Inconel 625 Pipe Fittings – UNS N06625 Compression Tube Fittings Supplier

Alloy 625 Compression Fittings manufacturer and exporter, ASTM B366 UNS N06625 Buttweld Elbow and Alloy 625 Fittings, Inconel UNS N06625 Pipe Elbow

Table of Content

- Inconel 625 Fittings – Material Properties & Standards

- Welding Inconel 625 Tube Fittings

- ASTM B366 / ASME SB366 / ASME B16.9 Standards & Specification

- Composition Chart of Inconel 625 Pipe Fittings

- Mechanical Properties of Inconel 625 Pipe Fittings

- Equivalent Grades of Alloy 625 Fittings

- Physical Properties of UNS N06625 Adapter Fittings

- Inconel 625 Tube Fittings Types

- Alloy 625 Pipe Fittings Weight Chart

- Inconel 625 Tube Fitting Sizes & Dimensions

- Inconel 625 Pipe Fittings Dimensions Chart

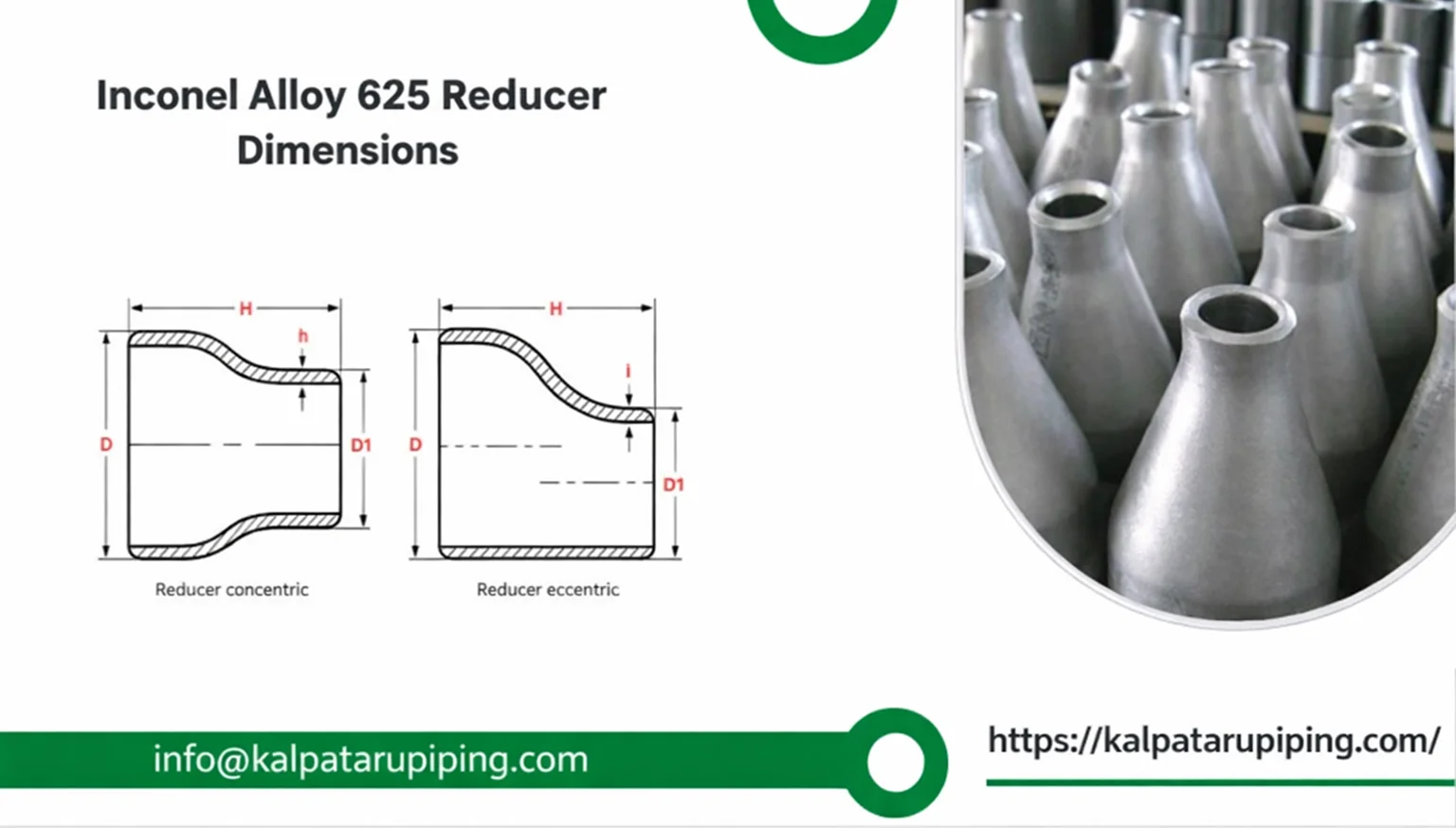

- Inconel Alloy 625 Reducer Dimensions

- Properties of Inconel 625 Pipe & Compression Tube Fittings

- Documentation for Inconel 625 Compression Tube & Pipe Fittings

- Quality Assurance & Testing of Inconel 625 Fittings

- Inconel 625 Pipe Fittings Price

Kalpataru Piping Solutions is a trustworthy supplier of nickel alloy buttweld fittings and a supplier of the full range of Inconel 625 tube fittings and Inconel 625 pipe fittings that are produced under the ASTM B366 and ASME SB366 specifications. We have maintain huge stock of ASME SB366 Inconel 625 long radius bends, which are made with a bigger radius to allow the fluid to flow smoothly.

Available Stock of Inconel 625 Pipe & Tube Fittings

We supply high quality Inconel 625 pipe fittings & tube fittings designed to offer leak-free connections in critical piping systems. As a trusted Inconel fittings supplier, our products are manufactured using state-of-the-art technology & available in multiple types and sizes.

Our fitting range includes:

- Inconel 625 butt weld fittings

- Inconel 625 socket weld fittings

- Inconel 625 forged fittings

Contact us to get detailed specifications, check availability & pricing for Inconel 625 pipe and tube fittings, test certificates & fast delivery.

Check Inconel 625 Tube Fittings Price

Kalpataru Piping, being a worldwide stockist and exporter, offers UNS N06625 Reducing Tee, Inconel 625 Pipe Cap, and UNS N06625 Stub End and ASME SB366 Long Radius Elbows at reasonable prices.

UNS N06625 Reducing Tee

Inconel 625 Pipe Cap

UNS N06625 Stub End

Know More About Alloy 625 Buttweld Elbow and UNS N06625 Tee

UNS N06625 Tee

