Copper Nickel Pipes & Copper Nickel Tubes

Home – Copper Nickel Products – Copper Nickel Pipes & Tubes

Kalpataru Piping is a top Copper Nickel Pipes & Tubes in India, which is involved in supplying high quality copper nickel products at competitive prices. Our Copper Nickel Seamless Tubes are produced using hot billets and have no joints, hence they are stronger, accurate in dimensions and have high pressure handling capacity. These tubes possess tensile strength of about 43,900 psi to 60 000 psi and yield strength of about 16 000 psi to 57 000 psi and can be used in harsh industrial applications.

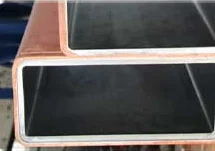

We also provide ASME SB552 Copper Nickel Welded Tubes, which are made by welding quality copper nickel sheets or coils. They are inexpensive, long-lasting and come in schedules of Sch 5 to Sch 160. The copper-nickel tubes ASTM B466 that we have provided have good ductility. These tubes come with single random length, two random length and custom cut lengths. The Copper Nickel Pipes and Tubes that we supply are all manufactured by adhering to national and international standards. Our competent workforce employs technologically superior technology and high-quality raw materials to produce products of high quality as required. We also provide the customization of chemical composition, size, shape, and finish to particular project requirements. Please contact our team in case of technical questions or price information.

About Copper Nickel Pipes and Tubes

Copper nickel alloy, or cupronickel as it is commonly referred to, is a versatile material composed mainly of copper with moderated additions of nickel, iron, manganese, as well as other elements. The copper nickel alloys, even though they have a significant amount of copper, still have a unique silver look, and that is why they can be used for functional and aesthetical purposes. Copper nickel pipes and tubes are used in marine applications for manufacturing of propellers, propeller shafts, and boat hulls as they resist seawater corrosion and biofouling. Copper nickel condenser tubes find extensive application in petrochemical facilities, power generation facilities, electrical systems and defence systems. When cupro nickel tubing is provided in an annealed state it has a natural resistance to macrofouling, high tensile strength, and high ductile characteristics. These tubes preserve their mechanical properties to cryogenic temperatures and offer antimicrobial surface properties and so, are applicable in hygienic and critical fluid-handling systems.

Grades of copper nickel pipes and tubes are C70600 (90/10), C71500 (70/30) and other combinations depending on the proportion of copper and nickel. Copper Nickel 90/10 pipes are used in seawater applications, whereas Copper Nickel 70/30 pipes have more strength, better oxidation resistance, and work better in high temperature and high velocity environment. Copper nickel tubes are also offered in a large variety of sizes, wall thicknesses, and specifications to suit a wide variety of industrial requirements. The supply may be in form of copper nickel pipes and tubes that have a seamless quality finishing which guarantees consistency in the performance of products in extreme operating environments.

Copper Nickel Pipe & Tubes Grades

Copper Nickel 70/30 Pipes And Copper Nickel 70/30 Tubes

Copper Nickel 90/10 (UNS C70600), which contains approximately 90% copper and 10% nickel with small additions of iron and manganese. This grade offers excellent resistance to seawater corrosion, good thermal conductivity, and easy fabrication.

Copper-Nickel 90/10 Pipes And Copper-Nickel 90/10 Tubes

Copper Nickel Pipe Specification

| Cupro Nickel Pipe Specification | ASTM B 466 ASME SB 466 / ASTM B 467 ASME SB 467 |

| Cupro Nickel Seamless Pipe size | 4 to 219mm W. T.: 0.5 to 20mm |

| Copper Nickel Welded Pipe size | 5.0 mm – 1219.2 mm |

| Cupro Nickel EFW Pipe size | 5.0 mm – 1219.2 mm |

| Copper Nickel Pipe Schedule | SCH5, SCH10, SCH40, STD, SCH80, SCH160 |

| Copper Nickel Pipe Form | Hollow, Square, Round, Rectangular , Straight Pipes, Hydraulic Etc. |

