Air Headers Distribution Manifolds

Instrument Air Manifold, Air Manifold With Valves, Air Header Manifold, Air Distribution Manifold.

Air Headers Distribution Manifolds Suppliers, Manufacturer & Exporter in India.

Introduction to Air Header Distribution Manifold

Air headers — also called air distribution manifolds — are used when you need to split compressed air from one source and send it out to different tools or equipment. They’re especially used when the pressure from the compressor isn’t always stable. The header helps to keep the airflow steady & reliable across the system. They are made from die-cast aluminum resulting in a lightweight structure but still tough enough to handle rough industrial use. These systems help divert a single air, gas or liquid feed line to multiple locations for ensuring optimal performance & minimizing the risk of system failure.

Air headers — also called air distribution manifolds — are used when you need to split compressed air from one source and send it out to different tools or equipment. They’re especially used when the pressure from the compressor isn’t always stable. The header helps to keep the airflow steady & reliable across the system. They are made from die-cast aluminum resulting in a lightweight structure but still tough enough to handle rough industrial use. These systems help divert a single air, gas or liquid feed line to multiple locations for ensuring optimal performance & minimizing the risk of system failure.

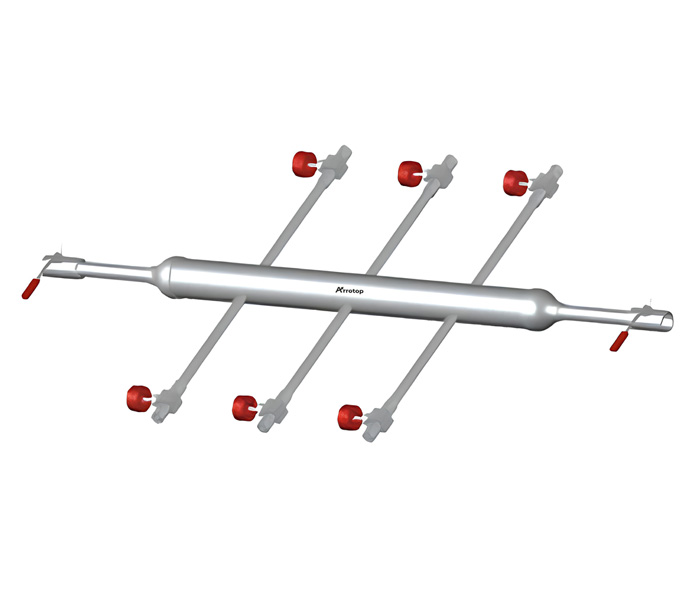

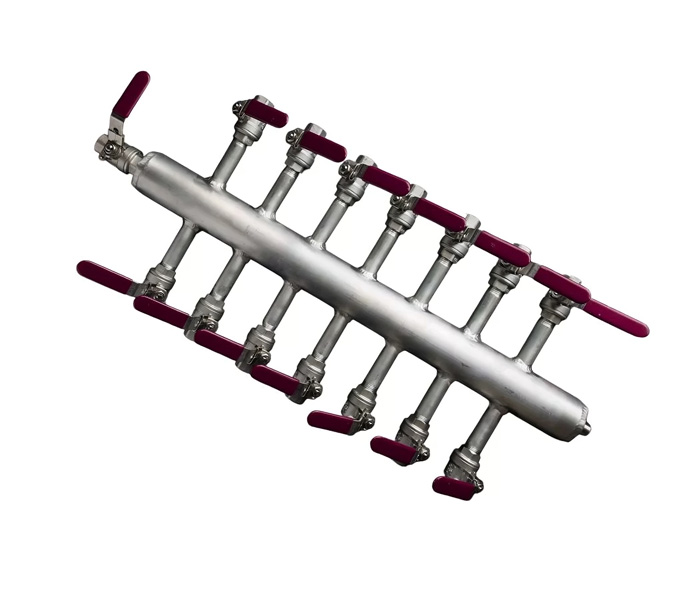

Air distribution manifolds come in various configurations to suit the needs of different industries. A 6-way air header, for example, is often used in places like plastic processing, petrochemical plants, or power stations – anywhere you need to get air to several outlets at once. They are built to handle that kind of workload. One of the key features of an air header is the inclusion of multiple outlet options, which eliminate the need for complex piping systems. A 4-way air header can save a lot of time during install & cut down on how much assembly work is needed. Depending on the setup, some come with needle valves, flanged ends, or threaded inlets – so you can adjust based on what your system needs..

