Home › Inconel Products › Inconel Round Bars › Inconel 625 Round Bars Supplier & Exporters

Inconel 625 Round Bars Supplier & Exporters

ASTM B446 UNS N06625 Rod and Nickel Alloy 625 Hex Bar supplier in India, Alloy 625 Forged Bar Stock, Inconel Alloy 625 Cold Finished Bars Suppliers in India.

Table of Content

- Inconel 625 Bars Specifications

- Chemical Composition of Inconel 625

- Equivalent Material Grade Chart for Inconel 625

- Mechanical Properties of Inconel 625

- Physical Properties of Inconel 625 Bars

- Inconel 625 Bar Thermal Conductivity

- Machining Tips for Inconel 625 Round Bar

- Machining Best Practices for Inconel 625

- Welding Methods for Inconel 625

- Many Types of Inconel 625 Round Bars

- 625 Inconel Round Bars & Rods Weight Chart

- Inconel 625 Round Bar Sizes, Lengths, Tolerances & Surface Finish

- Applications of Inconel 625 Round Bars

- Quality Assurance & Testing of Inconel 625 Round Bars

- Inconel 625 Round Bar Price in India

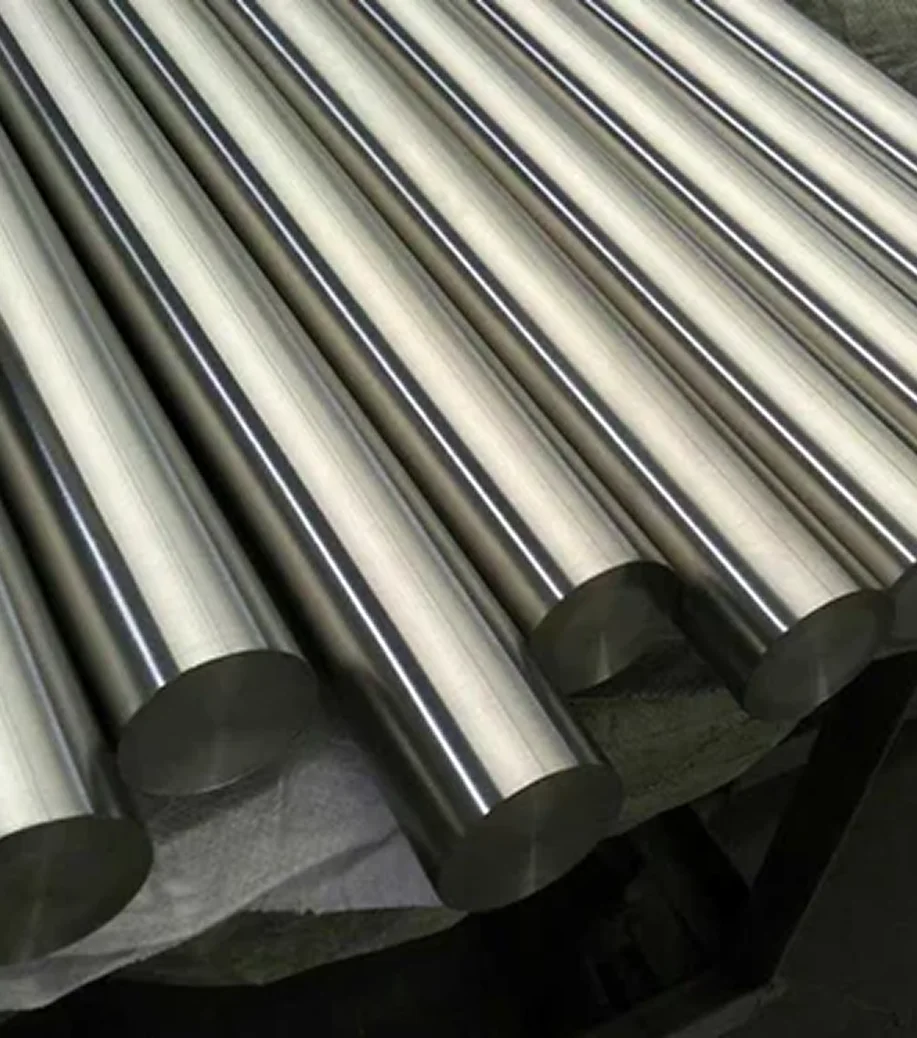

Kalpataru Piping Solutions is a trusted supplier & exporter of high-quality nickel alloy steel products globally with a full line of Inconel Alloy 625 Rods and Inconel 625 Round Bars to be used in industrial purposes. Designed and made of a high-quality nickel-chromium-molybdenum alloy to provide excellent mechanical strength, corrosion resistance and stability at high temperatures. We manufacture products that meet international standards, including ASTM B446, ASME SB 446, AMS 5666, ASTM B564, and the resulting products are uniform in quality and durability.

Inconel 625 Round Bars are available in both standard and custom sizes and in various finishing options (black, bright and polished) to suit the needs of a variety of industries. We are a reliable stockholder of Nickel Alloy 625 Round Bars and we have a large size availability between small-scale to heavy industrial usage. We also produce and distribute Alloy 625 Rod 2.4856 which is in full adherence to the engineering and safety standard regulations in the world. Our ASTM B446 UNS N06625 Bar Stock all receives intensive testing at government-approved and third party laboratories. Under Inconel products, we have Inconel 625 Round Bars, which is used in demanding sectors such as oil and gas, marine engineering and chemical processing, and we have ready inventories that we can quickly export to all parts of the world.