UNS N06625 Elbows are available in a variety of types/angles, including 45-degree and 90-degree, so the direction can be changed without interfering with the integrity of the pipeline. Inconel 625 Bends are capable of operation in high temperatures because they exhibit a high melting point of about 1350 °C. Tee Fittings are available in equal and unequal to fit three pipes, combining two lines into one and are available in two versions, DIN 2.4856 Tee Fittings. ASTM B366 Inconel 625 Short and Long Radius Elbows are especially famous because of their great fatigue strength and durability. ASTM B564 UNS N06625 Inconel 625 Threaded Fittings are used to create leak-free connections without welding, such as Alloy 625 Buttweld Elbows to direct the pipelines and UNS N06625 Tees to join multiple pipelines.

Available Types of Inconel Alloy 625 Compression Tube Fittings

Inconel 625 Tube to Male Pipe Thread

Inconel 625 UNS N06625 Weld Fitting

Inconel Alloy 625 Tube to Tube

Alloy 625 Tube to Female Pipe Thread

Alloy 625 UNS N06625 Port Connector

ASME SB564 UNS N06625 Tube Ends

Ready Stock of Inconel 625 (UNS N06625) Socket Buttweld Pipe Fittings

UNS N06625 Inconel 625 Full Coupling

UNS N06625 Inconel 625 Pipe Cross

UNS N06625 Inconel 625 Pipe Tee

N06625 Inconel 625 90 Degree Elbow

UNS N06625 Inconel 625 Eccentric Reducer

UNS N06625 Inconel 625 Forged Union

Inconel 625 Fittings – Material Properties & Standards

Inconel 625 is a non-magnetic nickel-based superalloy known for its excellent

strength, toughness, and corrosion resistance in extreme environments.

Key properties and standards include:

- Superior impact strength and mechanical stability

- Excellent corrosion and oxidation resistance

- Enhanced strength due to niobium addition

- Wide operating temperature range from cryogenic conditions up to 1093 °C

- High melting point of approximately 1350 °C

- Available pressure classes: 1000 psi, 3000 psi, 6250 psi, and 10000 psi

Inconel 625 pipe fittings and compression tube fittings are designed to deliver secure, leak-free performance in critical and high-pressure Inconel 625 pipes and tubes. These fittings are

fully annealed seamless and welded-redrawn tubing. The product range includes elbows, tees, and connectors, with butt weld elbows available in 45° and 90° angles for efficient flow direction changes. UNS N06625 tees are offered in both equal and unequal configurations, allowing flexibility in piping system design.

