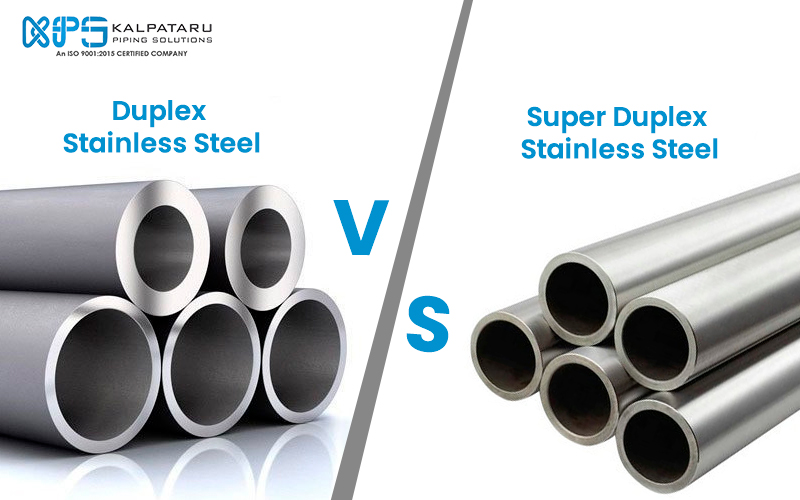

Difference Between Duplex and Super Duplex Stainless Steel

What is the Difference Between Duplex and Super Duplex Stainless Steel?

Significant difference between Super Duplex Stainless Steel and Duplex Stainless Steel. Super Duplex variants are characterized by a higher alloying addition of 25% chromium, in contrast to Duplex Stainless Steels with 22% chromium. Elevating the chromium content enhances the resistance to pitting corrosion. It’s important to note that these factors are not the sole determinants; other variables also play a role.

Duplex and Super duplex stainless steels are unique in that they feature both ferritic and austenitic phases within their metallurgic microstructure. This dual-phase structure allows them to exhibit the beneficial properties of both ferritic and austenitic stainless steels. The key components of these alloys include chromium, nickel, and molybdenum, with additional elements present in smaller quantities.

There are several key differences between duplex stainless steels and super duplex stainless steels. One of the main differences lies in their chromium content. Duplex stainless steels are typically composed of around 22% chromium, while super duplex stainless steels contain about 25% chromium. This increase in chromium content significantly enhances the pitting corrosion resistance of super duplex steels, making them more suitable for highly corrosive environments.

Price Difference Between Duplex and Super Duplex Stainless Steel

Super duplex materials, owing to their higher chromium, nickel, and molybdenum content, are more expensive compared to the standard duplex grades. Within both standard duplex and super duplex categories, various grades exist, each with its distinct material composition. As a result, the prices differ based on these compositions. Generally, a super duplex is pricier than the standard duplex grades due to its enhanced alloy content and superior properties.

What is Duplex Stainless Steel?

Duplex Stainless Steel is named for its dual-phase metallurgical structure, which includes both austenitic (face-centered cubic lattice) and ferritic (body-centered cubic lattice) phases. Unlike traditional austenitic stainless steels, duplex stainless steels have a higher chromium content (20-28%), up to 5% molybdenum, lower nickel content (around 9%), and a small amount of nitrogen (0.05-0.5%). This unique composition provides superior strength, corrosion resistance, and stress corrosion cracking resistance compared to standard austenitic stainless steels.

What is Super Duplex Stainless Steel?

The Pitting Resistance Equivalent Number (PREN) is calculated using the formula: PREN = %Cr + 3.3 x %Mo + 16 x %N, where Cr stands for chromium, Mo for molybdenum, and N for nitrogen. Increasing the chromium content boosts the PREN from 34 to over 40, which signifies enhanced resistance to pitting corrosion across various environments. Super duplex grades are the preferred choice for subsea and marine applications because of their proven durability in seawater.

