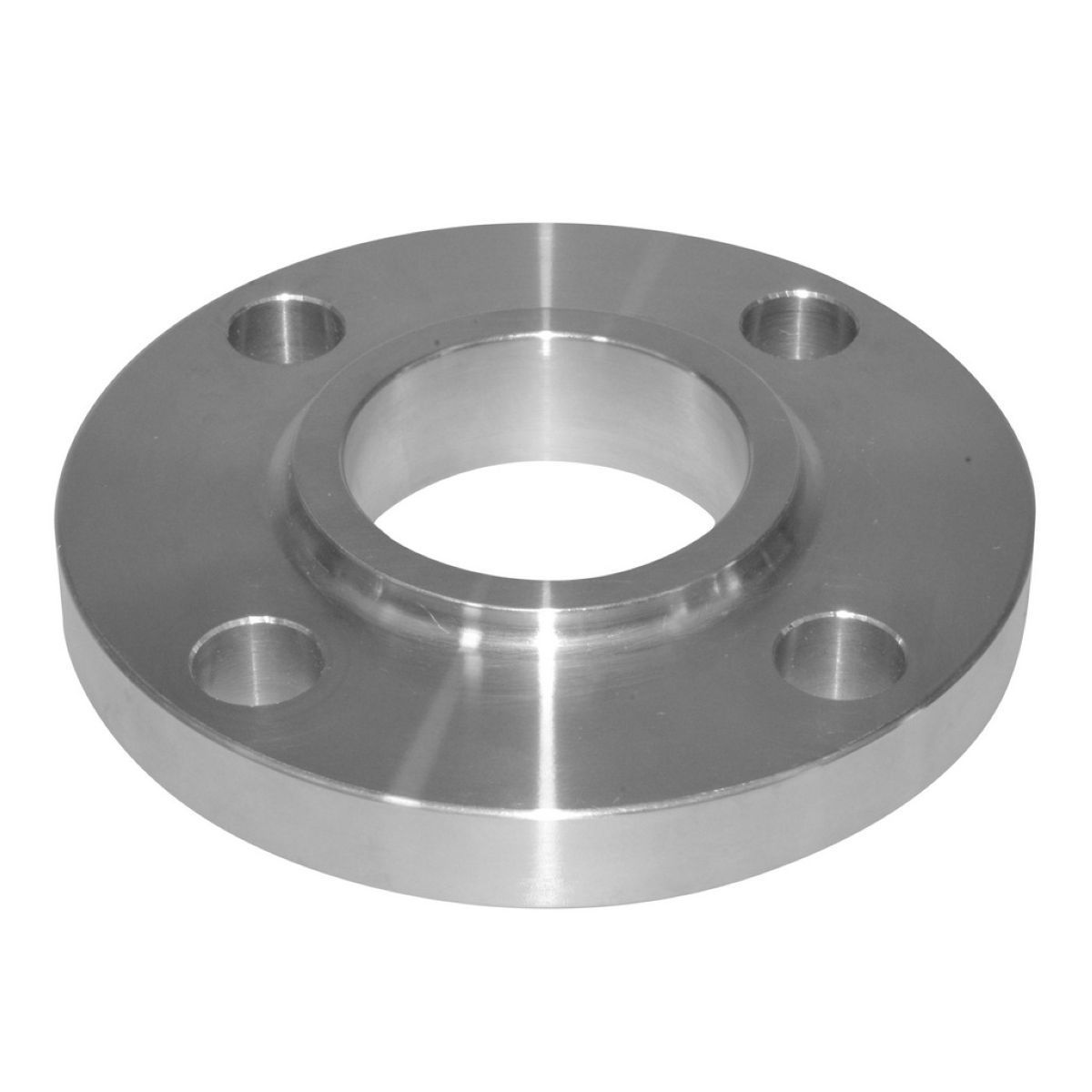

Slip On Flanges

Top notch Supplier of Slip On Flange, Slip On Raised Face Flanges, Flat Face Slip On Flanges, SOFF Flanges, ANSI B16.5 Slip On Flanges Stockist, SORF Flange, Slip On Flanges Supplier, ASTM A182 Stainless Steel Slip On Flanges, Slip On Plate Flange, Check Threaded Slip On Flange Dimensions and Weight Chart.

Table of Content

- Slip-On Flanges Manufacturer

- Slip On Flanges Specifications

- Types of Slip On Flange Welding

- RTJ (Ring Type Joint) slip-on flanges

- Raised Face Slip-On Flanges

- Slip on Flange Dimensions

- Slip On SO Flange Material Grades:

- Slip On Flanges Sizes for Class 150 ASME B16.5

- Slip On Flanges Sizes for Class 300 ASME B16.5

- Slip On Flanges Sizes for Class 600 ASME B16.5

- Slip On Flanges Weight Chart in Kg for Class 150

- Slip On Flanges Weight Chart for Class 300

- Slip On Flanges Weight Chart for Class 600

- Slip On Flange vs Weld Neck Flange

- Advantages of slip-on flanges

- Slip On Flanges Uses

The Slip On Flange(SO Flange) is a kind of pipe flange, which is constructed in such a way that it can easily slide over the end of a pipe due to the inner diameter being slightly bigger than the outer diameter of the pipe. This is one of the most convenient and economical designs that can be easily aligned prior to welding and hence, it is used in piping systems. The slip-on flange connection is normally welded internally and externally giving it an excellent connection that is leak free as well as strong.

Their design does not require accuracy of cuts and beveling of pipes, which makes them applicable to those projects that require flexibility and speedy construction. Slip-on flanges are offered in raised face and ring-type constructions and are commonly used in the oil and gas industry, petrochemical industry, power generation sector, water treatment, or shipbuilding sector. Slip-on flanges are also used in preference to weld neck flanges due to their cost-saving nature and their need to cut less precision when joining the pipe to a length.

Slip On Flanges Manufacturer

Kalpataru Piping Solutions is an Indian-based manufacturer, supplier/ exporter of Slip On Flanges with high-quality flanges constructed to ASME, ANSI, and DIN standards. Our slip-on flanges are made to be reliable in their operation and easily installed in various applications in industries and have a long service life. We also produce and distribute various carbon steel flange, stainless steel flange, alloy steel flange, and nickel alloy slip-on flange in all sizes, pressure rating and in different dimensions. Our standard and customized flange solutions are supplied at the right time, and this is made possible by having the stock and fast delivery.