Welding Inconel 625 Tube Fittings

Welding Inconel 625 tube fittings must be done under controlled conditions because of its high nickel–chromium composition and heat resistance. TIG ( Gas Tungsten Arc ) welding is the method that is best recommended to join Inconel 625 fittings and provides less cracking during the process of fusion. Maintaining clean surfaces and controlled heat input helps prevent defects, while using automated equipment can improve consistency and weld quality in repetitive or complex welding operations.

ASTM B366 / ASME SB366 / ASME B16.9 Standards & Specification of Inconel 625 Pipe

Fittings

ASTM B366 / ASME SB366 defines the material requirements for Inconel 625 wrought pipe fittings, while ASME B16.9 covers the dimensions and tolerances for factory-made butt-weld fittings. Together, these standards ensure high strength, excellent corrosion resistance, precise dimensions, and reliable performance of Inconel 625 pipe fittings in high-temperature and high-pressure applications.

Standard Configurations Of Inconel 625 Tube Fittings

- Tube to Tube – Tee, Bulk Head, Straight, Elbow, Cross

- Tube to Male – Male Tee, Male Elbow, Male Stud

- Female Connector – Female Elbow, Tee, Straight

- Tube Closure – Cap, Plug Ferrule Set, Weld Connector & Nu

| ASTM B366 /ASME SB366 | UNS N02200/WPN /CRN | UNS N02201/WPNL /CRNL | UNS N04400/WPNC /CRNC |

| UNS N06022/WPHC22 /CR HC22 | UNS N06025/WPV602 /CRV602 | UNS N06030/WPHG30 /CR HG30 | |

| UNS N06200/WHC2000 /CR HC2000 | UNS N06230/WPH230 /CRH230 | UNS N06455/WPHC4 /CR HC 4 | |

| UNS N06625/WPNCMC /CRNCMC | UNS N06985/WPHG3 /CR HG3 | UNS N08020/WP20CB /CR20CB | |

| UNS N08120/WPH120 /CRH120 | UNS N08330/WP330 /CR330 | UNS N08367/WP6XN /CR6XN | |

| UNS N08811/WPNIC11 /CRNIC11 | UNS N08825/WPNICMC /CRNICMC | UNS N08925/WP1925 /CR1925 | |

| UNS N10003/WPHN /CR HN | UNS N10276/WPHC276 /CR HC 276 | UNS N10629/WPVB4 /CRVB4 | |

| UNS N12160/WPH160 /CRH160 | UNS R20033/WP3033 /CR3033 | UNS R30556/WPH556 /CRH556 | |

| UNS N06002/WPHX /CR HX | UNS N06007/WPHG /CR HG | UNS N06045/WPV45TM /CRV45TM | |

| UNS N06600/WPNCI /CRNCI | UNS N06059/WP5923 /CR5923 | UNS N06603/WP603GT /CR603GT | |

| UNS N08904/WP904L /CR904L | UNS N08031/WP3127 /CR3127 | UNS N08800/WPNIC /CRNIC | |

| UNS N08926/WP1925N /CR1925N | UNS N08810/WPNIC10 /CRNIC10 | UNS N10001/WPHB /CR HB | |

| UNS N10665/WPHB-2 /CR HB2 | UNS N10675/WPHB-3 /CR HB3 |

| BS 3799 | |

| Size | 1/8″~4″ (DN6~DN100) |

| Inconel 600 Pressure Class | 3000LBS, 6000LBS, 9000LBS |

| Alloy 600 Threaded Pipe Fittings Products | Elbow 90 Degree, Elbow 45 Degree, Tee, Cross, Union, Street Elbow, Coupling, Half Coupling, Reducing Coupling, Cap, Hex Head Bushing, Hex Head Plug, Square Head Plug, Round Head Plug, Bull Plug, Boss, Outlet, Hex Nipple, Swage Nipple |

| Dimension Specifications | ASME 16.11, MSS SP-79, 83, 95, 97, BS 3799 |

| Size | 1/8″~4″ (DN6~DN100) |

| Specifications | ASTM B366 / ASME SB366 |

| Size | Seamless Butt Weld Fittings: 1/2″ – 10″, Welded Butt Weld Fittings: 1/2″ – 48″ |

