Inconel 625 Plates & Sheets – UNS N06625 Plates Supplier & Exporter

Table of Content

- Features of DIN 2.4856 (Inconel 625) Plate

- About Inconel 625 Plates & Sheets

- Inconel 625 Plates vs Inconel 625 Sheets

- Comparison Between Inconel and Incoloy

- Inconel 625 Plates Standards & Specifications

- Inconel 625 Plate Chemical Composition

- Equivalent Material of Alloy 625 Sheets

- Properties of Inconel 625 Plates

- Mechanical Properties of Inconel 625 Plates

- Inconel 625 Plate Thermal Conductivity

- Inconel 625 Plate Electrical Resistivity

- Various Types of Inconel 625 Plates & Sheets

- Weight per Unit of Alloy 625 Inconel Plate

- Inconel 625 Plates & Sheets Sizes, Lengths & Tolerances

- Dimensions Chart of Inconel 625 Plate

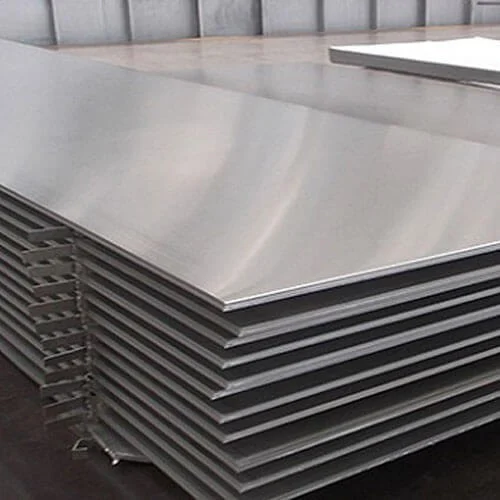

Kalpataru piping is a major manufacturer and supplier of high-quality nickel alloy steel products, providing high-quality Inconel 625 plates and sheets to industries all over the world. The metal Inconel 625 (UNS N06625) is a nickel-chromium-molybdenum alloy that can boast of its superior strength, welding and excellent resistance characteristics of both high temperature corrosion and oxidation. The particular chemical make-up provides high pitting, crevice corrosion, stress-corrosion cracking, and hostile acid resistance.

We have regular and custom-cut Alloy 625 plates, which fully conform to ASTM B443, ASME SB 446, AMS 5666 and AMS 5837. Kalpataru Piping has stock levels of large ex-stock quantities, which are immediately delivered to the customer, thus providing quality Inconel 625 sheets to the customers in marine engineering, chemical processing, pollution control, aerospace, and oil and gas. We conduct business with great stock holding of Inconel products and a network of distributors worldwide which promises fast, reliable supply of Inconel 625 plate needs of all customers.

Introduction to Inconel 625 Material

Inconel 625 (UNS N06625 / W.Nr. 2.4856) is a high-performance nickel- chromium-molybdenum alloy with a high level of strength, superior corrosion resistance, and good fabricability. This alloy is engineered to operate over a broad temperature span of 1800 °F -980 °C, and this material is commonly used in harsh industrial applications. Solid-solution strengthening effect of molybdenum and niobium gives the alloy its strength, so that precipitation-hardening treatments are not required. This special alloy also provides exceptional pitting, crevice corrosion, oxidation and stress-corrosion cracking resistance under chloride conditions of Inconel 625. Alloy 625 is used in the chemical processing industry as a versatile corrosion-resistant material, commonly used in heat exchangers, reaction vessels, transfer piping, valves, and distillation equipment.

Features of DIN 2.4856 (Inconel 625) Plate

- They are excellent for heat and cold resistance for high-temperature and cryogenic applications

- Superior scaling and oxidation resistance

- High resistance to saltwater, freshwater, and alkaline chemicals

- Exceptional corrosion cracking resistance

- Strong chloride stress resistance in harsh environments

- Maintains stability during welding and fabrication

About Inconel 625 Plates & Sheets

Inconel 625 plates are thicker, high-strength nickel-chromium-molybdenum alloy products that are designed to be used in heavy-duty applications by industries. They provide excellent corrosion, oxidation, and high-temperature resistance. Inconel 625 plates have superior mechanical strength and great weldability, making them have long performance under very harsh environments. The Inconel 625 sheets are lighter, thinner, and can be easily shaped, which makes them suitable in areas where precision is needed, and materials are easy to fabricate. These sheets have high resistance to corrosion, flexibility, and thermal stability. They could be used in medium-duty duty because of their strength and formability.