Stainless Steel Flanges

Alloy Steel Flanges

Carbon Steel Flanges

Nickel Alloy Slip On Flanges

Material & Grades of Slip On Flanges (SORF)

Our slip-on flanges are popular in piping systems of low-pressure and medium temperatures and provide relatively cheap and safe connections. They fit the oil and gas, petrochemical, power generation, shipbuilding, water treatment, paper mills, as well as pharmaceuticals industries. Call about the best prices of these high quality flanges.| Carbon Steel | ASTM /ASME A/SA105(N), A350 LF2/LF3, A694 F52, F56, F60, F65, F70 |

| Alloy Steel | ASTM/ASME A/SA 182 F5, F9, F11, F22, F91 |

| Stainless Steel | ASTM/ASME A/SA 182 F304, 304L, 304H, 310H, 316, 316H, 316L, 316Ti, 317, 317L, 321, 321H, 347, 347H, 904L |

| Duplex and Super Duplex | ASTM/ASME A/SA 182 F44, F45, F51, F53, F55, F60, F61, S31803, S32205, S32550, S31254, SMO254, S32750, S32760, S32950 |

| Nickel Alloy Steel | ASTM/ASME B/SB 564 UNS N02200(NICKEL 200), UNS N04400, (MONEL 400), UNS N08825( INCOLOY 825), UNS N06600(INCONEL 600), UNS N06601(INCONEL 601), UNS N06625(INCONEL 625), UNS N10276(HASTELLOY C276) |

| ASTM/ASME B/SB160 UNS N02201(NICKEL 201), ASTM B/SB472 UNS N08020(Alloy 20) | |

| Copper Alloy | ASTM/ASME B/SB151 UNS N07060, 71500, C70600(CuNi 90/10), C71500(CuNi 70/30) |

| Titanium | ASTM/ASME B/SB381 Grade 2, Grade 5, Grade 7 |

Slip On Flanges Welding

There is no tool in the welding of slip-on flanges: the flange is simply slipped over the pipe until the position is reached. The flange face must be made to hit the pipe end flat at the end and slightly above (not more than 1/16 of the wall thickness of the pipe). After a positioning, a single fillet weld or a double fillet weld is used to secure the flange. Where there is a double weld, both the inner and the outer weld are welded to provide a leakless and strong connection. The process offers a robust, dependable joint that can be used in the piping systems with low and medium pressure.

Slip On Flanges Specifications

| Product Name | Slip On Flanges | SO Flange | SORF Flange | SOFF Flange |

| Size Range | 1/2″ (15 NB) to 48″ (1200NB) |

| Class / Pressure Rating | 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc. |

| Standards / Dimensions | ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, BS, GOST, MSS SP-44, ISO70051, JISB2220, BS1560-3.1, API7S-15, API7S-43, API605 |

| Flange Face Types / Connection Type | Flat Face Flange (FF), Raised Face Flange (RF), Ring Joint Flange (RTJ), Lap Joint Flange, Male and Female Flange (M&F), Large and Small Tongue-and-Groove Flange (T&G) |

| Dimensions | ANSI B16.5, ANSI B16.47 Series A & B, ASA, API-605, MSS SP44, AWWA, Custom Drawings |

| Custom Design | As per your drawing | AS, BS, ANSI, DIN, JIS | Equal and Reducing Configurations |

| Material Test Certificates (MTC) | As per EN 10204 3.2 and EN 10204 3.1, Test Certificates certifying NACE MR0175, NACE MR0103 |

Slip on Flanges Types

The flanges come in a different design to suit different industrial needs and operating systems. Each of these flanges comes with different alignment and performance. All types of slip-on flanges information is given below.

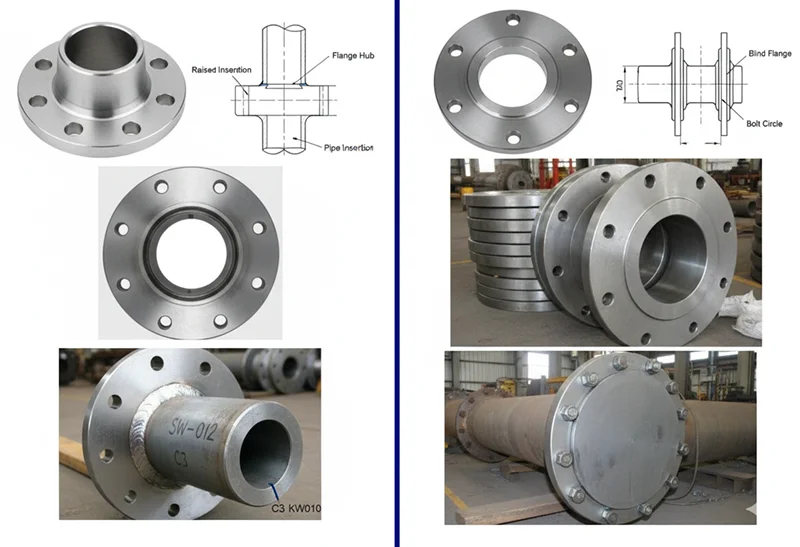

Raised Face Slip-On Flanges

The very common type of flange is a Raised Face slip-on Flange whose surface is round for the placement of a gasket. It’s made with the qualities of leak resistance and can easily survive in moderate temperature and pressure applications.

Flat Face Slip-On Flange (FF SO Flange)

This flange has a smooth and flat surface with no raised face. It’s made with cast iron and fiberglass pipe to ensure the proper pressure distribution and prevent flange distortion.

Lap Joint Slip-On Flange (LJ SO Flange)

The lap joint slip-on flanges are made with backing flanges, easy rotation, and alignment. This makes it suitable for industries that require frequent assembly and maintenance.

Ring Type Joint Slip-On Flange (RTJ SO Flange)

These flanges are made up with a machine’s groove for a metal ring gasket. The oil and gas industry uses these flanges to manage high-pressure and high-temperature environments.

Slip-On Flanges Price

The price of the Slip-On flags depends on many factors, such as size, pressure rating, and specification. Usually, carbon steel slip-on flanges are cheaper than other flanges because they have more resistance to corrosion and durability, like stainless steel and alloy steel.

For accurate pricing based on your project requirements, request a quote from us.

