by kalpataru | Mar 1, 2023 | Blog

The beryllium copper heating time encompasses both the heating and heat preservation (soaking) times. Short heating times, high heating rates, and uniform heating are needed to minimise ingot oxidation and energy consumption. It is essential to add up and take into account the heating temperature, the type of alloy, and the ingot’s dimensions in order to calculate the beryllium copper heating time.

The beryllium copper should be heated quickly and for the proper amount of time. Heat conduction is quick, the furnace temperature is high, and the temperature increases quickly. High-temperature heating has many advantages, especially for metals and alloys with excellent thermal conductivity. For some metals, however, the ingot will merely result in the overburn of coarse grains. The primary purpose of the soaking procedure is to prevent an excessive temperature difference between the ingot’s various components. Generally speaking, the temperature differential cannot be greater than 15-20 degrees Celsius; consequently, the better the ingot’s temperature uniformity, the better. Uneven heating will result in issues like cracks, waves, sickle curves, uneven thickness, and challenging biting when hot rolling. When the ingot size is big, the beryllium copper heating time should be appropriately prolonged, or the heating furnace temperature should be appropriately raised.

The beryllium copper heating components are more intricate. Therefore, during the actual production process, we must always remember the beryllium copper heating principle, accurately and flexibly apply the beryllium copper heating techniques, and constantly enhance the beryllium copper processing quality and power.

On the ageing characteristic curve, the relative maximum strength value will be visible when ageing at a temperature greater than 340 degrees Celsius. If the quantity of cold working remains constant, the strength corresponding to this maximum strength will diminish as the ageing temperature rises. If the ageing temperature is set and the rate of cold deformation is increased, the relative maximum strength value will slightly increase and the time of presentation will also be shortened. This results in a shorter ageing time to achieve the corresponding strength value. The ageing hardening of beryllium bronze only creates a meta-stable sedimentary phase below 330 degrees Celsius; above 330 degrees Celsius, it can create an equilibrium sedimentary phase or a meta-stable phase, with the latter being centred on the grain boundaries.

To prevent under and over-ageing, the temperature of beryllium copper during the ageing process needs to be carefully regulated. Under-ageing can also be made up for by ageing to achieve the necessary mechanical function, but once over-ageing begins, it is difficult to reverse without repeated solution heat treatment. Of course, the necessary functions can also be achieved by maximising the interaction between cold work, underaging, and averaging. For instance, when the strength is less than the maximum value asked, cold work and under- or over-ageing (lowering temperature, extending the time, or increasing temperature, shortening the time) are used to achieve the mechanical function of beryllium bronze that is desired.

Read More :