Inconel 625 Plates vs Inconel 625 Sheets

| Feature / Property | Inconel 625 Plates | Inconel 625 Sheets |

| Thickness | Thicker, used for heavy-duty applications | Thinner, used for lightweight applications |

| Strength | Higher mechanical strength | Moderate strength, suitable for medium loads |

| Formability | Less formable due to thickness | Highly formable and easy to fabricate |

| Applications | Pressure vessels, heat exchangers, chemical process equipment, offshore structures | Aerospace ducting, heat shields, marine hardware, chemical linings |

| Weight | Heavier | Lighter |

| Corrosion Resistance | Excellent | Excellent |

| Temperature Resistance | Very high | High |

| Fabrication | Requires heavy machinery | Easy to cut, bend, and weld |

Comparison Between Inconel and Incoloy

One of the most common categories of high-performance superalloys is Inconel and Incoloy, as these two major families boast of a high-level corrosion resistance, high-temperature strength, and high durability in harsh environments. Although the two materials are in the classification of nickel-based alloy, they differ in their composition, performance, and application environment.

Key Differences: Inconel vs Incoloy (Summary Table)

| Feature / Property | Inconel | Incoloy |

| Base Composition | Nickel-Chromium Superalloy | Nickel-Iron-Chromium Superalloy |

| Nickel Content | Very high (up to ~72%) | Moderate (usually 30–45%) |

| Temperature Resistance | Excellent—ideal for extreme heat (up to 1800°F / 982°C) | Good—best for moderate to high temperatures |

| Corrosion Resistance | Outstanding (pitting, crevice, oxidation, chloride attack) | Very good (oxidizing & reducing conditions) |

| Strength at High Temp | Higher — retains strength at extreme heat | Moderate — suitable but not as strong as Inconel |

| Cost | Expensive | More economical due to higher iron content |

| Typical Applications | Aerospace, gas turbines, marine components, chemical plants | Heat exchangers, furnace parts, petrochemicals, power plants |

Inconel 625 Plates Standards & Specifications (ASTM B443, ASME SB 446, AMS 5666, and AMS 5837)

Kalpataru piping offers Inconel 625 plates and sheets that are produced in accordance with major international standards. We manufacture our products according to ASTM B443 and ASME SB 446, and they are highly strong, resistant to corrosion and the surface is of high quality. We also provide materials that meet AMS 5666 and AMS 5837 as to critical and aerospace grade. These standards are used to ensure dependable operation in chemical processing, marine, oil and gas and high temperature industrial applications.

Specifications of Inconel 625 Plates

| Type | Plate, Sheet, Strip, Coils, Foils, Flats, Clad Plate, Plain Sheet, Rolling Sheet, Rolling Plate, Flat Shim, Flat Sheet, Shim Sheet, Rolls, Blank (Circle), sheared, annealed, soft annealed, descaled, tread plate, Checker Plate |

| 625 Inconel Plate Length | 0-12mm or as required |

| ASTM B443 Alloy 625 Plate Width | 0-2500mm or as required |

| UNS N06625 Plate Thickness | 0.3 to 1200 mm or as required |

| ASTM B443 Alloy 625 Plate Process | Hot/ Cold Rolled |

| 625 Inconel Plate surface | No.1, No. 2D, No. 2B, BA, No.3, No.4, No.6, No.7, 2B, 2D, BA NO(8), Cold rolled sheet (CR), Hot rolled plate (HR), SATIN (Met with Plastic Coated), No.1 finish hot rolled ASTM B443 Alloy 625 Plate, 1D, 2B, No.4, BA, 8K, satin, hairline, brush, mirror etc. |

| 625 Plate, Sheet, and Coil |

|

Inconel 625 Plate Chemical Composition

| Ni | Cr | Fe | Mo | Nb+Ta | C | Mn | Si | Ph | S | Al | Ti | Co | |

| Min | Bal | 20 | – | 8 | 3.15 | – | – | – | – | – | – | – | – |

| Max | – | 23 | 5 | 10 | 4.15 | 0.10 | 0.50 | 0.50 | 0.015 | 0.015 | 0.40 | 0.40 | 1.0 |