Class 150 Slip-on Flange Dimensions

| Size in Inch | Size in mm | Outer Dia. | Flange Thick. | Hub OD | Flange Length | RF Dia. | RF Height | PCD | Socket Bore | No of Bolts | Bolt Size UNC | Machine Bolt Length | RF Stud Length | Hole Size | ISO Stud Size | Weight in kg |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | E | F | G | H | |||||||||

| 1/2 | 15 | 90 | 9.6 | 30 | 14 | 34.9 | 2 | 60.3 | 22.2 | 4 | 1/2 | 50 | 55 | 5/8 | M14 | 0.8 |

| 3/4 | 20 | 100 | 11.2 | 38 | 14 | 42.9 | 2 | 69.9 | 27.7 | 4 | 1/2 | 50 | 65 | 5/8 | M14 | 0.9 |

| 1 | 25 | 110 | 12.7 | 49 | 16 | 50.8 | 2 | 79.4 | 34.5 | 4 | 1/2 | 55 | 65 | 5/8 | M14 | 0.9 |

| 1 1/4 | 32 | 115 | 14.3 | 59 | 19 | 63.5 | 2 | 88.9 | 43.2 | 4 | 1/2 | 55 | 70 | 5/8 | M14 | 1.4 |

| 1 1/2 | 40 | 125 | 15.9 | 65 | 21 | 73 | 2 | 98.4 | 49.5 | 4 | 1/2 | 65 | 70 | 5/8 | M14 | 1.4 |

| 2 | 50 | 150 | 17.5 | 78 | 24 | 92.1 | 2 | 120.7 | 61.9 | 4 | 5/8 | 70 | 85 | 3/4 | M16 | 2.3 |

| 2 1/2 | 65 | 180 | 20.7 | 90 | 27 | 104.8 | 2 | 139.7 | 74.6 | 4 | 5/8 | 75 | 90 | 3/4 | M16 | 3.2 |

| 3 | 80 | 190 | 22.3 | 108 | 29 | 127 | 2 | 152.4 | 90.7 | 4 | 5/8 | 75 | 90 | 3/4 | M16 | 3.7 |

| 3 1/2 | 90 | 215 | 22.3 | 122 | 30 | 139.7 | 2 | 177.8 | 103.4 | 8 | 5/8 | 75 | 90 | 3/4 | M16 | 5 |

| 4 | 100 | 230 | 22.3 | 135 | 32 | 157.2 | 2 | 190.5 | 116.1 | 8 | 5/8 | 75 | 90 | 3/4 | M16 | 5.9 |

| 5 | 125 | 255 | 22.3 | 164 | 35 | 185.7 | 2 | 215.9 | 143.8 | 8 | 3/4 | 85 | 95 | 7/8 | M20 | 6.8 |

| 6 | 150 | 280 | 23.9 | 192 | 38 | 215.9 | 2 | 241.3 | 170.7 | 8 | 3/4 | 85 | 100 | 7/8 | M20 | 8.6 |

| 8 | 200 | 345 | 27 | 246 | 43 | 269.9 | 2 | 298.5 | 221.5 | 8 | 3/4 | 90 | 110 | 7/8 | M20 | 13.7 |

| 10 | 250 | 405 | 28.6 | 305 | 48 | 323.8 | 2 | 362 | 276.2 | 12 | 7/8 | 100 | 115 | 1 | M24 | 19.5 |

| 12 | 300 | 485 | 30.2 | 365 | 54 | 381 | 2 | 431.8 | 327 | 12 | 7/8 | 100 | 120 | 1 | M24 | 29 |

| 14 | 350 | 535 | 33.4 | 400 | 56 | 412.8 | 2 | 476.3 | 359.2 | 12 | 1 | 115 | 135 | 1 1/8 | M27 | 41 |

| 16 | 400 | 595 | 35 | 457 | 62 | 469.9 | 2 | 539.8 | 410.5 | 16 | 1 | 115 | 135 | 1 1/8 | M27 | 54 |

| 18 | 450 | 635 | 38.1 | 505 | 67 | 533.4 | 2 | 577.9 | 461.8 | 16 | 1 1/8 | 125 | 145 | 1 1/4 | M30 | 59 |

| 20 | 500 | 700 | 41.3 | 559 | 71 | 584.2 | 2 | 635 | 513.1 | 20 | 1 1/8 | 140 | 160 | 1 1/4 | M30 | 75 |

| 24 | 600 | 815 | 46.1 | 663 | 81 | 692.2 | 2 | 749.3 | 616 | 20 | 1 1/4 | 150 | 170 | 1 3/8 | M33 | 100 |

Class 300 Slip-on Flange Dimensions

| Size in Inch | Size in mm | Outer Dia. | Flange Thick. | Hub OD | Flange Length | RF Dia. | RF Height | PCD | Socket Bore | No of Bolts | Bolt Size UNC | Machine Bolt Length | RF Stud Length | Hole Size | ISO Stud Size | Weight in kg |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | E | F | G | H | |||||||||

