Inconel 718 Pipes & Tubes – Nickel Alloy 718 Seamless Pipes & Tubes Supplier

Table of Content

- Introduction To Inconel 718 Alloy

- Types of Inconel 718 Tubes

- Alloy 718 Seamless Vs Welded Pipes & Tubes

- Specification Chart for Inconel 718 (UNS N00718) Pipes

- Inconel 718 Alloy Tube Chemical Composition

- Mechanical Properties Chart of Inconel 718 Pipe

- Equivalent Material of Alloy 718 Pipe

- Pressure Rating of DIN 2.4668 Pipe and Tube

- Size Ranges & Dimensional Standards for Inconel 718 Pipes

- Dimensional Technical Standard of Inconel Alloy 718 Pipe

- Size Chart in mm of Inconel 718 Capillary Tube

- Available Size of Alloy 718 Square Tube

- ASTM B163 Alloy 718 Welded Pipe Size Range

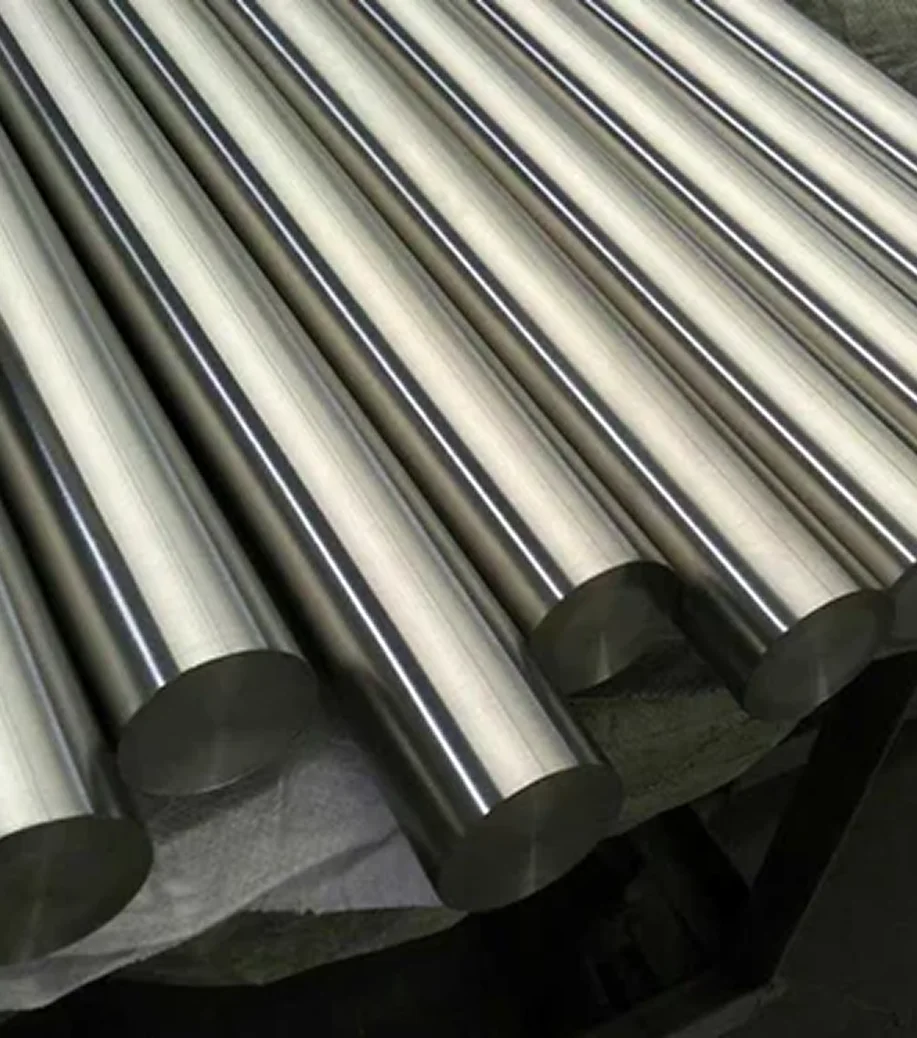

Kalpataru Piping is a leading manufacturer and supplier that exports in high-performance nickel alloy piping products. We are a large supplier of Inconel 718 Pipes and tubes. We designed Inconel 718 seamless and welded pipes in accordance with standards such as ASTM, ASME, & many other international standards. We are a leading stockist of UNS N07718 Inconel 718 pipes and tubes & offering products in various sizes, thicknesses and specifications. These are Inconel pipes of alloy 718 that are produced with high pressure, high temperatures, and corrosion conditions.

We also provide customized Inconel 718 pipes and tubes according to client specifications and technical specifications. Our Inconel products are quality examined and performance tested & supplied at competitive prices and assured delivery on time.

Introduction To Inconel 718 Alloy

Inconel Alloy 718 (UNS N07718 / W.Nr. 2.4668) is a high-performance nickel-chromium alloy product. It is very reliable in a wide temperature range, with cryogenic temperatures of -423 °C as well as 1300 °C and it has excellent tensile, fatigue, creep, and rupture strength. These properties have formed the basis of Inconel 718 pipes and tubes, which provide outstanding performance under both low temperature corrosive conditions and high temperature and pressure services.

The Inconel alloy 718 tubes slow age-hardening reaction permits annealing and welding without abrupt hardening in heating and cooling, which facilitates easy fabrication and welding with other alloys. Alloy 718 pipes and tubes are commonly used in heat exchangers, anaerobic

Product Features of Inconel 718 Pipes & Tubes:

- Excellent corrosion and oxidation resistance

- Accurate dimensions and smooth surface finish

- Good weldability and fabrication characteristics

- Long service life in harsh environments

Types of Inconel 718 Tubes

Alloy 718 Seamless Vs Welded Pipes & Tubes

Inconel 718 pipes and tubes have two types, and these are mostly welded and seamless. Inconel 718 Seamless Pipes and Tubes are manufactured using the hot working and cold drawing processes, the result of which does not leave any welded joints. Because of the lack of seam, these tubes offer better structural integrity, even strength and increased pressure and stress resiliency.