Introduction To Inconel 625 Round Bars

Inconel 625 Round Bar is a superior nickel-based alloy bar that has great strength, long-lasting corrosion, and extreme environmental performance. This alloy is manufactured in accordance with the ASTM B446 UNS N06625 rod specification, and it has high levels of nickel (approximately 58%), chromium, molybdenum, niobium, and iron, which combine to give excellent mechanical and chemical stability. Alloy 625 Rod also has high strength without extra heat treatment, as is the case with many other materials. It has a minimum tensile strength of 930 MPa and a yield strength of 517 MPa; therefore, it is applicable in high-stress and high-temperature environments. The Alloy 625 Rod’s solid-solution strengthening has better fatigue strength and longevity. Alloy 625 bars have an outer diameter of typically 32 mm to 250 mm with different surface finishes being offered to increase the corrosion resistance and hardness of the surface. UNS N06625 rod is highly nickel-enriched and thus the rod does remarkably well in all marine environments withstanding pitting, crevice corrosion and stress corrosion cracking by chlorides. It is also very impressive in resistance to caustic environments and aggressive chemicals such as magnesium chloride boiling. Read the full guide on the UNS N06625 Standards and Certification of Inconel 625 material.

Available Types of Inconel Alloy 625 Bars & Rods

Various Inconel 625 Round Bars, such as hot rolled, cold drawn, polished, annealed, bright, forged, Inconel 625 Tig Rod, Inconel 625 filler rod, Inconel 625 welding rod, threaded bars, available in a large range. Use the following list to identify the correct Alloy 625 bar to use in your industrial task.

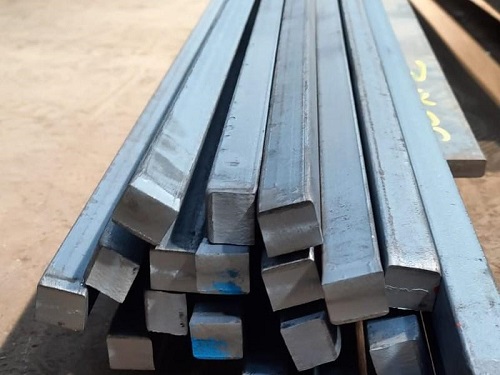

Alloy 625 Flat Bar

UNS N06625 Rod

Alloy 625 Hex Bar

Alloy 625 Square Bar

Alloy 625 Forged Bar

Alloy 625 Bright Bar

Inconel 625 vs Inconel 718: Key Differences Explained

An overall comparison of Inconel 625 and Inconel 718 with reference to their chemical composition, temperature range, corrosion behavior, formability, applications, as well as special properties to guide you in the selection of an appropriate alloy to use in high-performance industrial applications. To get more specific instructions, go to our blog Inconel 625 vs 718.