| 1/2 | 15 | 95 | 12.7 | 38 | 21 | 34.9 | 2 | 66.7 | 22.2 | 4 | 1/2 | 55 | 65 | 5/8 | M14 | 1.2 |

| 3/4 | 20 | 115 | 14.3 | 48 | 24 | 42.9 | 2 | 82.6 | 27.7 | 4 | 5/8 | 65 | 75 | 3/4 | M16 | 1.4 |

| 1 | 25 | 125 | 15.9 | 54 | 25 | 50.8 | 2 | 88.9 | 34.5 | 4 | 5/8 | 65 | 75 | 3/4 | M16 | 1.4 |

| 1 1/4 | 32 | 135 | 17.5 | 64 | 25 | 63.5 | 2 | 98.4 | 43.2 | 4 | 5/8 | 70 | 85 | 3/4 | M16 | 1.8 |

| 1 1/2 | 40 | 155 | 19.1 | 70 | 29 | 73 | 2 | 114.3 | 49.5 | 4 | 3/4 | 75 | 90 | 7/8 | M20 | 2.7 |

| 2 | 50 | 165 | 20.7 | 84 | 32 | 92.1 | 2 | 127 | 61.9 | 8 | 5/8 | 75 | 90 | 3/4 | M16 | 3.2 |

| 2 1/2 | 65 | 190 | 23.9 | 100 | 37 | 104.8 | 2 | 149.2 | 74.6 | 8 | 3/4 | 85 | 100 | 7/8 | M20 | 4.6 |

| 3 | 80 | 210 | 27 | 117 | 41 | 127 | 2 | 168.3 | 90.7 | 8 | 3/4 | 90 | 110 | 7/8 | M20 | 5.9 |

| 3 1/2 | 90 | 230 | 28.6 | 133 | 43 | 139.7 | 2 | 184.2 | 103.4 | 8 | 3/4 | 95 | 110 | 7/8 | M20 | 7.7 |

| 4 | 100 | 255 | 30.2 | 146 | 46 | 157.2 | 2 | 200 | 116.8 | 8 | 3/4 | 95 | 115 | 7/8 | M20 | 10 |

| 5 | 125 | 280 | 33.4 | 178 | 49 | 185.7 | 2 | 235 | 144.4 | 8 | 3/4 | 110 | 120 | 7/8 | M20 | 12.7 |

| 6 | 150 | 320 | 35 | 206 | 51 | 215.9 | 2 | 269.9 | 171.4 | 12 | 3/4 | 110 | 120 | 7/8 | M20 | 17.7 |

| 8 | 200 | 380 | 39.7 | 260 | 60 | 269.9 | 2 | 330.2 | 222.2 | 12 | 7/8 | 120 | 140 | 1 | M24 | 26 |

| 10 | 250 | 445 | 46.1 | 321 | 65 | 323.8 | 2 | 387.4 | 277.4 | 16 | 1 | 140 | 160 | 1 1/8 | M27 | 36 |

| 12 | 300 | 520 | 49.3 | 375 | 71 | 381 | 2 | 450.8 | 328.2 | 16 | 1 1/8 | 145 | 170 | 1 1/4 | M30 | 52 |

| 14 | 350 | 585 | 52.4 | 425 | 75 | 412.8 | 2 | 514.4 | 360.2 | 20 | 1 1/8 | 160 | 180 | 1 1/4 | M30 | 75 |

| 16 | 400 | 650 | 55.6 | 483 | 81 | 469.9 | 2 | 571.5 | 411.2 | 20 | 1 1/4 | 165 | 190 | 1 3/8 | M33 | 86 |

| 18 | 450 | 710 | 58.8 | 533 | 87 | 533.4 | 2 | 628.6 | 462.3 | 24 | 1 1/4 | 170 | 195 | 1 3/8 | M33 | 113 |

| 20 | 500 | 775 | 62 | 587 | 94 | 584.2 | 2 | 685.8 | 514.4 | 24 | 1 1/4 | 185 | 205 | 1 3/8 | M33 | 143 |

| 24 | 600 | 915 | 68.3 | 702 | 105 | 692.2 | 2 | 812.8 | 616 | 24 | 1 1/2 | 205 | 230 | 1 5/8 | M39 | 216 |

Class 300 Slip-on Flange Dimensions

| Size in Inch | Size in mm | Outer Dia. | Flange Thick. | Hub OD | Flange Length | RF Dia. | RF Height | PCD | Socket Bore | No of Bolts | Bolt Size UNC | Machine Bolt Length | RF Stud Length | Hole Size | ISO Stud Size | Weight in kg |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | E | F | G | H | |||||||||

| 1/2 | 15 | 95 | 12.7 | 38 | 21 | 34.9 | 2 | 66.7 | 22.2 | 4 | 1/2 | 55 | 65 | 5/8 | M14 | 1.2 |

| 3/4 | 20 | 115 | 14.3 | 48 | 24 | 42.9 | 2 | 82.6 | 27.7 | 4 | 5/8 | 65 | 75 | 3/4 | M16 | 1.4 |

| 1 | 25 | 125 | 15.9 | 54 | 25 | 50.8 | 2 | 88.9 | 34.5 | 4 | 5/8 | 65 | 75 | 3/4 | M16 | 1.4 |

| 1 1/4 | 32 | 135 | 17.5 | 64 | 25 | 63.5 | 2 | 98.4 | 43.2 | 4 | 5/8 | 70 | 85 | 3/4 | M16 | 1.8 |

| 1 1/2 | 40 | 155 | 19.1 | 70 | 29 | 73 | 2 | 114.3 | 49.5 | 4 | 3/4 | 75 | 90 | 7/8 | M20 | 2.7 |

| 2 | 50 | 165 | 20.7 | 84 | 32 | 92.1 | 2 | 127 | 61.9 | 8 | 5/8 | 75 | 90 | 3/4 | M16 | 3.2 |

| 2 1/2 | 65 | 190 | 23.9 | 100 | 37 | 104.8 | 2 | 149.2 | 74.6 | 8 | 3/4 | 85 | 100 | 7/8 | M20 | 4.6 |

| 3 | 80 | 210 | 27 | 117 | 41 | 127 | 2 | 168.3 | 90.7 | 8 | 3/4 | 90 | 110 | 7/8 | M20 | 5.9 |

| 3 1/2 | 90 | 230 | 28.6 | 133 | 43 | 139.7 | 2 | 184.2 | 103.4 | 8 | 3/4 | 95 | 110 | 7/8 | M20 | 7.7 |

| 4 | 100 | 255 | 30.2 | 146 | 46 | 157.2 | 2 | 200 | 116.8 | 8 | 3/4 | 95 | 115 | 7/8 | M20 | 10 |

| 5 | 125 | 280 | 33.4 | 178 | 49 | 185.7 | 2 | 235 | 144.4 | 8 | 3/4 | 110 | 120 | 7/8 | M20 | 12.7 |

| 6 | 150 | 320 | 35 | 206 | 51 | 215.9 | 2 | 269.9 | 171.4 | 12 | 3/4 | 110 | 120 | 7/8 | M20 | 17.7 |

| 8 | 200 | 380 | 39.7 | 260 | 60 | 269.9 | 2 | 330.2 | 222.2 | 12 | 7/8 | 120 | 140 | 1 | M24 | 26 |

| 10 | 250 | 445 | 46.1 | 321 | 65 | 323.8 | 2 | 387.4 | 277.4 | 16 | 1 | 140 | 160 | 1 1/8 | M27 | 36 |

| 12 | 300 | 520 | 49.3 | 375 | 71 | 381 | 2 | 450.8 | 328.2 | 16 | 1 1/8 | 145 | 170 | 1 1/4 | M30 | 52 |

| 14 | 350 | 585 | 52.4 | 425 | 75 | 412.8 | 2 | 514.4 | 360.2 | 20 | 1 1/8 | 160 | 180 | 1 1/4 | M30 | 75 |

| 16 | 400 | 650 | 55.6 | 483 | 81 | 469.9 | 2 | 571.5 | 411.2 | 20 | 1 1/4 | 165 | 190 | 1 3/8 | M33 | 86 |

| 18 | 450 | 710 | 58.8 | 533 | 87 | 533.4 | 2 | 628.6 | 462.3 | 24 | 1 1/4 | 170 | 195 | 1 3/8 | M33 | 113 |

| 20 | 500 | 775 | 62 | 587 | 94 | 584.2 | 2 | 685.8 | 514.4 | 24 | 1 1/4 | 185 | 205 | 1 3/8 | M33 | 143 |

| 24 | 600 | 915 | 68.3 | 702 | 105 | 692.2 | 2 | 812.8 | 616 | 24 | 1 1/2 | 205 | 230 | 1 5/8 | M39 | 216 |

Class 400 Slip-on Flange Dimensions

| Size in Inch | Size in mm | Outer Dia. | Flange Thickness | Hub OD | Flange Length | RF Dia. | RF Height | PCD | Socket Bore | No of Bolts | Bolt Size UNC | RF Stud Length | Hole Size | ISO Stud Size | Weight in kg |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | E | F | G | H | ||||||||