Inconel 718 Welded Pipes and Tubes Inconel 718 Welded Pipes and Tubes are developed by bending metal strips into the shape of a cylinder and welding them at the seam by using the latest welding methods. These pipes provide high mechanical strength, dimensional precision and are cost-effective, thus applicable in moderate pressures of operation. Both welded and seamless Alloy Inconel 718 pipes and tubes are well-welded and have high resistance against cracking of the post-weld. The customers may select the most appropriate type depending on the application, pressure requirements and operating conditions. Besides Inconel 718 there are also other nickel alloy grades like Inconel 600 pipes and tubes, which are produced to satisfy various industry requirements.

Inconel 718 Pipes Standards & Specifications: ASTM A163 / ASME SB163 / AMS 5590 & AMS 5589

The Inconel 718 piping is produced following ASTM B163 / ASME SB163 / AMS 5590 / AMS 5589, with the consistency of chemical composition, mechanical strength, dimensional accuracy, as well as surface quality.

Specification Chart for Inconel 718 (UNS N00718) Pipes

|

ASTM Specification |

AMS 5590, AMS 5589 |

|

International Specification |

WERKSTOFF Nr 2.4668 , UNS N07718 |

|

Standard |

GB, DTD, ASME, AISI, ASTM, TOCT, JIS, NF, SAE, DIN, AMS, DS, EN |

|

Size of Seamless Pipe |

Wall thickness.: 0.05- 20 milimeter, 4 – 219 milimeter |

|

Size of Welded Pipe |

5.0 to 1219.02 milimeter |

|

size of EFW Pipe |

5.0 to 1219.02 milimeter |

|

Seamless Tube Size |

3.35 milimeter To 101.6 milimeter OD |

|

Welded Tube Size |

6.35 milimeter To 152 milimeter OD |

|

Bwg & Swg |

18 Swg., 14 20 Swg., Swg. Swg., 12 16 Swg., 10 Swg. |

|

Tubing wall thickness |

0.020″ –0.220″, (custom wall thicknesses available) |

|

Pipe Schedule |

SCH20, XS, STD, XXS, SCH60, SCH140, SCH80, SCH80, SCH5, SCH40S, SCH40, SCH120, SCH10S, SCH10, SCH30, SCH160 |

|

Length |

Standard & Cut length , Single Random, Double Random Pipe |

|

Finish |

AP (Annealed & Pickled), BA (Bright & Annealed), NO.1, 2B, Polished, MF, HL, NO.4, Mirror finish, BA, 8K etc |

|

End |

Plain End, Beveled End, Treaded Pipe, Screwed ends |

|

Form |

Hydraulic, Rectangular, Coiled, Square, Hollow, Round, Straight Pipes/tubes, “U” Shape, Pan Cake Coils, Boiler, LSAWetc. |

|

Application |

Dairy Pipe, Oil Pipe/tube, Gas Pipe/tube, Fluid Pipe/tube, Boiler Tube, Heat exchanger Tube |

|

Type |

Seamless /ERW/ EFW / Welded / Fabricated /CDW /DOM/CEW Inconel 718 Pipe |

|

Marking |

Heat No. (Or as per need.), Thickness, OD, Grade, Standard Length |

|

Value Added Service |

Expansion and Draw as per needed Length and Size, , Polish (Comilimeterercial and Electro), Machining, Annealed & Pickled Bending Etc. |

|

Specialize in |

|

Inconel 718 Alloy Tube Chemical Composition

| Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr |

| Inconel 718 | 0.08 max | 0.35 max | 0.35 max | 0.015max | 0.30 max | – | 50.00 – 55.00 | 17.00 – 21.00 |

Mechanical Properties Chart of Inconel 718 Pipe

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 718 | 8.14 g/cm3 | 1400 °C (2550 °F) | Psi – 80,000 , MPa – 550 | Psi – 32,000 , MPa – 220 | 30 % |

Equivalent Material of Alloy 718 Pipe

|

Grade |

UNS No |

Old British |

Euronorm |

GOST |

Japanese JIS |

||

|

BS |

En |

No |

AFNOR |

||||

|

Inconel 718 |

N07718 |

– |

– |

2.4668 |

– |

– |

– |

Physical Properties Of Alloy 718 Pipe

|

Density |

g/centimeter3 |

8.019 |

|

Thermal Conductivity |

W.m -1.°K-1 |

11.04 |

|

Electrical Resistivity |

μohm/cm |

1.032 |

|

Specific Heat (0-100°C) |

J.kg-1.°K-1 |

435 |

|

Modulus Elasticity |

GPa |

200 |

|

Thermal Expansion |

μm/μm/°C |

13 |

Pressure Rating of DIN 2.4668 Pipe and Tube

|

Inconel 718 Pipe O.D. (in.) |

Wall Thickness of Inconel 718 Pipe (inches) | |||||||

| 0.028 | 0.035 | 0.083 | 0.049 | 0.065 | 0.095 | 0.109 | 0.120 | |

| Working Pressure (psig) | ||||||||

| 1/8 | 7900 | 10100 | ||||||

| 1/4 | 3700 | 4800 | 7000 | 9500 | ||||

| 5/16 | 3700 | 5400 | 7300 | |||||

| 3/8 | 3100 | 4400 | 6100 | |||||

| 1/2 | 2300 | 3200 | 4400 | |||||

| 3/4 | 4000 | 2200 | 3000 | 4600 | ||||

| 1 | 2900 | 2200 | 3400 | 3900 | 4300 | |||

Size Ranges & Dimensional Standards for Inconel 718 Pipes

Inconel 718 pipes and tubes are manufactured in a wide range of sizes and dimensional standards to meet diverse industrial requirements. Available in various outer diameters, wall thicknesses, and lengths, these pipes and tubes conform to international standards, ensuring high strength, excellent corrosion resistance, and reliable performance in high-temperature and high-pressure applications.

