Home › Inconel Products › Inconel Round Bars › Inconel 600 Round Bars

Inconel 600 Round Bars & Rods Supplier

ASTM B166 Inconel 600 Bright Bar, AMS 5665 Inconel 600 Flat Bar, Inconel 600 Bar Stock, Inconel 600 Rod, Alloy 600 Bar, ASME SB 166, Inconel 600 Round Bar, ASTM B166 Inconel Alloy 600 Bright Bar

Table of Content

- Supplier of Inconel Alloy 600 Round Bars/Rods

- Manufacturing of Inconel 600 Round Bars

- Inconel 600 Bar Stock

- Specification of Inconel 600 Round Bars

- Chemical Composition of Alloy 600 Rods

- Mechanical Properties of Inconel 600 Round Bars

- ASTM B166 Inconel 600 Bars Equivalent Grades

- Dimensions Chart for Inconel 600 Rods

- Inconel 600 Round Bar Sizes in Stock

- Weight Chart for Inconel 600 Round Bars

- Alloy 600 Rod Physical Properties

- Inconel 600 (UNS N06600) Bar Surface Finish

- Other Types of Inconel Alloy 600 Bars

- Application Industries for Inconel 600 Round Bars

- Frequently Asked Questions About Inconel 600 Round Bars

Kalpataru Piping Solutions is a reputable manufacturer, stockist, and exporter of high-performance Inconel round bar products that manufacture Inconel 600 Round Bars (Alloy 600 Rods) in India. Inconel 600 Rods (UNS N06600) are available in both round and hexagonal shapes with a diameter of 3 mm to 800 mm. Such bars come in various sizes, standards. The quality of all products is thoroughly tested to meet the national and international standards, such as ASTM B166, AMS 5665, and DIN 2.4816, and all of them are tested on a rigorous basis, such as mechanical, tensile, hardness, chemical, PMI, and intergranular corrosion tests.

Manufacturing Process of Inconel 600 Round Bars

Inconel 600 bars at Kalpataru Piping Solutions are also made through hot forging, hot rolling, cold drawing, and solution annealing. Hot rolling increases strength and toughness and cold drawing tightens dimensional tolerances and provides a smooth finish. Annealing is then performed at intermediate temperatures of 1700°F -2300°F in order to regain ductility and maximize machinability to produce precision components. Our Alloy 600 Bars are corrosion, oxidation and wear resistant, through the careful heat treatment processes. They are supplied in tempered and quenched states with machining allowances and strong tolerance limits.

The individual bars are finished on the surface to give it a smooth, polished finish and given either a satin or bright black finish to ensure that the bars do not rust or oxidize. These bars are characterized by great machinability, weldability, and formability, which makes them suitable in furnace parts, heat exchangers, and chemical processing units. Get to know more about the uses of Inconel 600 round bars and its advantages by reading our elaborate blog on Inconel 600 Round Bar Applications and Advantages.

We also provide Inconel 600 Round Bar Weight Calculator, which will assist in estimating the weight of different kinds of bars (Cold Drawn Bars, Bright Bars and Metric Bright Bars) according to their size and dimension. Nominal dimensions and weight data may be found in the ASTM B166 Inconel Bright Bar Size Chart below.

Call us now to get a quote or talk to us about specialized needs of high-grade Inconel 600 Round Bars.

