Inconel Plates/Sheets

Inconel UNS N06600 / N06625 / N07718 Sheets, Plates & Coils, inconel sheet price, ASTM B168 Inconel 718 HR Sheets and Plate Manufacturer, Inconel 2.4851 Plates, Alloy 601 Coils, Inconel Alloy Cold Rolled Sheet, Inconel Alloy Strip, Inconel Plates Stockist, Inconel Hot Rolled Plate, Inconel Circle, Inconel Sheets Supplier

Table of Content

- Inconel Sheet and Plate suppliers

- Available Types of Inconel Sheets, Plates & Coils

- Inconel Plate Price

- Inconel Sheets and Plates Specifications

- Chemical Composition of Inconel Alloy Sheets & Plates

- Grades of Inconel Plates

- Mechanical Properties of Inconel Sheets

- Equivalent Grades of Inconel Plates

- Thickness Measurement for Inconel Sheets

- Weight Chart of Inconel Plates

- Physical Properties of Inconel Sheet Metal

- Size Chart for Inconel Plates & Sheets

- Application of Inconel Plates & Sheets

- Frequently Asked Questions About Inconel Plates & Sheets

Inconel plates and sheets are high-performance nickel-chromium alloys which are highly resistant to heat and corrosion. The main benefit of this type of material is that it can be used in high temperature processes over 1000 0 C (1832 °F) and is thus perfect in the operation of high heat engines such as gas turbines, heat exchanger and exhaust systems. These Inconel products have oxidation resistance which enables it to have a protective oxide which prevents further degradation of the product that improves its life in harsh environments. Also, the alloys have a high creep strength, which allows them to stand their shape and strength at high load and temperature at all times.

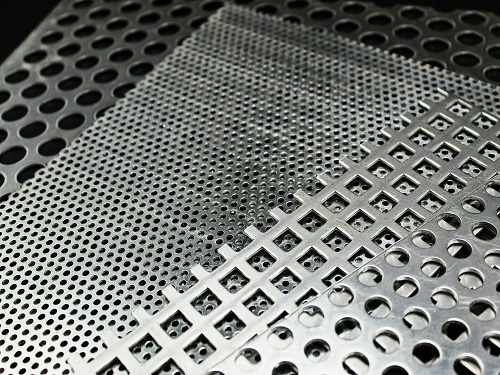

Inconel sheets provide an excellent resistance to numerous forms of corrosive media. Its soft-annealed state (grade 1). Inconel strips are preferably machined when annealed, since the material is likely to be work-hardened. In order to avoid premature wear, low cutting speed and appropriate feed rates are advisable when machining. Inconel coils and plates are a superalloy that is applied in special work that requires the resistance of heat. Inconel perforated plates and cold-rolled plates are cold-formed using conventional techniques, and thus can be used in many manufacturing operations.

Inconel Sheet and Plate suppliers

Kalpataru Piping Solutions is a major manufacturer and distributor of Inconel plates and sheets in different grades, sizes and specifications to satisfy the different requirements of our great customers. With the latest technology and equipment, we make sure to produce the best quality Inconel plates and Inconel sheets that meet all the international and national standards of quality such as ASTM B168, ASME SB168, and DIN. Kalpataru Piping Solutions offers mill test certificates (MTC) to all Inconel sheets that contain detailed documentation in the form of radiographic tests, third-party inspection reports, and raw material certificates. This will ensure maximum transparency and quality assurance to our clients. Inconel products have a great surface finish, high tensile strength, dimensional accuracy and rugged construction and they can be used in demanding applications.