Dimensional Technical Standard of Inconel Alloy 718 pipe

|

Nominal Thickness (in) MM |

Pipe Size (in) |

Transverse Areas (in2) MM2 |

Diameter (in) MM |

Volume (ft3/ft) |

Number of Threads per inch of Screw | Weight |

Length of Pipe (ft per sq.0 foot of surface) |

|||||

| Internal | External | Steel | Internal | External | (kg/m) | (lb/ft) |

Internal Surface (ft) |

External Surface (ft) |

||||

| 0.007 | 1/8 | 0.006 | 0.013 | 0.007 | 0.027 | 0.0405 | 0.00004 | 27 | 0.036 | 0.024 | 14.020 | 9.043 |

| 0.009 | ¼ | 0.010 | 0.023 | 0.013 | 0.036 | 0.0540 | 0.00007 | 18 | 0.063 | 0.042 | 10.049 | 7.007 |

| 0.009 | 3/8 | 0.019 | 0.036 | 0.017 | 0.049 | 0.0675 | 0.00013 | 18 | 0.084 | 0.057 | 7.075 | 5.066 |

| 0.011 | ½ | 0.030 | 0.055 | 0.025 | 0.062 | 0.0840 | 0.00021 | 14 | 1.026 | 0.085 | 6.014 | 4.055 |

| 0.011 | ¾ | 0.053 | 0.087 | 0.033 | 0.082 | 1.0050 | 0.00037 | 14 | 1.068 | 1.013 | 4.064 | 3.064 |

| 0.013 | 1 | 0.086 | 1.036 | 0.049 | 1.005 | 1.0315 | 0.00060 | 11 ½ | 2.050 | 1.068 | 3.064 | 2.090 |

| 0.014 | 1 ¼ | 1.050 | 2.016 | 0.067 | 1.038 | 1.0660 | 0.00104 | 11 ½ | 3.038 | 2.027 | 2.077 | 2.030 |

| 0.015 | 1 ½ | 2.004 | 2.084 | 0.080 | 1.061 | 1.0900 | 0.00141 | 11 ½ | 4.004 | 2.072 | 2.037 | 2.001 |

| 0.015 | 2 | 3.036 | 4.043 | 1.008 | 2.007 | 2.0375 | 0.00233 | 11 ½ | 5.043 | 3.065 | 1.085 | 1.061 |

| 0.020 | 2 ½ | 4.079 | 6.049 | 1.070 | 2.047 | 2.0875 | 0.00333 | 8 | 8.062 | 5.079 | 1.055 | 1.033 |

| 0.022 | 3 | 7.039 | 9.062 | 2.023 | 3.007 | 3.0500 | 0.00513 | 8 | 11.027 | 7.058 | 1.025 | 1.009 |

| 0.023 | 3 ½ | 9.089 | 12.056 | 2.068 | 3.055 | 4.0000 | 0.00687 | 8 | 13.056 | 9.011 | 1.008 | 0.095 |

| 0.024 | 4 | 12.073 | 15.090 | 3.017 | 4.003 | 4.0500 | 0.00884 | 8 | 16.006 | 10.079 | 0.095 | 0.085 |

| 0.026 | 5 | 20.000 | 24.030 | 4.030 | 5.005 | 5.0563 | 0.01389 | 8 | 21.074 | 14.061 | 0.076 | 0.069 |

| 0.028 | 6 | 28.089 | 34.047 | 5.058 | 6.007 | 6.0625 | 0.02006 | 8 | 28.023 | 18.097 | 0.063 | 0.058 |

| 0.032 | 8 | 50.002 | 58.042 | 8.040 | 7.098 | 8.0625 | 0.03552 | 8 | 42.049 | 28.055 | 0.048 | 0.044 |

| 0.037 | 10 | 78.085 | 90.076 | 11.090 | 10.002 | 10.0750 | 0.05476 | 8 | 60.024 | 40.048 | 0.038 | 0.036 |

| 0.041 | 12 | 111.090 | 127.064 | 15.074 | 11.094 | 12.0750 | 0.07763 | 8 | 79.077 | 53.060 | 0.032 | 0.030 |

| 0.044 | 14 | 135.030 | 153.094 | 18.064 | 13.013 | 14.0000 | 0.09354 | 8 | 93.075 | 63.000 | 0.028 | 0.027 |

| 0.050 | 16 | 176.070 | 201.005 | 24.035 | 15.000 | 16.0000 | 1.02230 | 8 | 116.008 | 78.000 | 0.025 | 0.024 |

| 0.056 | 18 | 224.000 | 254.085 | 30.085 | 16.088 | 18.0000 | 1.05550 | 8 | 156.026 | 105.000 | 0.023 | 0.021 |

| 0.059 | 20 | 278.000 | 314.015 | 36.015 | 18.081 | 20.0000 | 1.09260 | 8 | 183.005 | 123.000 | 0.020 | 0.019 |

| 0.069 | 24 | 402.010 | 452.040 | 50.030 | 22.063 | 24.0000 | 2.07930 | 8 | 254.048 | 171.000 | 0.017 | 0.016 |

Size Chart In Mm of Inconel 718 Capillary Tube

| Regular Wall (RW) mm | Gauge | Extra Thin Wall (XTW) mm | Outside Diameter Tolerance mm | Ultra Thin Wall (UTW) mm | Thin Wall (TW) mm |

| 0.0064 to 0.0089 | 30 | 0.0304 to 0.0317 | |||

| 0.0064 to 0.0089 | 29 | o.0330 to 0.0342 | |||

| 0.0076 to 0.0102 | 28 | 0.0355 to 0.0368 | |||

| 0.0089 to 0.0115 | 27 | 0.0406 to 0.0419 | 0.0064 to 0.0089 | ||

| 0.0089 to 0.0114 | 26 | 0.0457 to 0.0469 | |||

| 0.0115 to 0.0140 | 25 | 0.0508 to 0.0520 | 0.0089 to 0.0114 | ||

| 0.0114 to 0.0140 | 24 | 0.0558 to 0.0571 | 0.0051 to 0.0102 | 0.0089 to 0.0114 | |

| 0.0140 to 0.0165 | 23 | 0.0635 to 0.0647 | 0.0051 to 0.0102 | 0.0089 to 0.0114 | |

| 0.0140 to 0.0165 | 22 | 0.0077 to 0.0102 | 0.0711 to 0.0723 | 0.0051 to 0.0102 | 0.0096 to 0.0121 |

| 0.0140 to 0.0165 | 21 | 0.0812 to 0.0825 | 0.0051 to 0.0102 | 0.0102 to 0.0127 | |

| 0.0108 to 0.0165 | 20 | 0.0901 to 0.0914 | 0.0108 to 0.0134 | ||

| 0.0166 to 0.0216 | 19 | 0.0070 to 0.0108 | 1.0054 to 1.0079 | 0.0102 to 0.0140 | |

| 0.0191 to 0.0241 | 18 | 0.0083 to 0.0121 | 1.0257 to 1.0282 | 0.0051 to 0.0102 | 0.0127 to 0.0165 |

| 0.0177 to 0.0229 | 17 | 0.0083 to 0.0127 | 1.0460 to 1.0485 | 0.0057 to 0.0102 | 0.0115 to 0.0152 |