Introduction to Inconel 600 Round Bars

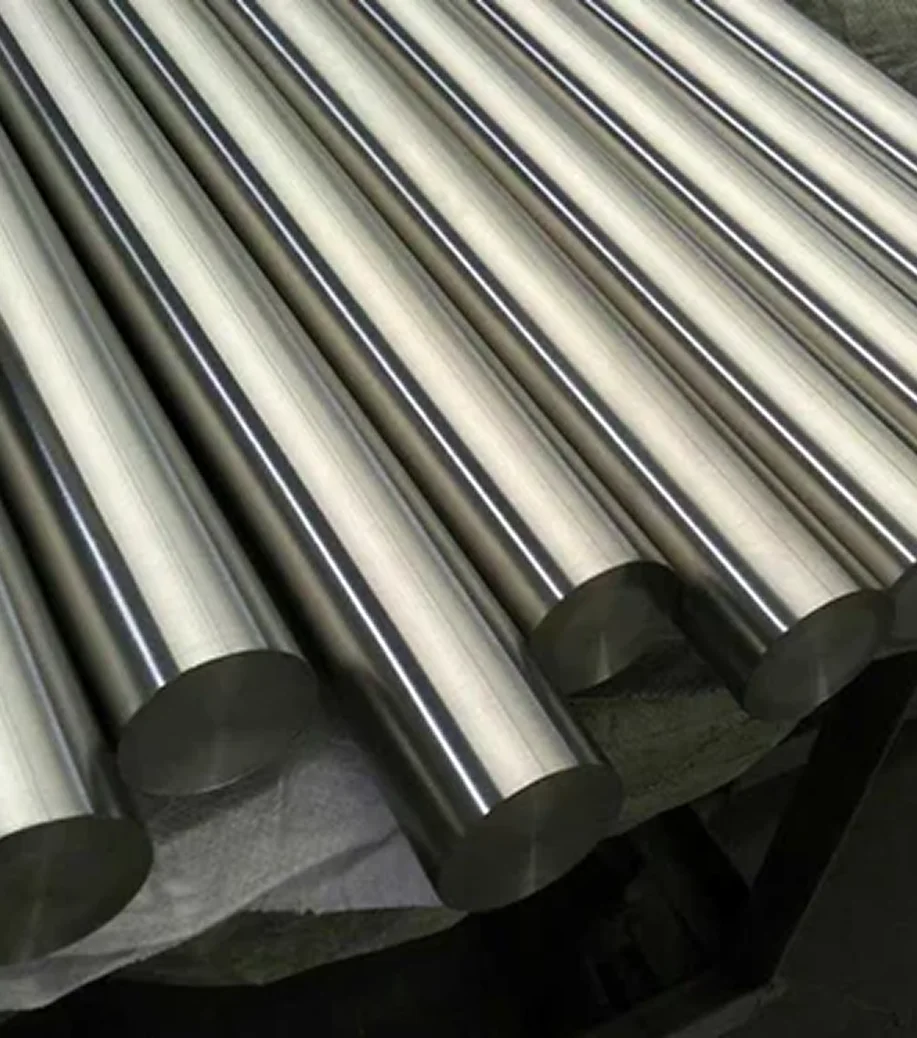

Inconel 600 Round Bars (UNS N06600) are produced as precision cylindrical bars through a high-performance nickel-chromium alloy that is mainly recognized for outstanding resistance to heat and corrosion. Mainly containing about 72% nickel, 15% chromium, and the content of iron, these Alloy 600 bars deliver very good strength, stability, and excellent performance in extreme environments. Chromium provides the enhancement for resistance against oxidation at elevated temperatures, while nickel imparts excellent toughness and corrosion protection. Conformity with international standards like ASTM B166/B168, AMS 5665, and DIN 2.4816 is followed for manufacturing Inconel 600 Round Bars. These round bars present dimensional accuracy, homogeneity of structure, and good mechanical properties. Mechanical properties are very outstanding, considering its tensile strength range from 110–160 ksi and yield strength between 135–205 ksi, keeping these properties from ambient conditions up to 2000°F (1093°C). Details on the chemical composition and mechanical properties are given in the following tables.Buy Inconel 600 Flat Bars, ASTM B166 UNS N06600 Hex Bars, Alloy 600 Square Bars

ASTM B166 Alloy 600 Hex Bar

Inconel 600 Round Bar

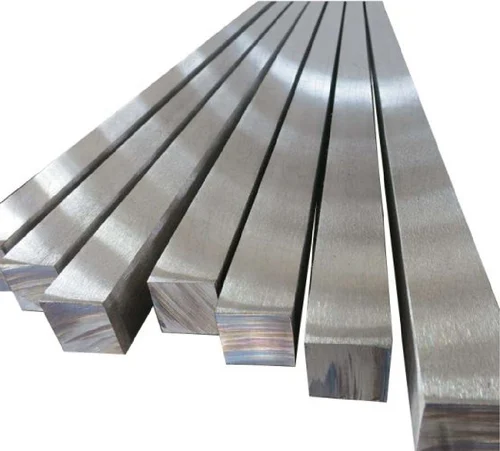

Inconel 600 Square Bar

Inconel 600 Bar Stock

We have a wide range of Inconel 600 Round Bars, including flat Bars, cold-drawn bars, Forged Rods, Polished Bars, Hollow Bars & square bars. These come in a variety of forms with different industrial standards and applications. We deal in all types of precision and quality-assured 600 Inconel round rods.

UNS N06600 Hex Bar

BS NA14 Cold Drawn Bar

BS NA14 Square Bar

Inconel 600 Hollow Bar

Inconel 600 Rectangular Bar

AMS 5665 Inconel 600 Polished Bar

ASTM B166 Inconel 600 Bright Bar

ASTM B166 Inconel 600 Flat Bar

ASTM B166 Inconel 600 Threaded Bar

Looking for the latest Inconel 600 Round Bar price?

Request a quick quote today for custom sizes tailored to your project needs. Get updated details on the Inconel 600 price per kg in India.

