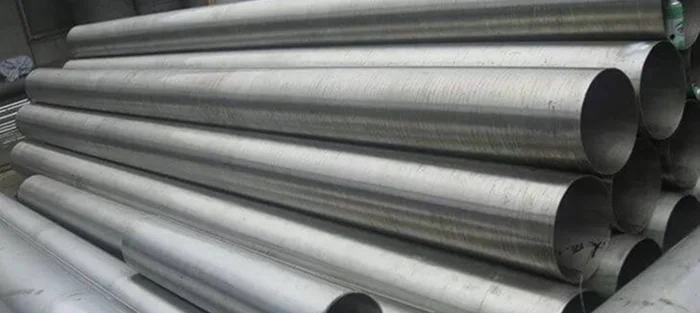

Incoloy 800 / 800H / 800HT Pipes & Tubes – Alloy 800 Seamless Pipe Manufacturer & Supplier

Table of Content

- Introduction to Incoloy 800 Series Alloys

- Key Differences: Incoloy 800 vs 800H vs 800HT

- Alloy 800 Seamless Pipe vs Welded Pipe

- ASTM B407 & ASME SB407 Specifications

- Equivalent Grades

- Chemical Composition

- Mechanical Properties

- Manufacturing Range & Dimensional Standards

- Various Types of Incoloy 800 Pipes & Tubes

- Pipe Weight Chart (Common Sizes)

- Applications & Industries Served

- Quality Assurance & Testing

- Export Destinations & Supply Chain

- Frequently Asked Questions

Introduction to Incoloy 800 Series Alloys

Incoloy 800 is a nickel-iron-chromium alloy available in three different forms and related forms (UNS N08800, Incoloy 800H, 800HT) that vary slightly in their composition. These superalloys are developed to give high strength and resist oxidation as well as carburization at high temperatures. The fundamental chemical composition is a high level of Nickel (30-35%), which gives the material resistance to chloride-ion stress-corrosion cracking, and Chromium (19-23%), which gives it resistance to oxidation.

The incoloy 800 pipes are normally applied where the temperature is up to 1100degF (593degC). Incoloy 800H and 800HT are preferred in application where the creep and rupture strength is needed above this temperature. These alloys find broad use in equipment by machines that require a high strength level and also have resistance to oxidation, carburization and other negative influences of high temperature exposures. We have all the three grades at Kalpataru piping so that we can have a chance to match the exact thermal needs of your project.

Key Differences: Incoloy 800 vs 800H vs 800HT

Although the foundation composition of Nickel, Chromium, and Iron is similar throughout the series, the decisive differences are in the carbon content and the supplementation of Titanium and Aluminum. Incoloy 800H pipe is an alloy 800 (0.05-0.10% Carbon) with a controlled amount of carbon, and a given grain size (ASTM No. 5 or finer) to maximize high temperature creep strength.

Incoloy 800HT is a step further. It has the same carbon range and grain size as 800H but must have the combined Titanium and Aluminum content of 0.85 to 1.20%. It is this specific chemistry which guarantees maximum high-temperature structural integrity. It is also worth mentioning that most current sources of 800H are in fact 800H/800HT certified since the chemistry of 800HT is within the range of 800H.

| Grade | UNS Designation | Carbon Content | Key Feature | Typical Application |

| Incoloy 800 | N08800 | 0.10% max | General corrosion resistance, good strength | Process piping, sheathing |

| Incoloy 800H | N08810 | 0.05 – 0.10% | Enhanced Creep Rupture Strength | Industrial furnaces, heat treating equipment |

| Incoloy 800HT | N08811 | 0.06 – 0.10% | Maximum High-Temp Strength (Ti+Al controlled) | Hydrogen reformers, petrochemical cracking |

Alloy 800 Seamless Pipe vs Welded Pipe

Kalpataru Piping provides seamless and welded. Alloy 800 seamless pipe is produced through extrusion or rotary piercing, and then cold worked and annealed. Smooth pipes are typically used in critical high-pressure and high-temperature applications (such as superheater tubes) since there is no weld seam, which is considered to be a weakness in high-stress applications.