| 0.0204 to 0.0254 | 16 | 0.0096 to 0.0133 | 1.0638 to 1.0663 | 0.0070 to 0.0121 | 0.0127 to 0.0165 |

| 0.0204 to 0.0254 | 15 | 0.0096 to 0.0134 | 1.0816 to 1.0841 | 0.0070 to 0.0121 | 0.0127 to 0.0165 |

| 0.0216 to 0.0292 | 14 | 0.0114 to 0.0165 | 2.0082 to 2.0133 | 0.0076 to 0.0134 | 0.0165 to 0.0229 |

| 0.0267 to 0.0343 | 13 | 2.0387 to 2.0438 | 0.0191 to 0.0267 | ||

| 0.0267 to 0.0321 | 12 | 2.0743 to 2.0749 | |||

| 0.0293 to 0.0368 | 11 | 3.0023 to 3.0073 | 0.0216 to 0.0292 | ||

| 0.0318 to 0.0394 | 10 | 0.0216 to 0.0292 | 3.0378 to 3.0429 |

Available size of Alloy 718 Square Tube

| DIMENSIONS | WEIGHT PER | WALL | DIMENSIONS | WEIGHT PER | WALL | |

| (MM) | METRE (KG) | (MM) | (MM) | METRE (KG) | (MM) | |

| 12.07 x 12.07 | 0.044 | 1.020 | 40 x40 | 1.049 | 1.020 | |

| 12.07 x 12.07 | 0.055 | 1.050 | 40 x40 | 1.085 | 1.050 | |

| 15 x 15 | 0.053 | 1.020 | 40 x40 | 2.045 | 2.000 | |

| 15 x 15 | 0.065 | 1.050 | 40 x40 | 3.075 | 3.000 | |

| 20 x 20 | 0.071 | 1.020 | 50 x50 | 2.032 | 1.050 | |

| 20 x 20 | 0.088 | 1.050 | 50 x50 | 3.008 | 2.000 | |

| 20 x 20 | 1.019 | 2.000 | 50 x50 | 4.065 | 3.000 | |

| 25 x 25 | 0.092 | 1.020 | 60 x60 | 3.071 | 2.000 | |

| 25 x 25 | 1.014 | 1.050 | 60 x60 | 5.049 | 3.000 | |

| 25 x 25 | 1.049 | 2.000 | 70 x70 | 6.053 | 3.000 | |

| 25 x 25 | 2.020 | 3.000 | 80 x80 | 4.098 | 2.000 | |

| 30 x 30 | 1.010 | 1.020 | 80 x80 | 7.053 | 3.000 | |

| 30 x 30 | 1.037 | 1.050 | 100 x 100 | 6.040 | 2.000 | |

| 30 x 30 | 1.084 | 2.000 | 100 x 100 | 9.053 | 3.000 | |

| 30 x 30 | 2.072 | 3.000 | ||||

Ranging in size from Astm B163 Alloy 718 welded pipe

|

Pipe WT mm |

ASME SB163 Alloy 718 Pipe OD mm |

Sch | in.0 | Kg/m |

| 1.065 | 13.072 | 10S | 1/4 | 0.050 |

| 2.024 | 13.072 | 40S | 1/4 | 0.064 |

| 3.002 | 13.072 | 80S | 1/4 | 0.081 |

| 1.065 | 17.015 | 10S | 3/8 | 0.064 |

| 2.031 | 17.015 | 40S | 3/8 | 0.086 |

| 3.020 | 17.015 | 80S | 3/8 | 1.012 |

| 2.011 | 21.034 | 10S | 1/2 | 1.002 |

| 2.077 | 21.034 | 40S | 1/2 | 1.029 |

| 3.073 | 21.034 | 80S | 1/2 | 1.065 |

| 2.011 | 26.067 | 10S | 3/4 | 1.030 |

| 2.087 | 26.067 | 40S | 3/4 | 1.071 |

| 3.091 | 26.067 | 80S | 3/4 | 2.023 |

| 2.077 | 33.040 | 10S | 1 | 2.013 |

| 3.038 | 33.040 | 40S | 1 | 2.054 |

| 4.055 | 33.040 | 80S | 1 | 3.029 |

| 6.0352) | 33.040 | 160 | 1 | 4.030 |

| 2.077 | 42.016 | 10S | 1¼ | 2.073 |

| 3.056 | 42.016 | 40S | 1¼ | 3.044 |

| 4.085 | 42.016 | 80S | 1¼ | 4.053 |

| 6.0352) | 42.016 | 160 | 1¼ | 5.069 |

| 2.077 | 48.026 | 10S | 1½ | 3.016 |

| 3.068 | 48.026 | 40S | 1½ | 4.011 |

| 5.008 | 48.026 | 80S | 1½ | 5.049 |

| 2.077 | 60.033 | 10S | 2 | 3.099 |

| 3.091 | 60.033 | 40S | 2 | 5.052 |

| 5.054 | 60.033 | 80S | 2 | 7.060 |

| 8.0742) | 60.033 | 160 | 2 | 11.029 |

| 3.005 | 73.003 | 10S | 2½ | 5.035 |

| 5.016 | 73.003 | 40S | 2½ | 8.077 |

| 7.001 | 73.003 | 80S | 2½ | 11.059 |

| 3.005 | 88.090 | 10S | 3 | 6.056 |

| 5.049 | 88.090 | 40S | 3 | 11.047 |

| 7.062 | 88.090 | 80S | 3 | 15.051 |

| 11.0132) | 88.090 | 160 | 3 | 21.067 |

| 3.005 | 101.060 | 10S | 3½ | 7.053 |

| 5.074 | 101.060 | 40S | 3½ | 13.078 |

| 8.008 | 101.060 | 80S | 3½ | 18.092 |

| 3.005 | 114.030 | 10S | 4 | 8.050 |

| 6.002 | 114.030 | 40S | 4 | 16.032 |

| 8.056 | 114.030 | 80S | 4 | 22.067 |

| 13.0492) | 114.030 | 160 | 4 | 34.005 |

| 6.055 | 141.030 | 40S | 5 | 22.010 |

| 9.053 | 141.030 | 80S | 5 | 31.044 |

| 15.0882) | 141.030 | 160 | 5 | 49.087 |

| 3.04 | 168.028 | 10S | 6 | 14.004 |

| 7.011 | 168.028 | 40S | 6 | 28.069 |

| 10.097 | 168.028 | 80S | 6 | 43.021 |

| 14.027 | 168.028 | 120 | 6 | 54.075 |

| 18.0262) | 168.028 | 160 | 6 | 68.059 |

| 8.018 | 219.008 | 40S | 8 | 43.020 |

| 12.07 | 219.008 | 80S | 8 | 65.063 |

| 18.023 | 219.008 | 120 | 8 | 91.030 |

| 23.0012) | 219.008 | 160 | 8 | 112.097 |

OD = Inconel 718 Pipe outside diameter

WT = Inconel 718 Pipe wall thickness

Outer Diameter (OD) of Inconel 718 Tube

| Types | Out diameter | Length | Wall thickness |

| NB Sizes (available) | 1/8” ~ 8” | Upto 6 Meters | SCH 40 /SCH 10 /SCH 160/ SCH 5 / SCH 80 |