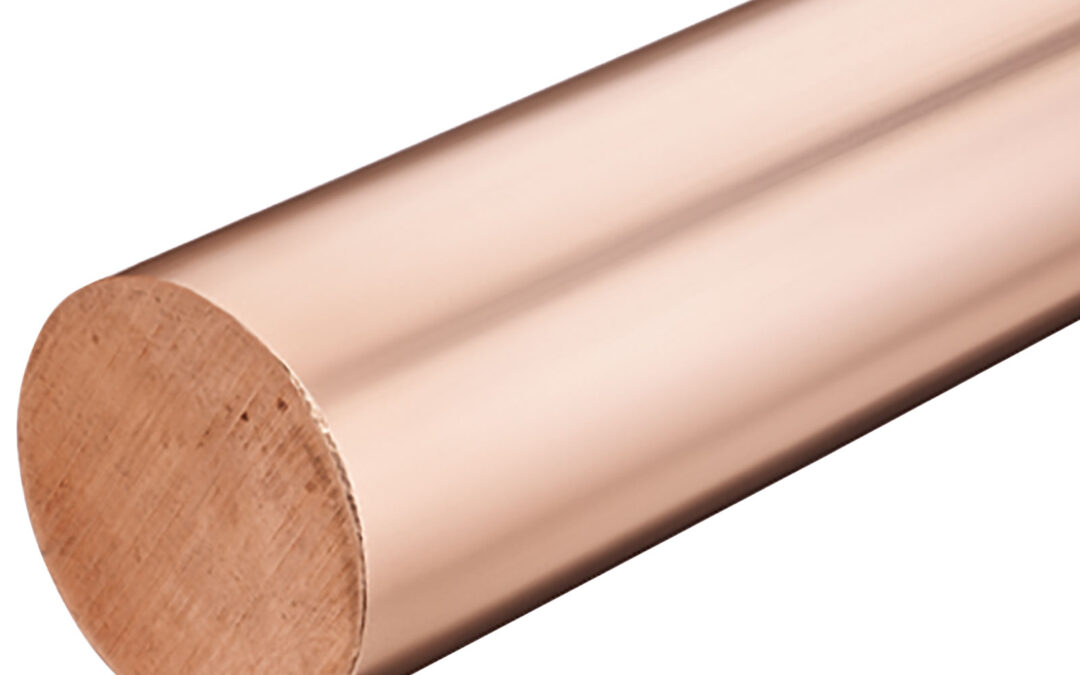

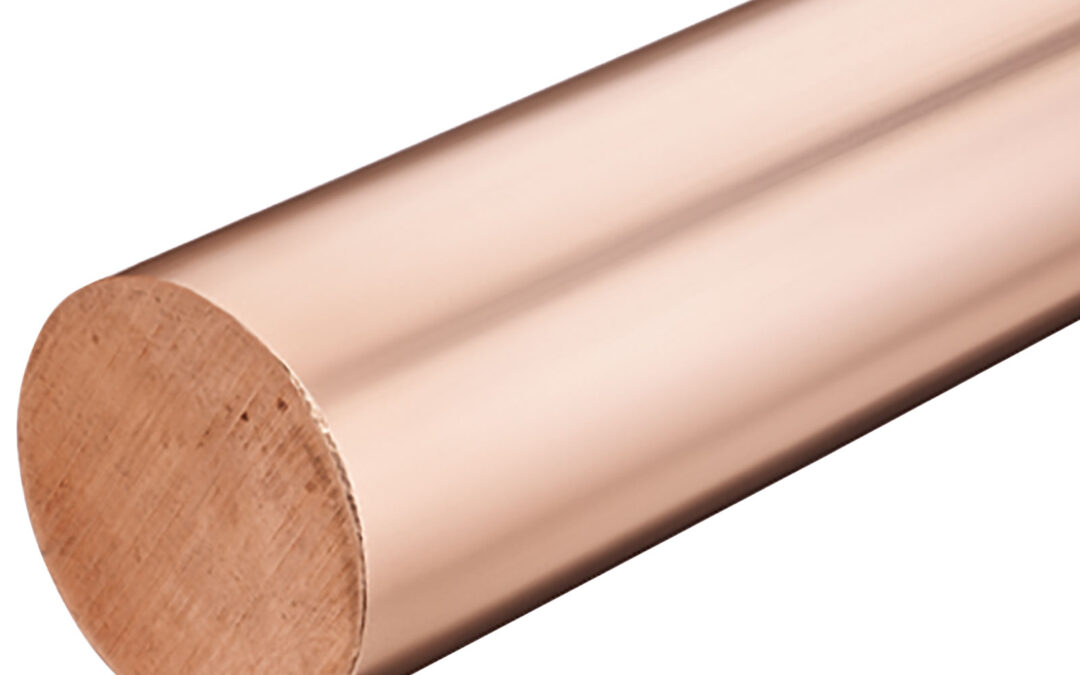

The Casting Shortening Rate Of Beryllium Copper Rod Is Small: Beryllium copper rods are used in the atmosphere, in seawater, in freshwater, and in steam for steam boilers and maritime ship components. Copper beryllium which contains phosphorus has mechanical properties and can be used in high-precision machine tools as polishing and elastic components.

C17200 Can Be Used As High Air Tightness Casting: It has been used for approximately 6,000 years. C17200 has excellent mechanical and technological properties, and it can be welded and brazed without sparks during impact.

by kalpataru | Mar 1, 2023 | Blog

Beryllium copper rods are used in the atmosphere, seawater, freshwater, and steam for steam boilers and maritime ship components. Copper beryllium which contains phosphorus has mechanical properties and can be used in high-precision machine tools as polishing and elastic components. Beryllium copper rods with lead content are frequently used as sliding bearings and cutting components. Beryllium copper bars with zinc content can be used to create extremely airtight castings.

Using pressure, the beryllium substance is processed using a copper-beryllium rod. The cast beryllium copper rod’s beryllium composition. A non-ferrous metal composition with a low casting shortening rate is a beryllium copper rod. Castings with clumsy shapes, obvious generalizations, and minimal air tightness standards can be made using this technique.