Welded pipes (ERW/EFW) are on the other hand manufactured using strip or plate. Recent manufacturing processes have rendered welded Incoloy 800H pipes highly dependable with a high degree of cost-effectiveness in large-diameter piping in low-pressure ducting or structural. We also have rigorous non-destructive testing of all welded pipes to make sure that the seams are intact.

ASTM B407 & ASME SB407 Specifications

Our manufacturing process strictly follows international standards. The primary specification for seamless pipe and tube is ASTM B407 (ASME SB407). Welded pipes typically follow ASTM B514 or B515.

Detailed Specifications for Incoloy 800 / 800H / 800HT Pipes & Tubes

| Specification | Details |

| Specification | ASTM B407, ASTM B514, ASTM B515 / ASME SB407, ASME SB514, ASME SB515 |

| Pipes & Tubes Size | 1/8″ NB to 24″ NB |

| EFW Pipe Size | 6″ NB to 48″ NB |

| Outside Diameter | 6.00 mm OD up to 914.4 mm OD | Sizes up to 24″ NB available Ex-stock |

| Manufacturing Techniques | Seamless / Welded / ERW / EFW / Fabricated / CDW / 100% X-Ray Welded |

| Schedule Thickness Range | SCH 5, SCH 10, SCH 10S, SCH 40, SCH 40S, SCH 80, SCH 80S, SCH 160, SCH XS, SCH XXS |

| End Types | Plain End, Beveled End, Threaded One End, TBE (Threaded Both Ends) |

| Delivery Condition | Annealed and Pickled, Polished, Bright Annealed, Cold Drawn |

| Value Added Services | Cutting, Beveling, Polishing, Threading, Destructive & Non-Destructive Testing, Ultrasonic Testing |

| Inspection & Test Reports | EN 10204 3.1, Mill Test Certificates, Chemical Reports, PMI Test Reports, Mechanical Reports, Third Party Inspection (TPI), NABL Approved Lab, Visual Inspection, Destructive & Non-Destructive Test Reports |

| Marking | Specification, Grade, Nominal Pipe Size, Pipe Schedule/Wall Thickness, Manufacturing Method (Seamless/Welded), Heat Number, Manufacturer’s Name or Custom Logo on request |

| Packing | Packed in Wooden Boxes, Plastic Bags, Steel Strips Bundled, or as per Customer’s Request |

| Specials | Sizes and Specifications other than above can be supplied on request |

a) Equivalent Grades (International Standards)

| Standard | Incoloy 800 | Incoloy 800H | Incoloy 800HT |

| UNS | N08800 | N08810 | N08811 |

| Werkstoff Nr. | 1.4876 | 1.4958 / 1.4876 | 1.4959 / 1.4876 |

| EN | X10NiCrAlTi32-20 | X5NiCrAlTi31-20 | X8NiCrAlTi32-21 |

| JIS | NCF 800 | NCF 800H | NCF 800HT |

| BS | NA 15 | NA 15(H) | NA 15(HT) |

| GOST | ЭП670 (XH32T) | ЭП670 (XH32T) | ЭП670 (XH32T) |

| AFNOR | Z8NC32-21 | Z8NC33-21 | – |

b) Chemical Composition (% Weight)

| Element | Incoloy 800 | Incoloy 800H | Incoloy 800HT |

| Nickel (Ni) | 30.0 – 35.0 | 30.0 – 35.0 | 30.0 – 35.0 |

| Chromium (Cr) | 19.0 – 23.0 | 19.0 – 23.0 | 19.0 – 23.0 |

| Iron (Fe) | 39.5 min | 39.5 min | 39.5 min |

| Carbon (C) | 0.10 max | 0.05 – 0.10 | 0.06 – 0.10 |

| Manganese (Mn) | 1.50 max | 1.50 max | 1.50 max |

| Silicon (Si) | 1.00 max | 1.00 max | 1.00 max |

| Sulfur (S) | 0.015 max | 0.015 max | 0.015 max |

| Copper (Cu) | 0.75 max | 0.75 max | 0.75 max |

| Aluminum (Al) | 0.15 – 0.60 | 0.15 – 0.60 | 0.15 – 0.60 |

| Titanium (Ti) | 0.15 – 0.60 | 0.15 – 0.60 | 0.15 – 0.60 |

| Al + Ti | – | – | 0.85 – 1.20 |

c) Mechanical Properties

| Property | Value (Room Temperature) |

| Density | 7.94 g/cm³ |

| Melting Point | 1357-1385 °C |

| Tensile Strength (min) | 75 ksi (520 MPa) |

| Yield Strength (0.2% Offset) | 30 ksi (205 MPa) |

| Elongation (min) | 30% |

Manufacturing Range & Dimensional Standards

Kalpataru Piping maintains a vast inventory to meet urgent project requirements. We can supply cut-to-length pipes or full random lengths based on your needs.