Available Types of Inconel Sheets, Plates & Coils

Inconel Shim Sheets

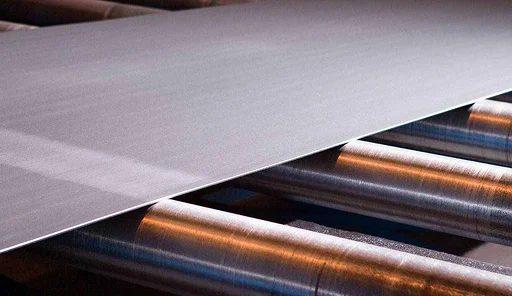

Inconel Hot Rolled (HR) Sheets

Inconel Cold rolled Plates (CR)

Inconel Chequered Plate

Clad Plates

Perforated Plates

Inconel Plate Price

The inconel sheets price is depends on factors like the alloy grade, size, thickness, and customization. Higher-grade alloys (like Inconel 625) and larger dimensions typically cost more. Additional costs may arise from special treatments, finishes, and shipping.

Looking to buy Inconel Sheet?

Contact us to get best Inconel Plate price for your needs.

Inconel Sheets and Plates Specifications

| Specifications | ASTM B168 / ASME SB168 |

| Width | 1000mm / 1219mm /1250mm / 1500mm / 2000mm |

| Length | 2000 mm / 2440 mm / 2500 mm / 3000 mm / 6000 mm |

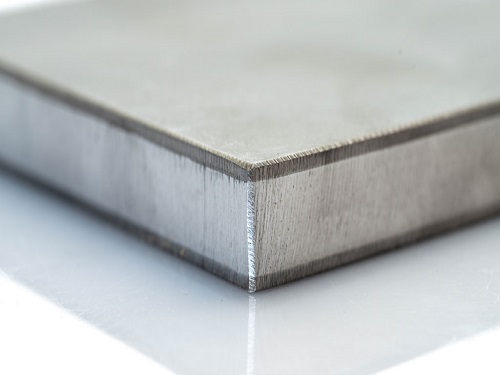

| Thickness | 0.1mm to 12 mm Thk |

| Hardness | Soft, Hard, Half Hard, Quarter Hard, Spring Hard etc. |

| Finish | Hot rolled plate (HR), Cold rolled sheet (CR) |

| Form | Coils, Foils, Rolls, Plain Sheet, Strip, Flats, Blank (Circle), Ring (Flange) etc. |

Chemical Composition of Inconel Alloy Sheets & Plates

We supplies Inconel alloy plates & sheets engineered with precise chemical composition, including elements like Co, Mo, Fe, Cr, Nb, Ni, Ti, Mn, Al, Cu, Si, S, C, B & P, ensuring superior strength, corrosion resistance & performance across all grades.

| Grade | Note: Inconel plate contain nickel between 72% and 90% | |||||||||||||||

| Co | Mo | Fe | Cr | Nb | Ni | Ti | Mn | Al | Cu | Si | S | C | B | P | ||

| 625 | 1.0 | 8.0-10.0 | 5.0 | 20.0-23.0 | 3.15-4.15 | 58.0 | 0.4 | 0.5 | 0.4 | 0.5 | 0.015 | 0.1 | 0.015 | |||

| 600 | 6.0-10.0 | 14.0-17.0 | 72.0 | 1.0 | 0.5 | 0.5 | 0.015 | 0.15 | ||||||||

| 718 | 1.0 | 2.8-3.3 | balance | 17.0-21.0 | 4.75-5.5 | 50.0-55.0 | 0.3 | 0.35 | 0.65-1.15 | 0.2-0.8 | 0.35 | 0.015 | 0.08 | 0.006 | 0.015 | |

| 800 | 39.5 min | 21.0 -23.0 | 30.0-35.0 | 0.15-0.60 | 1.5 | 0.15–0.60 | 1.0 | 0.015 | 0.10 | 0.015 | ||||||

| 825 | ≤1.0 | 2.5–3.5 | 22.0 min | 19.5–23.5 | 38.0–46.0 | ≤1.2 | 1.0 | 0.20 max | 1.5–3.0 | 0.5 | 0.03 | 0.05 | 0.006 | 0.03 | ||

Grades of Inconel Plates

We offer a wide range of Inconel plates in various grades, including Inconel 600, 625, 800, and 825. These high-performance alloys are available in different sizes and thicknesses. Each grade is designed for specific needs, ensuring reliability and durability in demanding conditions.

