Inconel 600 Tube Fittings, Pipe Fittings & Compression Fittings Supplier

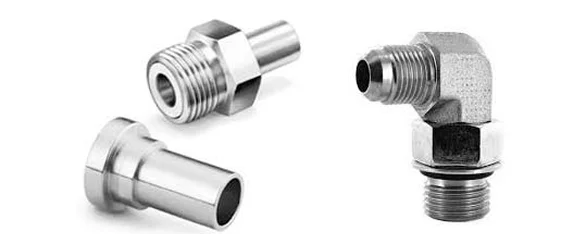

Manufacturer of ASTM B366 Alloy 600 Tube Fittings, Ready Stock Of Inconel 600 Bulkhead Union, Inconel Alloy 600 Male Connector, Alloy 600 Reducing Union, DIN 2.4816 Ferrule Fittings, UNS N06600 Tube Fittings, Incoloy 600 Female Connectors.

Table of Contents

- Introduction to Inconel 600 Pipe Fittings

- Types of Inconel 600 Compression & Tube Fittings

- Inconel 600 Tube Fittings & Compression Fittings Specifications

- Types of UNS N06600 Compression Tube Fittings

- Inconel 600 Pipe Fittings Manufacturing Standards

- ASTM B366 UNS N06600 Inconel 600 Fittings Composition and Properties

- Inconel 600 Compression Tube Fittings Equivalent Grades

- Pressure Rating for Inconel 600 Ferrule Tube Fittings

- Standard Dimensions Of Inconel 600 Elbow Pipe Fittings

- Inconel UNS N06600 Reducing Tee Tube Fittings Schedule Chart

- Size Chart Of Alloy 600 Tube Fittings

- Inconel 600 Tee Compression Tube Fittings Dimensions

- Inconel Alloy 600 Pipe Fittings Weight Chart

- Alloy 600 Tube Fittings Thickness Chart

- Ready Stock of Inconel 600 Tube Fittings

- Frequently Asked Questions About Inconel 600 Tube & Compression Pipe Fittings

Kalpataru Piping Solutions is one of the top manufacturers and suppliers of Inconel 600 pipe Fittings and Compression Tube Fittings in India & are used in high temperatures and corrosive conditions. All Inconel 600 Pipe Fittings are passed through stringent inspections, which include material inspection, dimensional inspection, PMI inspection, hardness inspection, and hydrostatic inspection.

Manufacturer of Nickel Alloy 600 Compression Fittings, ASTM B366 UNS N06600 Buttweld Tee and Alloy 600 Elbow in India

Trusted supplier and manufacturer of Inconel 600 Compression Tube Fittings, which are available in many types and forms, such as ferrule fittings, tube unions, elbows, tees, adapters, and instrumentation fittings. We have Inconel 600 Buttweld and Compression tube Fittings that come in a wide range of sizes, 1/2 to 24 inches. These inconel 600 fittings are manufactured in accordance with ANSI B16.9, ASME B16.28, and MSS-SP-43 dimensional standards. Concentric and eccentric reducers ensure smooth flow transitions between different pipe sizes and offer strong resistance to organic and inorganic acids. Inconel 600 elbows fittings available in 45, 90, and 180 degrees are used to redirect the flow and permit tight joints, which are leak-free. Every Inconel 600 pipe fitting is made of high-quality raw material and superior forming processes to assure the correct size, high strength, and long run wear and tear. Such inconel fittings sustain high oxidation, chloride stress cracking, and scaling at high temperatures.

We specialize in offering quality products at competitive prices with quick delivery. If you need large quantities or small and custom-designed products, please contact our team now.