| Standards | ASME/ANSI B16.9, ASME B16.28, MSS-SP-43 |

| Thickness | 5s, 10s, 40s, 80s, 10, 20, 40, STD, 60, 80, XS, 100, 120, 140, 160, XXS available with NACE MR 01-75 |

| Type | Seamless / Welded / Fabricated |

Composition Chart of Inconel 625 pipe fittings

| Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr |

| Inconel 625 | 0.10max | 0.50 max | 0.50 max | 0.015max | – | 5.0 max | 58.0 min | 20.0 – 23.0 |

Alloy 625 Pipe Fittings Mechanical Properties Chart

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Inconel 625 | 8.4 g/cm3 | 1350 °C (2460 °F) | Psi – 1,35,000 , MPa – 930 | Psi – 75,000 , MPa – 517 | 42.5 % |

Equivalent of Alloy 625 Fittings

| Grade | UNS No | Old British | Euronorm | GOST | Japanese JIS | ||

| BS | En | No | AFNOR | ||||

| Inconel 625 | N06625 | NA 21 | NiCr22Mo9Nb | 2.4856 | NC22DNB4M | –75—- | NCF 625 |

Inconel 625 Tube Fittings Types

Inconel Alloy 625 Tube to Male Pipe Thread

- Tube to Male Elbow

- Tube to Male Branch Tee

- Tube to Male Connector

- Tube to Bulkhead Male Connector

- Tube to Male Run Tee

Inconel Alloy 625 Tube to Female Pipe Thread

- Tube to Bulkhead Female Connector

- Tube to Female Elbow

- Tube to Female Connector

- Tube to Female Branch Tee

- Tube to Female Run Tee

Inconel Alloy 625 Tube Ends

- Grade Cap for Tube End

- Tube Cap

- Tube Plug

- Tube Caps and Plugs

- Tube Thread Cap

Inconel Alloy 625 Tube to Tube

- Tube to Tube Bulkhead Union

- Tube to Tube Union

- Tube to Tube Reducer Union

- Tube to Tube Bulkhead Reducer Union

- Tube to Tube Bulkhead Union Elbow

Inconel Alloy 625 Tube Port Connector

- Tube Male Adapter

- Tube Reducer

- Tube Bulkhead Reducer

- Tube Female Adapter

- Tube Weld Adapter

Physical Properties UNS N06625 Adapter Fittings

| Properties | Values | |

| Permeability | at 200 Oersted (15.9 kA/m) | 1.0006 |

| Curie Temperature | °F | <-320 |

| °C | -196 | |

| Density | lb/cu in | 0.305 |

| gram/cc | 8.44 | |

| Melting Range | °F | 2350 |

| °C | 1290 | |

Alloy 625 Pipe Fittings Weight Chart

The Alloy 625 pipe fittings weight chart provides accurate theoretical and actual weights based on standard dimensions. As a reliable Inconel 625 pipe fittings supplier in India, we offer precise weight details to help ensure correct material planning, cost estimation, and hassle-free installation.

| NPS | Weight In LBS | Weight In Kg |

| 10 | 43 | 19.5 |

| 12 | 62 | 28.12 |

| 1/2 | 0.09 | 0.04 |

| 1.1/2 | 0.4 | 0.18 |

| 3 | 2.63 | 1.19 |

| 4 | 4.5 | 2.04 |

| 5 | 7.5 | 3.4 |

| 6 | 12 | 5.44 |

| 8 | 23 | 10.43 |

| 14 | 80 | 36.29 |

| 20 | 160 | 72.57 |

| 2 | 0.81 | 0.37 |

| 2.1/2 | 1.75 | 0.79 |

| 1 | 0.25 | 0.11 |

| 16 | 100 | 45.36 |

| 18 | 126 | 57.15 |

| 1.1/4 | 0.38 | 0.17 |

| 3/4 | 0.09 | 0.04 |

| 36 | 531 | 240.86 |

| 22 | 197 | 89.36 |

| 3.1/2 | 3.5 | 1.59 |

| 30 | 367 | 166.47 |

| 24 | 238 | 107.95 |

| 26 | 275 | 124.74 |

Inconel 625 Tube Fitting Sizes, Dimensions

Inconel 625 Seamless Compression Fittings

| Specification | Details |

|---|---|

| Size | 1/8″ to 2″ |

| Pressure Rating | 3000 PSI – 10,000 PSI |

| Threads | NPT, BSPT, BSPP |

Alloy 625 Welded Compression Fittings & Tube Adapters

| Specification | Details |

|---|---|

| Size | 24″ to 96″ (or Custom) |

| Pressure Rating | 3000 PSI – 10,000 PSI |

| Threads | NPT, BSPT, BSPP |

625 Inconel Pipe Fittings Dimensions Chart

| Nominal Pipe Size | Outside Diameter | 90° Elbows | 45° Elbows | 180° Returns | ||||