| Property | Inconel 625 | Inconel 718 |

| Chemical Composition | High in nickel and chromium with added molybdenum and niobium for enhanced corrosion resistance. | Nickel-chromium alloy similar to 625 but includes higher levels of niobium (columbium) and other strengthening elements. |

| Temperature Resistance | Retains excellent strength up to 2,000°F (1093°C). | Provides superior creep-rupture strength up to 1,300°F (704°C) due to precipitation-hardening properties. |

| Corrosion Resistance | Outstanding performance against pitting, crevice corrosion, and marine environments. | Good overall corrosion resistance with additional emphasis on high-strength performance. |

| Formability | Highly formable; suitable for cold forming, stamping, and complex shapes. | Good formability; excellent for post-weld heat-treated applications. |

| Applications | Flexible metal hoses, chemical processing equipment, heat exchangers, marine components. | Aerospace parts, turbine engines, oil & gas equipment, high-temperature fasteners. |

| Special Characteristics | Strong oxidation resistance and high fatigue strength without heat treatment. | Exceptional durability under high stress with precipitation-hardening for added strength. |

Inconel 625 Round Bars Standrads – ASTM A446, AMS 5666 & ASME SB 466 Specifications

Our Inconel 625 Round Bars in Kalpataru Piping Solutions are produced in accordance to world standards in order to achieve high performance, reliability, and safety. Our bars comply with the requirements of ASTM A446, AMS 5666, and ASME SB 466, which is why they may be used in applications of significant interest.

Other Applicable Specifications

It is possible to provide material in accordance with AMS 5666 (Aerospace Material Specification) on demand, and VdTU V 499 and DIN 17752. Please clarify your standard of requirement during inquiry.

Scope of Manufacturing and Supply

We are making our bars with great precision and straight and tight dimensional control. We provide peeling, centerless grinding and polishing facilities so that the quality of the surface suits your specific requirement in terms of machining the surface or immediate usage.

| Solid Rod | ASME SB 466, ASTM B 446, VdTUV 499, ISO 9723, EN 10095, SME Code Case 1935, DIN 17752, BS 3076 NA21 |

| Solid Bar | ASME Code Case 1935, ASME SB 466, ISO 9723, AMS 5666, ASTM B 446, BS 3076 NA21, VdTUV 499, DIN 17752, EN 10095, |

| Forging Stock | DIN 17754, ASME SB 564, SME Code Case 1935, AMS 5666, ASTM B 564, ISO 9725, |

Inconel 625 Bars Specifications

| International Specifications | VdTüV 499, ISO 9723, ISO 9724, BS3076NA21, EN 10095, ISO 9725, DIN 17752, DIN 17754, DIN 17753, WERKSTOFF Nr 2.4856 |

| Grade | Inconel 625 – Nickel Alloy 625, ASTM B446, UNS N06625, AMS 5666, AMS 5837 |

| Specification of Bar | ASTM B 446, AMS 5666, ASME SB 466, VdTUV 499, ISO 9723, EN 10095, BS 3076 NA21, ASME Code Case 1935, DIN 17752 |

| Specification of Rod | ASME SB 466, ASTM B 446, VdTUV 499, ISO 9723, EN 10095, BS 3076 NA21, SME Code Case 1935, DIN 17752 |

| Hex Bar | 2-100mm A/F |

| Flat bar | Thickness: 2 -100mm |

| Width: 10 to 500mm | |

| Channel Bar | section; 5.0 to 6.0 thick, 80 x 40mm to 150 x 75mm |

| Round bar | Diameter: 3-~800mm |

| Square bar | 4 to 100mm |

| Section | 3 to 12 mm thick. |

| Rectangles | 33 x 30 to 295 x 1066 |

| Billet | 1/2″ to 495 Dia. |

| Angle bar | 3*20*20~12*100*100 mm |

| Hollow Bar | 32mm Outside Diameter x 16mm Inside Diameter to 250mm Outside Diameter x 200mm Inside Diameter |