Introduction to Inconel 600 Pipe Fittings

Inconel 600 pipe fittings are used to connect pipes, valves, and flanges in demanding piping systems. These inconel fittings are from nickel-chromium, and in addition to this, molybdenum is included to provide high levels of resistance to corrosion and oxidation. These fittings are supported by a minimum tensile strength of 655 Mpa and a minimum yield strength of 310 Mpa. Alloy 600 fittings work better and have a long service life due to their elongation ability of up to 40 percent and a melting point of around 1413C. They are hot or cold-formed, simple to weld and bend, come in Sch 5 to Sch 160 as well as Sch XXS.Inconel 600 Compression Tube Fittings – Leak-Proof & High-Temperature Design

Inconel 600 compression tube fittings, including types with two ferrules, are designed to provide leak free service under extreme conditions of either high or low temperature and pressure. Exposure to heat causes the alloy to form a stable layer of oxide that prevents the further damage. Having a high tensile strength over a very large temperature range, these fittings are well suited to work in the applications where carbon steel or aluminum fittings would have failed due to creep. Solid-solution or precipitation hardening can also be used to improve their mechanical properties.Types of Inconel 600 Compression & Tube Fittings

Compression fittings generally consist of a nut, body, and ferrule that secure tubes through friction with no special tools required. Common configurations include:

Tube to Male Fittings

Tube to Pipe Fittings

Tube to Union Fittings

Accessories such as Caps, Plugs & Adapters

Tube to Female Fittings

Inconel 600 Tube Fittings & Compression Fittings Specifications

Get full technical specification of Inconel 600 tube fittings, grade of material, sizes, pressure rating, threads, end connections, and production standards of high-performance compression fittings.

| Specifications | ASTM B366 / ASME SB366 |

|---|---|

| Size | 1/16 in. to 2 in. & 2mm to 50 mm. |

| Dimensional Range | 1/16 to 2 inches (imperial); 2 to 50 mm (metric) |

| Working Pressures | Upto 2000 to 6000 PSI |

| Thread Type | NPT – ASME B1.20.1, SAE AS71051 | ISO/BSP Parallel – ISO 228 | ISO/BSP Tapered – ISO 7, BS EN 10226-1 | SAE (Unified) – ASME B1.1 |

| End Connections | NPT, ISO/BP, SAE/MS, AN, weld ends, port connectors, sanitary flanges, tube adapters |

| Types | Tube to Union, Tube to Male, Tube to Female, Instrument Pipe Fittings, Accessories |

| Equivalent To | SWAGELOK, PARKER, DK-LOK, HOKE |

| Max Working Pressure | 8MPa | 1200psi Depending on The Tubing Material |

| Working Temperature | -40°C—250°C | -40°F—482°F Depending on The Tubing Material |

| Configurations | Straights, elbows, tees, crosses, caps, plugs, nuts and ferrules Chromatograph and Column End |

| Tube Fitting uses & application |

|

| Material Test Certificates (MTC) for Tube Fitting as per EN 10204 3.1 and EN 10204 3.2, Test Certificates certifying NACE MR0103, NACE MR0175 |

Types of UNS N06600 Compression Tube Fittings

Uncover all forms of UNS N06600 compression fittings; including elbows and tees, unions, bulkhead fittings, ferrule fittings, adapters, couplings, and connections to be used in providing leak-free high-temperature and pressurized uses.

ASME SB166 UNS N06600 Tube Fitting Accessories

DIN 2.4816 Alloy 600 Hose Fitting

Inconel 600 Tube Ends

Inconel Alloy 600 Special Fitting

Inconel Tube to Male Pipe Thread

Inconel UNS No 6600 Port Connector

UNS N06600 Tube to Tube

2.4816 Inconel 600 Weld Fitting

Alloy 600 Tube to Female Pipe Thread

Inconel 600 Pipe Fittings Manufacturing Standards

Inconel 600 fittings are made to the standard of the world standards, such as ASTM B366, ASME SB366, ANSI B16.9, MSS-SP-43, and ISO norms of compression fittings to make them as strong and dependable as possible.

| Category | Details |

|---|---|

| Standards | ASTM A182 – ASME SA182 – Standard Specification for Wrought Austenitic Stainless Steel Piping Fittings ASME B16.9 – Factory-Made Wrought Buttwelding Fittings ASME B16.11 – Socket Welding and Threaded Forged Fittings MSS SP-43 – Wrought and Fabricated Butt-Welding Fittings for Low Pressure, Corrosion Resistant Applications MSS SP-95 – Swage(d) Nipples and Bull Plugs BS3799 – Specification for Steel Pipe Fittings, Screwed and Socket-Welding for the Petroleum Industry |

| Origin & Mills | Indian Origin, Japanese Origin, Korean Origin, European Origin, US Origin, Ukraine Origin, Russian Origin, Indian Mills, Japanese Mills, Korean Mills, European Mills, US Mills, Russian Mills, Ukraine Mills |