| (inches) | Long Radius | Short Radius | Long Radius | Long Radius | ||||

| (mm) | (inches) | Center to Face

(inches) |

Center to Face

(inches) |

Center to Face

(inches) |

Radius

(inches) |

Center to Center

(inches) |

Back to face

(inches) |

|

| 1/2 | 21.3 | 0.840 | 1 1/2 | – | 5/8 | 2 | 1 7/8 | |

| 3/4 | 26.7 | 1.050 | 1 1/8 | – | 7/16 | 2 1/4 | 1 11/16 | |

| 1 | 33.4 | 1.315 | 1 1/2 | 1 | 7/8 | 3 | 2 3/16 | |

| 1 1/4 | 42.2 | 1.660 | 1 7/8 | 1 1/4 | 1 | 3 3/4 | 2 3/4 | |

| 1 1/2 | 48.3 | 1.900 | 2 1/4 | 1 1/2 | 1 1/8 | 3 | 4 1/2 | 3 1/4 |

| 2 | 60.3 | 2.375 | 3 | 2 | 1 3/8 | 4 | 6 | 4 3/16 |

| 2 1/2 | 73.0 | 2.875 | 3 3/4 | 2 1/2 | 1 3/4 | 5 | 7 1/2 | 5 3/16 |

| 3 | 88.9 | 3.500 | 4 1/2 | 3 | 2 | 6 | 9 | 6 1/4 |

| 3 1/2 | 101.6 | 4.000 | 5 1/4 | 3 1/2 | 2 1/4 | 7 | 10 1/2 | 7 1/4 |

| 4 | 114.3 | 4.500 | 6 | 4 | 2 1/2 | 8 | 12 | 8 1/4 |

| 5 | 141.3 | 5.563 | 7 1/2 | 5 | 3 1/8 | 10 | 15 | 10 5/16 |

| 6 | 168.3 | 6.625 | 9 | 6 | 3 3/4 | 12 | 18 | 12 5/16 |

| 8 | 219.1 | 8.625 | 12 | 8 | 5 | 12 | 24 | 16 5/16 |

| 10 | 273.1 | 10.750 | 15 | 10 | 6 1/4 | 15 | 30 | 20 3/8 |

| 12 | 323.9 | 12.750 | 18 | 12 | 7 1/2 | 18 | 36 | 24 3/8 |

Inconel Alloy 625 Reducer Dimensions

| Nominal

Pipe Size |

Outside

Diameter |

Reducers | ||

| Reduced from

(inches) |

(mm) | (inches) | Reduced to

(inches) |

Concentric & Eccentric Length

(inches) |

| 1/2 | 21.3 | 0.840 | 1/4 | 1 1/2 |

| 3/8 | 1 1/2 | |||

| 3/4 | 26.7 | 1.050 | 3/8 | 2 |

| 1/2 | 2 | |||

| 1 | 33.4 | 1.315 | 3/8 | 2 |

| 1/2 | 2 | |||

| 3/4 | 2 | |||

| 1 1/4 | 42.2 | 1.660 | 1/2 | 2 |

| 3/4 | 2 | |||

| 1 | 2 | |||

| 1 1/2 | 48.3 | 1.900 | 1/2 | 2 1/2 |

| 3/4 | 2 1/2 | |||

| 1 | 2 1/2 | |||

| 1 1/4 | 2 1/2 | |||

| 2 | 60.3 | 2.375 | 3/4 | 3 |

| 1 | 3 | |||

| 1 1/4 | 3 | |||

| 1 1/2 | 3 | |||

| 2 1/2 | 73.0 | 2.875 | 1 | 3 1/2 |

| 1 1/4 | 3 1/2 | |||

| 1 1/2 | 3 1/2 | |||

| 2 | 3 1/2 | |||

| 3 | 88.9 | 3.500 | 1 | 3 1/2 |

| 1 1/2 | 3 1/2 | |||

| 2 | 3 1/2 | |||

| 2 1/2 | 3 1/2 | |||

| 3 1/2 | 101.6 | 4.000 | 1 1/4 | 4 |

| 1 1/2 | 4 | |||

| 2 | 4 | |||

| 2 1/2 | 4 | |||

| 3 | 4 | |||