Specification of Inconel 600 Round bars

Discover detailed specifications of Inconel 600 round rods including dimensions, sizes, diameters, lengths, finishes, tolerances & available forms. We ensures precision engineered bars tailored to meet your exact industrial requirements.| International Specifications | BS 3072-3076 (NA14) DIN 17742, DIN 17750, DIN 17754 WERKSTOFF Nr 2.4816 TÜV 305 AFNOR-NC 15 Fe |

|---|---|

| Grade | Inconel 600 – UNS N06600, Nickel Alloy 600 |

| Specification | ASTM B166 UNS N06600, AMS 5665 |

| Flat bar size | Thickness: 2 -100mm |

| Width: 10 to 500mm | |

| Square bar size | 4 to 100mm |

| Round bar size | Diameter: 3-~800mm |

| Hex Bar size | 2-100mm A/F |

| Channel Bar | 80 x 40mm to 150 x 75mm section; 5.0 to 6.0mm thickness |

| Hollow Bar | 32mm OD x 16mm ID to 250mm OD x 200mm ID) |

| Angle bar size | 3mm*20mm*20mm~12mm*100mm*100mm |

| Section | 3.0 to 12.0mm thickness |

| Rectangles Size | 33 x 30mm to 295 x 1066mm |

| Billet Size | 1/2″ to 495mm Diameter |

| Finish | Cold (bright) drawn, centreless ground, hot rolled, smooth turned, peeled, slit rolled edge, hot rolled annealed, Rough Turned, Bright, Polish, Grinding, Centreless Ground & Black |

| Condition | Hardened & tempered, annealed |

| Technique | 600 Inconel Cold Drawn, Hot Rolled, Forged Round Bar, Rod, Cold Rolled |

| Tolerance | H8, H9, H10, H11, H12, H13K9, K10, K11, K12 or as per clients’ requirements |

| Surface | Cold Drawn, Bright, Sand Blasting Finished, Hot Rolled Pickled, Hairline, Polished |

| Processing | Bar cutting to 650mm |

| Form | Precision Ground Bar, Flat Bar, Square, Round, Half Round Bar, Rod, Rectangle, Hex (A/F), T-Bar, Channel Bar,Blocks, Round Rod, Threaded, Profiles, Billet, Ingot, I/H Bar, Forging, Rings, Hollow, Triangle etc. |

| Our 600 Inconel Round bar conforms to NACE MR0175/ISO 15156 | |

Alloy 600 Bars Chemical Composition

Alloy 600 Rods (Inconel 600 rods) are primarily composed of Nickel (72% min), Chromium (14–17%), and Iron (6–10%), with trace amounts of manganese, silicon, carbon, and other alloying elements. This composition provides:

- Exceptional resistance to corrosion in both reducing and oxidizing environments.

- High creep and oxidation resistance at elevated temperatures (up to 1093°C / 2000°F).

| International Specifications | BS 3072-3076 (NA14) DIN 17742, DIN 17750, DIN 17754 WERKSTOFF Nr 2.4816 TÜV 305 AFNOR-NC 15 Fe |

|---|---|

| Grade | Inconel 600 – UNS N06600, Nickel Alloy 600 |

| Specification | ASTM B166 UNS N06600, AMS 5665 |

| Flat bar size | Thickness: 2 -100mm |

| Width: 10 to 500mm | |

| Square bar size | 4 to 100mm |

| Round bar size | Diameter: 3-~800mm |

| Hex Bar size | 2-100mm A/F |

| Channel Bar | 80 x 40mm to 150 x 75mm section; 5.0 to 6.0mm thickness |

| Hollow Bar | 32mm OD x 16mm ID to 250mm OD x 200mm ID) |

| Angle bar size | 3mm*20mm*20mm~12mm*100mm*100mm |

| Section | 3.0 to 12.0mm thickness |

| Rectangles Size | 33 x 30mm to 295 x 1066mm |

| Billet Size | 1/2″ to 495mm Diameter |

| Finish | Cold (bright) drawn, centreless ground, hot rolled, smooth turned, peeled, slit rolled edge, hot rolled annealed, Rough Turned, Bright, Polish, Grinding, Centreless Ground & Black |

| Condition | Hardened & tempered, annealed |

| Technique | 600 Inconel Cold Drawn, Hot Rolled, Forged Round Bar, Rod, Cold Rolled |

| Tolerance | H8, H9, H10, H11, H12, H13K9, K10, K11, K12 or as per clients’ requirements |

| Surface | Cold Drawn, Bright, Sand Blasting Finished, Hot Rolled Pickled, Hairline, Polished |