Alloy 600 Fittings composition and properties

Note the chemical composition Alloy 600 which has nickel, chromium, and iron composition in addition to corrosion resistance, heat resistance, mechanical strength and the capacity of the alloy to resist extreme service conditions.ASTM B366 UNS N06600 Inconel 600 Fittings composition and properties

Chemical Composition of Inconel 600 Tube Fittings

| Element | Ni | C | Mn | Cu | S | Si | Cr | Fe |

| Inconel 600 | 72.0 min | 0.15 max | 1.0 max | 0.5 max | 0.015 max | 0.5 max | 14.0 – 17.0 | 6.0 – 10.0 |

Mechanical & Physical Properties of Inconel 600 Pipe Fittings

Consider the physical and mechanical properties specifications such as tensile strength, yield strength, elongation, hardness, density, melting point and thermal conductivity.| Density | 8.47 g/cm3 |

| Melting Point | 1413 °C (2580 °F) |

| Tensile Strength | Psi – 95,000 , MPa – 655 |

| Yield Strength (0.2%Offset) | Psi – 45,000 , MPa – 310 |

| Elongation | 40 % |

Inconel 600 Compression Tube Fittings Equivalent Grades

Compare the similar international grades of Inconel 600, e.g. UNS N06600, WNR 2.4816, Alloy 600 and other specifications used in the majority of industries around the world.| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| Inconel 600 | 2.4816 | N06600 | NCF 600 | NA 13 | МНЖМц 28-2,5-1,5 | NC15FE11M | NiCr15Fe |

Pressure Rating for Inconel 600 Ferrule Tube Fittings

Understand the working pressure ratings of ferrule tube fittings under various temperature ranges, including maximum allowable pressure for high-temperature and high-pressure systems.| NPT/ISO Pipe Size in. | Inconel | |

|---|---|---|

| Male | Female | |

| psig (bar) | psig (bar) | |

| 1/16 | 15 000 (1 033) | 12 900 (888) |

| 1/8 | 15 000 (1 033) | 12 500 (861) |

| 1/4 | 15 000 (1 033) | 12 700 (875) |

| 3/8 | 15 000 (1 033) | 10 200 (702) |

| 1/2 | 14 800 (1 019) | 9 400 (647) |

| 3/4 | 10 000 (689) | 8 900 (613) |

| 1 | 10 000 (689) | 8 500 (585) |

| 1 1/4 | 10 000 (689) | 9 600 (661) |

| 1 1/2 | 9 600 (661) | 8 900 (613) |

| 2 | 7 500 (516) | 7 500 (516) |

Standard Dimensions Of Inconel 600 Elbow Pipe Fittings

Find standard dimensional details of Alloy 600 elbows, including radius, thickness, centre-to-end dimensions, and sizing according to ASME and ASTM specifications.| NPS (Normal Pipe Size) | O.D. (Outside Daimeter) | Elbow 90 Deg | Elbow 45 Deg | Return Elbow 180 Deg | ||||

|---|---|---|---|---|---|---|---|---|

| (inch) | Long Radius Elbow | Short Radius | Long Radius Elbow | Long Radius Elbow | ||||