| Inconel 718 Seamless tube (as per need) | 5.00 milimeter ~ 203.02 milimeter | as per need | |

| Inconel 718 Welded tube (available + as per need) | 5.00 milimeter ~ 1219.02 milimeter | 1.00 ~ 15.00 milimeter |

Inconel Alloy 718 Pipe Schedule Chart

| 3 1/2″ IPS( 4.000″O. D.) | 1/8″ IPS(.405″O. D.) |

| SCH 40, 10, 160, 80, XXH | SCH 40, 80 |

| 4″ IPS(4.500″O. D.) | 1/4″ IPS(.540″O. D.) |

| SCH 40, 10, 160, 80, XXH | SCH 40, 10, 80 |

| 5″ IPS( 5.563″O. D.) | 3/8″ IPS(.675″O. D.) |

| SCH 40, 10, 160, 80, XXH | SCH 40, 10, 80 |

| 6″ IPS(6.625″O. D.) | 1/2″ IPS(.840″O. D.) |

| SCH 10, 5, 80, 40, 160, 120 XXH | SCH 5, 40, 10, 160, 80, XXH |

| 8 ” IPS(8.625″O. D.) | 3/4″ IPS(1.050″O. D.) |

| SCH 10, 5, 80, 40, 160, 120 XXH | SCH 40, 10, 160, 80, XXH |

| 10″ IPS(10.750″O. D.) | 1″ IPS:(1.315′O. D.) |

| SCH 10, 20, TRUE 80(.500), 40, 80 (.500), | SCH 5, 40, 10, 160, 80, XXH |

| 12″ IPS(12.750″O. D.) | 1-1/4″ IPS(1.660″O. D.) |

| SCH 10, 20, TRUE40(.406), 40(.375), SCH80(.500) | SCH 40, 10, 160, 80, XXH |

| 14″ IPS(14.000″O. D.) | 1-1/2″ IPS(1.900″O. D.) |

| SCH10(.188), SCH40(.375) | SCH 40, 10, 160, 80, XXH |

| 16″ IPS(16.000″O. D.) | 2″ IPS(2.375″O. D.) |

| SCH10(.188), SCH40(.375) | SCH 40, 10, 160, 80, XXH |

| 18″ IPS (18.000″O. D.) | 2 1/2″ IPS(2.875″O. D.) |

| SCH-40 (.375) | SCH 40, 10, 160, 80, XXH |

| 3″ IPS( 3.500″O. D.) | |

| SCH 5, 40, 10, 160, 80, XXH |

Inconel 718 Pipe Weight Chart

The following chart provides theoretical weights for commonly ordered sizes. For precise calculations, please use our Pipe Weight Calculator.

