Duplex Steel Perforated Sheet UNS S32205

Duplex steel perforated sheet UNS S32205 is designed for excellent performance in harsh & demanding applications. Known for its balanced microstructure of austenite & ferrite, it offers superior strength, stress corrosion resistance & durability as compared to standard stainless steel products. The S32205 duplex steel perforated sheet contains 22% chromium, 5 to 6% nickel & 3% molybdenum which makes it highly resistant to pitting, crevice corrosion & chloride induced stress corrosion cracking. Due to these properties, they are used for offshore structures, chemical processing equipment, heat exchangers & marine applications.

Our duplex UNS S32205 perforated sheet conforms to ASTM A240 & ASME SA240 standard ensuring great quality control & performance consistency. The perforations allow for excellent airflow, drainage & filtration in various industrial applications. With its enhanced weldability, high fatigue strength & exceptional corrosion resistance, the S32205 duplex stainless steel perforated sheet is the best choice for industries looking for reliable & cost effective solutions for long-term performance.

Duplex S32205 Perforated Sheet Manufacturer & Supplier

Kalpataru Piping Solutions is a leading manufacturer & supplier of duplex S32205 perforated sheets in India & international markets offering premium quality products designed for superior performance in corrosive & high-stress environments. Manufactured with precision & built to last, our S32205 perforated sheets are used for filtration systems, architectural applications, ventilation panels & other industrial uses.

These UNS S32205 duplex stainless steel perforated sheets are constructed with a balanced combination of austenitic-ferritic microstructure that provides high strength, excellent fatigue resistance & outstanding corrosion resistance. The fine perforation patterns add both functionality & aesthetic appeal. We offer custom perforation sizes, hole patterns, thicknesses & sheet dimensions to meet specific application requirements. Kalpataru Piping Solutions ensures each sheet undergoes rigorous quality testing, including PMI testing, mechanical tests, IGC tests & surface finish checks to guarantee optimal performance & durability.

As a trusted Duplex Stainless Steel supplier, we are committed to delivering reliable, high-quality stainless steel solutions with timely delivery & competitive pricing. Whether you need standard sizes or custom-designed sheets, we offer robust & corrosion resistant perforated sheet solutions. Contact us today to get the best quote on Duplex S32205 perforated sheets tailored to your specific needs.

Types of Duplex Steel Perforated Sheet UNS S32205

Types of Duplex Steel Perforated Sheet UNS S32205

Duplex Steel S32205 Cold Rolled Sheet

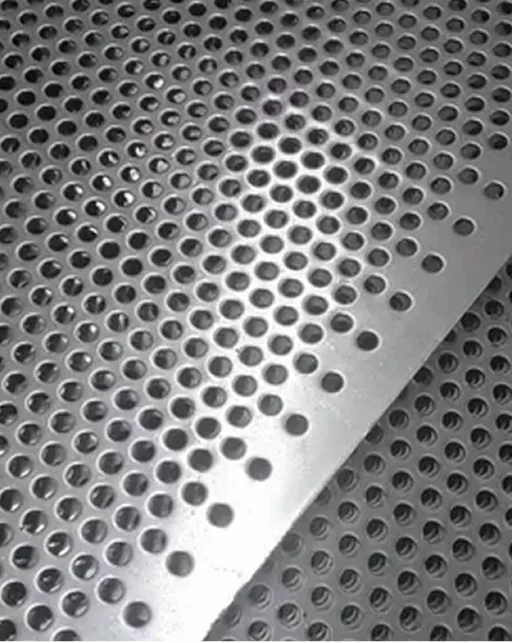

Duplex Steel S32205 Perforated Sheet

Duplex S32205 Perforated Sheet Specification

| Sheets Specifications | ASTM A240 / ASME SA240, BS EN 10088-2, en 10028-7, IS 6911 |

| Sheets Dimension Standard | MSRR, AMS, BS, JIS, AISI, ASTM, GB, DIN, EN, etc |

| DSS Sheets Thickness | 4mm-100mm |

| DSS Sheets Width | 1000mm, 1219mm, 1500mm, 1800mm, 2000mm etc |

| DSS Sheets Length | 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, etc |