| 4 | 114.3 | 4.500 | 1 1/2 | 4 |

| 2 | 4 | |||

| 2 1/2 | 4 | |||

| 3 | 4 | |||

| 3 1/2 | 4 | |||

| 5 | 141.3 | 5.563 | 2 | 5 |

| 2 1/2 | 5 | |||

| 3 | 5 | |||

| 3 1/2 | 5 | |||

| 4 | 5 | |||

| 6 | 168.3 | 6.625 | 2 1/2 | 5 1/2 |

| 3 | 5 1/2 | |||

| 3 1/2 | 5 1/2 | |||

| 4 | 5 1/2 | |||

| 5 | 5 1/2 | |||

| 8 | 219.1 | 8.625 | 3 | 6 |

| 3 1/2 | 6 | |||

| 4 | 6 | |||

| 5 | 6 | |||

| 6 | 6 | |||

| 10 | 273.1 | 10.750 | 4 | 7 |

| 5 | 7 | |||

| 6 | 7 | |||

| 8 | 7 | |||

| 12 | 323.9 | 12.750 | 5 | 8 |

| 6 | 8 | |||

| 8 | 8 | |||

| 10 | 8 | |||

Properties of Inconel 625 Pipe & Compression Tube Fittings

UNS N06625 Pipe Fittings Heat Treatment

Inconel 625 Pipe Fittings Supplier in India offers high strength and corrosion resistance

| Type | Cooling | Condition | Time | Temperature |

| Stress Relieve | Air | Annealed | 0.5 – 1hr |

|

Alloy 625 Fittings Pressure Rating

| NPS | Fittings Weight In KG | OD | Working Pressure Max. | Ave. ID | (Min.) WT |

| *3in | 1.488 | 3.500 | 260 | 3.042 | .216 |

| 3-1/2in | 1.789 | 4.000 | 240 | 3.521 | .226 |

| *4in | 2.118 | 4.500 | 220 | 3.998 | .237 |

| 3/8in | .115 | .675 | 620 | .473 | .091 |

| 2-1/2in | 1.136 | 2.875 | 300 | 2.445 | .203 |

| *10in | 7.966 | 10.750 | 140 | 9.976 | .365 |

| 1/2in | .170 | .840 | 590 | .602 | .109 |

| 3/4in | .226 | 1.050 | 480 | .804 | .113 |

| *16in | 16.286 | 16.000 | 130 | 14.940 | .500 |

| 1in | .333 | 1.315 | 450 | 1.029 | .133 |

| *1-1/4in | .450 | 1.660 | 370 | 1.360 | .140 |

| *12in | 10.534 | 12.750 | 130 | 11.889 | .406 |

| *8in | 5.619 | 8.625 | 160 | 7.942 | .322 |

| *1-1/2in | .537 | 1.900 | 330 | 1.590 | .145 |

| *2in | .720 | 2.375 | 280 | 2.047 | .154 |

| *14in | 12.462 | 14.000 | 130 | 13.073 | .437 |

| 5in | 2.874 | 5.563 | 190 | 5.016 | .258 |

| *6in | 3.733 | 6.625 | 180 | 6.031 | .280 |

| 1/4in | .086 | .540 | 780 | .344 | .088 |

WERKSTOFF Nr 2.4856 Weld Fittings Thermal Conductivity

Find Inconel 625 Pipe Fittings Stockist in India who provides Enhanced Thermal Properties

| Temperature Range | Linear of Thermal Expansion1 | Conductivity2 3 | Thermal | Coefficients . 10-6 | |