| Processing | Bar cutting to 650mm |

| Form | Precision Ground Bar, Flat Bar, Square, Round, Half Round Bar, Rod, Rectangle, Hex (A/F), T-Bar, Channel Bar,Blocks, Round Rod, Threaded, Profiles, Billet, Ingot, I/H Bar, Forging, Rings, Hollow, Triangle etc. |

| Our 600 Inconel Round bar conforms to NACE MR0175/ISO 15156 | |

Mechanical Properties Of Inconel 600 Bars

The alloy(ASTM B166 UNS N06600) has superior mechanical properties due to solid-solution strengthening and a uniform microstructure. It offers high tensile and yield strength, making it ideal for load-bearing applications, while its excellent ductility and toughness allow for both cold and hot forming. Additionally, the alloy maintains exceptional thermal stability in environments to support long lasting performance.| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.47 g/cm3 | 1413 °C (2580 °F) | 655 MPa, 95000 psi | 310 MPa, 45000 psi | 45 % |

ASTM B166 Inconel 600 Bars Equivalent Grades

Find international equivalents of Inconel 600 Round Bars across various standards including WERKSTOFF, UNS, JIS, BS, GOST, AFNOR, and EN. Kalpataru Piping ensures material traceability with globally recognized grade references for quality assurance in every supply.| Grade | Inconel 600 |

| WERKSTOFF NR. | 2.4816 |

| UNS | N06600 |

| JIS | NCF 600 |

| BS | NA 13 |

| GOST | МНЖМц 28-2,5-1,5 |

| AFNOR | NC15FE11M |

| EN | NiCr15Fe |

Dimensions Chart for Inconel 600 Rods

Refer to the below table to understand the dimension wise weight breakdown of Inconel 600 rods in kilograms per meter and foot, helping you choose the right rod for your application.| Size | Kgs / Mtr | Kgs / Foot | Size | Kgs / Mtr | Kgs / Foot | Size | Kgs / Mtr | Kgs / Foot |

| 3mm | 0.055 | 0.017 | 20mm | 2.470 | 0.753 | 3″ | 35.762 | 10.900 |

| 1/8″ | 0.062 | 0.019 | 22mm | 2.979 | 0.908 | 3-1/4″ | 41.996 | 12.800 |

| 5/32″ | 0.095 | 0.029 | 7/8″ | 3.038 | 0.926 | 3-1/2″ | 48.772 | 14.850 |

| 4mm | 0.098 | 0.030 | 24mm | 3.543 | 1.080 | 3-3/4″ | 55.780 | 17.001 |

| 3/16″ | 0.141 | 0.043 | 25mm | 3.871 | 1.180 | 4″ | 63.340 | 19.306 |

| 5mm | 0.154 | 0.047 | 1″ | 3.970 | 1.210 | 4-1/4″ | 72.249 | 21.908 |

| 7/32″ | 0.190 | 0.058 | 26mm | 4.170 | 1.271 | 4-1/2″ | 80.340 | 24.4487 |

| 6mm | 0.223 | 0.068 | 27mm | 4.490 | 1.368 | 4-3/4″ | 90.249 | 27.366 |

| 1/4″ | 0.249 | 0.076 | 1-1/8″ | 5.033 | 1.534 | 5″ | 99.940 | 30.461 |

| 7mm | 0.298 | 0.091 | 30mm | 5.548 | 1.691 | 5-1/2″ | 121.000 | 36.690 |

| 5/16″ | 0.387 | 0.118 | 1-1/4″ | 6.349 | 1.924 | 6″ | 143.900 | 43.860 |

| 8mm | 0.398 | 0.120 | 32mm | 6.314 | 1.894 | 6-1/2″ | 167.630 | 51.093 |

| 9mm | 0.498 | 0.152 | 1-3/8″ | 7.550 | 2.303 | 7″ | 196.000 | 59.432 |

| 3/8″ | 0.557 | 0.170 | 35mm | 7.553 | 2.390 | 7-1/2″ | 225.000 | 68.226 |

| 10mm | 0.620 | 0.189 | 36mm | 7.999 | 2.438 | 8″ | 254.55 | 77.586 |

| 11mm | 0.748 | 0.228 | 38mm | 8.903 | 2.792 | 10″ | 397.140 | 121.048 |

Inconel 600 Round Bar Sizes in Stock

Explore standard bar sizes for Inconel 600 across ASTM, Metric, Canadian, Japanese & US systems to ensure compatibility with global industrial specifications. Also, request custom sizes as per business needs.| ASTM/ Canadian | Metric | Japanese | US Bar | ||||

| Bar Size | Diam. (mm2) | Bar Size | Diam. (mm) | Bar Size | Diam. (mm) | Bar Size | Diam. (Inch) |