| 1/2 | 15 | 95 | 14.3 | 38 | 22 | 34.9 | 7 | 66.7 | 22.2 | 4 | 1/2 | 75 | 5/8 | M14 | 1.3 |

| 3/4 | 20 | 115 | 15.9 | 48 | 25 | 42.9 | 7 | 82.6 | 27.7 | 4 | 5/8 | 90 | 3/4 | M16 | 1.5 |

| 1 | 25 | 125 | 17.5 | 54 | 27 | 50.8 | 7 | 88.9 | 34.5 | 4 | 5/8 | 90 | 3/4 | M16 | 1.8 |

| 1 1/4 | 32 | 135 | 20.7 | 64 | 29 | 63.5 | 7 | 98.4 | 43.2 | 4 | 5/8 | 95 | 3/4 | M16 | 2.3 |

| 1 1/2 | 40 | 155 | 22.3 | 70 | 32 | 73 | 7 | 114.3 | 49.5 | 4 | 3/4 | 110 | 7/8 | M20 | 3.2 |

| 2 | 50 | 165 | 25.4 | 84 | 37 | 92.1 | 7 | 127 | 61.9 | 8 | 5/8 | 110 | 3/4 | M16 | 4.1 |

| 2 1/2 | 65 | 190 | 28.6 | 100 | 41 | 104.8 | 7 | 149.2 | 74.6 | 8 | 3/4 | 120 | 7/8 | M20 | 5.9 |

| 3 | 80 | 210 | 31.8 | 117 | 46 | 127 | 7 | 168.3 | 90.7 | 8 | 3/4 | 125 | 7/8 | M20 | 7.3 |

| 4 | 100 | 255 | 35 | 146 | 51 | 157.2 | 7 | 200 | 116.1 | 8 | 7/8 | 140 | 1 | M24 | 11.8 |

| 5 | 125 | 280 | 38.1 | 178 | 54 | 185.7 | 7 | 235 | 143.8 | 8 | 7/8 | 145 | 1 | M24 | 14.1 |

| 6 | 150 | 320 | 41.3 | 206 | 57 | 215.9 | 7 | 269.9 | 170.7 | 12 | 7/8 | 150 | 1 | M24 | 20 |

| 8 | 200 | 380 | 47.7 | 260 | 68 | 269.9 | 7 | 330 | 221.5 | 12 | 1 | 170 | 1 1/8 | M27 | 31 |

| 10 | 250 | 445 | 54 | 321 | 73 | 323.8 | 7 | 387.4 | 276.2 | 16 | 1 1/8 | 190 | 1 1/4 | M30 | 42 |

| 12 | 300 | 520 | 57.2 | 375 | 79 | 381 | 7 | 450.8 | 327 | 16 | 1 1/4 | 205 | 1 3/8 | M33 | 59 |

| 14 | 350 | 585 | 60.4 | 425 | 84 | 412.8 | 7 | 514.4 | 359.2 | 20 | 1 1/4 | 210 | 1 3/8 | M33 | 82 |

| 16 | 400 | 650 | 63.5 | 483 | 94 | 469.9 | 7 | 571.5 | 410.5 | 20 | 1 3/8 | 220 | 1 1/2 | M36 | 107 |

| 18 | 450 | 710 | 66.7 | 533 | 98 | 533.4 | 7 | 628.6 | 461.8 | 24 | 1 3/8 | 230 | 1 1/2 | M36 | 130 |

| 20 | 500 | 775 | 69.9 | 587 | 102 | 584.2 | 7 | 685.8 | 513.1 | 24 | 1 1/2 | 240 | 1 3/4 | M39 | 157 |

| 24 | 600 | 915 | 76.2 | 702 | 114 | 692.2 | 7 | 812.8 | 616 | 24 | 1 3/4 | 265 | 1 7/8 | M45 | 232 |

Class 600 Slip-on Flange Dimensions

| Size in Inch | Size in mm | Outer Dia. | Flange Thickness | Hub OD | Flange Length | RF Dia. | RF Height | PCD | Socket Bore | No of Bolts | Bolt Size UNC | RF Stud Length | Hole Size | ISO Stud Size | Weight in kg |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | E | F | G | H | ||||||||

| 1/2 | 15 | 95 | 14.3 | 38 | 22 | 34.9 | 7 | 66.7 | 22.2 | 4 | 1/2 | 75 | 5/8 | M14 | 1.3 |

| 3/4 | 20 | 115 | 15.9 | 48 | 25 | 42.9 | 7 | 82.6 | 27.7 | 4 | 5/8 | 90 | 3/4 | M16 | 1.4 |

| 1 | 25 | 125 | 17.5 | 54 | 27 | 50.8 | 7 | 88.9 | 34.5 | 4 | 5/8 | 90 | 3/4 | M16 | 1.8 |

| 1 1/4 | 32 | 135 | 20.7 | 64 | 29 | 63.5 | 7 | 98.4 | 43.2 | 4 | 5/8 | 95 | 3/4 | M16 | 2.3 |

| 1 1/2 | 40 | 155 | 22.3 | 70 | 32 | 73 | 7 | 114.3 | 49.5 | 4 | 3/4 | 110 | 7/8 | M20 | 3.2 |

| 2 | 50 | 165 | 25.4 | 84 | 37 | 92.1 | 7 | 127 | 61.9 | 8 | 5/8 | 110 | 3/4 | M16 | 4.1 |

| 2 1/2 | 65 | 190 | 28.6 | 100 | 41 | 104.8 | 7 | 149.2 | 74.6 | 8 | 3/4 | 120 | 7/8 | M20 | 5.9 |

| 3 | 80 | 210 | 31.8 | 117 | 46 | 127 | 7 | 168.3 | 90.7 | 8 | 3/4 | 125 | 7/8 | M20 | 7.3 |

| 4 | 100 | 275 | 38.1 | 152 | 54 | 157.2 | 7 | 215.9 | 116.1 | 8 | 7/8 | 145 | 1 | M24 | 16.8 |

| 5 | 125 | 330 | 44.5 | 189 | 60 | 185.7 | 7 | 266.7 | 143.8 | 8 | 1 | 165 | 1 1/8 | M27 | 29 |

| 6 | 150 | 355 | 47.7 | 222 | 67 | 215.9 | 7 | 292.1 | 170.7 | 12 | 1 | 170 | 1 1/8 | M27 | 36 |

| 8 | 200 | 420 | 55.6 | 273 | 76 | 269.9 | 7 | 349.2 | 221.5 | 12 | 1 1/8 | 190 | 1 1/4 | M30 | 52 |

| 10 | 250 | 510 | 63.5 | 343 | 86 | 323.8 | 7 | 431.8 | 276.2 | 16 | 1 1/4 | 215 | 1 3/8 | M33 | 77 |

| 12 | 300 | 560 | 66.7 | 400 | 92 | 381 | 7 | 489 | 327 | 20 | 1 1/4 | 220 | 1 3/8 | M33 | 91 |

| 14 | 350 | 605 | 69.9 | 432 | 94 | 412.8 | 7 | 527 | 359.2 | 20 | 1 3/8 | 235 | 1 1/2 | M36 | 105 |

| 16 | 400 | 685 | 76.2 | 495 | 106 | 469.9 | 7 | 603.2 | 410.5 | 20 | 1 1/2 | 255 | 1 5/8 | M39 | 150 |

| 18 | 450 | 745 | 82.6 | 546 | 117 | 533.4 | 7 | 654 | 461.8 | 20 | 1 5/8 | 275 | 1 3/4 | M42 | 182 |

| 20 | 500 | 815 | 88.9 | 610 | 127 | 584.2 | 7 | 723.9 | 513.1 | 24 | 1 5/8 | 285 | 1 3/4 | M42 | 232 |

| 24 | 600 | 940 | 101.6 | 718 | 140 | 692.2 | 7 | 838.2 | 616 | 24 | 1 7/8 | 330 | 2 | M48 | 332 |

Class 900 Slip-on Flange Dimensions

| Size in Inch | Size in mm | Outer Dia. | Flange Thickness | Hub OD | Flange Length | RF Dia. | RF Height | PCD | Socket Bore | No of Bolts | Bolt Size UNC | RF Stud Length | Hole Size | ISO Stud Size | Weight in kg |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | E | F | G | H | ||||||||