| °C | °F | 1°C | Btu/(hr/ft2/in/°F) | W/mK | 7°F |

| 982 | 1800 | – | 14,6 | 25.3 | – |

| 21 | 70 | – | 5.7 | 9.9 | – |

| 93 | 200 | 12.8 | 6.3 | 10.7 | 7.1 |

| 538 | 1000 | 14 | 10.1 | 17,5 | 7.8 |

| 760 | 1400 | 15.3 | 12 | 20.8 | 8.5 |

| 204 | 400 | 13.1 | 7.3 | 12.6 | 7.3 |

| -157 | -250 | – | 4.2 | 7.3 | – |

| -129 | -200 | – | 4.3 | 7.4 | – |

| -18 | 0 | – | 5.3 | 9.2 | – |

| 427 | 800 | 13.7 | 9.1 | 15.7 | 7,6 |

| 871 | 1600 | 15.8 | 13.2 | 22.8 | 8.8 |

Alloy 625 Seamless Pipe Fittings Temperature Range

| Temp. °C | Modulus of | Elasticity, GPa |

| Tension | ||

| Annealed | Solution- Treated | |

| 204 °C | 197.9 | 193.7 |

| 316 °C | 191.7 | 187.5 |

| 649 °C | 170.3 | 165.5 |

| 760 °C | 160.6 | 157.2 |

| 427 °C | 185.5 | 180.6 |

| 21 °C | 207.5 | 204.8 |

| 93 °C | 204.1 | 200.6 |

| 538 °C | 178.6 | 173.1 |

| 871 °C | 147.5 | 148.2 |

Documentation for Inconel 625 Compression Tube & Pipe Fittings

We carry out comprehensive documentation and make sure it is compliant globally, easy to clear without problems at customs, and trace all Inconel 625 fittings:

- Certificate of Origin (attested by Chamber /Embassy)

- Commercial Invoice HS code.

- List of Packing (boxes, weights, marks)

- Fumigation Certificate and Letter of Guarantee.

- Material Test Certificate (EN 10204 3.1 3.2)

- NACE MR0103 / MR0175 Certificates

- Raw Material Test Report and Heat Treatment Charts.

- WPS/PQR Material Traceability Records.

- Quality Assurance Plan (QAP) NABL Lab Reports.

Quality Assurance & Testing

All compression tube and pipe fittings of Inconel 625 are subjected to extensive destructive and non-destructive tests to guarantee excellent performance:

- PMI & Chemical Analysis

- Mechanical: Tensile, Yield, Elongation.

- Micro/Macro Tests & Hardness

- Pitting and Intergranular Corrosion (IGC)

- Flaring, Flattening and Hydrostatic Tests.

- HIC (NACE TM0284) & SSC (NACE TM0177)

- Radiography, Dye Penetrant, Ultrasonic, Eddy Current.

- Impact & Bend Tests

Inconel 625 Pipe Fittings Price

Inconel 625 Pipe fittings are priced based on the size, type (butt weld, socket weld, threaded), class of pressure, and quantity. The price depends on other factors that include the cost of the raw materials, the international standards, and the needs of customization. To get the detailed quotes, contact us with specifications and quantity requirements.

| Product Type | Size Range | Pressure Class | Estimated Price (INR / Piece) | Notes |

| Inconel 625 Butt Weld Elbow | 1/2″ – 24″ | 1000 – 10000 psi | 15,000 – 1,50,000 | Price varies with diameter, thickness, and standard (ASTM B366/ASME SB366) |

| Inconel 625 Socket Weld Fitting | 1/2″ – 6″ | 1000 – 3000 psi | 8,000 – 35,000 | Common for smaller pipe connections, quick installation |

| Inconel 625 Threaded Fittings | 1/4″ – 4″ | 1000 – 3000 psi | 5,000 – 20,000 | Includes NPT, BSPT, BSPP threads |

| Inconel 625 Tee (Butt Weld) | 1/2″ – 24″ | 1000 – 10000 psi | 20,000 – 1,80,000 | Equal and unequal tees available |

| Inconel 625 Compression Tube Fittings | 1/8″ – 2″ OD | Up to 5000 psi | 3,500 – 18,000 | Ideal for instrumentation and hydraulic lines |

| Inconel 625 Reducers | 1/2″ – 24″ | 1000 – 10000 psi | 12,000 – 1,40,000 | Concentric and eccentric reducers available |

Notes:

- Prices are indicative and can change depending on the cost of raw materials, quantity of orders and custom needs.

- To give the exact quotations, the products to be used should be specified, sizes and pressure required by the customer.

- All fittings are in conformity to the ASTM/ASME standards and are compatible with seamless and welded Inconel 625 pipes.