| 10M | 100 | 5 | 5 | 6 | 6 | #2 | 0.250 |

| 15M | 200 | 5.5 | 5.5 | 10 | 10 | #3 | 0.375 |

| 20M | 300 | 6 | 6 | 13 | 13 | #4 | 0.500 |

| 25M | 500 | 7 | 7 | 16 | 16 | #5 | 0.625 |

| 30M | 700 | 8 | 8 | 19 | 19 | #6 | 0.750 |

| 35M | 1000 | 9 | 9 | 22 | 22 | #7 | 0.875 |

| 45M | 1500 | 10 | 10 | 25 | 25 | #8 | 1.000 |

| 55M | 2500 | 11 | 11 | 29 | 29 | #9 | 1.125 |

| – | – | 12 | 12 | 32 | 32 | #10 | 1.250 |

| – | – | 14 | 14 | 35 | 35 | #11 | 1.375 |

| – | – | 16 | 16 | 38 | 38 | #12 | 1.500 |

| – | – | 18 | 18 | 41 | 41 | #13 | 1.625 |

| – | – | 20 | 20 | 44 | 44 | #14 | 1.750 |

| – | – | 22 | 22 | 48 | 48 | #15 | 1.875 |

| – | – | 25 | 25 | 51 | 51 | #16 | 2.000 |

| – | – | 28 | 28 | 57 | 57 | #18 | 2.250 |

Inconel 600 Bright Round Bar Tolerance Standards

Explore standard dimensional tolerances for Inconel 600 bright round bars, ensuring precise machining, fit, and structural consistency for critical applications.| Nominal Size | H12 | H11 | H10 | H9 | H8 | H7 | H6 | H5 |

| Diameter mm | ||||||||

| ~ to 3 | +0.1/0 | +0.06/0 | +0.04/0 | +0.025/0 | +0.014/0 | +0.01/0 | +0.006/0 | +0.004/0 |

| over 3 to 6 | +0.12/0 | +0.075/0 | +0.048/0 | +0.03/0 | +0.018/0 | +0.012/0 | +0.008/0 | +0.005/0 |

| over 6 to 10 | +0.15/0 | +0.09/0 | +0.058/0 | +0.036/0 | +0.022/0 | +0.015/0 | +0.009/0 | +0.006/0 |

| over 10 to 18 | +0.18/0 | +0.11/0 | +0.07/0 | +0.043/0 | +0.027/0 | +0.018/0 | +0.011/0 | +0.008/0 |

| over 18 to 30 | +0.21/0 | +0.13/0 | +0.084/0 | +0.052/0 | +0.033/0 | +0.021/0 | +0.013/0 | +0.009/0 |

| over 30 to 50 | +0.25/0 | +0.16/0 | +0.1/0 | +0.062/0 | +0.039/0 | +0.025/0 | +0.016/0 | +0.011/0 |

| over 50 to 80 | +0.3/0 | +0.19/0 | +0.12/0 | +0.074/0 | +0.046/0 | +0.03/0 | +0.019/0 | +0.013/0 |

| over 80 to 120 | +0.35/0 | +0.22/0 | +0.14/0 | +0.087/0 | +0.054/0 | +0.035/0 | +0.022/0 | +0.015/0 |

| over 120 to 180 | +0.4/0 | +0.25/0 | +0.16/0 | +0.1/0 | +0.063/0 | +0.04/0 | +0.025/0 | +0.018/0 |

| over 180 to 250 | +0.46/0 | +0.29/0 | +0.185/0 | +0.115/0 | +0.072/0 | +0.046/0 | +0.029/0 | +0.02/0 |

Modulus of Elasticity in Alloy 600 Bars

Learn about the modulus of elasticity for Alloy 600 round bars, defining their stiffness, flexibility, and resistance to deformation under stress.| Temp | Poissons Ratio | Shear Modulus | Young Modulus | ||||

| °F | °C | Ksi | GPa | Ksi | GPa | ||

| 72 | 22 | 0.327 | 0.324 | 11.72 | 80.8 | 31.1 | 214 |

| 1000 | 500 | 0.297 | 0.3 | 10.29 | 71.9 | 26.7 | 187 |

| 1200 | 600 | 0.297 | 0.301 | 9.83 | 69.2 | 25.5 | 180 |

| 200 | 100 | 0.319 | 0.319 | 11.56 | 79.6 | 30.5 | 210 |

| 1600 | 800 | 0.329 | 0.32 | 8.58 | 62.1 | 22.8 | 164 |

| 800 | 400 | 0.301 | 0.301 | 10.68 | 74.2 | 27.8 | 193 |

| 1400 | 700 | 0.315 | 0.305 | 9.24 | 65.9 | 24.3 | 172 |

| 400 | 200 | 0.312 | 0.314 | 11.32 | 78 | 29.7 | 205 |

| 600 | 300 | 0.307 | 0.306 | 11.02 | 76.2 | 28.8 | 199 |

| 1800 | 900 | 0.338 | 0.33 | 7.85 | 57.9 | 21 | 154 |

Weight Chart for Inconel 600 Round Bars

View weight data for 600 Inconel round bars per meter and foot to assist in material planning, structural design, and cost estimation.| Round Bar | ||||||||