| 1/2 | 15 | 120 | 22.3 | 38 | 32 | 34.9 | 7 | 82.6 | 22.2 | 4 | 3/4 | 110 | 7/8 | M20 | 1.8 |

| 3/4 | 20 | 130 | 25.4 | 44 | 35 | 42.9 | 7 | 88.9 | 27.7 | 4 | 3/4 | 115 | 7/8 | M20 | 2.3 |

| 1 | 25 | 150 | 28.6 | 52 | 41 | 50.8 | 7 | 101.6 | 34.5 | 4 | 7/8 | 125 | 1 | M24 | 3.6 |

| 1 1/4 | 32 | 160 | 28.6 | 64 | 41 | 63.5 | 7 | 111.1 | 43.2 | 4 | 7/8 | 125 | 1 | M24 | 4.1 |

| 1 1/2 | 40 | 180 | 31.8 | 70 | 44 | 73 | 7 | 123.8 | 49.5 | 4 | 1 | 140 | 1 1/8 | M27 | 5.5 |

| 2 | 50 | 215 | 38.1 | 105 | 57 | 92.1 | 7 | 165.1 | 61.9 | 8 | 7/8 | 145 | 1 | M24 | 11.5 |

| 2 1/2 | 65 | 245 | 41.3 | 124 | 64 | 104.8 | 7 | 190.5 | 74.6 | 8 | 1 | 160 | 1 1/8 | M27 | 16.5 |

| 3 | 80 | 240 | 38.1 | 127 | 54 | 127 | 7 | 190.5 | 90.7 | 8 | 7/8 | 145 | 1 | M24 | 12 |

| 4 | 100 | 290 | 44.5 | 159 | 70 | 157.2 | 7 | 235 | 116.1 | 8 | 1 1/8 | 170 | 1 1/4 | M30 | 24 |

| 5 | 125 | 350 | 50.8 | 190 | 79 | 185.7 | 7 | 279.4 | 143.8 | 8 | 1 1/4 | 190 | 1 3/8 | M33 | 38 |

| 6 | 150 | 380 | 55.6 | 235 | 86 | 215.9 | 7 | 317.5 | 170.7 | 12 | 1 1/8 | 190 | 1 1/4 | M30 | 50 |

| 8 | 200 | 470 | 63.5 | 298 | 102 | 269.9 | 7 | 393.7 | 221.5 | 12 | 1 3/8 | 220 | 1 1/2 | M36 | 78 |

| 10 | 250 | 545 | 69.9 | 368 | 108 | 323.8 | 7 | 469.9 | 276.2 | 16 | 1 3/8 | 235 | 1 1/2 | M36 | 112 |

| 12 | 300 | 610 | 79.4 | 419 | 117 | 381 | 7 | 533.4 | 327 | 20 | 1 3/8 | 255 | 1 1/2 | M36 | 148 |

| 14 | 350 | 640 | 85.8 | 451 | 130 | 412.8 | 7 | 558.8 | 359.2 | 20 | 1 1/2 | 275 | 1 5/8 | M39 | 182 |

| 16 | 400 | 705 | 88.9 | 508 | 133 | 469.9 | 7 | 616 | 410.5 | 20 | 1 5/8 | 285 | 1 3/4 | M42 | 193 |

| 18 | 450 | 785 | 101.6 | 565 | 152 | 533.4 | 7 | 685.8 | 461.8 | 20 | 1 7/8 | 325 | 2 | M48 | 258 |

| 20 | 500 | 855 | 108 | 622 | 159 | 584.2 | 7 | 749.3 | 513.1 | 20 | 2 | 350 | 2 1/8 | M52 | 317 |

| 24 | 600 | 1040 | 139.7 | 749 | 203 | 692.2 | 7 | 901.7 | 616 | 20 | 2 1/2 | 440 | 2 5/8 | M64 | 608 |

SORF Flanges Pressure Ratings

| Slip On Flange Weights by Pressure Class and Size | ||||||

|---|---|---|---|---|---|---|

| Pipe Size | 300 # | 1500 # | 150 # | 900 # | 600 # | 2500 # |

| 1/2″ | 1 | 4 | 1 | SEE 1500 # WEIGHTS | 2 | 7 |

| 3/4″ | 3 | 5 | 2 | SEE 1500 # WEIGHTS | 3 | 8 |

| 1″ | 3 | 8 | 2 | SEE 1500 # WEIGHTS | 4 | 11 |

| 1 1/2″ | 6 | 12 | 3 | SEE 1500 # WEIGHTS | 7 | 22 |

| 2″ | 7 | 25 | 5 | SEE 1500 # WEIGHTS | 9 | 37 |

| 2 1/2″ | 10 | 36 | 7 | SEE 1500 # WEIGHTS | 13 | 55 |

| 3″ | 13 | 48 | 8 | 26 | 16 | 83 |

| 4″ | 22 | 73 | 13 | 53 | 37 | 125 |

| 5″ | 28 | 130 | 15 | 83 | 63 | 210 |

| 6″ | 39 | 165 | 19 | 110 | 80 | 325 |

| 8″ | 58 | 260 | 30 | 170 | 115 | 485 |

| 10″ | 81 | 435 | 43 | 245 | 170 | 930 |

| 12″ | 115 | 580 | 64 | 325 | 200 | 1100 |

| 14″ | 165 | NA | 90 | 400 | 230 | NA |

| 16″ | 190 | NA | 98 | 425 | 330 | NA |

| 18″ | 250 | NA | 130 | 600 | 400 | NA |

| 20″ | 315 | NA | 165 | 730 | 510 | NA |

| 22″ | 370 | NA | 185 | NA | 590 | NA |

| 24″ | 475 | NA | 220 | 1400 | 730 | NA |

Class 600 Alloy Steel Slip On Flanges Dimensions in mm

| D mm |

T2 mm |

Size inch |

X mm |

t mm |

G mm |

B2 mm |

|---|---|---|---|---|---|---|

| 95 | 22.4 | 1/2 | 38.1 | 14.2 | 35.1 | 22.4 |

| 117 | 25.4 | 3/4 | 47.8 | 15.7 | 42.9 | 27.7 |

| 124 | 26.9 | 1 | 53.8 | 17.5 | 50.8 | 34.5 |

| 133 | 28.4 | 1¼ | 63.5 | 20.6 | 63.5 | 43.2 |

| 155 | 31.8 | 1½ | 69.9 | 22.4 | 73.2 | 49.5 |

| 165 | 36.6 | 2 | 84.1 | 25.4 | 91.9 | 62.0 |

| 191 | 41.1 | 2½ | 100.1 | 28.4 | 104.6 | 74.7 |

| 210 | 46.0 | 3 | 117.3 | 31.8 | 127.0 | 90.7 |

| 229 | 49.3 | 3½ | 133.4 | 35.1 | 139.7 | 103.4 |

| 273 | 53.8 | 4 | 152.4 | 38.1 | 157.2 | 116.1 |

