super Duplex Steel S32750 Wire |

| ASTM A581 | Standard Specification for Free-Machining Super Duplex Steel S32750 Wire and Wire Rods |

| ASTM A479 | Standard Specification for Super Duplex Steel S32750 Spring Wire |

| ASTM A368 | Standard Specification for Super Duplex Steel S32750 Wire Strand |

| ASTM A478 | Standard Specification for Chromium-Nickel Super Duplex Steel S32750 Weaving and Knitting Wire |

| ASTM A492 | Standard Specification for Super Duplex Steel S32750 Rope Wire |

| ASTM A493 | Standard Specification for Super Duplex Steel S32750 Wire and Wire Rods for Cold Heading and Cold Forging |

| ASTM A555/ | Standard Specification for General Requirements for Super Duplex Steel S32750 Wire and Wire Rods |

| ASTM A581 | Standard Specification for Free-Machining Super Duplex Steel S32750 Wire and Wire Rods |

| ASTM A1022 | Standard Specification for Deformed and Plain Super Duplex Steel S32750 Wire and Welded Wire for Concrete Reinforcement |

| ASTM F138 | Standard Specification for Wrought 18Chromium-14Nickel-2.5Molybdenum Super Duplex Steel S32750 Wire for Surgical Implants |

Price List of Super Duplex Steel S32750 Wire

Prices for Super Duplex S32750 Wire products are very affordable. To get the updated price list and ready stock information along with your specific requirements, please click on the request a quote button or click here to request the latest details.

Kalpataru Piping Solutions and Kalikund Steel & Engg. Co. maintain a stock of all standard items and can offer them at the best prices. Our range includes:

- ASME SA 276 S32750 Super Duplex Steel Wire

- Filler Wire

- Cold Heading Wire

- Wire Coil

- Spring Wire

- Bright Wire

Super Duplex Steel UNS S32750 Filler Wire Application

- Marine and Offshore: For components exposed to seawater and harsh marine conditions.

- Chemical Processing: In reactors, tanks, and pipelines where corrosion resistance is critical.

- Oil and Gas: For high-pressure equipment and pipelines.

- Aerospace: In turbine rotors and high-temperature parts.

- Power Generation: In heat exchangers and boiler tubes.

- Petrochemical: For refining equipment in harsh environments.