Incoloy 825 Round bar Supplier & Exporter

ASTM B425 UNS N08825 Flat Bar, Alloy 825 Hot Rolled Bar, DIN 2.4858 Square Bar, ASTM B425 Incoloy 825 Bright Bar & Inconel Alloy 825 Hex Bar supplier in India.

Table of Content

- Inconel 825 Round Bars

- Get Alloy DIN 2.4858 Rods, 825 Alloy Cold-Rolled / Hot-Rolled Bars

- Properties of Inconel 825 Round Bars

- Quality Assurance & On Time Delivery of Alloy 825 Round Bars

- Types of ASTM B425 UNS N08825 Incoloy 825 Rod

- Incoloy 825 Rod (ASTM B425 UNS N08825) Specification

- ASTM B425 UNS N08825 Incoloy 825 Rod Composition

- Inconel Alloy 825 Square Bar Chemical Composition

- Mechanical Properties Of Incoloy 825 Round Bar

- Incoloy 825 Round Bar Physical Properties

- ASTM B425 Incoloy 825 Bars Equivalent Grades

Kalpataru Piping being a reliable Incoloy round bars supplier that offers quality-tested products containing alloy Incoloy 825 round bars that can be used in the same application as Incoloy 020 Alloy. Those clients that seek Inconel Alloy 825 bright bars at good prices can count on us to offer them of high quality. Our products are fully customizable, depending on the needs of the clients, and we deliver ASTM B425 UNS N08825 Bars fast and reliably. Incoloy 825 Round Bars are dimensionally correct, and produced using high-grade raw materials. We provide high performance and long-term stability of products due to a constant chemical composition.

Inconel 825 Round Bars

The Incoloy 825 alloy consists mainly of nickel, chromium and iron with the added titanium, copper and molybdenum. This chemical composition grants a high degree of resistance to a number of chemically corrosive conditions. Incoloy 825 Round Bar is widely known as having high creeping corrosion, pitting, stress corrosion cracking and intergranular corrosion resistance. Its performance is also improved by the presence of chromium against the oxidizing salts, nitrates, and nitric acids. The Nickel Alloy 825 Rod with a titanium stabilization is properly heated to give it a high ability against intergranular corrosion sensitization. Nevertheless, due to the rapid work-hardening properties, Alloy 825 Round Bar is a challenging Inconel material for machining and forming with conventional tools because of its properties. When the hardened surface undergoes the initial machining pass, it will be able to either deform the workpiece or the cutting tool in the course of further operations. To circumvent this, most machining of UNS N08825 Round Bars is completed in solution annealed state, and subsequent finishing is done after the age hardening. Single-point lathing or thread rolling on solution-treated material can be used to obtain external threading. These WNR 2.4858 Round Bars can be purchased with different diameters, thicknesses, sizes with different prices and meet the needs of different industries.

Get Alloy DIN 2.4858 Rods, 825 Alloy Cold-Rolled / Hot-Rolled Bars & ASME SB 425 UNS N08825 Rods

Incoloy 825 Hot Rolled Bars

Incoloy 825 Cold Rolled Bars

Alloy DIN 2.4858 Rods

Properties of Inconel 825 Round Bars

Incoloy 825 Cold Forming:

Incoloy Alloy 825 has cold-forming similarities with Inconel Alloy 600. Even though its work-hardening rate is somewhat lower than that of the standard austenitic stainless steels, it is still quite high. As such, to enhance the plastic deformation, machinery piping up should be strong and endowed with high power to support the high yield strength.

Incoloy 825 Hot Forming:

Incoloy Alloy 825 should be used in hot-working between 1600 °F to 2150 °F (870 °C to 1180 °C). Final hot-working should take place between 1600 °F and 1800 °F (870 °C to 980 °C) to achieve maximum corrosion resistance. The material must cool in air or a quicker rate after the process of hot forming.

Quality Assurance & On Time Delivery of Alloy 825 Round Bars

We have a team of experts who conduct quality testing throughout the production process, including the choice of the material to use to the final dispatch. Through destructive and non-destructive testing, we are able to test all round bars to minimal quality standards. We are not only concerned about quality at Kalapataru Piping but also delivery. Our products have been packaged well, and they have prompt delivery. Incoloy 825 Round Bars We offer customized and standard Incoloy 825 Round Bars at competitive prices that match your particular industrial needs.

Contact us today to request a quote or learn more about our ASTM B425 UNS N08825 Incoloy 825 Round Bars.