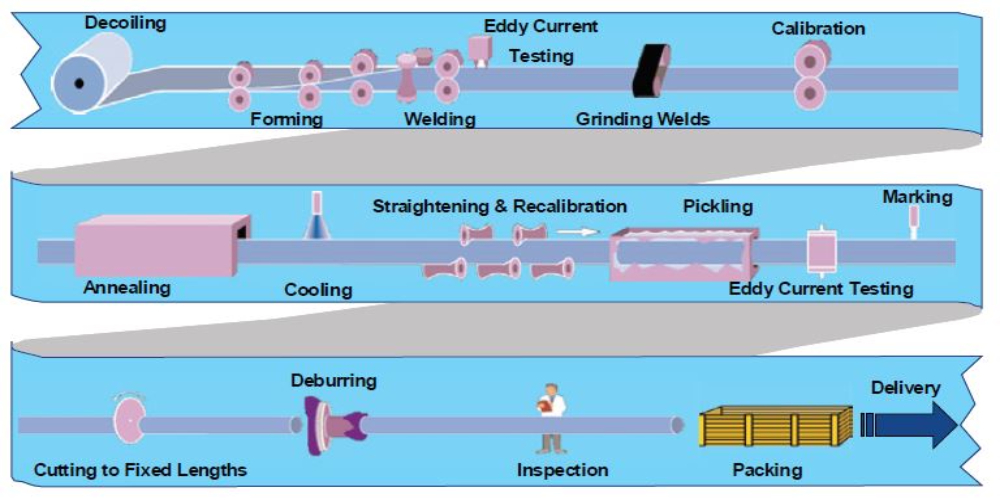

Welding Duplex And Super Duplex Stainless Steel

One of the significant challenges when welding metallic components involves dealing with chromium carbide precipitation. This phenomenon can lead to intergranular corrosion and localized corrosion over the long term. Because both duplex and super duplex stainless steel include a high chromium concentration, they are susceptible to chromium carbide precipitation.

However, the extent of carbide precipitation is also influenced by the carbon content present in these materials. To mitigate this issue, proper preheating prior to welding is essential, followed by post-weld heat treatment. Fortunately, due to their inherent resistance to corrosion, both these materials are viable for welding, provided that the appropriate procedures are meticulously followed, and the correct parameters are diligently maintained.

Unlike conventional austenitic stainless steel alloys, which are affected in their entirety during welding, duplex stainless steels mainly experience issues in the Heat-Affected Zone (HAZ). The key problems in the HAZ during welding include loss of toughness, post-weld cracking, and reduced corrosion resistance. To address these challenges, experienced welders are needed to weld duplex grades using techniques like SAW (Submerged Arc Welding), TIG (Tungsten Inert Gas welding), and MIG (Metal Inert Gas welding). Additionally, proper post-welding processing is essential to maintain the integrity and properties of the alloys.

Strength Super Duplex Stainless Steel

Duplex stainless steel ranks high in strength compared to other stainless steels. It can bear a substantial amount of weight and withstand significant physical stress.

However, super duplex stainless steel offers even greater strength. For use in high-stress, high-impact environments, super duplex is the superior choice.

Duplex And Super Duplex Corrosion Resistance

As previously said, integrating chromium, nickel, molybdenum, nitrogen, and tungsten into their alloys improves their corrosion resistance. Pitting resistance can reach amazing values of up to 45. Furthermore, these alloys may be used at high temperatures without oxidation damage. They are also extremely resistant to different alkaline, acidic, and neutral solutions.

Duplex & Super Duplex Stainless Steel Cutting Speed

Cutting through duplex and super duplex stainless steel can be a challenge, but fear not! We’ve got you covered. Achieving the perfect cutting speed is crucial for efficient machining.

Duplex grades can be cut and machined faster than super duplex due to their composition. Super duplex, with its higher chromium, nickel, and molybdenum content, demands more precision and patience.