Incoloy 800 Seamless Pipes

- Size Range: 1/8″ NB to 24″ NB

- Standards: ASTM B407, ASME SB407

- Wall Thickness: SCH 10S, SCH 40S, SCH 80S, SCH 160, SCH XXS

Incoloy 800H Welded / ERW Tubes

- Size Range: 6″ NB to 100″ NB (EFW/Fabricated)

- Standards: ASTM B514, ASTM B515

- Finish: Annealed & Pickled, Bright Annealed, Polished

Need Exact Dimensions?

Various Types of Incoloy 800 / 800H / 800HT Pipes & Tubes

Kalpataru Piping offers a diverse range of pipe and tube configurations to meet specific application requirements. Each type is manufactured to exact tolerances using advanced production techniques.

Inconel 800H Seamless Tube

Inconel Alloy 800HT Welded Tube

Alloy 800 Round Tubes

Inconel 800HT Decorative Tube

Inconel 800HT Heat Exchager Tube

Inconel 800 Instrumentation Tube

| Product Description | Wall Thickness (mm) | Outside Diameter (mm) |

| Incoloy 800 Seamless Round Pipe/Tube | 0.5 to 30 | 6 to 630 |

| Incoloy 800H Seamless Square Pipe/Tube | 0.5 to 30 | 12.7 × 12.7 to 300 × 300 |

| Incoloy 800 Seamless Rectangular Pipe/Tube | 0.5 to 30 | 10×20 to 100×200 |

| Incoloy 800HT Welded/ERW Pipe | 1.0 to 25 | 6 to 1000 |

| Incoloy 800 Seamless Ornamental Tubes | 0.5 to 2.0 | 12.7 to 76.2 |

| Incoloy 800H Seamless Electropolished Pipes/Tubes | 0.5 to 30 | 12.7 to 250 |

| Incoloy 800 Heat Exchanger Tubes | 0.7 to 3.0 | 6 to 50.8 |

| Incoloy 800HT Instrumentation Tubing | 0.5 to 2.5 | 3 to 25 |

Incoloy 800 / 800H / 800HT Pipe Weight Chart (Common Sizes)

The following chart provides theoretical weights for commonly ordered sizes. For precise calculations, please use our Pipe Weight Calculator.

| NPS (Inches) | DN (mm) | Outside Diameter (mm) | Schedule | Wall Thickness (mm) | Weight (Kg/Meter) |

| 1/2″ | 15 | 21.3 | SCH 40 | 2.77 | 1.27 |

| 3/4″ | 20 | 26.7 | SCH 40 | 2.87 | 1.69 |

| 1″ | 25 | 33.4 | SCH 40 | 3.38 | 2.50 |

| 1 1/2″ | 40 | 48.3 | SCH 40 | 3.68 | 4.05 |

| 2″ | 50 | 60.3 | SCH 40 | 3.91 | 5.44 |

| 2 1/2″ | 65 | 73.0 | SCH 40 | 5.16 | 8.63 |

| 3″ | 80 | 88.9 | SCH 40 | 5.49 | 11.29 |

| 4″ | 100 | 114.3 | SCH 40 | 6.02 | 16.07 |

| 6″ | 150 | 168.3 | SCH 40 | 7.11 | 28.26 |

| 8″ | 200 | 219.1 | SCH 40 | 8.18 | 42.56 |

| 10″ | 250 | 273.0 | SCH 40 | 9.27 | 60.31 |

| 12″ | 300 | 323.8 | SCH 40 | 9.53 | 73.86 |

| 14″ | 350 | 355.6 | SCH 40 | 9.53 | 81.33 |

| 16″ | 400 | 406.4 | SCH 40 | 9.53 | 93.27 |

| 18″ | 450 | 457.0 | SCH 40 | 9.53 | 105.16 |

| 20″ | 500 | 508.0 | SCH 40 | 9.53 | 117.48 |

| 24″ | 600 | 610.0 | SCH 40 | 9.53 | 141.30 |

Note: Weights are theoretical and based on nominal dimensions. Actual weights may vary by ±10% due to manufacturing tolerances. For heavy wall schedules (SCH 80, 160, XXS), please request detailed weight charts.