| NPS | Wall Thickness | Outside Diameter | Weight | Weight | |||

| inch | milimeter | inch | milimeter | kg/Mtr | Schedule | Lb/ft | |

| 1/2″ | 0.0109 | 2.0769 | 0.0840 | 21 | 1.0268 | 40 STD | 0.0851 |

| 0.0147 | 3.0734 | 1.0621 | 80 STD | 1.0088 | |||

| 3/4″ | 0.0113 | 2.0870 | 1.0050 | 27 | 1.0684 | 40 STD | 1.0131 |

| 0.0154 | 3.0912 | 2.0195 | 80 STD | 1.0474 | |||

| 1″ | 0.0133 | 3.0378 | 1.0315 | 33 | 2.0501 | 40 STD | 1.0679 |

| 0.0179 | 4.0547 | 3.0325 | 80 STD | 2.0172 | |||

| 1 1/4″ | 0.0140 | 3.0556 | 1.0660 | 42 | 3.0385 | 40 STD | 2.0273 |

| 0.0191 | 4.0851 | 4.0464 | 80 STD | 2.0997 | |||

| 1 1/2″ | 0.0145 | 3.0683 | 1.0900 | 48 | 4.0048 | 40 STD | 2.0718 |

| 0.0200 | 5.0080 | 5.0409 | 80 STD | 3.0361 | |||

| 2″ | 0.0154 | 3.0912 | 2.0375 | 60 | 5.0441 | 40 STD | 3.0653 |

| 0.0218 | 5.0537 | 7.0480 | 80 STD | 5.0022 | |||

| 2 1/2″ | 0.0203 | 5.0516 | 2.0875 | 73 | 8.0629 | 40 STD | 5.0793 |

| 0.0276 | 7.0010 | 11.0411 | 80 STD | 7.0661 | |||

| 3″ | 0.0216 | 5.0486 | 3.0500 | 89 | 11.0284 | 40 STD | 7.0576 |

| 0.0300 | 7.0620 | 15.0272 | 80 STD | 10.0253 | |||

| 4″ | 0.0237 | 6.0020 | 4.0500 | 114 | 16.0073 | 10.0790 | |

| 0.0337 | 8.0560 | 22.0318 | 14.0983 | ||||

| 6″ | 0.0188 | 4.0775 | 6.0625 | 168 | 19.0252 | 12.0924 | |

| 0.0203 | 5.0516 | 20.0739 | 13.0923 | ||||

| 0.0219 | 5.0563 | 22.0318 | 14.0983 | ||||

| 0.0250 | 6.0350 | 25.0354 | 17.0021 | ||||

| 0.0280 | 7.0112 | 58.0263 | 40 STD | 18.0974 | |||

| 0.0312 | 7.0925 | 31.0334 | 21.0036 | ||||

| 0.0375 | 9.0525 | 37.0285 | 25.0031 | ||||

| 0.0432 | 10.0973 | 42.0561 | 80 XHY | 28.0573 | |||

| 0.0500 | 12.0700 | 48.0719 | 32.0708 | ||||

| 8″ | 0.0188 | 4.0775 | 8.0625 | 219 | 25.0233 | 16.0940 | |

| 0.0203 | 5.0156 | 27.0198 | 18.0259 | ||||

| 0.0219 | 5.0563 | 29.0286 | 19.0661 | ||||

| 0.0250 | 6.0350 | 33.0308 | 20 | 22.0361 | |||

| 0.0277 | 7.0036 | 36.0786 | 30 | 24.0696 | |||

| 0.0322 | 8.0179 | 42.0352 | 40 | 28.0554 | |||

| 0.0375 | 9.0525 | 49.0216 | 33.0041 | ||||

| 0.0406 | 10.0312 | 53.0085 | 60 | 35.0638 | |||

| 0.0500 | 12.0700 | 64.0627 | 80 XHY | 43.0388 | |||

| 10″ | 0.0188 | 4.0775 | 10.0750 | 273 | 31.0588 | 21.0207 | |

| 0.0219 | 5.0563 | 36.0689 | 24.0631 | ||||

| 0.0250 | 6.0350 | 41.0759 | 20 | 28.0035 | |||

| 0.0307 | 7.0798 | 51.0002 | 30 | 34.0240 | |||

| 0.0344 | 8.0738 | 56.0946 | 38.0231 | ||||

| 0.0365 | 9.0271 | 63.0301 | 40 STD | 40.0483 | |||

| 0.0438 | 11.0125 | 71.0852 | 48.0238 | ||||

| 0.0500 | 12.0700 | 81.0530 | 60 XHY | 54.0735 | |||

| 0.0594 | 15.0088 | 95.0969 | 80 | 64.0429 | |||

| 12″ | 0.0188 | 4.0775 | 12.0750 | 324 | 37.0570 | 25.0222 | |

| 0.0219 | 5.0563 | 43.0657 | 29.0309 | ||||

| 0.0250 | 6.0350 | 49.0713 | 33.0375 | ||||

| 0.0281 | 7.0137 | 55.0739 | 37.0420 | ||||

| 0.0312 | 7.0925 | 61.0735 | 41.0445 | ||||

| 0.0375 | 9.0525 | 73.0824 | 49.0562 | ||||

| 0.0406 | 10.0312 | 79.0727 | 53.0525 | ||||

| 0.0500 | 12.0700 | 97.0438 | 65.0415 | ||||

| 0.0562 | 14.0275 | 108.0966 | 73.0154 | ||||

| 14″ | 0.0188 | 4.0775 | 14.0000 | 356 | 41.0308 | 27.0732 | |

| 0.0219 | 5.0563 | 48.0012 | 32.0233 | ||||

| 0.0250 | 6.0350 | 54.0685 | 20 | 36.0713 | |||

| 0.0281 | 7.0137 | 61.0327 | 41.0172 | ||||

| 0.0312 | 7.0925 | 67.0939 | 45.0611 | ||||

| 0.0375 | 9.0525 | 81.0281 | STD | 54.0568 | |||

| 0.0438 | 11.0125 | 94.0498 | 40 | 63.0441 | |||

| 0.0500 | 12.0700 | 107.0381 | XHY | 72.0090 | |||

| 0.0625 | 15.0875 | 132.0983 | 89.0278 | ||||

| 16” | 0.0188 | 4.0775 | 16.0000 | 406 | 47.0290 | 21.0748 | |

| 0.0219 | 5.0563 | 54.0980 | 36.0910 | ||||

| 0.0250 | 6.0350 | 62.0639 | 10 | 42.0053 | |||

| 0.0281 | 7.0137 | 70.0268 | 47.0174 | ||||

| 0.0312 | 7.0925 | 77.0866 | 20 | 52.0275 | |||

| 0.0344 | 8.0738 | 85.0677 | 57.0519 | ||||

| 0.0375 | 9.0525 | 93.0213 |

30 STD |

62.0578 | |||

| 0.0438 | 11.0125 | 108.0433 | 72.0797 | ||||

| 0.0500 | 12.0700 | 123.0289 |

40 XHY |

82.0770 | |||

| 18″ | 0.0219 | 5.0563 | 18.0000 | 457 | 61.0948 | 41.0588 | |

| 0.0250 | 6.0350 | 70.0593 | 47.0393 | ||||

| 0.0281 | 7.0137 | 79.0208 | 53.0176 | ||||

| 0.0312 | 7.0925 | 87.0792 | 20 | 58.0939 | |||

| 0.0375 | 9.0525 | 105.0144 | STD | 70.0588 | |||

| 0.0438 | 11.0125 | 122.0369 | 30 | 82.0152 | |||

| 0.0500 | 12.0700 | 139.0198 | XHY | 93.0450 | |||

| 0.0562 | 14.0275 | 155.0904 | 40 | 104.0666 | |||

| 0.0625 | 15.0875 | 172.0754 | 115.0978 | ||||

| 20″ | 0.0250 | 6.0350 | 20.0000 | 508 | 78.0547 | 52.0733 | |

| 0.0282 | 7.0163 | 88.0458 | 59.0386 | ||||

| 0.0312 | 7.0925 | 97.0719 | 65.0604 | ||||

| 0.0375 | 9.0525 | 117.0075 | 20 STD | 78.0598 | |||

| 0.0438 | 11.0125 | 136.0305 | 91.0508 | ||||

| 0.0500 | 12.0700 | 155.0106 | 30 XHY | 104.0130 | |||

| 0.0594 | 15.0088 | 183.0378 | 40 | 123.0110 | |||

| 0.0625 | 15.0875 | 192.0640 | 129.0328 | ||||

| 0.0688 | 17.0475 | 211.0368 | 141.0901 | ||||

| 24″ | 0.0250 | 6.0350 | 24.0000 | 610 | 94.0456 | 63.0413 | |

| 0.0281 | 7.0137 | 106.0029 | 71.0183 | ||||