Types of ASTM B425 UNS N08825 Incoloy 825 Rod

Exporter of Inconel Alloy 825 Round Bar With Multiple Forms Like Hex, Square, Rectangle, Flat, etc.

Inconel Alloy 825 Hexagonal Bar

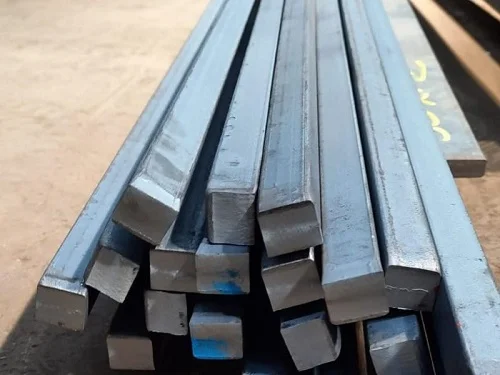

ASTM B425 N08825 Square Bar

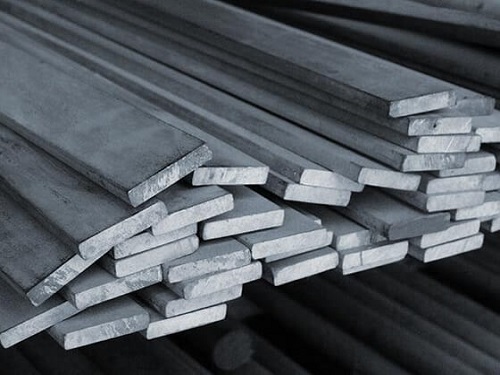

Alloy 825 Flat Bar

ASTM B425 UNS N08825 Threaded Bar

ASTM B425 UNS N08825 Wire Rod

ASTM B425 UNS N08825 Cold Drawn Rod

ASTM B425 UNS N08825 Forged Rod

Inconel 825 Rectangle Bar

Inconel Alloy 825 Rod

ASTM B425 N08825 Hexagonal Bars, Buy Nickel Alloy 825 Flat Bar, Alloy 825 Bar, Alloy 2.4858 Bright Bar Stockist, Alloy 825 Rod.

Incoloy 825 Rod (ASTM B425 UNS N08825) Specification

Refer to the available sizes, forms, lengths, finishes, and tolerances of Incoloy 825 Alloy Cold Rolled/Hot Rolled Bars and ASTM B425 UNS N08825 Round Bars.

| Specification | ASTM B425 UNS N08825, SB 425 |

| Standard | ASTM, ASME, API, GB, AISI, DIN, EN, SUS, UNS |

| Alloy 825 Round bar size | Diameter: 3~800mm |

| ASTM B425 N08825 Angle bar size | 3*20*20mm~12*100*100mm |

| Nickel Alloy 825 Square bar size | 4*4mm~100*100mm |

| B425 N08825 Billet Size | 1/2″ to 495mm Diameter |

| 2.4858 Incoloy 825 Rectangles Size | 33 x 30mm to 295 x 1066mm |

| Finish | Bright, Polish, Bright, Rough Turned, Grinding, Centreless Ground & Black |

| Tolerance | H8, H9, H10, H11, H12, H13, K9, K10, K11, K12 or as per clients’ requirements |

| Surface | Hot Rolled Pickled or Sand Blasting Finished, Cold Drawn, Bright, Polished, Hairline |

| Condition | Cold Drawnd Pulished Cold Drawn Centreless Ground & Polished, Annealed |

| Technique | ASTM B425 Gr 825 Hot Rolled, Cold Rolled, Cold Drawn, Forged |

| Form | Round, Rod, Ingot, Billet, Rings, Hex, T-Bars, Precision-Ground, Rectangle, Forging, Half-Round, Blocks, Angle, I/H, Hollow, Flat, Round-Rod, Square, Triangle, Profiles, Channel, Threaded |

| Our Incoloy 825 Round Bar conforms to NACE MR0175/ISO 15156 | |

ASTM B425 UNS N08825 Incoloy 825 Rod Composition and Properties

A detailed overview of the chemical makeup, mechanical strength, and physical attributes of Alloy 825 Rods for enhanced performance in corrosive environments.