| Size | Kgs / Foot | Kgs / Mtr | Size | Kgs / Foot | Kgs / Mtr | Size | Kgs / Foot | Kgs / Mtr |

| 3mm | 0.017 | 0.055 | 20mm | 0.753 | 2.470 | 3″ | 10.900 | 35.762 |

| 1/8″ | 0.019 | 0.062 | 22mm | 0.908 | 2.979 | 3-1/4″ | 12.800 | 41.996 |

| 5/32″ | 0.029 | 0.095 | 7/8″ | 0.926 | 3.038 | 3-1/2″ | 14.850 | 48.772 |

| 4mm | 0.030 | 0.098 | 24mm | 1.080 | 3.543 | 3-3/4″ | 17.001 | 55.780 |

| 3/16″ | 0.043 | 0.141 | 25mm | 1.180 | 3.871 | 4″ | 19.306 | 63.340 |

| 5mm | 0.047 | 0.154 | 1″ | 1.210 | 3.970 | 4-1/4″ | 21.908 | 72.249 |

| 7/32″ | 0.058 | 0.190 | 26mm | 1.271 | 4.170 | 4-1/2″ | 24.4487 | 80.340 |

| 6mm | 0.068 | 0.223 | 27mm | 1.368 | 4.490 | 4-3/4″ | 27.366 | 90.249 |

| 1/4″ | 0.076 | 0.249 | 1-1/8″ | 1.534 | 5.033 | 5″ | 30.461 | 99.940 |

| 7mm | 0.091 | 0.298 | 30mm | 1.691 | 5.548 | 5-1/2″ | 36.690 | 121.000 |

| 5/16″ | 0.118 | 0.387 | 1-1/4″ | 1.924 | 6.349 | 6″ | 43.860 | 143.900 |

| 8mm | 0.120 | 0.398 | 32mm | 1.894 | 6.314 | 6-1/2″ | 51.093 | 167.630 |

| 9mm | 0.152 | 0.498 | 1-3/8″ | 2.303 | 7.550 | 7″ | 59.432 | 196.000 |

| 3/8″ | 0.170 | 0.557 | 35mm | 2.390 | 7.553 | 7-1/2″ | 68.226 | 225.000 |

| 10mm | 0.189 | 0.620 | 36mm | 2.438 | 7.999 | 8″ | 77.586 | 254.55 |

| 11mm | 0.228 | 0.748 | 38mm | 2.792 | 8.903 | 10″ | 121.048 | 397.140 |

| 7/16″ | 0.232 | 0.761 | 1-1/2″ | 2.715 | 8.951 | |||

| 12mm | 0.271 | 0.889 | 40mm | 3.009 | 9.872 | |||

| 1/2″ | 0.303 | 0.994 | 1-5/8″ | 3.200 | 10.449 | |||

| 13mm | 0.318 | 1.043 | 1-3/4″ | 3.712 | 12.179 | |||

| 14mm | 0.368 | 1.207 | 45mm | 3.807 | 12.555 | |||

| 9/16″ | 0.383 | 1.256 | 1-7/8″ | 4.260 | 13.977 | |||

| 15mm | 0.424 | 1.391 | 48mm | 4.330 | 14.205 | |||

| 5/8″ | 0.473 | 1.551 | 50mm | 4.698 | 15.414 | |||

| 16mm | 0.481 | 1.578 | 2″ | 4.848 | 15.906 | |||

| 17mm | 0.543 | 1.791 | 2-1/8″ | 5.475 | 17.963 | |||

| 11/16″ | 0.573 | 1.880 | 2-1/4″ | 6.135 | 20.128 | |||

| 18mm | 0.610 | 2.001 | 60mm | 6.768 | 22.205 | |||

| 3/4″ | 0.682 | 2.237 | 2-3/8″ | 6.838 | 22.435 | |||

| 2-1/2″ | 7.576 | 24.856 | ||||||

| 2-5/8″ | 8.354 | 27.409 | ||||||

| 2-3/4″ | 9.169 | 30.083 | ||||||

Inconel 600 Round Bar Thermal Expansion & Conductivity

Explore the thermal properties of Nickel Alloy 600 round bars, including heat resistance, conductivity, and expansion characteristics.| Temperature | Coefficient of Expansion | Electrical Resistivity | Thermal Conductivity | Specific Heat | |||||