Air Header Manufacturer in India

At kalpataru piping solutions, we are a leading air header manufacturer in India. We provide high-quality air header manifolds built to support a wide range of industrial applications. Our air distribution systems are engineered to simplify the connection of multiple gas and fluid lines, helping ensure smooth and efficient airflow throughout your entire operation.

We understand the unique needs of different industries . That’s why we offer air distribution headers in a variety of sizes — 2″, 3″, and 4″, with options in Schedule 40, 80, and 160. Larger sizes are available upon request to meet the specifications of your project. Whether you’re working in a petrochemical plant, a refinery or a liquid petroleum setup, our air headers are made to handle tough conditions & keep your system running reliably.

Our air header manifold systems are built using high-grade materials like SS316, known for their durability and strong resistance to corrosion. We also offer tailored solutions to meet your specific project needs, whether standard or custom. Every product we manufacture goes through thorough testing at our facility and meets PED Module A SEP standards, so you can rely on both the quality and performance.

Using air distribution manifolds helps maintain steady airflow and consistent pressure — both critical for keeping pneumatic tools and equipment running smoothly. They also make the installation process more straightforward and cut down on maintenance efforts, helping reduce the risk of breakdowns and keeping operational costs in check.

Our air header manifolds are built to make monitoring and control easier, so if something goes wrong, you can catch it early and fix it fast. That kind of reliability keeps your system running better, cuts down on downtime & helps maintain overall productivity. At Kalpataru Piping Solutions, we’re here to provide air distribution headers that not only meet the required standards — but are made to perform better, last longer, and truly meet the demands of your work.

Types of Air Header

Specification of Air Header Distribution Manifold

|

Distribution Pipe size |

2″’ seamless Stainless steel 316 or 304 |

|

Header Inlet |

1″ Female Bsp or Npt threaded to ASME B16.1 or Flanged inlet optional |

|

Header Outlet/drain |

¼” Male Bsp or Npt threaded to ASME B16.1 or 150# cast fitting |

|

Outlet Ports |

From 4-way to 12-Way, ½” Male Bsp or Npt threaded |

|

Valves for Outlets |

½” Bar Stock valves, or ½”Needle valves |

|

Pressure test |

Pressure test optional, NDT to your requirements |

HSN Code of Air Distribution Manifold

| HS Code | Description |

| 73079990 | STAINLESS STEEL FITTINGS-AIR HEADER ASSEMBLY WITH 6 BRANCHES:SS316 2NB SCH:40,SMLS WITH SILVER PLATING,INLET:SS316 1NP |

| 84749000 | MACHINERY FOR COAL GRINDING PARTS DISCHVALVE AIR HEADER & PIPING ASSLY |

| 84199090 | HEADERS OF TUBE BUNDLE FOR AIR COOLER BAY – H & K (EXE-1753 & 1755) DETAILS AS PER INVOICE /P.LIST |

| 73079990 | STAINLESS STEEL FITTINGS-AIR HEADER ASSEMBLY WITH 10 BRANCHES:SS316 2NB SCH:40,SMLS WITH SILVER PLATING,INLET:SS316 1 |

| 84199090 | HEADERS OF TUBE BUNDLE FOR AIR COOLER BAY – G & J (EXE-1752 & 1754) DETAILS AS PER INVOICE /P.LIST |

Air Distribution Manifold Manufacturing Process

At Kalpataru Piping Solutions, we focus on building high-quality air distribution manifolds that are made to match the needs of different industries. Each air header is constructed using welded Schedule 80 pipe for added strength and durability. We also offer a range of port options including male, female, or half-couplings.