Inconel Alloy 825 Square Bar Chemical Composition

| Grade | C | Mn | Si | S | Ni | Cr | Al | Ti | Cu | Fe |

| 825 | 0.05 max | 1.00 max | 0.5 max | 0.03 max | 38.00 – 46.00 | 19.50 – 23.50 | 0.02 max | 0.06 – 1.20 | 1.50 – 3.00 | 22.00 min |

Mechanical Properties Of Incoloy 825 Round Bar

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.4 g/cm3 | 1350 °C (2460 °F) | Psi – 1,35,000 , MPa – 930 | Psi – 75,000 , MPa – 517 | 42.5 % |

Incoloy 825 Round Bar Physical Properties

| DENSITY (G/CM 3) | 8.14 |

| DENSITY (LB/IN 3) | 0.294 |

| MELTING POINT (°C) | 1370 – 1400 |

| MELTING POINT (°F) | 2500 – 2550 |

ASTM B425 Incoloy 825 Bars Equivalent Grades

Find the international equivalent grades of ASTM B425 Incoloy 825 Bars, including UNS, DIN, JIS, and other global standards, for easy material comparison and selection.

| STANDARD | WERKSTOFF NR. | UNS | GOST | AFNOR | JIS | BS | EN | OR |

| Incoloy 825 | 2.4858 | N08825 | ЭП703 | NFE30C20DUM | NCF 825 | NA 16 | NiCr21Mo | XH38BT |

Tolerance Chart Of Alloy Incoloy 825 Round Bar

Check the standard manufacturing tolerances for Incoloy 825 Round Bars to ensure dimensional accuracy and compliance with ASTM B425 specifications.

| Diameter (inches) | Diameter (mm) | Tolerance (inches) | Tolerance (mm) |

| 1″ 2″ | 25.4 – 50.8 | +/- 0.003″ | +/-0.08mm |

| 1/4″ 1 | 6.35 – 25.4 | +/-0.002° | +/- 0.05mm |

| 2″ 3″ | 50.8 – 76.2 | +/- 0.004 | +/- 0.10mm |

Inconel 825 Bar Size Chart

View the complete size chart of Alloy 825 Bars, covering diameter, length, and cross-sectional options suitable for a wide range of industrial applications.

| Shape | Description | Diameter | Specification |

| ROD/BAR ROUND | 1.500 DIA | 1.5000 | ASTM B425 ASME SB425 |

| 2.000 DIA | 2.0000 | ASTM B425 ASME SB425 | |

| 1.250 DIA | 1.2500 | ASTM B425 ASME SB425 | |

| 1.000 DIA | 1.0000 | ASTM B425 ASME SB425 | |

| 2.500 DIA | 2.5000 | ASTM B425 ASME SB425 | |

| 3.000 DIA | 3.0000 | ASTM B425 ASME SB425 | |

| 4.000 DIA | 4.0000 | ASTM B425 ASME SB425 | |

| .500 DIA | 0.5000 | ASTM B425 ASME SB425 | |

| 3.500 DIA | 3.5000 | ASTM B425 ASME SB425 | |

| .625 DIA | 0.6250 | ASTM B425 ASME SB425 |

Weight Chart for Incoloy (UNS N08825) Round Bars

Refer to the Incoloy 825 Round Bar weight chart to calculate approximate weights per meter or foot for different sizes and dimensions.