| Form | Flat Bar, Hollow, Round, Square, Triangle, Rectangle, Half Round Bar, Rod, T-Bar, Precision Ground Bar, Hex (A/F), Blocks, Channel Bar, Threaded, Round Rod, Billet, Profiles, I/H Bar, Ingot, Rings, Forging etc. |

| Technique | Hot Rolled, Cold Drawn, Rod, Forged Round Bar, Cold Rolled |

| Condition | annealed, Hardened & tempered |

| Surface | Bright, Cold Drawn, Hot Rolled Pickled, Sand Blasting Finished, Polished, Hairline |

Chemical Composition (%)

| Grade | Fe | Ni | C | Cr | Si | Mn | Mo | Al | Co | Ti | P | Nb + Ta | S |

| Inconel 625 | 5.0 max | 58.0 min | 0.10 max | 20.0 – 23.0 | 0.50 max | 0.50 max | 8.0 – 10.0 | 0.40 max | 1.0 max | 0.40 max | 0.015 max | 3.15 – 4.15 | 0.015 max |

Equivalent Material Grade Chart

| STANDARD | Inconel 625 |

| UNS | N06625 |

| WNR | 2.4856 |

| GOST | ХН75МБТЮ |

| BS | NA 21 |

| OR | ЭИ602 |

| EN | NiCr22Mo9Nb |

| JIS | NCF 625 |

| AFNOR | NC22DNB4M |

Mechanical Properties

| Grade | Tensile Strength | Yield Strength (0.2%Offset) | Density | Melting Point | Elongation |

| Inconel 625 | Psi – 1,35,000. MPa – 930 | Psi – 75,000. MPa – 517 | 8.4 g/cm3 | 1350 °C (2460°F) | 42.5% |

Inconel 625 Bar Thermal Conductivity

| Temperature Range | Linear Coefficients of Thermal Expansion1 · 10-6 | Thermal Conductivity 2 3 | |||

| °C | °F | /°C | /°F | W/m·K | Btu/(hr/ft²/in/°F) |

| -157 | -250 | – | – | 7.3 | 4.2 |

| -129 | -200 | – | – | 7.4 | 4.3 |

| -73 | -100 | – | – | 8.3 | 4.8 |

| -18 | 0 | – | – | 9.2 | 5.3 |

| 21 | 70 | – | – | 9.9 | 5.7 |

| 38 | 100 | – | – | 10.0 | 5.8 |

| 93 | 200 | 12.8 | 7.1 | 10.7 | 6.3 |

| 204 | 400 | 13.1 | 7.3 | 12.6 | 7.3 |

| 316 | 600 | 13.3 | 7.4 | 14.2 | 8.2 |

| 427 | 800 | 13.7 | 7.6 | 15.7 | 9.1 |

| 538 | 1000 | 14.0 | 7.8 | 17.5 | 10.1 |

| 649 | 1200 | 14.8 | 8.2 | 19.0 | 11.0 |

| 760 | 1400 | 15.3 | 8.5 | 20.8 | 12.0 |

| 871 | 1600 | 15.8 | 8.8 | 22.8 | 13.2 |

| 927 | 1700 | 16.2 | 9.0 | – | – |

| 982 | 1800 | – | – | 25.3 | 14.6 |

Inconel 625 Bar Electrical Resistivity

| Temperature | microhm-cm | |

| °C | °F | |

| 21 | 70 | 128.9 |

| 38 | 100 | 129.6 |

| 93 | 200 | 131.9 |

| 204 | 400 | 133.9 |

| 316 | 600 | 134.9 |

| 427 | 800 | 135.9 |

| 538 | 1000 | 137.9 |

| 649 | 1200 | 137.9 |

| 760 | 1400 | 136.9 |

| 871 | 1600 | 135.9 |

| 982 | 1800 | 134.9 |

| 1093 | 2000 | 133.9 |

Inconel 625 Round Bars Supply Condition & Heat Treatment

Inconel 625 bars are most often delivered in the Annealed state (Grade 1), usually heat-treated at temperatures between 871 °C and 1093 °C. This provides the best tensile property and corrosion resistance for general usage. Solution Annealed (Grade 2) material that is treated at temperatures of 1093 °C or more is suggested where maximum creep and rupture values are desired at temperatures exceeding 593 °C. We provide material in conditions that would fit your fabrication process. Bar annealed is simpler to machine, whereas cold-drawn bars have restrictions and values in tighter tolerances and surface finishes.