Applications & Industries Served

Incoloy 800HT pipes are essential in various heavy industries because of their capacity to withstand the high temperatures without breaking due to prolonged exposure to heat.

Chemical & Petrochemical Processing.

Incoloy 800 tube is applied in ethylene furnace convection tubing, and quench boilers. Carburation resistance of the alloy is such that it finds application in hydrocarbon cracking furnaces where corrosion of materials is a constant menace.

Power Generation (Nuclear & Thermal)

Applied in large amounts in superheater and reheater tubing. These alloys are employed in the steam generator tubing in nuclear power plants because they have a high resistance to chloride-ion stress-corrosion cracking and high purity water corrosion.

Heat Exchanger Applications

Incoloy 800 tubes are the popular choice in heat exchanger in challenging applications. The high thermal stability and corrosion resistance of the alloy make it suitable in shell-and-tube heat exchangers, condensers, and evaporators that are used at high temperatures. In our detailed guide, learn more about the selection of the material that suits your needs in terms of a heat exchanger

Read our blog on heat exchanger applications

Heat Treatment Furnaces

Radiant tubes, muffles, retorts, and assorted furnace fixtures rely on alloy 800 pipe to maintain structural integrity during repeated thermal cycling.

For more specific components, view our Matching Incoloy 800 Flanges and Buttweld Fittings.

Quality Assurance & Testing

At Kalpataru Piping, quality is non-negotiable. Every Incoloy 800 pipe we supply undergoes a battery of tests to ensure compliance with ASTM B407. Our testing regime includes:

- Chemical Analysis: PMI (Positive Material Identification) to verify Nickel/Chromium content.

- Mechanical Testing: Tensile, Yield, and Elongation tests.

- NDT: Ultrasonic Testing (UT) and Hydrostatic Testing to ensure leak-proof performance.

- Grain Size Analysis: Specific checks for 800H/800HT to verify grain size (ASTM No. 5 or coarser).

We provide EN 10204 3.1 Mill Test Certificates (MTC) with every shipment. Third-party inspection (TPI) is also available upon request.

Export Destinations & Supply Chain

We are a leading exporter of Incoloy 800/800H/800HT Pipes & Tubes to over 40 countries. Our robust supply chain ensures timely delivery to major industrial hubs including:

Middle East: Saudi Arabia (Riyadh, Jubail), UAE (Dubai, Abu Dhabi), Qatar (Doha), Kuwait.

Asia: Singapore, Malaysia, Thailand, Indonesia.

Europe & Americas: Germany, UK, USA, Canada, Brazil.

We offer specialized packaging (wooden crates, plastic end caps) to prevent transit damage.

Frequently Asked Questions

What is the price of Incoloy 800H pipe per kg?

Incoloy 800H price fluctuates depending on the market price of nickel, OD/Wall thickness and quantity. It is usually between 25 and 45 USD per kg. Our sales team would be happy to request a quote with the most up to date pricing.

What is the difference between Inconel and Incoloy 800?

Inconel is a superalloy made of Nickel-Chromium (Nickel > 50%), whereas Incoloy is made of Nickel-Iron-Chromium (Nickel < 50%). Incoloy 800 has approximately 30-35% Nickel and is therefore more economical than high-nickel Inconel grades yet it has superior high-temperature characteristics.

Is Incoloy 800 magnetic?

No, Incoloy 800 (and 800H/HT) is not magnetic in an annealed state. It can however acquire a small amount of magnetic permeability following prolonged cold working.

What is the temperature rating for 800HT pipe?