| 0.0312 | 7.0925 | 117.0573 | 18.0932 | ||||

| 0.0375 | 9.0525 | 140.0938 | 20 STD | 64.0618 | |||

| 0.0438 | 11.0125 | 164.0176 | 110.0219 | ||||

| 0.0500 | 12.0700 | 186.0923 | XHY | 125.0490 | |||

| 0.0625 | 15.0875 | 232.0410 | 156.0028 | ||||

| 0.0688 | 17.0475 | 255.0148 | 40 | 171.0293 | |||

| 0.0750 | 19.0050 | 277.0401 | 186.0233 | ||||

| 30″ | 0.0250 | 6.0350 | 30.0000 | 762 | 118.0318 | 79.0433 | |

| 0.0281 | 7.0137 | 132.0851 | 89.0189 | ||||

| 0.0312 | 7.0925 | 147.0353 | 10 | 98.0925 | |||

| 0.0375 | 9.0525 | 176.0731 | STD | 118.0648 | |||

| 0.0438 | 11.0125 | 205.0983 | 138.0286 | ||||

| 0.0500 | 12.0700 | 234.0647 | 20 XHY | 157.0530 | |||

| 0.0625 | 15.0875 | 292.0066 | 30 | 196.0078 | |||

| 0.0688 | 17.0475 | 320.0817 | 215.0380 | ||||

| 0.0750 | 19.0050 | 348.0988 | 234.0293 | ||||

| 36″ | 0.0250 | 6.0350 | 36.0000 | 914 | 142.0180 | 95.0453 | |

| 0.0281 | 7.0137 | 159.0672 | 107.0196 | ||||

| 0.0312 | 7.0925 | 177.0133 | 10 | 118.0918 | |||

| 0.0375 | 9.0525 | 215.0525 | STD | 142.0678 | |||

| 0.0438 | 11.0125 | 247.0790 | 166.0353 | ||||

| 0.0500 | 12.0700 | 282.0372 | 20 XHY | 198.0570 | |||

| 0.0625 | 15.0875 | 351.0723 | 236.0128 | ||||

| 0.0688 | 17.0475 | 386.0487 | 259.0467 | ||||

| 0.0750 | 19.0050 | 420.0576 | 282.0353 | ||||

| 42″ | 0.0312 | 7.0925 | 42.0000 | 1067 | 206.0914 | 138.0911 | |

| 0.0375 | 9.0525 | 248.0319 | STD | 166.0708 | |||

| 0.0500 | 12.0700 | 33.0097 | XHY | 221.0610 | |||

| 0.0750 | 19.0050 | 492.0163 | 330.0413 | ||||

| 48″ | 0.0375 | 9.0525 | 48.0000 | 1219 | 284.0112 | STD | 190.0738 |

| 0.0438 | 11.0125 | 331.0404 | 222.0487 | ||||

| 0.0500 | 12.0700 | 377.0822 | XHY | 253.0650 | |||

| 0.0750 | 19.0050 | 563.0750 | 378.0473 | ||||

| 0.0875 | 22.0225 | 655.0969 | 440.0383 | ||||

Note: All listed weights are theoretical and calculated on nominal dimensions. Actual weights may vary by up to ±10% due to manufacturing tolerances. For heavy wall schedules such as SCH 80, SCH 160, and XXS, please contact us for a detailed and accurate weight chart.

718 Inconel Welded Tube Tolerances

| WALL THICKNESS INCHES | OD +/- INCHES | OD INCHES |

| 0.0025 – 0.0065 | 0.0005 | 1/2″ – 1″ incl0.0 |

| Over 0.0065 – 0.0134 | 0.0010 | |

| 0.0025 – 0.0065 | 0.0008 | 1 – 1-1/2″ incl0.0 |

| Over 0.0065 – 0.0134 | 0.0010 | |

| 0.0025 – 0.0049 | 0.0010 | 1-1/2″ – 2″ incl0.0 |

| Over 0.0049 – 0.0083 | 0.0011 | |

| Over 0.0083 – 0.0148 | 0.0012 | |

| 0.0032 – 0.0065 | 0.0012 | 2″ – 2-1/2″ incl0.0 |

| Over 0.0065 – 0.0109 | 0.0013 | |

| Over 0.0109 – 0.0165 | 0.0014 | |

| 0.0032 – 0.0165 | 0.0014 | 2-1/2″ – 3-1/2″ incl0.0 |

| Over 0.0165 – 0.0220 | 0.0020 | |

| 0.0083 – 0.0165 | 0.0020 | 3-1/2″ – 5″ incl0.0 |

| Over 0.0165 – 0.0220 | 0.0025 |

Finishes and Coatings of Inconel Alloy 718 Heat Exchanger Tube

- Novolac Epoxy

- High Functionality Epoxy – Curran Coating

- liquid epoxy coatings

- Thin Film Engineered Polymer Coatings

- HVAC Chillers and Heat Exchanger Coatings

- Sakaphen- Shell and tube heat exchanger lining

- Surface Condenser Tube Sheets

- IGS high velocity thermal spray (HVTS) coating solutions

- Phenol Epoxy

- Curran 1000 T Hybrid Epoxy

Applications of Inconel 718 Pipes

Inconel 718 pipes are applicable in high-pressure and high-temperature applications where the strength and resistance to corrosion are essential.

- Aerospace & Aviation: The aircraft engines, exhaust systems and turbine components are fitted with inconel 718 pipes because they are very strong and can withstand extreme heat and stress.

- Oil & Gas Industry: These pipes are suitable in high-pressure pipeline services, offshore platforms, and sour gas services, where there is a need to have corrosion-inhibiting and NACE-conformity services.

- Chemical Processing/Petrochemical: Reactors, pressure vessels, and process piping that operate with aggressive chemicals and at high temperatures utilize Inconel 718 pipes.

- Power Generation: Applied to gas turbines, nuclear plants, and high-temperature steam systems due to their ability to retain strength and stability at thermal stress.

- Heat Exchangers: Heat exchangers and heat recovery systems make heavy use of the alloy 718 pipes and seamless tubes that are effective in transferring heat and having a long life.

- Marine & Offshore: These pipes resist corrosion by seawater and other severe marine environments and are, therefore, applicable in offshore structures and shipbuilding.

- Cryogenic Applications: Inconel 718 pipes can be applied at extremely low temperatures and in cryogenic storage, LNG systems, and low-temperature process lines.

Testing & Documentation

Every Inconel 718 pipe goes through quality testing and is provided with the full documentation to maintain authenticity of the material used, reliability of performance of the material and conformity to the international standards.

Alloy 718 Welded Pipe Testing

- Flaring Test – Checks ductility and weld soundness.