Equivalent Material of Alloy 625 Sheets

| Grade | UNS | Werkstoff NR. | BS | JIS | EN | GOST | AFNOR |

| Inconel 625 | N06625 | 2.4856 | NA 21 | NCF 625 | NiCr23Fe | ХН75МБТЮ | NC22DNB4MNiCr22Mo9Nb |

Properties of Inconel 625 Plates

| Property | Metric | Imperial |

| Density | 8.44 g/cm3 | 0.305 lb/in3 |

| Melting point | 1350 °C | 2460 °F |

| Co-Efficient of Expansion | 12.8 µm/m.°C(20-100°C) | 7.1×10-6 in/in.°F(70-212°F) |

| Modulus of rigidity | 79 kN/mm2 | 11458 ksi |

| Modulus of elasticity | 205.8 kN/mm2 | 29849 ksi |

Mechanical Properties

| 0.2% Proof Stress | Tensile Strength | Elongation | Reduction of area | Hardness |

| MPA | MPA | % | % | HRB |

| Min | Min | Min | Min | Min |

| 414 | 827 | 30 | 40 | 145 |

Inconel 625 Plate Thermal Conductivity

| Temperature Range | Thermal Conductivity2 3 | Linear Coefficients of Thermal Expansion1 · 10-6 | |||

| °C | °F | W/m·K | Btu/(hr/ft²/in/°F) | /°C | /°F |

| -157 | -250 | 7.3 | 4.2 | – | – |

| -129 | -200 | 7.4 | 4.3 | – | – |

| -73 | -100 | 8.3 | 4.8 | – | – |

| -18 | 0 | 9.2 | 5.3 | – | – |

| 21 | 70 | 9.9 | 5.7 | – | – |

| 38 | 100 | 10.0 | 5.8 | – | – |

| 93 | 200 | 10.7 | 6.3 | 12.8 | 7.1 |

| 204 | 400 | 12.6 | 7.3 | 13.1 | 7.3 |

| 316 | 600 | 14.2 | 8.2 | 13.3 | 7.4 |

| 427 | 800 | 15.7 | 9.1 | 13.7 | 7.6 |

| 538 | 1000 | 17.5 | 10.1 | 14.0 | 7.8 |

| 649 | 1200 | 19.0 | 11.0 | 14.8 | 8.2 |

| 760 | 1400 | 20.8 | 12.0 | 15.3 | 8.5 |

| 871 | 1600 | 22.8 | 13.2 | 15.8 | 8.8 |

| 927 | 1700 | – | – | 16.2 | 9.0 |

| 982 | 1800 | 25.3 | 14.6 | – | – |

Inconel 625 WNR 2.4856 Plate Electrical Resistivity

| Temperature | microhm-cm | |

| °F | °C | |

| 70 | 21 | 128.9 |

| 100 | 38 | 129.6 |

| 200 | 93 | 131.9 |

| 400 | 204 | 133.9 |

| 600 | 316 | 134.9 |

| 800 | 427 | 135.9 |

| 1000 | 538 | 137.9 |

| 1200 | 649 | 137.9 |

| 1400 | 760 | 136.9 |

| 1600 | 871 | 135.9 |

| 1800 | 982 | 134.9 |

| 2000 | 1093 | 133.9 |

Various Types of Inconel 625 Plates & Sheets

Kalpataru Piping has a large variety of Inconel 625 plates and sheets, which cater to various needs of the industries. These nickel-chromium-molybdenum alloys are high-performance materials that are offered in various shapes and finishes, which can be efficiently used in chemical processing, marine, aerospace and oil and gas sectors.

Types of Inconel 625 Plates & Sheets:

- Hot Rolled Plates: Heavy plates that are strong and extremely durable (suitable in the construction industry).

- Cold Rolled Sheets: Finish skin, accuracy in size, increased strength, can be used in precision engineering.