| °F | °C | 10-6in/in•°F | mm/m•°C | ohm•circ•mil/ft | mL•m | Btu•in/ft2•h•°F | W/m•°C | Btu/lb•°F | J/kg•°C |

| -250 | -150 | 6 | 10.9 | – | – | 86 | 12.5 | 0.073 | 310 |

| -200 | -100 | 6.3 | 11.7 | – | – | 89 | 13.1 | 0.079 | 352 |

| -100 | -50 | 6.7 | 12.3 | – | – | 93 | 13.6 | 0.09 | 394 |

| 70 | 20 | 5.8 | 10.4 | 620 | 1.03 | 103 | 14.9 | 0.106 | 444 |

| 200 | 100 | 7.4 | 13.3 | 625 | 1.04 | 109 | 15.9 | 0.111 | 465 |

| 400 | 200 | 7.7 | 13.8 | 634 | 1.05 | 121 | 17.3 | 0.116 | 486 |

| 600 | 300 | 7.9 | 14.2 | 644 | 1.07 | 133 | 19 | 0.121 | 502 |

| 800 | 400 | 8.1 | 14.5 | 657 | 1.09 | 145 | 20.5 | 0.126 | 519 |

| 1000 | 500 | 8.4 | 14.9 | 680 | 1.12 | 158 | 22.1 | 0.132 | 536 |

| 1200 | 600 | 8.6 | 15.3 | 680 | 1.13 | 172 | 23.9 | 0.14 | 578 |

| 1400 | 700 | 8.9 | 15.8 | 680 | 1.13 | 186 | 25.7 | 0.145 | 595 |

| 1600 | 800 | 9.1 | 16.1 | 686 | 1.13 | 200 | 27.5 | 0.149 | 611 |

| 1800 | 900 | 9.3 | 16.4 | 698 | 1.15 | – | – | – | 628 |

Alloy 600 Rod Physical Properties

| Density | 0.305 | lb/in³ |

|---|---|---|

| 8.44 | Mg/m³ | |

| Specific Heat | 0.106 | Btu/lb°F (J/kg°C) |

| 444 | J/kg-°C | |

| Melting Range | 2470-2575 | °F |

| 1354-1413 | °C | |

| Electrical Resistivity | 620 | ohm-circ mil/ft |

| 1.03 | μΩ-m | |

| Curie Temperature | -192 | °F |

| -124 | °C | |

| Permeability | 1.01 | 200 oersted (15.9 kA/m) |

Inconel 600 Round Bar Sizes in Stock

Explore standard bar sizes for Inconel 600 across ASTM, Metric, Canadian, Japanese & US systems to ensure compatibility with global industrial specifications. Also, request custom sizes as per business needs.

| ASTM/ Canadian | Metric | Japanese | US Bar | ||||

| Bar Size | Diam. (mm2) | Bar Size | Diam. (mm) | Bar Size | Diam. (mm) | Bar Size | Diam. (Inch) |