Incoloy 800HT is also used in services that run at a temperature exceeding 1100degF (593degC) and primary.

Ready to Order?

Get high-grade Incoloy 800/800H/800HT Pipes directly from the manufacturer. We offer Ex-Stock delivery for urgent shutdowns.

Contact Us for Ex-Stock Delivery

Also check: Incoloy 800 Fasteners | Plates & Sheetsb>

Related Products

- Incoloy 800/800H/800T Perforated Sheets

- Incoloy 800/800H/800T Forged Fittings

- Incoloy 800/800H/800T Olets

- Incoloy 800/800H/800T Fasteners

- Incoloy 800/800H/800T Compression Tube Fittings

- Incoloy 825 Perforated Sheets

- Incoloy 825 Forged Fittings

- Incoloy 825 Fasteners

- Incoloy 825 Compression Tube Fittings

- Incoloy 800/800H/800T Instrumentation Valves

- Incoloy 800/800H/800T Filler Wire

- Incoloy 800/800H/800T Long Radius Bends

- Incoloy 800/800H/800T Pipes Spools

- Incoloy 800/800H/800T Wiremesh

- Incoloy 825 Instrumentation Valves

- Incoloy 825 Filler Wire

- Incoloy 825 Long Radius Bends

- Incoloy 825 Pipes Spools

- Incoloy 825 Wiremesh

Cities We deliver

Bhopal, Lahore, Milan, Hyderabad, Pune, Vadodara, Pimpri-Chinchwad, Aberdeen, Howrah, Jeddah, Riyadh, Bogota, Petaling Jaya, Dallas, Lagos, Nagpur, Houston, Brisbane, Busan, Karachi, Coimbatore, Seoul, Caracas, Atyrau, Perth, Haryana, Bengaluru, Jaipur, Al Jubail, Kuwait City, Al Khobar, Sydney, Ranchi, Chiyoda, Noida, Chandigarh, Secunderabad, Ahvaz, Port-of-Spain, Singapore, Gurgaon, Rajkot, Rio de Janeiro, Abu Dhabi, Hong Kong, Surat, Sharjah, Hanoi, London, Muscat, Jakarta, Navi Mumbai, Istanbul, Kolkata, Cairo, Mumbai, Santiago, Montreal, Faridabad, Vung Tau, Bangkok, Ankara, Ahmedabad, Granada, Melbourne, Tehran, Visakhapatnam, New Delhi, Los Angeles, Ho Chi Minh City, Edmonton, La Victoria, Baroda, Thane, Nashik, Kuala Lumpur, Moscow, Ernakulam, Courbevoie, Calgary, Geoje-si, Indore, New York, Mexico City, Gimhae-si, Ludhiana, Kanpur, Ulsan, Thiruvananthapuram, Manama, Doha, Chennai, Madrid, Jamshedpur, Algiers, Dammam

Countries We Deliver

Iran, Venezuela, Saudi Arabia, Slovakia, Romania, Zimbabwe, Spain, Kazakhstan, Canada, Nigeria, Bulgaria, Afghanistan, Thailand, Bangladesh, Poland, United Kingdom, Bahrain, Jordan, Lithuania, Malaysia, France, Nigeria, Japan, Oman, Lebanon, Germany, Croatia, Australia, Puerto Rico, South Korea, Hungary, United States, Bhutan, Mexico, Mexico, Yemen, Singapore, New Zealand, Ecuador, Gabon, Qatar, Denmark, Iran, Netherlands, Norway, Sri Lanka, Belgium, Libya, Kuwait, Pakistan, Gambia, Sweden, Azerbaijan, Argentina, Chile, Ghana, United Arab Emirates, Finland, Nepal, Trinidad andamp; Tobago,Tunisia, Kenya, Peru, Austria, Russia, Ukraine, Italy, Belarus, Bolivia, Serbia, Poland, Mongolia, Turkey, Czech Republic, South Africa, Angola, India, Vietnam, Indonesia, Tibet, Ireland, Costa Rica, Greece, Colombia, Namibia, Iraq, Estonia, Israel, Macau, Philippines, Brazil, Switzerland, Algeria, Morocco, Chile, Portugal, Egypt, Taiwan, China, Hong Kong.