| (millimeter/ MM) | (inch./ Inches) | Center to Face (Inches) |

Center to Face (Inches) |

Center to Face (Inches) |

Radius (Inches) |

Center to Center (Inches) |

Back to face (Inches) |

|

| 1/2 | 21.3 | 0.840 | 1 1/2 | – | 5/8 | 2 | 1 7/8 | |

| 3/4 | 26.7 | 1.050 | 1 1/8 | – | 7/16 | 2 1/4 | 1 11/16 | |

| 1 | 33.4 | 1.315 | 1 1/2 | 1 | 7/8 | 3 | 2 3/16 | |

| 1 1/4 | 42.2 | 1.660 | 1 7/8 | 1 1/4 | 1 | 3 3/4 | 2 3/4 | |

| 1 1/2 | 48.3 | 1.900 | 2 1/4 | 1 1/2 | 1 1/8 | 3 | 4 1/2 | 3 1/4 |

| 2 | 60.3 | 2.375 | 3 | 2 | 1 3/8 | 4 | 6 | 4 3/16 |

| 2 1/2 | 73.0 | 2.875 | 3 3/4 | 2 1/2 | 1 3/4 | 5 | 7 1/2 | 5 3/16 |

| 3 | 88.9 | 3.500 | 4 1/2 | 3 | 2 | 6 | 9 | 6 1/4 |

| 3 1/2 | 101.6 | 4.000 | 5 1/4 | 3 1/2 | 2 1/4 | 7 | 10 1/2 | 7 1/4 |

| 4 | 114.3 | 4.500 | 6 | 4 | 2 1/2 | 8 | 12 | 8 1/4 |

| 5 | 141.3 | 5.563 | 7 1/2 | 5 | 3 1/8 | 10 | 15 | 10 5/16 |

| 6 | 168.3 | 6.625 | 9 | 6 | 3 3/4 | 12 | 18 | 12 5/16 |

| 8 | 219.1 | 8.625 | 12 | 8 | 5 | 12 | 24 | 16 5/16 |

| 10 | 273.1 | 10.750 | 15 | 10 | 6 1/4 | 15 | 30 | 20 3/8 |

| 12 | 323.9 | 12.750 | 18 | 12 | 7 1/2 | 18 | 36 | 24 3/8 |

Inconel UNS N06600 Reducing Tee Tube Fittings Schedule Chart

View the schedule chart for Inconel 600 reducing tees with details on wall thickness (Sch 5 to Sch XXS), diameter combinations, and pressure class compatibility.|

DN (Normal Pipe Size) For ASME B16.9 |

Schedule 10S |

Schedule 40S |

Schedule 80S | ||||||

|

Elbow 90 Deg | Elbow 45 Deg | B16.9 Equal Tee |

Elbow 90 Deg | Elbow 45 Deg |

B16.9 Equal Tee | Elbow 90 Deg | Elbow 45 Deg |

B16.9 Equal Tee | |

|

8 |

0.02 |

0.01 |

0.03 |

0.03 |

0.02 |

0.06 |

0.04 |

0.03 |

0.07 |

|

10 |

0.03 |

0.02 |

0.05 |

0.03 |

0.02 |

0.03 |

0.06 |

0.04 |

0.09 |

|

15 |

0.06 |

0.03 |

0.09 |

0.08 |

0.04 |

0.10 |

0.10 |

0.05 |

0.14 |

|

20 |

0.07 |

0.03 |

0.13 |

0.08 |

0.04 |

0.17 |

0.11 |

0.05 |

0.20 |

|

25 |

0.14 |

0.08 |

0.28 |

0.15 |

0.11 |

0.29 |

0.22 |

0.14 |

0.38 |

|

32 |

0.23 |

0.11 |

0.49 |

0.26 |

0.17 |

0.59 |

0.40 |

0.23 |

0.68 |

|

40 |

0.30 |

0.17 |

0.68 |

0.40 |

0.23 |

0.86 |

0.51 |

0.29 |

1.02 |

|

50 |

0.50 |

0.25 |

0.85 |

0.70 |

0.4 |

1.28 |

0.91 |

0.59 |

1.59 |

|

65 |

0.85 |

0.48 |

1.41 |

1.40 |

0.77 |

2.19 |

1.81 |

0.99 |

3.13 |

|

80 |

1.25 |

0.63 |

1.77 |

2.20 |

1.08 |

3.31 |

2.97 |

1.50 |

4.45 |

|

90 |

1.70 |

0.75 |

2.67 |

2.83 |

1.42 |

4.08 |

4.00 |

2.00 |

5.44 |

|

100 |

2.10 |

1.08 |

3.46 |

4.47 |

2.09 |

5.27 |

6.18 |

2.81 |

7.71 |

|

150 |

5.45 |

2.72 |

8.07 |

10.89 |

5.44 |

10.99 |

16.32 |

8.16 |

13.61 |

|

200 |

10.20 |

5.33 |

15.65 |

21.54 |

10.77 |

20.91 |

33.11 |

16.56 |

28.12 |

|

250 |

18.15 |

9.75 |

26.46 |

38.56 |

19.27 |

35.38 |

51.71 |

25.86 |

49.90 |

|

300 |

25.80 |

13.62 |

39.46 |

59.42 |

29.71 |

62.14 |

79.38 |

39.69 |

83.91 |

Size Chart Of Alloy 600 Tube Fittings

Access the complete size chart featuring OD sizes, tube thickness, connection types, and fitting dimensions to help select the right fittings for your piping system.| O.D. or I.D. Diameter | Equivalent Decimal | Nominal Diameter | Typical Threads In Inch |