| Sizes |

|

| Copper Nickel Pipe Hardness | 1/16 hard, 1/8 hard, 3/8 hard, 1/4 hard, 1/2hard, full hard, soft etc |

| Test |

|

| Copper Nickel Pipe Length | Single Random, Double Random & Cut Length. |

| Our Presence | USA, Canada, Australia, UK, Malaysia, Poland, Iran, Italy, Singapore, UAE |

| CuNi Pipe Finish | Mill, polished, bright, oiled, hair line, brush, mirror, sand blast, or as required. |

| Marking | All Copper Nickel Pipes are marked as follows: Standard, Grade, OD, Thickness, Length, Heat No. (Or according to the customer’s request.) |

| Copper Nickel Pipe Application |

|

| Material Test Certificates (MTC) | Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2 |

| Cupro Nickel Pipe End | Plain End, Beveled End, Treaded. |

| Specialized in | Large Diameter Cupro Nickel Pipe |

| We can also cut, thread, and groove Copper Nickel Pipes to meet your specifications. | |

American standard and specification of Copper Nickel Pipe manufacturers

| ASTM B469 | Seamless Copper Alloy Tubes for Pressure Applications |

| ASTM B466 | Seamless Copper Nickel Pipe suppliers |

| ASTM B552 | Seamless & Welded Cupro Nickel Tube suppliers for Water Desalting |

| ASTM B543 | Welded Copper & Copper Alloy Heat Exchanger Tube |

| ASTM B608 | Welded Copper Nickel Tube/ Pipe |

| ASTM B467 | Welded Cupro Nickel Pipe manufacturer India |

| ASTM B111 | Copper & Copper Alloy Seamless Condenser Tubes & Ferrule Stock |

| ASTM B359 | Copper & Copper Alloy Seamless Condenser & Heat Exchanger Tubes with Integral Fins |

Various types of Copper Nickel Pipe

Copper Nickel Alloy Pipe

Copper Nickel Heat Exchanger Tube

Copper Nickel Tube

Cunifer Pipe

Eemua 146 Cuni Pipe

ASTM B466 Cupro Nickel Pipe

Equivalent Grades of Copper Nickel Alloy Tube

| STANDARD | WERKSTOFF NR. | UNS |

| Copper Nickel 90/10 | 2.0872 | C70600 |

| Copper Nickel 70/30 | 2.0882 | C71500 |

Copper Nickel (CuNi Pipe) Composition Chart

| Grade | Cu | Mn | Pb | Ni | Fe | Zn |

| Cu-Ni 90-10 | 88.6 min | 1.00 max | 0.5 max | 9-11 max | 1.8 max | 1.00 max |

| Cu-Ni 70-30 | 65.0 min | 1.00 max | 0.5 max | 29-33 max | 0.4-1.0 | 1.00 max |

Cu-Ni Tubes Physical Properties

| Grade | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Cu-Ni 90/10 | 0.323 lb/in3 at 68 F | 2260 F | 50000 psi | 20000 psi | 30 % |

| Cu-Ni 70/30 | 0.323 lb/in3 at 68 F | 2260 F | 50000 psi | 20000 psi | 30 % |

Copper Nickel Pipe Weight Per Foot

Knowing the exact weight per foot of Copper Nickel Pipes is essential for project planning, material handling, and cost estimation. The weight depends on the pipe’s outer diameter, wall thickness, and alloy grade. For quick and accurate calculations, use our Pipe & Tube Weight Calculator to determine the precise weight of Copper Nickel Pipes and Tubes for your project requirements.