To tackle these materials like a pro, you’ll need top-notch tools and a slower cutting pace. Luckily, there are tests like the turning, chip formation, and drilling tests to help determine the ideal cutting speeds for various grades.

With the right approach, you’ll be cutting through duplex and super duplex stainless steel like a hot knife through butter!

Super Duplex Stainless Steel 2507

Super Duplex SS 2507 is a highly durable stainless steel alloy known for its exceptional strength and corrosion resistance. It has a dual-phase microstructure consisting of both austenite and ferrite, which provides superior mechanical properties compared to regular duplex and austenitic stainless steels. With high chromium (around 25%), molybdenum (around 4%), and nickel (around 7%) content, SS 2507 is particularly resistant to pitting, crevice corrosion, and chloride stress corrosion cracking. This makes it ideal for demanding applications in harsh environments, such as offshore oil and gas platforms, chemical processing, and marine industries.

Kalpataru Piping Solutions is a manufacturer and supplier of Duplex 2207 in a variety of shapes, sizes and more.

Duplex Stainless Steel Chemical Composition

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N | Fe |

| S31803 | 0.030 max | 2.00 max | 1.00 max | 0.030 max | 0.020 max | 22.0 – 23.0 | 3.0 – 3.5 | 4.50 – 6.50 | 0.14 – 0.20 | 63.72 min |

| S32205 | 0.030 max | 2.00 max | 1.00 max | 0.030 max | 0.020 max | 21.0 – 23.0 | 2.50 – 3.50 | 4.50 – 6.50 | 0.8 – 0.20 | 63.54 min |

2205 Duplex Stainless Steel Equivalent

| S31803 / S32205 | Density | Melting Point | Yield Strength (0.2%Offset) | Tensile Strength | Elongation |

| 7.8 g/cm3 | 1350 °C (2460 °F) | Psi – 80000 , MPa – 550 | Psi – 116000 , MPa – 800 | 15 % |

Mechanical Properties of UNS S31803 Duplex 2205

| STANDARD | WERKSTOFF NR. | UNS |

| Duplex 2205 | 1.4462 | S31803 / S32205 |

Super Duplex SS 2507 Equivalent

| Grade | UNS | EN | W-Nr | DIN | AFNOR | SS |

| Duplex 2707 HD Bars | S32707 | – | – | – | – | – |

| Duplex 2507 Bars | S32750 | 1.4410 | – | X 2 CrNiMoN 25 7 4 | – | 2328 |

Super Duplex 2507 Chemical Composition

| C | Si | Mn | P | S | Cr | Ni | Mo | N | Cu |

| ≤0.030 | ≤0.8 | ≤1.2 | ≤0.035 | ≤0.015 | 25 | 7 | 4 | 0.3 | ≤0.5 |

Mechanical Properties of Super Duplex UNS S32750

| Proof strength | Tensile strength | Elong. | Hardness |

| Rp0.2a) | Rm | Ab) | Rockwell C |

| ksi | ksi | % | |

| ≥80 | 110-135 | ≥25 | ≤28 |

In conclusion, both duplex and super duplex steel offer significant advantages in various applications due to their excellent corrosion resistance, high strength, and durability. Duplex steel is ideal for environments where moderate to high corrosion resistance is required, offering a cost-effective solution with good mechanical properties. Super duplex steel, on the other hand, is suited for more demanding applications with higher levels of chloride and aggressive environments, providing enhanced performance and longer service life.

When choosing between duplex and super duplex steel, it’s crucial to consider the specific requirements of your project, including the environmental conditions, mechanical stress, and desired longevity. Both types of steel are exceptional choices, but the right selection will depend on the balance of cost, performance, and the specific demands of the application.

For more detailed information on our range of products, please visit our Duplex Steel and Super Duplex Steel product pages. These pages provide comprehensive insights into the specifications, applications, and benefits of each type of steel, helping you make an informed decision for your next project.To Know More About Our Product Click Here