- Flattening Test – Verifies pipe strength and weld integrity

- Micro & Macro Examination – Evaluates weld structure and grain flow

- Intergranular Corrosion (IGC) Test – Confirms resistance to intergranular attack

- Pitting Resistance Test – Ensures performance in aggressive environments

- Chemical Analysis (Spectro Analysis) – Verifies correct alloy composition

- Mechanical Testing (Tensile Test) – Confirms tensile strength and elongation

- Hardness Test – Measures material hardness and uniformity

- Positive Material Identification (PMI) – Confirms material grade and traceability

Nickel Alloy 718 Pipe Documentation

- NABL-approved laboratory test reports

- Material traceability records

- Raw material test reports

- EN 10204 3.1 & EN 10204 3.2 Material Test Certificates (MTC)

- Test certificates complying with NACE MR0103 & NACE MR0175

- Welding Procedure Specification / Procedure Qualification Record (WPS / PQR)

- Heat treatment charts

- Quality Assurance Plan (QAP)

- Commercial invoice with HS code

- Form A (GSP) certificate

- Guarantee letter

- Fumigation certificates

Frequently Asked Questions About Inconel 718 Pipes & Tubes

What are Inconel 718 pipes and tubes used for?

Inconel 718 pipes and tubes find their application in the high-temperature and high-pressure systems like gas turbine, jet engines, heat exchanger, nuclear reactor, oil and gas equipment, chemical plant, and power generation systems.

Are Inconel 718 pipes available in seamless and welded forms?

Yes. Inconel 718 pipe and tubes are offered in either seamless, welded, ERW, redrawn, and cold-drawn types based on the application and requirements of such standards as ASTM B163, B516, AMS 5589 & 5590.

What standards are Inconel 718 pipes and tubes manufactured to?

Other typical standards are ASTM B163 / B516, AMS 5589 / 5590, ASME SB163, DIN 17751 and API specifications. There are also certification bodies such as the NACE, IBR and PED.

What size range is available for Inconel 718 seamless tubes?

The seamless range has options between 0.030 inch up to 1.250 inch OD, wall thickness ranging between 0.003 inch to 0.280 inch and custom lengths such as coiled, straight and even cut-to-size.

Can Inconel 718 tubes be used in heat exchanger and condenser applications?

Yes. Due to their high-temperature stability, corrosion resistance, and mechanical strength, Inconel 718 tubes are widely used in heat exchangers, condensers, boilers, and cooling systems.

How resistant are Inconel 718 pipes to corrosion?

Inconel 718 has great pitting, crevice corrosion, stress corrosion cracking, oxidative, and acid, chloride and sulfide attack resistance. This renders them suitable in hostile operating conditions.

Is custom cutting available for Inconel 718 pipes and tubes?

Yes. Depending on the needs, the suppliers may supply cut-to-length tubes, custom OD/ID, special tempers, and custom surface finishes.

What is the working temperature of Inconel 718 pipes?

Inconel 718 is useful in the range of -423F to 1300F (-253C to 704C) and in some applications is resistant to oxidation even up to 1800F (1154C).

Related Products

- Inconel 600 Perforated Sheets

- Inconel 600 Forged Fittings

- Inconel 600 Olets

- Inconel 600 Fasteners

- Inconel 600 Compression Tube Fittings

- Inconel 600 Pipes & Tubes

- Inconel 600 Flanges

- Inconel 600 Round Bars & Wires

- Inconel 600 Plates & Sheets

- Inconel 600 Buttweld Fittings

- Inconel 600 Instrumentation Valves

- Inconel 600 Filler Wire

- Inconel 600 Long Radius Bends

- Inconel 600 Pipes Spools

- Inconel 600 Shims

- Inconel 600 Wiremesh

Cities We deliver:

Bhopal, Lahore, Milan, Hyderabad, Pune, Vadodara, Pimpri-Chinchwad, Aberdeen, Howrah, Jeddah, Riyadh, Bogota, Petaling Jaya, Dallas, Lagos, Nagpur, Houston, Brisbane, Busan, Karachi, Coimbatore, Seoul, Caracas, Atyrau, Perth, Haryana, Bengaluru, Jaipur, Al Jubail, Kuwait City, Al Khobar, Sydney, Ranchi, Chiyoda, Noida, Chandigarh, Secunderabad, Ahvaz, Port-of-Spain, Singapore, Gurgaon, Rajkot, Rio de Janeiro, Abu Dhabi, Hong Kong, Surat, Sharjah, Hanoi, London, Muscat, Jakarta, Navi Mumbai, Istanbul, Kolkata, Cairo, Mumbai, Santiago, Montreal, Faridabad, Vung Tau, Bangkok, Ankara, Ahmedabad, Granada, Melbourne, Tehran, Visakhapatnam, New Delhi, Los Angeles, Ho Chi Minh City, Edmonton, La Victoria, Baroda, Thane, Nashik, Kuala Lumpur, Moscow, Ernakulam, Courbevoie, Calgary, Geoje-si, Indore, New York, Mexico City, Gimhae-si, Ludhiana, Kanpur, Ulsan, Thiruvananthapuram, Manama, Doha, Chennai, Madrid, Jamshedpur, Algiers, Dammam

Countries We Deliver:

Iran, Venezuela, Saudi Arabia, Slovakia, Romania, Zimbabwe, Spain, Kazakhstan, Canada, Nigeria, Bulgaria, Afghanistan, Thailand, Bangladesh, Poland, United Kingdom, Bahrain, Jordan, Lithuania, Malaysia, France, Nigeria, Japan, Oman, Lebanon, Germany, Croatia, Australia, Puerto Rico, South Korea, Hungary, United States, Bhutan, Mexico, Mexico, Yemen, Singapore, New Zealand, Ecuador, Gabon, Qatar, Denmark, Iran, Netherlands, Norway, Sri Lanka, Belgium, Libya, Kuwait, Pakistan, Gambia, Sweden, Azerbaijan, Argentina, Chile, Ghana, United Arab Emirates, Finland, Nepal, Trinidad andamp; Tobago,Tunisia, Kenya, Peru, Austria, Russia, Ukraine, Italy, Belarus, Bolivia, Serbia, Poland, Mongolia, Turkey, Czech Republic, South Africa, Angola, India, Vietnam, Indonesia, Tibet, Ireland, Costa Rica, Greece, Colombia, Namibia, Iraq, Estonia, Israel, Macau, Philippines, Brazil, Switzerland, Algeria, Morocco, Chile, Portugal, Egypt, Taiwan, China, Hong Kong.