Our air distribution headers are available with a variety of connection options to suit your setup including male, female, socket weld, or 150# raised face flanged inlets. For the outlets, you can choose from threaded, capped, or vent valve types, which help make condensation removal simple. To make things even easier, we also supply ball and vent valves to streamline the purchasing and assembly process. Each manifold is designed to ensure reliable performance in air distribution systems, providing a cost-effective solution that reduces downtime and enhances system efficiency.

Air Manifold Materials

Air header manifolds are most commonly made from two main materials — stainless steel and carbon steel. Each has its own set of strengths & the best choice depends on where and how the manifold will be used:

Stainless Steel: This one’s your best bet if you’re dealing with harsh environments. It doesn’t rust easily, can take the heat & holds up under wear. It ensures that air manifolds remain robust & reliable over time, even in harsh industrial settings.

Carbon steel: It is a more cost-effective option for air manifolds. Its is less corrosion resistance than stainless steel, it is still a durable material suited for many standard applications. It provides good strength at a more affordable price.

Aluminum: While aluminum is lightweight & resistant to corrosion. Its not recommended for steam header manifolds due to its relatively weak nature, which could lead to potential failures under high pressure and stress conditions.

304SS and 316SS: If you are working in a place with a lot of chemicals or salty air to build your manifolds using 304 or 316 stainless steel. These materials are good at handling corrosion, particularly in environments exposed to harsh chemicals.

Pressure Testing for Air Distribution Manifolds

Before we ship anything, we pressure test every air header manifold. We check the whole thing — welds, valves, threads to make sure there are no leaks and it’s ready to go. You get a unit that works straight out of the box, without any surprises.

Leak Testing: This is how we make sure air isn’t escaping where it shouldn’t. A proper seal means steady pressure and no unexpected drops, so your system keeps running the way it should.

Weld and Valve Testing: If you need it, we can also do X-ray or dye penetrant tests on the welds. These give us a closer look to make sure every connection is solid, clean, and won’t fail under pressure.

Custom Testing: Got specific requirements? No problem. Just tell us what you need & we’ll run the tests to match. We’re here to make sure you get exactly what works for your setup.

Air Header Price

At Kalpataru Piping Solutions, we’ve been manufacturing air headers that people trust — tough, reliable, and built to last. Whether you’re running a small setup or a large industrial operation, our air distribution manifolds are designed to handle the job without breaking your budget.

Every unit we build goes through careful quality checks because we know how important it is to have equipment you can count on. Need something specific? No problem — we offer customization for size, material, and design so you get exactly what your project needs. For the latest pricing and stock availability, simply send your inquiry or follow the provided link. Trust Instrumxx Industries for all your air header solutions.

Benefits of Air Headers

Air headers make it a lot easier to manage compressed air across your system. They’re practical, reliable, and come with a bunch of real benefits:

- Centralized Air Distribution: Instead of running separate pipes everywhere, you can send air from one spot to multiple places. It keeps things simple and clean.

- Space-Saving Design: With fewer pipes and connections, your setup stays compact — great when space is limited or you want things tidy.

- Cost-Efficiency: You use fewer fittings and pipes, which means lower costs up front and less to maintain over time.

- Improved Safety: With fewer joints and connections, there’s less chance of something going wrong or causing a hazard.

- Easy Installation and Maintenance: Setting up or fixing things is quicker because everything’s in one place. Less chasing lines, less time wasted.

- Enhanced Performance: You get consistent pressure, which means your equipment runs better and more efficiently.

- Durability: These are built to last — they handle harsh environments without wearing out fast.

- Reduced Pressure Drops: Less distance, fewer bends — that means the air flows better and stronger where it needs to.