| Size | kg/m | kg/ft | Size | kg/m | kg/ft | Size | kg/m | kg/ft |

| 22mm | 2.979 | 0.908 | 1/8″ | 0.062 | 0.019 | 3-1/4″ | 41.996 | 12.800 |

| 24mm | 3.543 | 1.080 | 4mm | 0.098 | 0.030 | 3-3/4″ | 55.780 | 17.001 |

| 7/8″ | 3.038 | 0.926 | 5/32″ | 0.095 | 0.029 | 3-1/2″ | 48.772 | 14.850 |

| 25mm | 3.871 | 1.180 | 3/16″ | 0.141 | 0.043 | 4″ | 63.340 | 19.306 |

| 26mm | 4.170 | 1.271 | 7/32″ | 0.190 | 0.058 | 4-1/2″ | 80.340 | 24.4487 |

| 1″ | 3.970 | 1.210 | 5mm | 0.154 | 0.047 | 4-1/4″ | 72.249 | 21.908 |

| 27mm | 4.490 | 1.368 | 6mm | 0.223 | 0.068 | 4-3/4″ | 90.249 | 27.366 |

| 30mm | 5.548 | 1.691 | 7mm | 0.298 | 0.091 | 5-1/2″ | 121.000 | 36.690 |

| 1-1/8″ | 5.033 | 1.534 | 1/4″ | 0.249 | 0.076 | 5″ | 99.940 | 30.461 |

| 1-1/4″ | 6.349 | 1.924 | 5/16″ | 0.387 | 0.118 | 6″ | 143.900 | 43.860 |

| 1-3/8″ | 7.550 | 2.303 | 9mm | 0.498 | 0.152 | 7″ | 196.000 | 59.432 |

| 32mm | 6.314 | 1.894 | 8mm | 0.398 | 0.120 | 6-1/2″ | 167.630 | 51.093 |

| 35mm | 7.553 | 2.390 | 3/8″ | 0.557 | 0.170 | 7-1/2″ | 225.000 | 68.226 |

| 20mm | 2.470 | 0.753 | 3mm | 0.055 | 0.017 | 3″ | 35.762 | 10.900 |

| 38mm | 8.903 | 2.792 | 11mm | 0.748 | 0.228 | 10″ | 397.140 | 121.048 |

| 36mm | 7.999 | 2.438 | 10mm | 0.620 | 0.189 | 8″ | 254.55 | 77.586 |

| 1-1/2″ | 8.951 | 2.715 | 7/16″ | 0.761 | 0.232 | – | – | – |

| 1-5/8″ | 10.449 | 3.200 | 1/2″ | 0.994 | 0.303 | – | – | – |

| 40mm | 9.872 | 3.009 | 12mm | 0.889 | 0.271 | – | – | – |

| 1-3/4″ | 12.179 | 3.712 | 13mm | 1.043 | 0.318 | – | – | – |

| 1-7/8″ | 13.977 | 4.260 | 9/16″ | 1.256 | 0.383 | – | – | – |

| 45mm | 12.555 | 3.807 | 14mm | 1.207 | 0.368 | – | – | – |

| 48mm | 14.205 | 4.330 | 15mm | 1.391 | 0.424 | – | – | – |

| 2″ | 15.906 | 4.848 | 16mm | 1.578 | 0.481 | – | – | – |

| 50mm | 15.414 | 4.698 | 5/8″ | 1.551 | 0.473 | – | – | – |

| 2-1/8″ | 17.963 | 5.475 | 17mm | 1.791 | 0.543 | – | – | – |

| 60mm | 22.205 | 6.768 | 18mm | 2.001 | 0.610 | – | – | – |

| 2-1/4″ | 20.128 | 6.135 | 11/16″ | 1.880 | 0.573 | – | – | – |

| 2-3/8″ | 22.435 | 6.838 | 3/4″ | 2.237 | 0.682 | – | – | – |

| 2-5/8″ | 27.409 | 8.354 | – | – | – | – | – | – |

| 2-1/2″ | 24.856 | 7.576 | – | – | – | – | – | – |

| 2-3/4″ | 30.083 | 9.169 | – | – | – | – | – | – |

Huge Stock Of ASTM B425 Incoloy 825 Round Bar

| Incoloy UNS N08825 Hollow Bar | Inconel 825 Threaded Bar |

| 825 Incoloy Alloy Round Bar | ASME SB425 Incoloy 825 Alloy Bars |

| ASTM B425 Incoloy 825 Solid Rod | ASTM B425 Incoloy 825 Forged Rods |

| Inconel 825 Round Bar Supplier | 825 Alloy Polish Bar |

| Incoloy 825 Threaded Rod | ASTM B425 Incoloy 825 Rod and Bar |

| Incoloy 825 Cold Drawn Round bar | Incoloy 825 Black Bar |

| SB 425 Incoloy 825 Triangle Bar | Incoloy 825 Bars |

| Incoloy 825 Bar Stock | Inconel Alloy 825 Round Rods |

| Polished Incoloy 825 Rod | Alloy 825 Hexagon Bars |

| ASTM B425 UNS N08825 Incoloy Bar | Inconel 825 Solid Bar |

| Incoloy 825 Bar Suppliers | Incoloy 825 ASTM B425 Rods |

| Inconel 2.4858 Rectangle Bar | UNS N08825 ASTM B425 Rod |

| 825 Incoloy Industrial Bars & Rods | ASTM B425 UNS N08825 Bar |

| Incoloy 825 Rods in India | ASME SB425 825 Incoloy Half Round Bars |

Frequently Questions About Inconel 825 Round Bars & Rod

What is an alloy 825 round bar?

Alloy 825 round bar is a nickel-based superalloy known for its excellent corrosion resistance and mechanical strength. It is widely used in industries such as aerospace, chemical processing, nuclear power, gas turbines, and manufacturing of valves, fasteners & springs.

What types of testing and heat treatment are applied to alloy 825 flat bars?