| 330 | 60.5 | 5 | 189.0 | 44.5 | 185.7 | 143.8 |

| 356 | 66.5 | 6 | 222.3 | 47.8 | 215.9 | 170.7 |

| 419 | 76.2 | 8 | 273.1 | 55.6 | 269.7 | 221.5 |

| 508 | 85.9 | 10 | 342.9 | 63.5 | 323.9 | 276.4 |

| 559 | 91.9 | 12 | 400.1 | 66.5 | 381.0 | 327.2 |

| 603 | 93.7 | 14 | 431.8 | 69.9 | 412.8 | 359.2 |

| 686 | 106.4 | 16 | 495.3 | 76.2 | 469.9 | 410.5 |

| 743 | 117.3 | 18 | 546.1 | 82.6 | 533.4 | 461.8 |

| 813 | 127.0 | 20 | 609.6 | 88.9 | 584.2 | 513.1 |

| 940 | 139.7 | 24 | 717.6 | 101.6 | 692.2 | 616.0 |

Class 150 Copper Alloy Steel Slip On Flanges Dimensions in mm

| G mm |

Size inch |

T2 mm |

X mm |

t mm |

D mm |

B2 mm |

|---|---|---|---|---|---|---|

| 35.1 | 1/2 | 15.7 | 30.2 | 11.2 | 89 | 22.4 |

| 42.9 | 3/4 | 15.7 | 38.1 | 12.7 | 99 | 27.7 |

| 50.8 | 1 | 17.5 | 49.3 | 14.2 | 108 | 34.5 |

| 63.5 | 1¼ | 20.6 | 58.7 | 15.7 | 117 | 43.2 |

| 73.2 | 1½ | 22.4 | 65.0 | 17.5 | 127 | 49.5 |

| 91.9 | 2 | 25.4 | 77.7 | 19.1 | 152 | 62.0 |

| 104.6 | 2½ | 28.4 | 90.4 | 22.4 | 178 | 74.7 |

| 127.0 | 3 | 30.2 | 108.0 | 23.9 | 191 | 90.7 |

| 139.7 | 3½ | 31.8 | 122.2 | 23.9 | 216 | 103.4 |

| 157.2 | 4 | 33.3 | 134.9 | 23.9 | 229 | 116.1 |

| 185.7 | 5 | 36.6 | 163.6 | 23.9 | 254 | 143.8 |

| 215.9 | 6 | 39.6 | 192.0 | 25.4 | 279 | 170.7 |

| 269.7 | 8 | 44.5 | 246.1 | 28.4 | 343 | 221.5 |

| 323.9 | 10 | 49.3 | 304.8 | 30.2 | 406 | 276.4 |

| 381.0 | 12 | 55.6 | 365.3 | 31.8 | 483 | 327.2 |

| 412.8 | 14 | 57.2 | 400.1 | 35.1 | 533 | 359.2 |

| 469.9 | 16 | 63.5 | 457.2 | 36.6 | 597 | 410.5 |

| 533.4 | 18 | 68.3 | 505.0 | 39.6 | 635 | 461.8 |

| 584.2 | 20 | 73.2 | 558.8 | 42.9 | 699 | 513.1 |

| 692.2 | 24 | 82.6 | 663.4 | 47.8 | 813 | 616.0 |

Class 300 Nickel Alloy Slip On Flanges Dimensions in mm

| G mm |

Size inch |

X mm |

T2 mm |

t mm |

D mm |

B2 mm |

|---|---|---|---|---|---|---|

| 35.1 | 1/2 | 38.1 | 22.4 | 14.2 | 95 | 22.4 |

| 42.9 | 3/4 | 47.8 | 25.4 | 15.7 | 117 | 27.7 |

| 50.8 | 1 | 53.8 | 26.9 | 17.5 | 124 | 34.5 |

| 63.5 | 1¼ | 63.5 | 26.9 | 19.1 | 133 | 43.2 |

| 73.2 | 1½ | 69.9 | 30.2 | 20.6 | 155 | 49.5 |

| 91.9 | 2 | 84.1 | 33.3 | 22.4 | 165 | 62.0 |

| 104.6 | 2½ | 100.1 | 38.1 | 25.4 | 191 | 74.7 |

| 127.0 | 3 | 117.3 | 42.9 | 28.4 | 210 | 90.7 |

| 139.7 | 3½ | 133.4 | 44.5 | 30.2 | 229 | 103.4 |

| 157.2 | 4 | 146.1 | 47.8 | 31.8 | 254 | 116.1 |

| 185.7 | 5 | 177.8 | 50.8 | 35.1 | 279 | 143.8 |

| 215.9 | 6 | 206.2 | 52.3 | 36.6 | 318 | 170.7 |

| 269.7 | 8 | 260.4 | 62.0 | 41.1 | 381 | 221.5 |

| 323.9 | 10 | 320.5 | 66.5 | 47.8 | 445 | 276.4 |

| 381.0 | 12 | 374.7 | 73.2 | 50.8 | 521 | 327.2 |

| 412.8 | 14 | 425.5 | 76.2 | 63.8 | 584 | 359.2 |

| 469.9 | 16 | 482.6 | 82.6 | 57.2 | 648 | 410.5 |

| 533.4 | 18 | 533.4 | 88.9 | 60.5 | 711 | 461.8 |

| 584.2 | 20 | 587.2 | 95.3 | 63.5 | 775 | 513.1 |

| 692.2 | 24 | 701.5 | 106.4 | 69.9 | 914 | 616.0 |

Slip On Flanges Weight Chart in Kg for Class 150

| NOMINAL SIZE | WEIGHT (KG) | |||

|

NPS (Inches) |

DN (mm) |

SOW SW |

WN | BLIND |

| 1/2 | 15 | 0.4 | 0.5 | 0.4 |

| 3/4 | 20 | 0.6 | 0.7 | 0.6 |

| 1 | 25 | 0.8 | 1 | 0.9 |

| 1 1/4 | 32 | 1 | 1.3 | 1.2 |

| 1 1/2 | 40 | 1.3 | 1.7 | 1.5 |

| 2 | 50 | 2.1 | 2.6 | 2.4 |

| 2 1/2 | 65 | 3.3 | 4.1 | 3.9 |

| 3 | 80 | 3.9 | 4.9 | 4.9 |

| 3 1/2 | 90 | 4.8 | 6.1 | 6.2 |

| 4 | 100 | 5.3 | 6.8 | 7.0 |

| 5 | 125 | 6.1 | 8.6 | 8.6 |

| 6 | 150 | 7.5 | 10.6 | 11.3 |

| 8 | 200 | 12.1 | 17.6 | 19.6 |

| 10 | 250 | 16.5 | 24 | 28.6 |

| 12 | 300 | 26.2 | 36.5 | 43.2 |

| 14 | 350 | 34.6 | 48.4 | 58.1 |

| 16 | 400 | 44.8 | 60.6 | 76.1 |

| 18 | 450 | 48.9 | 68.3 | 93.7 |

| 20 | 500 | 61.9 | 84.5 | 122.0 |