| Outside diameter of pipe | EEMUA 144 | |||||

| 16 bar | 20 bar | |||||

| ØD | Wall | Theoretical | Wall | Theoretical | ||

| thickness | weight | thickness | weight | |||

| nominal | actual | actual | actual | |||

| inch | ND | mm | mm | Kg/m | mm | Kg/m |

| 0.125 | 10 | 1 | 0.26 | 1 | 0.26 | |

| 0.25 | 12 | 1 | 0.31 | 1 | 0.31 | |

| 0.38 | 10 | 16 | 2 | 0.79 | 2 | 0.79 |

| 0.5 | 15 | 20 | 2 | 1.01 | 2 | 1.01 |

| 0.75 | 20 | 25 | 2 | 1.3 | 2 | 1.3 |

| 1 | 25 | 30 | 2.5 | 1.93 | 2.5 | 1.93 |

| 1.25 | 32 | 38 | 2.5 | 2.5 | 2.5 | 2.5 |

| 1.5 | 40 | 44.5 | 2.5 | 2.95 | 2.5 | 2.95 |

| 2 | 50 | 57 | 2.5 | 3.83 | 2.5 | 3.83 |

| 2.5 | 65 | 76.1 | 2.5 | 5.17 | 2.5 | 5.17 |

| 3 | 80 | 88.9 | 2.5 | 6.07 | 2.5 | 6.07 |

| 4 | 100 | 108 | 3 | 8.85 | 3 | 8.85 |

| 5 | 125 | 133 | 3 | 10.95 | 3 | 10.95 |

| 6 | 150 | 159 | 3 | 13.14 | 3.5 | 15.29 |

| 7 | 175 | 193.7 | 3 | 16.07 | 3.5 | 18.7 |

| 8 | 200 | 219.1 | 4 | 24.17 | 4.5 | 27.12 |

| 10 | 250 | 267 | 4.5 | 33.18 | 5.5 | 40.39 |

| 12 | 300 | 323.9 | 5.5 | 49.18 | 7 | 62.3 |

| 14 | 350 | 368 | 6.5 | 65.99 | 8 | 80.89 |

| 16 | 400 | 419.1 | 7 | 81 | 9 | 103.64 |

| 18 | 450 | 457.2 | 8 | 100.93 | 9.5 | 119.45 |

| 20 | 500 | 508 | 8.5 | 119.24 | 11 | 153.54 |

| 24 | 600 | 610 | 10.5 | 176.79 | 13 | 217.97 |

| 28 | 700 | 711 | 12 | 235.58 | 15 | 293.22 |

| 32 | 800 | 813 | 13.5 | 303.14 | 17 | 380.06 |

| 36 | 900 | 914 | 15.5 | 391.14 | 19 | 477.6 |

Copper (CuPro) Nickel Pipe Schedule Chart

| 1/8″ IPS(.405″ O.D.) | 3 1/2″ IPS( 4.000″ O.D.) |

| SCH 40, 80 | SCH 10, 40, 80, 160, XXH |

| 1/4″ IPS(.540″ O.D.) | 4″ IPS(4.500″ O.D.) |

| SCH 10, 40, 80 | SCH 10, 40, 80, 160, XXH |

| 3/8″ IPS(.675″ O.D.) | 5″ IPS( 5.563″ O.D.) |

| SCH 10, 40, 80 | SCH 10, 40, 80, 160, XXH |

| 1/2″ IPS(.840″ O.D.) | 6″ IPS(6.625″ O.D.) |

| SCH 5, 10, 40, 80, 160, XXH | SCH 5, 10, 40, 80, 120, 160, XXH |

| 3/4″ IPS(1.050″ O.D.) | 8 ” IPS(8.625″ O.D.) |

| SCH 10, 40, 80, 160, XXH | SCH 5, 10, 40, 80, 120, 160, XXH |

| 1″ IPS:(1.315′ O.D.) | 10″ IPS(10.750″ O.D.) |

| SCH 5, 10, 40, 80, 160, XXH | SCH 10, 20, 40, 80 (.500), TRUE 80(.500) |

| 1-1/4″ IPS(1.660″ O.D.) | 12″ IPS(12.750″ O.D.) |

| SCH 10, 40, 80, 160, XXH | SCH 10, 20, 40(.375), TRUE40(.406), SCH80(.500) |

| 1-1/2″ IPS(1.900″ O.D.) | 14″ IPS(14.000″ O.D.) |

| SCH 10, 40, 80, 160, XXH | SCH10 (.188), SCH40 (.375) |

| 2″ IPS(2.375″ O.D.) | 16″ IPS(16.000″ O.D.) |

| SCH 10, 40, 80, 160, XXH | SCH10(.188), SCH40(.375) |