Applications of Air Header Distribution Manifold

Air headers are used in all kinds of industries — anywhere there’s a need to move compressed air efficiently. Here’s where you’ll usually find them:

Air distribution systems: These are the workhorses in factories and plants, sending compressed air from one spot to multiple tools or machines.

Blow-down systems: Used when you need to safely release air or gas during maintenance or testing — simple but essential.

Chemical and petrochemical plants: Here, air headers help feed clean, reliable air to instruments and control systems that need to run without fail.

Power plants: They’re used to move instrument air to different parts of the plant, helping control systems and machinery run the way they should.

Oil and gas: Whether it’s a refinery or processing site, air headers supply air where it’s needed — for valves, actuators, and other equipment.

Water treatment facilities: These systems rely on compressed air for things like aeration and operating control valves — air headers keep that process smooth and steady.

Frequently Asked Questions on Air Header Distribution Manifold

What is an Air Header?

An air header is a pipe assembly that takes compressed air from one source and sends it to multiple instruments. It has several outlets and is built to spread air efficiently through its internal chambers and branches.

Why use Air Headers?

What is the difference between an Air Header & an Air Manifold?

What is the function of an air manifold?

Cities We deliver:

Bhopal, Lahore, Milan, Hyderabad, Pune, Vadodara, Pimpri-Chinchwad, Aberdeen, Howrah, Jeddah, Riyadh, Bogota, Petaling Jaya, Dallas, Lagos, Nagpur, Houston, Brisbane, Busan, Karachi, Coimbatore, Seoul, Caracas, Atyrau, Perth, Haryana, Bengaluru, Jaipur, Al Jubail, Kuwait City, Al Khobar, Sydney, Ranchi, Chiyoda, Noida, Chandigarh, Secunderabad, Ahvaz, Port-of-Spain, Singapore, Gurgaon, Rajkot, Rio de Janeiro, Abu Dhabi, Hong Kong, Surat, Sharjah, Hanoi, London, Muscat, Jakarta, Navi Mumbai, Istanbul, Kolkata, Cairo, Mumbai, Santiago, Montreal, Faridabad, Vung Tau, Bangkok, Ankara, Ahmedabad, Granada, Melbourne, Tehran, Visakhapatnam, New Delhi, Los Angeles, Ho Chi Minh City, Edmonton, La Victoria, Baroda, Thane, Nashik, Kuala Lumpur, Moscow, Ernakulam, Courbevoie, Calgary, Geoje-si, Indore, New York, Mexico City, Gimhae-si, Ludhiana, Kanpur, Ulsan, Thiruvananthapuram, Manama, Doha, Chennai, Madrid, Jamshedpur, Algiers, Dammam

Countries We Deliver:

Iran, Venezuela, Saudi Arabia, Slovakia, Romania, Zimbabwe, Spain, Kazakhstan, Canada, Nigeria, Bulgaria, Afghanistan, Thailand, Bangladesh, Poland, United Kingdom, Bahrain, Jordan, Lithuania, Malaysia, France, Nigeria, Japan, Oman, Lebanon, Germany, Croatia, Australia, Puerto Rico, South Korea, Hungary, United States, Bhutan, Mexico, Mexico, Yemen, Singapore, New Zealand, Ecuador, Gabon, Qatar, Denmark, Iran, Netherlands, Norway, Sri Lanka, Belgium, Libya, Kuwait, Pakistan, Gambia, Sweden, Azerbaijan, Argentina, Chile, Ghana, United Arab Emirates, Finland, Nepal, Trinidad andamp; Tobago,Tunisia, Kenya, Peru, Austria, Russia, Ukraine, Italy, Belarus, Bolivia, Serbia, Poland, Mongolia, Turkey, Czech Republic, South Africa, Angola, India, Vietnam, Indonesia, Tibet, Ireland, Costa Rica, Greece, Colombia, Namibia, Iraq, Estonia, Israel, Macau, Philippines, Brazil, Switzerland, Algeria, Morocco, Chile, Portugal, Egypt, Taiwan, China, Hong Kong.