Alloy 20 Pipe Spools Manufacturer & Supplier in India

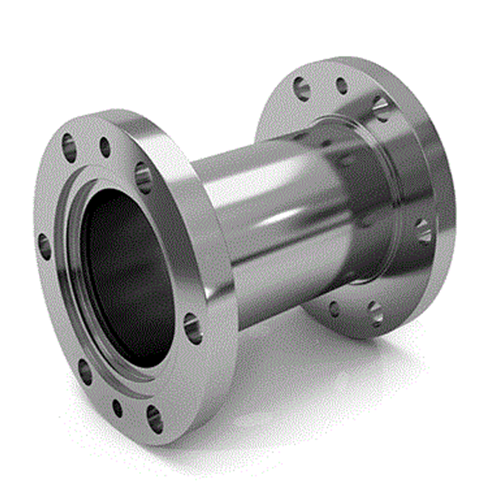

Alloy 20 Pipe Spools are ready-to-use piping systems, consisting of welded pipes, fittings, and flanges, which are intended to be used in corrosive service environments to simplify installation and also to be leak-free. The pipe spools are extensively utilized in chemical and process industries where resistance to sulphuric acid and aggressive chemicals is a big concern. Carpenter 20 or UNS N08020 is a nickel-iron-chromium alloy containing controlled amounts of molybdenum and copper. Its common chemical composition consists of 32-38 % nickel, 19-21 % chromium, and copper and molybdenum that offer it great resistance to pitting, crevice corrosion, and stress corrosion cracking.

Alloy 20 Pipe Spools have high physical and mechanical characteristics with a tensile strength of at least 551 Mpa, a yield strength of 241 Mpa and an elongation of up to 30%, which means that they are resistant to high-pressure and temperature conditions. These spools are produced according to ASTM B729, ASME SB729, and come in different sizes and thicknesses. Alloy 20 Pipe Spools are used in chemical processing plants, oil and gas facilities, pharmaceutical units, heat exchangers, and pollution control systems where long service life and operational reliability are required. Kalpataru Piping offers high-quality manufactured products with strict quality management, on-time delivery, and complete material traceability to satisfy the challenging industrial needs.

Table of Content

Specifications of Alloy 20 Pipe Spools

Alloy 20 Pipe Spools Manufacturer, Alloy UNS N08020 Pipe Spools Fitting Exporter, Carpenter 20 Pipe Spool Fitting, Alloy 20 Pipes Spools Stockist & Exporters in India

ASTM B471 Alloy 20 Pipe Spool Fitting Manufacturer, Alloy UNS N08020 Pipe Spools, Alloy 20 Prefabricated Pipe Spool, ASTM B471 Alloy 20 Pipe Spool Fittings Supplier

|

Category |

Specification Details |

|

Specifications |

ASTM B463 / ASME SB463 |

|

Dimensions |

ASTM, ASME, and API |

|

Size Range |

15NB to 150NB In |

|

Thickness |

0.3 mm to 120 mm |

|

Finish |

Hot rolled plate (HR), Cold rolled sheet (CR), 2B, 2D, BA NO(8), SATIN (Met with Plastic Coated) |

|

Form |

Coils, Foils, Rolls, Plain Sheet, Strip, Flats, Blank (Circle), Ring (Flange) etc. |

|

Hardness |

Soft, Hard, Half Hard, Quarter Hard, Spring Hard etc. |

UNS N08020 Pipe Spools Chemical Composition

Alloy 20 Pipe Spools are made of different metals, and detailed information is provided below.

|

Element |

Ni |

Fe |

C |

Mn |

Si |

Cu |

Cr |

Mo |

S |

P |

Nb |

|

Alloy 20 (%) |

32 – 38 |

Bal |

0.02 max |

1 – 2 |

0.7 max |

3 – 4 |

19 – 21 |

2 – 3 |

0.005 max |

0.02 max |

0.1 – 0.3 |

Carpenter 20 Pipe Spools Mechanical Properties

The mechanical properties of the Alloy 20 Pipe Spools are provided below.

|

Element |

Density |

Melting Point |

Tensile Strength |

Yield Strength (0.2% Offset) |

Elongation |

|

Alloy 20 |

8.1 g/cm³ |

1443 °C (2430 °F) |

80,000 Psi (551 MPa) |

35,000 Psi (241 MPa) |

30 % |

ASTM B729 Alloy 20 Pipe Spools Equivalent Material

The UNS N08020 pipe spools are manufactured in different standards, which are given below.

Different Types of Alloy 20 Pipe Spools

Applicational Uses of Alloy 20 Pipe Spools

Frequently Asked Questions ( FAQ)

What are UNS N08020 pipe spools?

The UNS N08020 pipe spools are prefabricated piping assemblies made from Alloy 20, designed for use in corrosive and acidic environments.

What are the benefits of Alloy 20 pipe spools?

They offer excellent resistance to sulfuric acid, chlorides, and corrosion, provide long service life, and reduce on-site installation time.

What is the difference between welded and seamless Alloy 20 pipe spools?

The welded pipe spools are made from welded pipes and are cost-effective, while seamless pipe spools offer higher strength and are used for high-pressure applications.

What sizes and thicknesses are Alloy 20 pipe spools available in?

Alloy 20 pipe spools are available in various diameters, wall thicknesses, and lengths as per ASTM and ASME standards or custom requirements.

How are Alloy 20 pipe spools fabricated?

They are fabricated through cutting, welding, fitting, and inspection processes following ASTM and ASME specifications.