| 2 1/2″ IPS(2.875″ O.D.) | 18″ IPS (18.000″ O.D.) |

| SCH 10, 40, 80, 160, XXH | SCH-40 (.375) |

| 3″ IPS( 3.500″ O.D.) | |

| SCH 5, 10, 40, 80, 160, XXH |

Copper Nickel (CuNi) Pipe Pressure Rating

| Tube O.D.(in.) | Wall Thickness of Tube (inches) | |||||||

| .028 | .035 | .049 | .065 | .083 | .095 | .109 | .120 | |

| Working Pressure (psig) | ||||||||

| 1/8 | 7900 | 10100 | ||||||

| 1/4 | 3700 | 4800 | 7000 | 9500 | ||||

| 5/16 | 3700 | 5400 | 7300 | |||||

| 3/8 | 3100 | 4400 | 6100 | |||||

| 1/2 | 2300 | 3200 | 4400 | |||||

| 3/4 | 2200 | 3000 | 4000 | 4600 | ||||

| 1 | 2200 | 2900 | 3400 | 3900 | 4300 | |||

Copper Nickel (CuNi) Tube Pressure Rating

Maximum Allowable Working Pressure (PSIG)

| Tube O.D. in. |

Wall Thickness of Copper Nickel Tube (inches) | |||||||||

| .028 | .030 | .035 | .049 | .065 | .083 | .095 | .109 | .120 | 0.134 | |

| Working Pressure (psig) | ||||||||||

| 1/8 | 2700 | 3000 | 3600 | |||||||

| 3/16 | 1800 | 1900 | 2300 | 3400 | ||||||

| 1/4 | 1300 | 1400 | 1600 | 2700 | 3500 | |||||

| 5/16 | 1300 | 2200 | 2700 | |||||||

| 3/8 | 1000 | 1600 | 2200 | |||||||

| 1/2 | 800 | 1100 | 1600 | 2100 | ||||||

| 5/8 | 900 | 1200 | 1600 | 1900 | ||||||

| 3/4 | 700 | 1000 | 1300 | 1500 | 1800 | |||||

| 7/8 | 600 | 800 | 1100 | 1300 | 1500 | |||||

| 1 | 500 | 700 | 900 | 1100 | 1300 | 1500 | ||||

| 1 1/8 | 600 | 800 | 1000 | 1100 | 1300 | 1400 | ||||

Copper Nickel (CuPro Nickel) Heat Exchanger Tube Pressure Rating

| O.D.(in.) | Wall Thickness of Tube (inches) | |||||||

| .028 | .035 | .049 | .065 | .083 | .095 | .109 | .120 | |

| Working Pressure (psig) | ||||||||

| 1/8 | 7900 | 10100 | ||||||

| 1/4 | 3700 | 4800 | 7000 | 9500 | ||||

| 5/16 | 3700 | 5400 | 7300 | |||||

| 3/8 | 3100 | 4400 | 6100 | |||||

| 1/2 | 2300 | 3200 | 4400 | |||||

| 3/4 | 2200 | 3000 | 4000 | 4600 | ||||

| 1 | 2200 | 2900 | 3400 | 3900 | 4300 | |||

Cupro Nickel Pipe Dimension Tolerance

| Dimension Tolerance | |||||

| Material | Ultimate Tensile Strength1000 psi (MPa) | Yield Strength 0.5% Ext.under Load 1000 psi (MPa) | YElongation % in 2 in. | Fatigue Strength (10×7 cycles) 1000 psi (MPa) | Burst Pressure* 1000 psi (MPa) |

| Copper-brazed Steel | 48-55 (0.330-0.380) | 28-34 (0.190-0.235) | 30-40 | 30(0.210) | 19.5 (0.135) |

| C12200-Phosphorus deoxidized Copper | 32-38 (0.220-0.265) | 10-14 (0.070-0.100) | 45-60 | 10 (0.070) | 12 (0.083) |

| C70600-Copper Nickel 90-10 | 48-54 (0.330-0.370) | 16-22 (0.110-0.150) | 40-55 | 15 (0.100) | 19(0.130) |