The dispersion-strengthening particles in the beryllium copper rod alloy are primarily intermetallic composites made of cobalt or nickel and beryllium because more cobalt or nickel is added to the alloy. In order to achieve a complete strengthening effect of cold work hardening and age hardening, a certain amount of cold working is frequently done on the alloy after solution heat treatment and before aging heat treatment. The alloy maker should typically perform the solution heat treatment.

A directional ventilation system is required in the workplace. Processes like cutting, polishing, and others must be done while damp from the refrigerant. The required practice is to routinely sample the air in the production workshop for beryllium copper rod goods as well as the area around it.

As demonstrated by the beryllium copper rod used today, which exhibits the “elasticity” of copper alloys and has a high electrical conductivity, beryllium copper rod alloy actually refers to a composite material of two metals. Benefits include wear resistance, corrosion resistance, superb casting performance, and a wide range of applications, including tools that can withstand explosions and wear components like cams, gears, worm gears, bearings, etc.

Read More :

C17200 Can Be Used As High Air Tightness Casting: It has been used for approximately 6,000 years. C17200 has excellent mechanical and technological properties, and it can be welded and brazed without sparks during impact.

Talking about the Application of Beryllium Copper in Plastic Mould: There is a growing trend in the use of beryllium copper mold materials in the production of plastic molds today. What causes this occurrence, and why? Let me discuss with the editor how and why beryllium copper is used in plastic castings

by kalpataru | Feb 23, 2023 | Blog

Additionally, C17200 beryllium copper tape frequently interacts with other elements like lead, zinc, and phosphorous. It is a metal that was used by humans long ago. There have been about 6,000 years of use. It performs well mechanically and technologically and brazes and welds superbly without sparking when struck. The amount of beryllium in a copper sheet made from C17200 beryllium for pressure processing. The beryllium concentration of copper strip C17200. A non-ferrous metal composition with a low casting shortening rate is a C17200 beryllium copper strip. Castings with clumsy shapes, obvious generalisations, and minimal air tightness standards can be made using this technique.

The C17200 beryllium copper belt is used in steam boilers, marine ship components, seawater, fresh water, and the atmosphere. A belt made of C17200 beryllium copper and phosphorus has good mechanical properties and can be used as an elastic component and grinding component in high-precision machine tools. For grinding components and sliding bearings, C17200 beryllium copper tape is frequently employed. Castings with a high airtightness can be made from the C17200 beryllium copper sheet, which contains zinc.

The primary low-pressure feature of the high-function C17200 beryllium copper tape is around some non-ferrous metals. It has operating circumstances if used in a gravity-casting mould. According to extensive studies, it might be the reason why beryllium bronze failed. The corrosion strength of molten metal and this composition are correlated above.

It can successfully create a high-performance beryllium bronze mould material that combines high conductivity, heat resistance, wear resistance, high resistance, and corrosion resistance of the molten metal. This material can better address domestic non-ferrous metals, gravity or low-pressure casting moulds’ problems with simple cracks and simple wear, leading to a significant mould life, quick demolding, and gradual strength.

Read More :

Talking about the Application of Beryllium Copper in Plastic Mould: There is a growing trend in the use of beryllium copper mould materials in the production of plastic moulds today. What causes this occurrence, and why? Let me discuss with the editor how and why beryllium copper is used in plastic castings

Types of Beryllium Copper Alloys: Beryllium-copper alloys are split into two groups based on what they are made of and what physical properties they have. Pieces of beryllium copper can be forged or cast, and they can be sold as plates, rods, strips, and wires, among other things.

by kalpataru | Feb 23, 2023 | Blog

There is a growing trend in the use of beryllium copper mould materials in the production of plastic moulds today. What causes this occurrence, and why? Let me discuss with the editor how and why beryllium copper is used in plastic castings.

Sufficient hardness and strength – Engineers can learn and master the hardening conditions, working conditions, alloy precipitation, and mass characteristics of beryllium copper after many tests (this is the point on which the beryllium copper alloy is based); beryllium copper materials need to go through numerous cycles of tests before they are used in plastic moulds to finally determine the physical proper conditions; When copper is hrc36-42 hard, it can achieve the hardness, strength, and high heat conductivity needed for the manufacture of tungsten dies. It can also be easily and conveniently machined, have a long mould life, and shorten the development and production cycle.