Ready Stock of Inconel 625 Tube Fittings

|

|

Application of Inconel 625 Compression Tube Fittings

The fittings of Inconel 625 compression tubes are well utilized in the industry that needs high strength and resistance to corrosion, and the connections that cannot be easily leaked. Key applications include:

- Oil & Gas: Hydraulic systems and high-pressure instrumentation lines.

- Chemical and Petrochemical Plants: To deal with corrosive fluids and high-temperature operations.

- Power Generation: Steam, water and cooling systems that demanded robust and reliable tubing connections.

- Marine & Aerospace: The fluid transfer lines are high-performance and operate under severe conditions.

- Instrumentation & Control Systems: Where the accuracy of connections (leak-proof) is important.

Other Types of Inconel 625 Tube Fittings

- Inconel 600 Perforated Sheets

- Inconel 600 Forged Fittings

- Inconel 600 Olets

- Inconel 600 Fasteners

- Inconel 600 Compression Tube Fittings

- Inconel 600 Pipes & Tubes

- Inconel 600 Flanges

- Inconel 600 Round Bars & Wires

- Inconel 600 Plates & Sheets

- Inconel 600 Buttweld Fittings

- Inconel 600 Instrumentation Valves

- Inconel 600 Filler Wire

- Inconel 600 Long Radius Bends

- Inconel 600 Pipes Spools

- Inconel 600 Shims

- Inconel 600 Wiremesh

Frequently Asked Questions About Inconel 625 Pipe & Compression Tube Fittings

What are the key applications of Inconel 625 pipe and tube fittings?

What types & sizes of Alloy 625 fittings are available for high-pressure systems?

How does Inconel 625 tube fittings ensure corrosion resistance in extreme environments?

Cities We deliver:

Bhopal, Lahore, Milan, Hyderabad, Pune, Vadodara, Pimpri-Chinchwad, Aberdeen, Howrah, Jeddah, Riyadh, Bogota, Petaling Jaya, Dallas, Lagos, Nagpur, Houston, Brisbane, Busan, Karachi, Coimbatore, Seoul, Caracas, Atyrau, Perth, Haryana, Bengaluru, Jaipur, Al Jubail, Kuwait City, Al Khobar, Sydney, Ranchi, Chiyoda, Noida, Chandigarh, Secunderabad, Ahvaz, Port-of-Spain, Singapore, Gurgaon, Rajkot, Rio de Janeiro, Abu Dhabi, Hong Kong, Surat, Sharjah, Hanoi, London, Muscat, Jakarta, Navi Mumbai, Istanbul, Kolkata, Cairo, Mumbai, Santiago, Montreal, Faridabad, Vung Tau, Bangkok, Ankara, Ahmedabad, Granada, Melbourne, Tehran, Visakhapatnam, New Delhi, Los Angeles, Ho Chi Minh City, Edmonton, La Victoria, Baroda, Thane, Nashik, Kuala Lumpur, Moscow, Ernakulam, Courbevoie, Calgary, Geoje-si, Indore, New York, Mexico City, Gimhae-si, Ludhiana, Kanpur, Ulsan, Thiruvananthapuram, Manama, Doha, Chennai, Madrid, Jamshedpur, Algiers, Dammam

Countries We Deliver:

Iran, Venezuela, Saudi Arabia, Slovakia, Romania, Zimbabwe, Spain, Kazakhstan, Canada, Nigeria, Bulgaria, Afghanistan, Thailand, Bangladesh, Poland, United Kingdom, Bahrain, Jordan, Lithuania, Malaysia, France, Nigeria, Japan, Oman, Lebanon, Germany, Croatia, Australia, Puerto Rico, South Korea, Hungary, United States, Bhutan, Mexico, Mexico, Yemen, Singapore, New Zealand, Ecuador, Gabon, Qatar, Denmark, Iran, Netherlands, Norway, Sri Lanka, Belgium, Libya, Kuwait, Pakistan, Gambia, Sweden, Azerbaijan, Argentina, Chile, Ghana, United Arab Emirates, Finland, Nepal, Trinidad andamp; Tobago,Tunisia, Kenya, Peru, Austria, Russia, Ukraine, Italy, Belarus, Bolivia, Serbia, Poland, Mongolia, Turkey, Czech Republic, South Africa, Angola, India, Vietnam, Indonesia, Tibet, Ireland, Costa Rica, Greece, Colombia, Namibia, Iraq, Estonia, Israel, Macau, Philippines, Brazil, Switzerland, Algeria, Morocco, Chile, Portugal, Egypt, Taiwan, China, Hong Kong.