Copper Nickel Seamless Pipes Wall Thickness

| NPS | O.D. | I.D. | Wall Thickness | ||||||

| K | L | M | DWV | K | L | M | DWV | ||

| 1/4″ | 3/8″ | 0.305 | 0.315 | – | – | 0.035 | 0.030 | – | – |

| 3/8″ | 1/2″ | 0.402 | 0.430 | 0.450 | – | 0.049 | 0.035 | 0.025 | – |

| 1/2″ | 5/8″ | 0.527 | 0.545 | 0.569 | – | 0.049 | 0.040 | 0.028 | – |

| 5/8″ | 3/4″ | 0.652 | 0.666 | – | – | 0.049 | 0.042 | – | – |

| 3/4″ | 7/8″ | 0.745 | 0.785 | 0.811 | – | 0.065 | 0.045 | 0.032 | – |

| 1″ | 1-1/8″ | 0.995 | 1.025 | 1.055 | – | 0.065 | 0.050 | 0.035 | – |

| 1-1/4″ | 1-3/8″ | 1.245 | 1.265 | 1.291 | 1.295 | 0.065 | 0.055 | 0.042 | 0.040 |

| 1-1/2″ | 1-5/8″ | 1.481 | 1.505 | 1.527 | 1.541 | 0.072 | 0.060 | 0.049 | 0.042 |

| 2″ | 2-1/8″ | 1.959 | 1.985 | 2.009 | 2.041 | 0.083 | 0.070 | 0.058 | 0.042 |

| 2-1/2″ | 2-5/8″ | 2.435 | 2.465 | 2.495 | – | 0.095 | 0.080 | 0.065 | – |

| 3″ | 3-1/8″ | 2.907 | 2.945 | 2.981 | 3.030 | 0.109 | 0.090 | 0.072 | 0.045 |

Application Industries for Cupro Nickel Tubes

- High Capacity Power Plants

- Heat Condensers & Exchangers

- Ship Building & Ship Repairs

- Distiller Tubes

- Evaporators & Ferrules

- Desalination Plants

- Power Plants

- Refineries

- Defence

Documentation You Can Expect with Your Copper Nickel Tube Order

To buy Copper Nickel Tubes & Pipes, connect with the trusted copper nickel pipes & tubes suppliers & manufacturers where full documentation should be issued to get quality, compliance and traceability. Typical documents include:

- Material Certificate: These certificates attest to the fact that the Copper Nickel Tubes are of international standards like ASTM or ASME. They give comprehensive data of the chemical composition and mechanical property of the material.

- Test Reports: Test reports can also contain tensile strength, hardness, and corrosion resistance tests, which prove that the tubes are at the necessary quality and performance standards.

- Shipping Documents: Papers such as the bill of lading, invoice, packing list and shipping information give a full history of your order and also assist in tracing the shipment of the manufacturer to the location where you receive them.

- Welding Certificate and Inspection Certificate: In the case of welded Copper Nickel Tubes, such certificates confirm that the welding and inspection were done in line with industry standards and hence the structural integrity and reliability.

- Warranty Information: Authoritative manufacturers of copper nickel pipes will have warranty information on defects or performance failure and hence you will be assured on the lifespan of your tubes.

- Compliance Certificates: When you are using tubes used in the marine or offshore or any other regulated use, then compliance certificates are used to assure that products are in line with the required industry regulations and standards.

Frequently Asked Questions About Copper Nickel Pipes & Tubes

What are Copper Nickel Pipes?

What grades of Copper Nickel Pipes are available?

Are Copper Nickel Pipes stronger than regular copper pipes?

Can Copper Nickel Pipes be welded?

What are the key benefits of Copper Nickel Tubes?

- Excellent corrosion resistance, especially in seawater

- High tensile strength and durability

- Good thermal conductivity for heat exchangers

- Resistance to biofouling and mechanical stress

- Suitable for high-pressure and high-temperature applications