Good thermal conductivity: It is advantageous to control the temperature of the plastic machining mould using beryllium copper because of the material’s high thermal conductivity; in addition, it is simpler to control the moulding cycle while ensuring that the temperature of the mould wall is consistent. The cycle is much shorter, and it is possible to lower the mould’s typical temperature by about 20%. Use the beryllium copper mould material to cool when there is little variation between the average ejection temperature and the average mould wall temperature (for instance, when the mould parts are difficult to cool). You can cut the duration by 40%. The characteristics of the beryllium copper mould materials mentioned above will provide several benefits to the mould makers using this material to shorten the moulding cycle and increase output, even though the mould wall temperature is only reduced by 15%; The grade of the drawn products is improved by the uniformity of the mould wall temperature; Because there are fewer cooling lines, it is possible to raise the temperature of the material, which reduces the product’s wall thickness and lowers the cost of the final product.

The long service life of the mould: For the manufacturer, it’s crucial to budget for the mould’s price, output continuity, and expected service life. The temperature of beryllium copper increases when it reaches the required levels of strength and toughness. Stress insensitivity can significantly lengthen the mould’s useful life. The yield strength, elastic modulus, thermal conductivity, and temperature expansion rate of beryllium copper should also be taken into account before deciding on the use of beryllium copper mould materials. Compared to die steel, beryllium copper has a much higher thermal stress resilience. The service life of beryllium copper is astounding from this perspective!

High thermal penetration rate: In addition to the pull’s thermal conductivity, the powder metallurgy mould material’s thermal penetration rate is crucial for plastic goods. The remains of overheating can be removed from the mould using beryllium bronze. The contact temperature of the distal region of the mould wall will be higher if the thermal penetration rate is low, increasing the temperature difference of the mould and, in some cases, causing the sink mark at one end of the plastic product to change to a trace of overheated product at the other end.

Excellent surface quality: Because of its excellent adhesion properties and ease of polishing, beryllium copper is a very effective material for surface finishing and can be directly electroplated.

Contact Us to Buy Beryllium Copper Sheets & Plates

Read More :

Comparing Beryllium Copper, Brass, and Bronze: Alloys are made by mixing metal with other metal or non-metallic elements to improve their properties. Copper is used to make brass, bronze, and beryllium copper.

Types of Beryllium Copper Alloys: Beryllium-copper alloys are split into two groups based on what they are made of and what physical properties they have. Pieces of beryllium copper can be forged or cast, and they can be sold as plates, rods, strips, and wires, among other things.

by kalpataru | Feb 2, 2023 | Blog

Alloys are made by mixing metal with other metal or non-metallic elements to improve their properties. Copper is used to making brass, bronze, and beryllium copper. Copper is the “solvent” or main element that makes these mixtures work together. Copper has properties like resistance to corrosion, biofouling, and heat and electricity conductivity.

Brass – Zinc and copper are mixed together to make brass. Zinc’s properties make it a metal that is both strong and easy to shape. It can be shaped better than bronze. It has been used since prehistoric times, but it wasn’t found until about 1,400 BCE. In the past, it was called “yellow copper.” Depending on how much zinc is mixed into it, its color ranges from dull yellowish to reddish. Brass is used to making musical instruments, plumbing supplies, and parts for guns. Gold-colored jewelry is sometimes made out of brass that has been dyed to look like gold.

Bronze – This alloy is made of copper and other metals like tin, manganese, and phosphorus. Tin is the main metal added to this alloy. It was found before brass, around 3,500 B.C.E., and dates back to that time. It has a higher melting point than brass and is hard and brittle. It stands out because its color is reddish gold. Bronze is used to make statues, musical instruments, electrical connectors and springs, fittings, and many other things.

Beryllium Copper – This alloy is made of beryllium, copper, and a small number of elements that help them stick together. There are 30 types of minerals that contain beryllium. It’s a steel-gray metal that is soft and not very dense. When it is mixed with copper, it gets stronger, harder, and better at conducting electricity and heat. In the next chapters, we’ll talk about more of beryllium copper’s properties and how it can be used.

Read More :

Types of Beryllium Copper Alloys: Beryllium-copper alloys are split into two groups based on what they are made of and what physical properties they have. Pieces of beryllium copper can be forged or cast, and they can be sold as plates, rods, strips, and wires, among other things.

Common Uses For Beryllium Copper: Beryllium Copper is used in a lot of different fields and industries. This is mostly because it is strong, can conduct electricity and heat, and doesn’t spark or attract magnets. Today, I’ll talk about the unique things about Beryllium Copper that make it such a popular choice.