Machining Tips for Inconel 625 Round Bar

The Inconel 625 Round Bars are described as high-strength and corrosion-resistant, and the nature is related to their hardness to machine. The right approach to things gets the right results and extends the life of the tools.

| Tip | Benefit |

| Use carbide or ceramic tools | Handles work hardening & heat |

| Use water-soluble coolants | Reduces tool wear |

| Prefer low speed & high feed | Avoids work hardening |

| Keep cuts continuous | Improves tool life & finish |

Machining Best Practices

- Avoid Dwell Time: Keep the cutting tool moving to prevent work hardening at one spot.

- Rigid Setup: Ensure the workpiece is firmly clamped to reduce vibration and chatter.

- Sharp Tools: Replace or resharpen tools before they become dull to maintain cutting efficiency.

- Adequate Cooling: Use high-volume coolant to dissipate heat and flush chips away.

- Progressive Cuts: Take multiple light cuts rather than one heavy cut when possible.

- Avoid Rubbing: Maintain positive cutting action; rubbing creates excessive heat and hardening.

Welding Methods for Inconel 625

Inconel 625 Round Bars are widely used in industries requiring high corrosion resistance and strength. Proper welding techniques ensure structural integrity and long-term performance.

| Welding Method | Description |

| TIG | complete control over the input of heat and weld. |

| MIG | Faster, suitable for thicker materials. |

| SMAW | Versatile with a consumable electrode. |

| Plasma Arc Welding | Similar to TIG, uses a constricted arc. |

Many Types of Inconel 625 Round Bars

Kalpataru Piping Solutions offers a wide range of Inconel 625 Round Bars in various forms, finishes, and diameters to meet diverse industrial requirements.

| Product Form | Dimensions |

| Rod; cold drawn, annealed | Dia=12.0 mm, Weight=1.0 kg/m |

| Rod; cold drawn, annealed | Dia=16.0 mm, Weight=1.7 kg/m |

| Rod; annealed, peeled | Dia=16.0 mm, Weight=1.7 kg/m |

| Rod; cold drawn, annealed | Dia=16.0 mm, Weight=1.7 kg/m |

| Rod; annealed, peeled | Dia=20.0 mm, Weight=2.7 kg/m |

| Rod; hot worked, annealed, peeled | Dia=25.0 mm, Weight=4.5 kg/m |

| Rod; hot finished, machined, annealed | Dia=30.0 mm, Weight=6.1 kg/m |

| Rod; hot worked, annealed, peeled | Dia=40.0 mm, Weight=10.6 kg/m |

| Rod; hot finished, annealed, peeled | Dia=44.5 mm, Weight=13.1 kg/m |

| Rod; peeled, annealed | Dia=50.8 mm, Weight=17.1 kg/m |

| Rod; forged, peeled, annealed | Dia=65.4 mm, Weight=26.7 kg/m |

| Rod; machined, annealed, forged | Dia=76.2 mm, Weight=38.5 kg/m |

| Rod; annealed, peeled, hot worked | Dia=81.0 mm, Weight=42.5 kg/m |

| Rod;hot worked, peeled, annealed, | Dia=85.0 mm, Weight=47.9 kg/m |

| Rod; hot worked, annealed, peeled | Dia=101.6 mm, Weight=68.4 kg/m |

| Rod; hot worked, annealed, peeled | Dia=130.0 mm, Weight=112 kg/m |

| Rod; hot worked, annealed, peeled | Dia=160.0 mm, Weight=160 kg/m |

| Rod; forged, annealed | Dia=190.0 mm, Weight=234 kg/m |

625 Inconel Round Bars & Rods Weight Chart

| Round Bar | ||||||||

| Size | Kgs / Mtr | Kgs / Foot | Size | Kgs / Mtr | Kgs / Foot | Size | Kgs / Mtr | Kgs / Foot |