- Annealed Sheets & Plates: Heated to enhance ductile properties and strength.

| Product Form | Dimensions |

| Strip; cold rolled, annealed | 0.25×196 mm x coil, 0.4 kg/m |

| Strip; cold rolled, annealed, quenched, bright, slit edge | 0.30×300 mm x coil, 0.76 kg/m |

| Cold rolled tape, hard rolled, spring temper | 0.40×5 mm x coil, 0.0017 kg/m |

| Strip; cold rolled, hard rolled, special temper | 0.40×25 mm x coil, 0.007 kg/m |

| Plate; cold rolled, annealed, LCF Quality | 0.4×914 mm x coil, 3.1 kg/m |

| Plate; cold rolled, annealed | 0.4x1000x2000 mm, 7.36 kg/pc |

| Plate; cold rolled, annealed | 0.5×914 mm x coil, 3.77 kg/m |

| Strip; cold rolled, hard rolled spool | 0.60×5 mm x coil, 0.02 kg/m |

| Strip; cold rolled, hard rolled, special temper | 0.60×25 mm x coil, 0.011 kg/m |

| Plate; cold rolled, annealed | 0.6x914x3000 mm, 14.15 kg/pc |

| Plate; cold rolled, annealed | 0.73×1219 mm x coil, 7.6 kg/m |

| Plate; cold rolled, annealed | 0.8x1000x2000 mm, 13.7 kg/pc |

| Plate; cold rolled, annealed, LCF | 0.9x1220X3000 mm, 27.9 kg/pc |

| Plate; cold rolled, annealed, bellows quality | 1.0×1200 mm x coil, 9.91 kg/m |

| Plate; cold rolled, DDQ, annealed | 1.2x1000x2000 mm, 20.75 kg/pc |

| Strip; cold rolled, bright annealled | 1.30×5 mm x coil, 0.02 kg/m |

| Plate; cold rolled, annealed, pickled | 1.6x1220x3600 mm, 58 kg/pc |

| Plate; cold rolled, annealed | 2.0x1200x3000 mm, 62.9 kg/pc |

| Plate; cold rolled, annealed, pickled | 3.0x1200x3000 mm, 90.7 kg/pc |

| Plate; hot rolled, soft annealed, descaled, sheared, tread plate, Checker Plate | 4.0x2000x4000 mm, 275.7 kg/pc |

| Plate; hot rolled, soft annealed, descaled, sheared, tread plate, Checker Plate | 5.0x2440x6000 mm, 626 kg/pc |

| Plate; hot rolled, annealed | 8.0x2000x3000 mm, 397 kg/pc |

| Plate; hot rolled, annealed | 20.0x985x1995 mm, 344 kg/pc |

Inconel 625 Hot Rolled Plate Width Tolerance

| – | Trimmed edge | Mill edge | ||

| Width (mm) | Minus | Plus | Minus | Plus |

| w > 1500 | 0 | 5 | 0 | 20 |

| 1200 < w ≤ 1500 | 0 | 5 | 0 | 20 |

| w < 1200 | 0 | 3 | 0 | 20 |

Alloy 625 Cold Rolled Plate Average Rupture Strength

| Test Temperature,°F(°C) | Average Rupture Strength, ksi (MPa)for Time Indicated | ||

| 10 hrs | 100 hrs | 1000 hrs | |

| 1600 (871) | 12 (83) | 6.7 (46) | 3.7 (26)** |

| 1200 (649) | 82 (565) | 71 (490) | 60 (414) |

| 1400 (760) | 36 (248) | 27 (186) | 20 (138)** |

Weight per Unit of Alloy 625 Inconel Plate

The following chart provides theoretical weights for plates per unit. For precise calculations, please use our Plates & Sheets Weight Calculator.

| Thickness | Plate Weight per Unit Area | Density |

| 3/16 inches | 0.06000 lbs/in²42.184176 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

| 1/4 inches | 0.08 lbs/in²56.245568 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

| 3/8 inches | 0.121 lbs/in²85.0714216 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

| 1/2 inches | 0.161 lbs/in²113.1942056 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

| 5/8 inches | 0.196 lbs/in²137.8016416 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

| 3/4 inches | 0.235 lbs/in²165.221356 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

| 7/8 inches | 0.274 lbs/in²192.6410704 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

| 1 inches | 0.313 lbs/in²220.0607848 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

| 1 1/4 inches | 0.391 lbs/in²274.9002136 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

| 1 1/2 inches | 0.47 lbs/in²330.442712 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

| 1 3/4 inches | 0.549 lbs/in²385.9852104 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

| 2 inches | 0.627 lbs/in²440.8246392 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

| 2 1/4 inches | 0.705 lbs/in²495.664068 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

| 2 1/2 inches | 0.784 lbs/in²551.2065664 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