| 5/16 | 0.313 | 1/16 | 27 |

| 13/32 | 0.405 | 1/8 | 27 |

| 35/64 |

0.540 |

1/4 | 18 |

| 43/64 | 0.675 | 3/8 | 18 |

| 27/32 | 0.840 | 1/2 | 14 |

| 1-3/64 | 1.050 | 3/4 | 14 |

| 1-5/16 | 1.315 | 1 | 11-1/2 |

|

1-21/32 |

1.660 | 1-1/4 | 11-1/2 |

| 1-29/32 | 1.900 | 1-1/2 | 11-1/2 |

| 2-3/8 | 2.375 | 2 | 11-1/2 |

| 2-7/8 | 2.875 | 2-1/2 | 8 |

| 3-1/2 | 3.500 | 3 | 8 |

| 4 | 4.000 | 3-1/2 | 8 |

| 4-1/2 | 4.500 | 4 | 8 |

Inconel 600 Tee Compression Tube Fittings Dimensions

Get detailed dimensional data for Inconel 600 tee compression fittings including branch sizes, run dimensions, ferrule size, nut size, and thread types.| NPS Of Equal Tee | O.D. (Outer Daimeter) at bevel | Center-End | |

|---|---|---|---|

| Run (C) | Outlet (M) | ||

| 1/2″ | 21.3 | 25 | 25 |

| 3/4″ | 26.7 | 29 | 29 |

| 1″ | 33.4 | 38 | 38 |

| 1 1/4″ | 42.2 | 48 | 48 |

| 1 1/2″ | 48.3 | 57 | 57 |

| 2″ | 60.3 | 64 | 64 |

| 2 1/2″ | 73.0 | 76 | 76 |

| 3″ | 88.9 | 86 | 86 |

| 3 1/2″ | 101.6 | 95 | 95 |

| 4″ | 114.3 | 105 | 105 |

| 5″ | 141.3 | 124 | 124 |

| 6″ | 168.3 | 143 | 143 |

| 8″ | 219.1 | 178 | 178 |

| 10″ | 273.0 | 216 | 216 |

| 12″ | 323.8 | 254 | 254 |

| 14″ | 355.6 | 279 | 279 |

| 16″ | 406.4 | 305 | 305 |

| 18″ | 457.0 | 343 | 343 |

| 20″ | 508.0 | 381 | 381 |

| 22″ | 559.0 | 419 | 419 |

| 24″ | 610.0 | 432 | 432 |

Inconel Alloy 600 Pipe Fittings Weight Chart

Browse the weight chart covering all types of Alloy 600 fittings such as elbows, tees, reducers, caps, and crosses for accurate planning and procurement.|