| DSS Sheets Thickness | 0.1, 0.2/0.3/0.5/0.6/0.7/0.8/0.9/1.0/1.5, 2.0/2.5/3.0/4.0/5.0/6.0/8.0/9/10/12/16/18/20/ 22/25/30 mm |

| International Standard of Duplex Stainless Steel Sheets |

ASTM A480 ASTM A959 ASME IID EN ISO 9445 EN ISO 18286 EN 10051 EN 10088-1 ISO 15510 |

| Tolerances (width / thickness) of Duplex Stainless Steel Sheets |

EN 10258/ DIN 59381 EN 10151 ASME SA240 DSS Sheet EN 10088 SA240 Sheet |

| Finish of DSS Sheets | 2B, 2D, BA NO (8), Cold rolled Sheet (CR), Hot rolled sheet (HR), Checkered, No.4, BA, 8K, satin, mirror etc. |

| Hardness | Half Hard, Soft, Hard, Quarter Hard, Spring Hard |

| Value Added Service | Cladding, Heat Treatment, Annealed, Pickling, Polish, Rolling, Cutting, Bending, Forging, Minor Fabrication Etc. |

| Duplex Stainless Steel Profiling |

Plasma Sheet Cutting Laser Sheet Cutting Oxy-propane Flame Cutting |

Chemical Composition of S32205 Duplex Stainless Steel Perforated Sheet

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N | Fe |

| Duplex S32205 | 0.05 max | 1.00 max | 1.00 max | 0.030 max | 0.010 max | 24.00 – 26.00 | 3.00 – 4.00 | 6.00 – 8.00 | 0.20 – 0.30 | 57.61 min |

Duplex Steel Perforated Sheet S32205 Equivalent Material

| STANDARD | WERKSTOFF NR. | UNS |

| Duplex 2205 | 1.4462 | S32205 |

Duplex Steel Perforated Sheet S32205 Mechanical Properties

| Grades | Density (g/cm 3) | Density (lb/in 3) | Melting Point (°C) | Melting Point (°F) |

| S32205 | 7.805 | 0.285 | 1420 – 1465 | 2588 – 2669 |

Manufacturing Process of UNS S32205 Duplex Steel Perforated Sheets

Manufacturing Process of UNS S32205 Duplex Steel Perforated Sheets

As a leading Duplex S32205 Perforated Sheet Manufacturer in India, we follow a stringent manufacturing process to ensure superior performance, precision & durability.

- Reheating Furnace: Raw duplex steel slabs are heated in a controlled reheating furnace, preparing the material for hot rolling by achieving optimal rolling temperatures.

- Scale Breaker: The heated slab passes through a scale breaker to remove surface oxide layers using vertical rolls & high-pressure water jets to ensure a clean metal surface.

- Finish Rolling & Cold Rolling: After hot rolling, the slab undergoes cold rolling to achieve precise thickness & a smooth finish which is critical for high-strength duplex stainless S32205 perforated sheets.

- Cooling/Quenching: The rolled sheets are rapidly cooled or quenched to improve hardness and toughness for enhancing mechanical and corrosion-resistant properties.

- Perforation Process: The sheets are then perforated using advanced punching or laser technology to create evenly spaced holes suited for airflow, filtration or aesthetic design in industrial applications.

- Final Finishing: A final light rolling step ensures surface finish uniformity and mechanical consistency improving the sheet’s deep-drawing strength.

- Marking & Packing: Products are marked with batch numbers, grade & specifications. Sheets are then securely packed to prevent damage during transit meeting international shipping standards.

Applications of UNS S32205 Duplex Steel Perforated Sheets

Due to their balanced composition of chromium, nickel, molybdenum & nitrogen, corrosion-resistant UNS S32205 perforated sheets deliver high performance in applications. Here are some key application areas:

- Chemical & Petrochemical Industry: Used in filters, screens & structural components where chemical exposure is high. Their resistance to acid & alkali corrosion used to process harsh substances.

- Oil & Gas Equipment: UNS S32205 Perforated Sheets are used in applications such as offshore platforms, piping, separators & supports where high strength and chloride corrosion resistance are vital.

- Desalination & Water Treatment Plants: These sheets resist pitting & crevice corrosion making them perfect for filtration screens, trays, and panels in seawater and water purification systems.