| 3mm | 0.0055 | 0.0017 | 20mm | 2.0470 | 0.0753 | 3″ | 35.0762 | 10.0900 |

| 1/8″ | 0.0062 | 0.0019 | 22mm | 2.0979 | 0.0908 | 3 to 1/4″ | 41.0996 | 12.0800 |

| 5/32″ | 0.0095 | 0.0029 | 7/8″ | 3.0038 | 0.0926 | 3 to 1/2″ | 48.0772 | 14.0850 |

| 4mm | 0.0098 | 0.0030 | 24mm | 3.0543 | 1.0080 | 3 to 3/4″ | 55.0780 | 17.0001 |

| 3/16″ | 0.0141 | 0.0043 | 25mm | 3.0871 | 1.0180 | 4″ | 63.0340 | 19.0306 |

| 5mm | 0.0154 | 0.0047 | 1″ | 3.0970 | 1.0210 | 4 to 1/4″ | 72.0249 | 21.0908 |

| 7/32″ | 0.0190 | 0.0058 | 26mm | 4.0170 | 1.0271 | 4 to 1/2″ | 80.0340 | 24.04487 |

| 6mm | 0.0223 | 0.0068 | 27mm | 4.0490 | 1.0368 | 4 to 3/4″ | 90.0249 | 27.0366 |

| 1/4″ | 0.0249 | 0.0076 | 1 to 1/8″ | 5.0033 | 1.0534 | 5″ | 99.0940 | 30.0461 |

| 7mm | 0.0298 | 0.0091 | 30mm | 5.0548 | 1.0691 | 5 to 1/2″ | 121.0000 | 36.0690 |

| 5/16″ | 0.0387 | 0.0118 | 1 to 1/4″ | 6.0349 | 1.0924 | 6″ | 143.0900 | 43.0860 |

| 8mm | 0.0398 | 0.0120 | 32mm | 6.0314 | 1.0894 | 6 to 1/2″ | 167.0630 | 51.0093 |

| 9mm | 0.0498 | 0.0152 | 1 to 3/8″ | 7.0550 | 2.0303 | 7″ | 196.0000 | 59.0432 |

| 3/8″ | 0.0557 | 0.0170 | 35mm | 7.0553 | 2.0390 | 7 to 1/2″ | 225.0000 | 68.0226 |