| 2 3/4 inches | 0.862 lbs/in²606.0459952 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

| 3 inches | 0.941 lbs/in²661.5884936 kg/m² | 0.315 lbs/in³8.72 g/cm³ |

Inconel 625 Plates & Sheets Sizes, Lengths, Tolerances & Surface Finish

Inconel 625 Plate Sizes

| Stocked Sizes | |

| Size (in inches) | Size (in mm) |

| .125″ | 3.18mm |

| .134″ | 3.40mm |

| .156″ | 3.96mm |

| .187″ | 4.75mm |

| .250″ | 6.35mm |

| .312″ | 7.92mm |

| .375″ | 9.53mm |

| .500″ | 12.7mm |

| .600″ | 15.9mm |

| .750″ | 19.1mm |

| .875″ | 22.2mm |

| 1″ | 25.4mm |

| 1.125″ | 28.6mm |

| 1.250″ | 31.8mm |

| 1.500″ | 38.1mm |

| 1.750″ | 44.5mm |

| 2″ | 50.8mm |

| 2.500″ | 63.5mm |

| 3″ | 76.2mm |

thickness tolerance chart of Nickel Alloy 625 plate

Tolerances on thickness of steel plates

| Tolerance over and under nominal thickness t (mm) | ||||||||||

| Width w (mm) | 2.5<t <4.5 | 4.5<t <6.0 | 6.0<t <8.0 | 8.0<t <10.0 | 10.0<t <12.5 | 12.5<t <16.0 | 16.0<t <20.0 | 20.0<t <25.0 | 25.0<t <30.0 | 30<t <40.0 |

| w < 1200 | 0.20 | 0.23 | 0.30 | 0.32 | 0.35 | 0.80 | 0.80 | 0.80 | 1.0 | 1.4 |

| 1200< w <1500 | 0.20 | 0.25 | 0.30 | 0.35 | 0.38 | 0.80 | 0.80 | 0.90 | 1.0 | 1.4 |

| 1500< w <1800 | 0.20 | 0.28 | 0.32 | 0.38 | 0.40 | 0.80 | 0.80 | 0.90 | 1.1 | 1.5 |

| 1800< w <2100 | 0.20 | 0.30 | 0.36 | 0.40 | 0.45 | 0.80 | 0.80 | 0.90 | 1.1 | 1.5 |