| 24 | 600 | 86.9 | 115 | 185.0 |

Slip On Flanges Weight Chart for Class 300

| NOMINAL SIZE | WEIGHT (KG) | |||

|

NPS (Inches) |

DN (mm) |

SOW SW |

WN | BLIND |

| 1/2 | 15 | 0.6 | 0.8 | 0.6 |

| 3/4 | 20 | 1.1 | 1.3 | 1.1 |

| 1 | 25 | 1.4 | 1.5 | 1.4 |

| 1 1/4 | 32 | 1.7 | 2.0 | 1.8 |

| 1 1/2 | 40 | 2.5 | 2.9 | 2.7 |

| 2 | 50 | 2.9 | 3.4 | 3.2 |

| 2 1/2 | 65 | 4.3 | 5.2 | 4.9 |

| 3 | 80 | 5.9 | 6.9 | 6.8 |

| 3 1/2 | 90 | 7.3 | 8.7 | 8.7 |

| 4 | 100 | 9.6 | 11.2 | 11.5 |

| 5 | 125 | 12.3 | 15.1 | 15.6 |

| 6 | 150 | 15.6 | 19.1 | 20.9 |

| 8 | 200 | 24.2 | 29.9 | 34.3 |

| 10 | 250 | 34.1 | 42.7 | 53.3 |

| 12 | 300 | 49.8 | 61.8 | 78.8 |

| 14 | 350 | 69.9 | 85.8 | 105.0 |

| 16 | 400 | 88.1 | 106.0 | 137.0 |

| 18 | 450 | 109.0 | 131.0 | 175.0 |

| 20 | 500 | 134.0 | 158.0 | 221.0 |

| 24 | 600 | 201.0 | 230.0 | 339.0 |

Slip On Flanges Weight Chart for Class 600

| NOMINAL SIZE | WEIGHT (KG) | |||

|

NPS (Inches) |

DN (mm) |

SOW SW |

WN | BLIND |

| 1/2 | 15 | 0.7 | 0.9 | 0.8 |

| 3/4 | 20 | 1.3 | 1.5 | 1.3 |

| 1 | 25 | 1.5 | 1.8 | 1.6 |

| 1 1/4 | 32 | 2 | 2.5 | 2.2 |

| 1 1/2 | 40 | 3 | 3.5 | 3.3 |

| 2 | 50 | 3.6 | 4.4 | 4.2 |

| 2 1/2 | 65 | 5.3 | 6.4 | 6.1 |

| 3 | 80 | 7 | 8.5 | 8.4 |

| 3 1/2 | 90 | 8.8 | 10.7 | 11 |

| 4 | 100 | 14.5 | 17.4 | 17.3 |

| 5 | 125 | 24.4 | 29.2 | 29.4 |

| 6 | 150 | 28.7 | 34.9 | 36.1 |

| 8 | 200 | 43.4 | 53.9 | 58.9 |

| 10 | 250 | 70.3 | 86.5 | 97.5 |

| 12 | 300 | 84.2 | 103.0 | 124 |

| 14 | 350 | 98.7 | 122.0 | 151 |

| 16 | 400 | 142.0 | 170.0 | 214 |

| 18 | 450 | 173.0 | 204.0 | 272 |

| 20 | 500 | 220.0 | 254.0 | 349.0 |

| 24 | 600 | 312.0 | 358.0 | 533.0 |

Slip-On Flanges Uses

Slip-on Flanges come in different sizes, shapes, and applications. So, according to different industries’ needs, they use these flanges. Below is the list of different industries that use slip-on flanges.

- Water and Wastewater Treatment

- Oil and Gas

- Chemical Processing

- Power Generation

- Food and Pharmaceutical Processing

- HVAC and Plumbing

- Fire Protection

- Marine

- Textile and Automotive

- General Piping

Ready Stock Of Slip On Flanges Manufacturer

| Stainless Steel Slip On Flange | Alloy Steel Slip On Flanges |

| Hastelloy C22 Slip On Flanges | Type of Monel K500 Slip On Flanges |

| Incoloy 800 Slip On Flange | Slip On Raised Face Flanges |

| Alloy 825 Slip On Flanges | Inconel 601 Slip On Flanges |

| Monel 400 Slip On Flange | 625 Inconel Slip On Flanges |

| ANSI/ASME B16.5 Raised Face Slip On Flanges | Carbon Steel A105 Slip On Flanges |

| ASME B16.5 Slip On Flanges | Titanium Grade 2 / 5 Slip On Flanges |

| Stainless Steel 304H Slip On Flanges | SS Industrial Slip On Plate Flange |

| SS 304L Slip On (SORF) Flanges | Carbon Steel SOFF Flanges |

| Copper Nickel SORTJ Flanges | Stainless Steel 316TI Slip On Flanges |

| ASTM A350 Low Temperature Steel Slip On Flanges | Super Duplex Steel S32760 Slip On Flanges |

| Duplex Steel S32205 Slip On Flanges |

FAQs

1.What are slip-on flanges?

Slip-on flanges (SO flanges) slide over pipe ends and are welded inside and outside for a secure seal. They’re cost-effective, ideal for lower pressure applications, and available in materials like carbon steel, stainless steel, and alloy steel for simple installation and reliable performance.

2. What is the difference between a slip on flange and a threaded flange?

3. What is the typical pressure rating of a slip-on flange?

Slip-on flanges typically have pressure ratings ranging from 150 to 2500 pounds per square inch (PSI), depending on their size and material.