| 10mm | 0.0620 | 0.0189 | 36mm | 7.0999 | 2.0438 | 8″ | 254.055 | 77.0586 |

| 11mm | 0.0748 | 0.0228 | 38mm | 8.0903 | 2.0792 | 10″ | 397.0140 | 121.0048 |

| 7/16″ | 0.0761 | 0.0232 | 1 to 1/2″ | 8.0951 | 2.0715 | |||

| 12mm | 0.0889 | 0.0271 | 40mm | 9.0872 | 3.0009 | |||

| 1/2″ | 0.0994 | 0.0303 | 1 to 5/8″ | 10.0449 | 3.0200 | |||

| 13mm | 1.0043 | 0.0318 | 1 to 3/4″ | 12.0179 | 3.0712 | |||

| 14mm | 1.0207 | 0.0368 | 45mm | 12.0555 | 3.0807 | |||

| 9/16″ | 1.0256 | 0.0383 | 1 to 7/8″ | 13.0977 | 4.0260 | |||

| 15mm | 1.0391 | 0.0424 | 48mm | 14.0205 | 4.0330 | |||

| 5/8″ | 1.0551 | 0.0473 | 50mm | 15.0414 | 4.0698 | |||

| 16mm | 1.0578 | 0.0481 | 2″ | 15.0906 | 4.0848 | |||

| 17mm | 1.0791 | 0.0543 | 2 to 1/8″ | 17.0963 | 5.0475 | |||

| 11/16″ | 1.0880 | 0.0573 | 2 to 1/4″ | 20.0128 | 6.0135 | |||

| 18mm | 2.0001 | 0.0610 | 60mm | 22.0205 | 6.0768 | |||

| 3/4″ | 2.0237 | 0.0682 | 2 to 3/8″ | 22.0435 | 6.0838 | |||

| 2 to 1/2″ | 24.0856 | 7.0576 | ||||||

| 2 to 5/8″ | 27.0409 | 8.0354 | ||||||

| 2 to 3/4″ | 30.0083 | 9.0169 | ||||||

Inconel 625 Round Bar Sizes, Lengths, Tolerances & Surface Finish

Sizes & Lengths We have diameters as small as precision wires, as large as forged bars (350mm+). Lengths are normally provided in random lengths (2-6 meters) and are occasionally cut to exact predetermined lengths as per the customer’s requirements.

Tolerances

Standard bars tend to be h9, h10 or h11 tolerant with peeled or black bars k9 to k12. Stricter tolerances such as h8 are also available where necessary such as in the pump shaft.

Detailed Tolerance Values (ISO H-Series) Below are typical tolerance values for precision Inconel 625 round bars as per ISO 286-2:

| RT | Rough turned/peeled | P&T | Peeled and turned |

| SRE | Slit rolled edge | BD | Bright drawn |

| P | Polished | CD | Cold drawn |

| HRAP | Hot rolled annealed and pickled | CF | Cold finished |

| HF | Hot finished | CG | Centreless ground |

| PR | Peeled and reeled | ST | Smooth turned |

Applications of Inconel 625 Round Bars

- Seawater Components: Corrosion-resistant springs, seals, bellows, fasteners and oceanographic instruments.

- Offshore Marine Equipment: Pumps, valves and structural components of harsh offshore environments.

- Aerospace: Aircraft ducting, engine exhausts, fuel/hydraulic lines, spray bars and bellows.

- Bellows: Expansion joints and flexible connectors that need a high level of strength and resistance to corrosion.

- Chemical Processing: Reactors, heat exchangers and high-temperature and acid-exposed pipes.

- Flare Stacks: Oil and gas plant components of high temperature and resistance to oxidation.

- Nuclear Applications: Used in Radiation and corrosion-resistant components of the reactor, heat exchangers, and piping systems.

Quality Assurance & Testing of Inconel 625 Round Bars

At Kalpataru Piping Solutions, our strict quality checks and tests are done on all the Inconel 625 Round Bars to guarantee that they match the international standard and can perform as expected in high-pressure jobs.

Testing Methods Used to Measure the Hardness of Inconel 625

| Testing Method | Typical Use |

| Brinell | Larger samples; average hardness. |

| Rockwell | Quick, common for metals (HRC, HRB). |

| Vickers | Versatile, wide range of materials. |

| Knoop | Brittle materials; thin films. |

| Leeb | Portable, large components. |

| Mohs | Rough hardness comparison for minerals. |

Documents Provided:

- Manufacturer Test Certificate (MTC) as per EN 10204 3.1.

- NABL Approved Lab Test Reports.

- Certificate of Conformity.

- Heat Treatment Charts (if applicable).

Inconel 625 Round Bar Price in India

Inconel 625 round bars price varies according to various factors that are both international and domestic. The London Metal Exchange (LME) rates of Nickel and Molybdenum which are the most important alloying elements control the prices. Other things that impact on the final quote are:

- Dimensions & radius: Above average or very big size could be premium-priced.

- Condition: Bright, ground, or polished bars demand more processing than hot-rolled black bars.

- Quantity: Bulk orders are usually subject to volume discounts.

- Testing Requirement: extra third party Inspections (TPI) or special.

- Non-destructive testing (NDT) increases the cost.

To get the most accurate and current price, please submit a Request for Quote. (RFQ) with your specific bill of materials

Send us your requirements: Size, Grade, Quantity, and Delivery Location.