| 2100< w <2400 | 0.80 | 0.80 | 0.80 | 0.80 | 0.80 | 0.90 | 1.0 | 1.1 | 1.5 | |

| 2400< w <2700 | 0.80 | 0.80 | 0.80 | 0.80 | 0.90 | 1.0 | 1.1 | 1.3 | 1.7 | |

| 2700< w <3000 | 0.80 | 0.90 | 1.0 | 1.0 | 1.0 | 1.1 | 1.3 | 1.4 | 1.8 | |

Tolerances on length of plates

| Tolerance(mm) | ||

| Nominal length (mm) | Minus | Plus |

| L < 2,000 | 0 | 10 |

| 2,000 < L < 8,000 | 0 | 0.005 times L |

| L > 8,000 | 0 | 40 |

Tolerances on width of plates

| Tolerance (mm) | ||||

| Trimmed edge | Mill edge | |||

| Nominal width (mm) | Minus | Plus | Minus | Plus |

| w < 1200 | 0 | 3 | 0 | 20 |

| 1200 < w < 1500 | 0 | 5 | 0 | 20 |

| w > 1500 | 0 | 5 | 0 | 20 |

Dimensions chart of Inconel 625 Plate

ASTM B443 Alloy 625 Plate Imperial Dimensions

| Plate Surface finish | Gauge (in) | Width (max in) |

| 2B – Cold rolled, heat treated, pickled, skin passed Plate | 10–24 | 72* |

| 2D – Cold rolled, heat treated, pickled plate | 12–24 | 60 |

| BA Mexinox only | 18–28 | 48 |

| Polished plate (not brushed) | 11–24 | 60 |

| Temper rolled plate Mexinox only | 13–29 | 48 |

625 alloy Plate Metric Dimensions

| Plate Surface finish | Thickness (mm) | Width (max mm) |

| 2B – Cold rolled, heat treated, pickled, skin passed plate | 0.25–8.0 | 2032 |

| 2D – Cold rolled, heat treated, pickled plate | 0.4–6.35 | 1524 |

| 2E – Cold rolled, heat treated, mechanically descaled plate | 0.4–8.0 | 2032 |

| 2R – Cold rolled, bright annealed plate | 0.25–3.5 | 1524 |

| 2H – Work hardened plate | 0.4–6.35 | 1524 |

| Polished, brushed plate | 0.5–4.0 | 1524 |

Inconel Alloy 625 Plate Surface Finish

| Surface Finish | Width (in.) | Gauge (in.) |

| Polished plate | 60 max | 11 – 24 |

| 2D – Heat treated, pickled plate | 60 max | 12 – 24 |

| BA Mexin.ox only | 48 max | 18 – 28 |

| 2B – Cold rolled, pickled, skin, passed Plate | 72 max | 10 – 24 |

| Temper rolled plate Mexin | 48 max | 13 – 29 |

Inconel 625 Plate Price

Inconel 625 plates are premium nickel-based alloy plates known for their exceptional strength, corrosion resistance, and high-temperature performance. Due to their superior properties, the pricing varies based on thickness, size, and certifications. Below is an estimated price range for Inconel 625 plates in India to help buyers, engineers, and procurement teams plan effectively.

| Thickness (mm) | Approx. Price (INR per kg) |

| 1.0 – 2.0 mm | ₹1,000 – ₹1,600 |

| 3.0 – 5.0 mm | ₹1,500 – ₹2,200 |

| 6.0 – 10 mm | ₹1,700 – ₹2,800 |

| 12 – 20 mm | ₹2,000 – ₹3,000 |

| 25 mm & above | ₹2,500 – ₹3,200 |

Note

- Prices vary based on thickness, width, length, finish (hot rolled/cold rolled), and quantity.

- Rates are indicative market estimates and may vary by supplier and order volume.

- Certifications like ASTM B443, NACE, or EN standards can increase the price bracket.

Applications of Inconel 625 Plates

Inconel 625 plates and sheets are applicable in most industries that require high strength and resistance to corrosion as well as high performance in harsh environments. Key applications include:

- Gas Turbine Engines: Stress and high-temperature-resistant components.

- Aircraft Ducting Systems: Sustainable and highly resistant airframe and engine ducting.

- Heat Exchanger Tubing: Consistent activity under hot and caustic liquids.

- Chemical Processing Equipment: Acid/alkali/and other hostile chemical resistance.

- Oil & Gas Industry: Goods like offshore and onshore equipment that are exposed to sea water and severe environments.

- Nuclear Reactors: Parts that must have high strength and radiation and corrosion resistance.

- Implantable Parts and Surgical Equipment: Used to ensure precision and durability in biocompatible.

- Marine: Commonly used to make blades, fittings and other objects that are in contact with seawater.

- Boiler Furnaces and Dehydration gear: Structural and processing items of high temperature.

Quality Assurance & Testing of Inconel 625 Plates

Our Inconel plates and sheets are produced to be in strict compliance with international standards, such as ASTM, ASME, BS, MSS, EN, DIN, and WERKSTOFFE. Each product will pass through the strict quality checkpoints and guarantee the same performance, durability and reliability. We have a detailed Quality Assurance Plan (QAP) that helps us to ensure that the production is maintained at all the steps to make sure that the products satisfy the industry requirements as well as the customers.

Testing & Documentation

Complete transparency and reliability are our priority, engaged in wide testing and detailed documentation.

Key material tests include:

- PMI Testing- tests alloy.

- Ultrasonic Tests and Flaring Tests- identify internal defects.

- Mechanical & Spectrochemical Analysis – complies with grade requirements.

- IGC or NACE MR0103 /MR0175 Certifications- corrosive resistance.

Any shipments that come along with the necessary documents, like:

- Certificate of Origin

- Mill Test Certificates (EN 10204 3.1 / 3.2)

- Traceability Records of Material.

- Heat Treatment Charts

- Commercial Inv Inc HS Codes.

- If necessary, Third-Party Inspection Reports.

We also support the stage-by-stage checks of the products by the representatives of the customer or other third parties, guaranteeing the final confidence in the quality of the products.

Frequently Asked Question About Inconel 625 Plates

What is an inconel 625 plate & why is it used?