| 10M | 100 | 5 | 5 | 6 | 6 | #2 | 0.250 |

| 15M | 200 | 5.5 | 5.5 | 10 | 10 | #3 | 0.375 |

| 20M | 300 | 6 | 6 | 13 | 13 | #4 | 0.500 |

| 25M | 500 | 7 | 7 | 16 | 16 | #5 | 0.625 |

| 30M | 700 | 8 | 8 | 19 | 19 | #6 | 0.750 |

| 35M | 1000 | 9 | 9 | 22 | 22 | #7 | 0.875 |

| 45M | 1500 | 10 | 10 | 25 | 25 | #8 | 1.000 |

| 55M | 2500 | 11 | 11 | 29 | 29 | #9 | 1.125 |

| – | – | 12 | 12 | 32 | 32 | #10 | 1.250 |

| – | – | 14 | 14 | 35 | 35 | #11 | 1.375 |

| – | – | 16 | 16 | 38 | 38 | #12 | 1.500 |

| – | – | 18 | 18 | 41 | 41 | #13 | 1.625 |

| – | – | 20 | 20 | 44 | 44 | #14 | 1.750 |

| – | – | 22 | 22 | 48 | 48 | #15 | 1.875 |

| – | – | 25 | 25 | 51 | 51 | #16 | 2.000 |

| – | – | 28 | 28 | 57 | 57 | #18 | 2.250 |

Inconel 600 (UNS N06600) Bar Surface Finish

| P | Polished |

|---|---|

| SRE | Slit rolled edge |

| HF | Hot finished |

| CG | Centreless ground |

| CF | Cold finished |

| P&T | Peeled and turned |

| HRAP | Hot rolled annealed and pickled |

| RT | Rough turned/peeled |

| PR | Peeled and reeled |

| CD | Cold drawn |

| BD | Bright drawn |

| ST | Smooth turned |

Other Types Of Inconel Alloy 600 Bars

| 2.4816 Round Bar | Inconel 600 Polished Bar |

| 600 Inconel Alloy Forged Hex bars | Inconel Alloy 2.4816 Square Bar |

| ASME SB166 600 Inconel Bar | Inconel 600 Hexagonal Bar |

| ASTM B166 Nickel 600 Hex Bar | Inconel 600 Forged Square Bars |

| Nickel Alloy UNS N06600 Round Bar | Alloy 600 Forged Hex bars |

| Nickel® Alloy 600 Hollow Bars | Inconel Alloy 600 Rod Price Per Kg |

| Inconel® Alloy 600 Forged Square Bars | Inconel 625 Threaded Rod |

| ASME SB166 600 Inconel Rod | Inconel Alloy 600 Rod |

| 600 Inconel T-Bar | Inconel 600 Forged Square Bars Stock |

| 600 Inconel Bright Bar | ASTM B166 Inconel Alloy 600 Rods |

| 600 Inconel Hot Rolled Round Bar | Alloy 600 Forged Hex bars |

| Inconel Alloy 600 Cold Drawn Bars | UNS N06600 Inconel Rectangular Bar |

| UNS N06600 Inconel Forged Square Bars | Inconel 600 Threaded Bar |

| Alloy 600 Half-Round Bar | Alloy 600 Precision Ground Bar |

| Alloy 600 Hollow Bars | Nickel Alloy 600 Forged Hex bars |

Application Industries for Inconel 600 Round Bars

- Construction

- Bridges

- Petrochemical Industry

- Ship Building

- Engineering

- General Structural Purposes

- Offshore and Onshore Services

Frequently Asked Questions About Inconel 600 Round Bars

What is Inconel 600 Bar?

Inconel 600 bar is a high-performance nickel-chromium alloy bar used in high-temperature, corrosive environments such as heat exchangers, chemical processing, aerospace, and nuclear reactors.

Why Choose Inconel 600 Bars Over Other Alloys?

Inconel 600 offers excellent resistance to oxidation, corrosion, and high temperatures. Its superior mechanical strength and stress-corrosion resistance make it ideal for harsh industrial conditions compared to other alloys.

What are the Key Properties of Inconel 600 Round Bars?

Key properties include high tensile strength, good weldability, oxidation resistance up to 1175°C, excellent thermal conductivity, and resistance to chloride-ion stress corrosion cracking.

Which Welding Techniques Are Suitable for Inconel 600 Round Bars?

Common welding methods include GTAW (TIG), GMAW (MIG), and SMAW (stick welding). These techniques ensure strong, corrosion-resistant joints for Inconel 600 bars.

Is Inconel 600 Flat Bar Magnetic?

No, Inconel 600 is a non-magnetic alloy in annealed condition, making it suitable for applications where magnetic interference must be avoided.

How Does Inconel 600 Bright Bar Differ From Cold Rolled Square Bar?

Bright bars have a smooth, reflective finish and tight tolerances, suitable for aesthetic or precise machining applications. Cold rolled square bars may have a matte surface and are shaped through cold working for improved strength.

What Surface Finishes Are Available for Inconel 600 Round Bars?

Inconel 600 round bars are available in various finishes, including:

- Hot Rolled (HR): Scale-covered, as-rolled surface

- Cold Drawn (CD): Smooth finish with tighter tolerances

- Ground Finish: Precision ground for close dimensions

- Polished Finish: Shiny, decorative surface for clean applications

- Pickled Finish: Acid-treated to remove scale and oxides

- Passivated Finish: Chemically treated to enhance corrosion resistance

- Bright Finish: Smooth, reflective surface with high dimensional accuracy

Explore Other Inconel Products We Offer

- Inconel 600 Perforated Sheets

- Inconel 600 Forged Fittings

- Inconel 600 Olets

- Inconel 600 Fasteners

- Inconel 600 Compression Tube Fittings

- Inconel 600 Pipes & Tubes

- Inconel 600 Flanges

- Inconel 600 Round Bars & Wires

- Inconel 600 Plates & Sheets

- Inconel 600 Buttweld Fittings

- Inconel 600 Instrumentation Valves

- Inconel 600 Filler Wire

- Inconel 600 Long Radius Bends

- Inconel 600 Pipes Spools

- Inconel 600 Shims

- Inconel 600 Wiremesh