Incoloy alloy 825 flat bars undergo rigorous testing including tensile, hardness, impact, and corrosion resistance tests. Heat treatment options such as annealing and solution treatment are used to enhance mechanical properties and corrosion resistance depending on application requirements.

How does Incoloy 825 differ from Incoloy 800 bars?

Incoloy 825 offers superior resistance to acid corrosion, stress corrosion cracking, and pitting compared to Incoloy 800. While both have excellent high-temperature strength, Alloy 825 is better suited for highly corrosive and reducing environments.

What is the operating temperature range for alloy 825 round bars?

Alloy 825 round bars typically perform well within a temperature range of -253°C (-423°F) up to approximately 927°C (1700°F), maintaining strength and corrosion resistance over this wide range.

What is the typical hardness of Inconel alloy 825 flat bars?

Inconel alloy 825 flat bars generally have a Brinell hardness range of 140 to 200 HB, depending on the heat treatment and manufacturing process.

Are Inconel 825 round bars magnetic?

Inconel 825 round bars are generally non-magnetic in their annealed condition due to their austenitic crystal structure. However, cold working or welding can introduce slight magnetic properties.

Related Products

- Inconel 600 Pipes & Tubes

- Inconel 600 Flanges

- Inconel 600 Round Bars & Wires

- Inconel 600 Plates & Sheets

- Inconel 600 Buttweld Fittings

- Inconel 625 Pipes & Tubes

- Inconel 625 Flanges

- Inconel 625 Round Bars & Wires

- Inconel 625 Plates & Sheets

- Inconel 625 Buttweld Fittings

- Inconel 600 Shims

- Inconel 625 Shims

Cities We deliver

Bhopal, Lahore, Milan, Hyderabad, Pune, Vadodara, Pimpri-Chinchwad, Aberdeen, Howrah, Jeddah, Riyadh, Bogota, Petaling Jaya, Dallas, Lagos, Nagpur, Houston, Brisbane, Busan, Karachi, Coimbatore, Seoul, Caracas, Atyrau, Perth, Haryana, Bengaluru, Jaipur, Al Jubail, Kuwait City, Al Khobar, Sydney, Ranchi, Chiyoda, Noida, Chandigarh, Secunderabad, Ahvaz, Port-of-Spain, Singapore, Gurgaon, Rajkot, Rio de Janeiro, Abu Dhabi, Hong Kong, Surat, Sharjah, Hanoi, London, Muscat, Jakarta, Navi Mumbai, Istanbul, Kolkata, Cairo, Mumbai, Santiago, Montreal, Faridabad, Vung Tau, Bangkok, Ankara, Ahmedabad, Granada, Melbourne, Tehran, Visakhapatnam, New Delhi, Los Angeles, Ho Chi Minh City, Edmonton, La Victoria, Baroda, Thane, Nashik, Kuala Lumpur, Moscow, Ernakulam, Courbevoie, Calgary, Geoje-si, Indore, New York, Mexico City, Gimhae-si, Ludhiana, Kanpur, Ulsan, Thiruvananthapuram, Manama, Doha, Chennai, Madrid, Jamshedpur, Algiers, Dammam

Countries We Deliver

Iran, Venezuela, Saudi Arabia, Slovakia, Romania, Zimbabwe, Spain, Kazakhstan, Canada, Nigeria, Bulgaria, Afghanistan, Thailand, Bangladesh, Poland, United Kingdom, Bahrain, Jordan, Lithuania, Malaysia, France, Nigeria, Japan, Oman, Lebanon, Germany, Croatia, Australia, Puerto Rico, South Korea, Hungary, United States, Bhutan, Mexico, Mexico, Yemen, Singapore, New Zealand, Ecuador, Gabon, Qatar, Denmark, Iran, Netherlands, Norway, Sri Lanka, Belgium, Libya, Kuwait, Pakistan, Gambia, Sweden, Azerbaijan, Argentina, Chile, Ghana, United Arab Emirates, Finland, Nepal, Trinidad andamp; Tobago,Tunisia, Kenya, Peru, Austria, Russia, Ukraine, Italy, Belarus, Bolivia, Serbia, Poland, Mongolia, Turkey, Czech Republic, South Africa, Angola, India, Vietnam, Indonesia, Tibet, Ireland, Costa Rica, Greece, Colombia, Namibia, Iraq, Estonia, Israel, Macau, Philippines, Brazil, Switzerland, Algeria, Morocco, Chile, Portugal, Egypt, Taiwan, China, Hong Kong.