Inconel 625 plate is consists of nickel-chromium alloy (UNS N06625 / W.Nr. 2.4856) known for its excellent strength, weldability & resistance to extreme temperatures or corrosion. It performs reliably in environments ranging from cryogenic temperatures up to 982°C.

How much does inconel 625 sheet or plate cost?

The Inconel 625 plate price or Inconel 625 sheet price depends on factors like thickness, size and surface finish. For the best pricing, connect with our team to request a quote from trusted to get competitive rates.

How do you calculate the weight of inconel 625 sheets and plates?

The weight of Inconel 625 sheets and plates is calculated using the formula:

Weight = Length × Width × Thickness × Density

(Approximate density of Inconel 625 = 8.44 g/cm³). Most Inconel 625 sheet suppliers provide weight charts based on standard dimensions.

What sizes are available for inconel 625 sheets and plates?

Explore to Inconel Products

- Inconel 600 Perforated Sheets

- Inconel 600 Forged Fittings

- Inconel 600 Olets

- Inconel 600 Fasteners

- Inconel 600 Compression Tube Fittings

- Inconel 600 Pipes & Tubes

- Inconel 600 Flanges

- Inconel 600 Round Bars & Wires

- Inconel 600 Plates & Sheets

- Inconel 600 Buttweld Fittings

- Inconel 600 Instrumentation Valves

- Inconel 600 Filler Wire

- Inconel 600 Long Radius Bends

- Inconel 600 Pipes Spools

- Inconel 600 Shims

- Inconel 600 Wiremesh

Countries We Deliver

Iran, Venezuela, Saudi Arabia, Slovakia, Romania, Zimbabwe, Spain, Kazakhstan, Canada, Nigeria, Bulgaria, Afghanistan, Thailand, Bangladesh, Poland, United Kingdom, Bahrain, Jordan, Lithuania, Malaysia, France, Nigeria, Japan, Oman, Lebanon, Germany, Croatia, Australia, Puerto Rico, South Korea, Hungary, United States, Bhutan, Mexico, Mexico, Yemen, Singapore, New Zealand, Ecuador, Gabon, Qatar, Denmark, Iran, Netherlands, Norway, Sri Lanka, Belgium, Libya, Kuwait, Pakistan, Gambia, Sweden, Azerbaijan, Argentina, Chile, Ghana, United Arab Emirates, Finland, Nepal, Trinidad andamp; Tobago,Tunisia, Kenya, Peru, Austria, Russia, Ukraine, Italy, Belarus, Bolivia, Serbia, Poland, Mongolia, Turkey, Czech Republic, South Africa, Angola, India, Vietnam, Indonesia, Tibet, Ireland, Costa Rica, Greece, Colombia, Namibia, Iraq, Estonia, Israel, Macau, Philippines, Brazil, Switzerland, Algeria, Morocco, Chile, Portugal, Egypt, Taiwan, China, Hong Kong.

Cities We deliver

Bhopal, Lahore, Milan, Hyderabad, Pune, Vadodara, Pimpri-Chinchwad, Aberdeen, Howrah, Jeddah, Riyadh, Bogota, Petaling Jaya, Dallas, Lagos, Nagpur, Houston, Brisbane, Busan, Karachi, Coimbatore, Seoul, Caracas, Atyrau, Perth, Haryana, Bengaluru, Jaipur, Al Jubail, Kuwait City, Al Khobar, Sydney, Ranchi, Chiyoda, Noida, Chandigarh, Secunderabad, Ahvaz, Port-of-Spain, Singapore, Gurgaon, Rajkot, Rio de Janeiro, Abu Dhabi, Hong Kong, Surat, Sharjah, Hanoi, London, Muscat, Jakarta, Navi Mumbai, Istanbul, Kolkata, Cairo, Mumbai, Santiago, Montreal, Faridabad, Vung Tau, Bangkok, Ankara, Ahmedabad, Granada, Melbourne, Tehran, Visakhapatnam, New Delhi, Los Angeles, Ho Chi Minh City, Edmonton, La Victoria, Baroda, Thane, Nashik, Kuala Lumpur, Moscow, Ernakulam, Courbevoie, Calgary, Geoje-si, Indore, New York, Mexico City, Gimhae-si, Ludhiana, Kanpur, Ulsan, Thiruvananthapuram, Manama, Doha, Chennai, Madrid, Jamshedpur, Algiers, Dammam