Product range and theoretical weights (kg) |

|||||||||

|

DN |

Schedule 10S |

Schedule 40S |

Schedule 80S |

||||||

|

900 Elbow |

450 Elbow |

Equal tee |

900 Elbow |

450 Elbow |

Equal tee |

900 Elbow |

450 Elbow |

Equal tee |

|

|

8 |

0.02 |

0.01 |

0.03 |

0.03 |

0.02 |

0.06 |

0.04 |

0.03 |

0.07 |

|

10 |

0.03 |

0.02 |

0.05 |

0.03 |

0.02 |

0.03 |

0.06 |

0.04 |

0.09 |

|

15 |

0.06 |

0.03 |

0.09 |

0.08 |

0.04 |

0.10 |

0.10 |

0.05 |

0.14 |

|

20 |

0.07 |

0.03 |

0.13 |

0.08 |

0.04 |

0.17 |

0.11 |

0.05 |

0.20 |

|

25 |

0.14 |

0.08 |

0.28 |

0.15 |

0.11 |

0.29 |

0.22 |

0.14 |

0.38 |

|

32 |

0.23 |

0.11 |

0.49 |

0.26 |

0.17 |

0.59 |

0.40 |

0.23 |

0.68 |

|

40 |

0.30 |

0.17 |

0.68 |

0.40 |

0.23 |

0.86 |

0.51 |

0.29 |

1.02 |

|

50 |

0.50 |

0.25 |

0.85 |

0.70 |

0.4 |

1.28 |

0.91 |

0.59 |

1.59 |

|

65 |

0.85 |

0.48 |

1.41 |

1.40 |

0.77 |

2.19 |

1.81 |

0.99 |

3.13 |

|

80 |

1.25 |

0.63 |

1.77 |

2.20 |

1.08 |

3.31 |

2.97 |

1.50 |

4.45 |

|

90 |

1.70 |

0.75 |

2.67 |

2.83 |

1.42 |

4.08 |

4.00 |

2.00 |

5.44 |

|

100 |

2.10 |

1.08 |

3.46 |

4.47 |

2.09 |

5.27 |

6.18 |

2.81 |

7.71 |

|

150 |

5.45 |

2.72 |

8.07 |

10.89 |

5.44 |

10.99 |

16.32 |

8.16 |

13.61 |

|

200 |

10.20 |

5.33 |

15.65 |

21.54 |

10.77 |

20.91 |

33.11 |

16.56 |

28.12 |

|

250 |

18.15 |

9.75 |

26.46 |

38.56 |

19.27 |

35.38 |

51.71 |

25.86 |

49.90 |

|

300 |

25.80 |

13.62 |

39.46 |

59.42 |

29.71 |

62.14 |

79.38 |

39.69 |

83.91 |

Alloy 600 Tube Fittings Thickness Chart

Check thickness specifications for different schedules and pressure classes to ensure correct selection based on your system’s temperature and pressure requirements.| NPS (inches) |

OD | ASTM B366 Inconel 600 Cap | Nickel Alloy 600 Tee Fittings (Straight) | Inconel 600 Cross fittings (Straight) | Alloy 600 Stub End Fittings | |||

|---|---|---|---|---|---|---|---|---|

| (mm) | (inches) | Length (inch) |

Center to End (inch) |

Center to End (inch) |

Lap Diameter (inch) |

Long Length (inch) |

Short Length (inch) |

|

| 1/2 | 21.3 | 0.840 | 1 | 1 | – | 1 3/8 | 3 | 2 |

| 3/4 | 26.7 | 1.050 | 1 | 1 1/8 | – | 1 11/16 | 3 | 2 |

| 1 | 33.4 | 1.315 | 1 1/2 | 1 1/2 | 1 1/2 | 2 | 4 | 2 |

| 1 1/4 | 42.2 | 1.660 | 1 1/2 | 1 7/8 | 1 7/8 | 2 1/2 | 4 | 2 |

| 1 1/2 | 48.3 | 1.900 | 1 1/2 | 2 1/4 | 2 1/4 | 2 7/8 | 4 | 2 |

| 2 | 60.3 | 2.375 | 1 1/2 | 2 1/2 | 2 1/2 | 3 5/8 | 6 | 2 1/2 |

| 2 1/2 | 73.0 | 2.875 | 1 1/2 | 3 | 3 | 4 1/8 | 6 | 2 1/2 |

| 3 | 88.9 | 3.500 | 2 | 3 3/8 | 3 3/8 | 5 | 6 | 2 1/2 |

| 3 1/2 | 101.6 | 4.000 | 2 1/2 | 3 3/4 | 3 3/4 | 5 1/2 | 6 | 3 |

| 4 | 114.3 | 4.500 | 2 1/2 | 4 1/8 | 4 1/8 | 6 3/16 | 6 | 3 |

| 5 | 141.3 | 5.563 | 3 | 4 7/8 | 4 7/8 | 7 5/16 | 8 | 3 |

| 6 | 168.3 | 6.625 | 3 1/2 | 5 5/8 | 5 5/8 | 8 1/2 | 8 | 3 1/2 |

| 8 | 219.1 | 8.625 | 4 | 7 | 7 | 10 5/8 | 8 | 4 |

| 10 | 273.1 | 10.750 | 5 | 8 1/2 | 8 1/2 | 12 3/4 | 10 | 5 |

| 12 | 323.9 | 12.750 | 6 | 10 | 10 | 15 | 10 | 6 |

Ready Stock of Inconel 600 Tube Fittings

|

|

Frequently Asked Questions About Inconel 600 Tube & Compression Pipe Fittings

What are Inconel 600 tube fittings?