- Pulp & Paper Industry: Employed in bleaching and chemical processing units for their resistance to acidic and alkaline media.

- Food & Beverage Processing: Their hygienic surface and anti-corrosive nature make them suitable for drying racks, sieves & protective covers.

- Architectural & Structural Design: Widely used in decorative facades, sunscreens & partitions due to their aesthetic appeal, strength-to-weight ratio & longevity.

- Automotive & Aerospace: Utilized in ventilation components, exhausts & noise-control panels where lightweight and durability are required.

As a top supplier of S32205 duplex steel perforated sheets, we offer custom sizes, finishes & perforation patterns tailored to your industrial needs. Choose our UNS S32205 duplex steel perforated sheets for a perfect blend of strength, durability & corrosion resistance.

High Quality Duplex Steel UNS S32205 Perforated Sheets

Kalpataru Piping Solutions is a leading manufacturer, exporter, stockist & supplier of duplex steel UNS S32205 perforated sheets offering products with superior quality. Our S32205 perforated sheets are known for their excellent corrosion resistance, high strength & precision engineering suitable for critical industrial applications.

Quality You Can Trust

We follow strict quality control procedures throughout the manufacturing process to ensure that every Duplex Steel UNS S32205 Perforated Sheet meets international standards. Each sheet is thoroughly inspected at multiple stages & third-party inspection is also available upon client request. Additionally, we provide all relevant test certificates and documentation to ensure transparency & traceability.

Why Choose Kalpataru Piping Solutions?

Kalpataru Piping Solutions stands out for its commitment to quality, timely delivery & customer satisfaction. With a vast inventory, competitive pricing & global export capability, we provide certified industrial piping products that meet international standards.

- Large Inventory: We maintain a huge stock of Duplex Steel UNS S32205 Perforated Sheets to ensure fast deliveries.

- Custom Sizes Available: Sheets can be supplied in customized dimensions based on your project requirements.

- Best Price Guarantee: Get the highest quality perforated sheets at competitive prices.

- Third-Party Inspection Ready: We welcome independent inspections & provide full quality documentation.

- Safe & Secure Packaging: Sheets are packed carefully in wooden boxes to avoid damage during transit ensuring they reach you in perfect condition anywhere in the world.

Frequently Asked Question About Duplex UNS S32205 Perforated Sheet

What is the difference between mesh and a Duplex Steel Perforated Sheet UNS S32205?

What materials are used for S32205 Duplex Stainless Steel Perforated Sheets?

What is the standard thickness of Duplex UNS S32205 Perforated Sheets?

What are the different perforation patterns available in Duplex Steel S32205 Perforated Sheets?

S32205 Duplex Steel Perforated Sheets can be manufactured with a variety of perforation styles to suit different functional and aesthetic needs:

Simple: Evenly spaced round or square holes

Scalariform: Stepped or layered designs for directional flow

Reticulate: Grid or mesh-like structure for filtration

Foraminate: Irregular or custom-shaped holes

Pitting Patterns: Including scalariform, alternate, or transitional arrangements

These pattern choices make Duplex Steel Perforated Sheet UNS S32205 ideal for sectors like construction, chemical processing, and marine engineering.

Related Products

- Duplex UNS S31803 Buttweld Fittings

- Duplex UNS S32205 Buttweld Fittings

- Duplex UNS S31803 Forged Fittings

- Duplex UNS S32205 Forged Fittings

- Duplex UNS S31803 Olets

- Duplex UNS S32205 Olets

- Duplex Steel UNS S31803 Fasteners

- Duplex Steel UNS S32205 Fasteners

- Duplex UNS S31803 Instrumentation Valves

- Duplex UNS S32205 Instrumentation Valves

- Duplex UNS S32205 Plates and Duplex UNS S32205 Sheets

- Duplex UNS S31803 Perforated Sheet

- Duplex UNS S32205 Perforated Sheet

- Duplex UNS S31803 Compression Tube Fittings

- Duplex UNS S32205 Compression Tube Fittings

- Duplex UNS S31803 Wiremesh

- Duplex UNS S32205 Wiremesh

- Duplex UNS S31803 Pipe Spools

- Duplex UNS S32205 Pipe Spools

- Duplex UNS S31803 Long Radius Bends

- Duplex UNS S32205 Long Radius Bends