FAQ

What is ASTM B446 for Inconel 625 round bars?

What is UNS N06625?

What is the maximum service temperature of Inconel 625?

Is Inconel 625 weldable?

Do you provide EN 10204 3.1 MTC?

How do I calculate weight of an Inconel 625 round bar?

What finishes are available?

What are the lead time and delivery options?

What is the difference between Inconel 625 and Inconel 718?

What tests are done before dispatch?

What is the difference between Inconel 625 and Inconel 718?

Which industries use Inconel 625 round bars?

Explore Other Inconel 625 Products We Offer

- Inconel 600 Perforated Sheets

- Inconel 600 Forged Fittings

- Inconel 600 Olets

- Inconel 600 Fasteners

- Inconel 600 Compression Tube Fittings

- Inconel 600 Pipes & Tubes

- Inconel 600 Flanges

- Inconel 600 Round Bars & Wires

- Inconel 600 Plates & Sheets

- Inconel 600 Buttweld Fittings

- Inconel 600 Instrumentation Valves

- Inconel 600 Filler Wire

- Inconel 600 Long Radius Bends

- Inconel 600 Pipes Spools

- Inconel 600 Shims

- Inconel 600 Wiremesh

Cities We deliver

Bhopal, Lahore, Milan, Hyderabad, Pune, Vadodara, Pimpri-Chinchwad, Aberdeen, Howrah, Jeddah, Riyadh, Bogota, Petaling Jaya, Dallas, Lagos, Nagpur, Houston, Brisbane, Busan, Karachi, Coimbatore, Seoul, Caracas, Atyrau, Perth, Haryana, Bengaluru, Jaipur, Al Jubail, Kuwait City, Al Khobar, Sydney, Ranchi, Chiyoda, Noida, Chandigarh, Secunderabad, Ahvaz, Port-of-Spain, Singapore, Gurgaon, Rajkot, Rio de Janeiro, Abu Dhabi, Hong Kong, Surat, Sharjah, Hanoi, London, Muscat, Jakarta, Navi Mumbai, Istanbul, Kolkata, Cairo, Mumbai, Santiago, Montreal, Faridabad, Vung Tau, Bangkok, Ankara, Ahmedabad, Granada, Melbourne, Tehran, Visakhapatnam, New Delhi, Los Angeles, Ho Chi Minh City, Edmonton, La Victoria, Baroda, Thane, Nashik, Kuala Lumpur, Moscow, Ernakulam, Courbevoie, Calgary, Geoje-si, Indore, New York, Mexico City, Gimhae-si, Ludhiana, Kanpur, Ulsan, Thiruvananthapuram, Manama, Doha, Chennai, Madrid, Jamshedpur, Algiers, Dammam

Countries We Deliver

Iran, Venezuela, Saudi Arabia, Slovakia, Romania, Zimbabwe, Spain, Kazakhstan, Canada, Nigeria, Bulgaria, Afghanistan, Thailand, Bangladesh, Poland, United Kingdom, Bahrain, Jordan, Lithuania, Malaysia, France, Nigeria, Japan, Oman, Lebanon, Germany, Croatia, Australia, Puerto Rico, South Korea, Hungary, United States, Bhutan, Mexico, Mexico, Yemen, Singapore, New Zealand, Ecuador, Gabon, Qatar, Denmark, Iran, Netherlands, Norway, Sri Lanka, Belgium, Libya, Kuwait, Pakistan, Gambia, Sweden, Azerbaijan, Argentina, Chile, Ghana, United Arab Emirates, Finland, Nepal, Trinidad andamp; Tobago,Tunisia, Kenya, Peru, Austria, Russia, Ukraine, Italy, Belarus, Bolivia, Serbia, Poland, Mongolia, Turkey, Czech Republic, South Africa, Angola, India, Vietnam, Indonesia, Tibet, Ireland, Costa Rica, Greece, Colombia, Namibia, Iraq, Estonia, Israel, Macau, Philippines, Brazil, Switzerland, Algeria, Morocco, Chile, Portugal, Egypt, Taiwan, China, Hong Kong.