What standards do Inconel 600 fittings follow?

Most Inconel 600 tube fittings are manufactured as per ASTM B366 for wrought alloy fittings and UNS N06600 material specifications.

Do you supply custom sizes for Inconel 600 fittings?

What types of Inconel 600 fittings are available?

Are Inconel 600 tube fittings corrosion-resistant?

How do I choose the right Inconel 600 fitting for my application?

- Inconel 600 Perforated Sheets

- Inconel 600 Forged Fittings

- Inconel 600 Olets

- Inconel 600 Fasteners

- Inconel 600 Compression Tube Fittings

- Inconel 600 Pipes & Tubes

- Inconel 600 Flanges

- Inconel 600 Round Bars & Wires

- Inconel 600 Plates & Sheets

- Inconel 600 Buttweld Fittings

- Inconel 600 Instrumentation Valves

- Inconel 600 Filler Wire

- Inconel 600 Long Radius Bends

- Inconel 600 Pipes Spools

- Inconel 600 Shims

- Inconel 600 Wiremesh

Cities We deliver:

Bhopal, Lahore, Milan, Hyderabad, Pune, Vadodara, Pimpri-Chinchwad, Aberdeen, Howrah, Jeddah, Riyadh, Bogota, Petaling Jaya, Dallas, Lagos, Nagpur, Houston, Brisbane, Busan, Karachi, Coimbatore, Seoul, Caracas, Atyrau, Perth, Haryana, Bengaluru, Jaipur, Al Jubail, Kuwait City, Al Khobar, Sydney, Ranchi, Chiyoda, Noida, Chandigarh, Secunderabad, Ahvaz, Port-of-Spain, Singapore, Gurgaon, Rajkot, Rio de Janeiro, Abu Dhabi, Hong Kong, Surat, Sharjah, Hanoi, London, Muscat, Jakarta, Navi Mumbai, Istanbul, Kolkata, Cairo, Mumbai, Santiago, Montreal, Faridabad, Vung Tau, Bangkok, Ankara, Ahmedabad, Granada, Melbourne, Tehran, Visakhapatnam, New Delhi, Los Angeles, Ho Chi Minh City, Edmonton, La Victoria, Baroda, Thane, Nashik, Kuala Lumpur, Moscow, Ernakulam, Courbevoie, Calgary, Geoje-si, Indore, New York, Mexico City, Gimhae-si, Ludhiana, Kanpur, Ulsan, Thiruvananthapuram, Manama, Doha, Chennai, Madrid, Jamshedpur, Algiers, Dammam

Countries We Deliver:

Iran, Venezuela, Saudi Arabia, Slovakia, Romania, Zimbabwe, Spain, Kazakhstan, Canada, Nigeria, Bulgaria, Afghanistan, Thailand, Bangladesh, Poland, United Kingdom, Bahrain, Jordan, Lithuania, Malaysia, France, Nigeria, Japan, Oman, Lebanon, Germany, Croatia, Australia, Puerto Rico, South Korea, Hungary, United States, Bhutan, Mexico, Mexico, Yemen, Singapore, New Zealand, Ecuador, Gabon, Qatar, Denmark, Iran, Netherlands, Norway, Sri Lanka, Belgium, Libya, Kuwait, Pakistan, Gambia, Sweden, Azerbaijan, Argentina, Chile, Ghana, United Arab Emirates, Finland, Nepal, Trinidad andamp; Tobago,Tunisia, Kenya, Peru, Austria, Russia, Ukraine, Italy, Belarus, Bolivia, Serbia, Poland, Mongolia, Turkey, Czech Republic, South Africa, Angola, India, Vietnam, Indonesia, Tibet, Ireland, Costa Rica, Greece, Colombia, Namibia, Iraq, Estonia, Israel, Macau, Philippines, Brazil, Switzerland, Algeria, Morocco, Chile, Portugal, Egypt, Taiwan, China, Hong Kong.