Inconel 600 Plates — (ASTM B168, B409)

Inconel 625 — (ASTM B443, B444, B453)

Inconel 718 — (ASTM B670, B637)

Inconel 825 — (ASTM B424, B443)

Inconel 800 – (ASTM B409,B408 & B407)

Mechanical Properties of Inconel Sheets

Discover the mechanical properties of Inconel sheets and plates, including yield and tensile strength, density, hardness, elongation, and melting range, ensuring optimal performance in high-temperature and corrosive environments.

| Alloy 625 | Alloy 600 | Nickel alloy 718 | Alloy 601 | |

| Yield strength – Mpa | 345min. | 240min. | 550 min. | 300min. |

| Density | 8.4 g/cm³ | 8.4 g/cm³ | 8.2 g/cm³ | 8.1g/cm³ |

| Tensile strength – Mpa | 760min. | 550min. | 965min | 650min. |

| Brinell hardness (HB) | ≤220 | ≤195 | ≤363 | ≤220 |

| Elongation % | 30 min. | 30min. | 30 min. | 30 min. |

| Melting Range,℃ | 1290-1350℃ | 1370-1425 ℃ | 1260-1340 ℃ | 1320-1370℃ |

Equivalent Grades of Inconel Plates

Explore equivalent grades of Inconel sheets and plates across global standards like UNS, WNR, BS, GOST, JIS, EN, and AFNOR, enabling accurate material selection for diverse engineering applications.

| STANDARD | WERKSTOFF NR. | UNS | BS | GOST | OR | JIS | EN | AFNOR |

| Inconel 625 | 2.4856 | N06625 | NA 21 | ХН75МБТЮ | ЭИ602 | NCF 625 | NiCr22Mo9Nb | NC22DNB4M |

| Inconel 600 | 2.4816 | N06600 | NA 13 | МНЖМц 28-2,5-1,5 | ЭИ868 | NCF 600 | NiCr15Fe | NC15FE11M |

| Inconel 718 | 2.4668 | N07718 | – | – | – | – | – | – |

| Incoloy 825 | 2.4858 | N08825 | NA 16 | ЭП703 | XH38BT | NCF 825 | NiCr21Mo | NFE30C20DUM |

| Incoloy 800 | 1.4876 | N08800 | NA 15 | ЭИ670 | XH32T | NCF 800 | X10NiCrAlTi32-20 | Z8NC32-21 |

Thickness Measurement for Inconel Sheets

Find detailed specifications of Inconel sheet metal, including available thicknesses and maximum widths in both millimeters and inches, to match precise industrial and fabrication needs.

| Thickness | Maximum Width | ||

| in mm | in inch | in mm | in inch |

| 0.635 – 0.08 | 0.025 – 0.003 | 444.5 to 431.8 | 17.5 (rolled edge) to 17.0(slit edge) |

| 0.0099 – 0.002 | 0.00039 – 0.00008 | 107.95 to 101.6 | 4.25 (rolled edge) to 4.0(slit edge) |

| 0.025 – 0.01 | 0.0009 – 0.0004 | 393.7 to 381.0 | 15.5 (rolled edge) to 15.0 (slit edge) |

| 0.079 – 0.0254 | 0.0029 – 0.001 | 419.1 to 406.4 | 16.5 (rolled edge) to 16.0(slit edge) |

Weight Chart of Inconel Plates

Get the information on weight chart for Inconel plates and sheets by thickness with calculated weights for widths of 1200mm, 1500mm, 1800mm & 2400mm aiding accurate material planning and procurement.

| Thickness of Plate(mm) | Weight (kg/m) | kg/meter(width 1200mm) | kg/meter(width 1500mm) | kg/meter(width 1800mm) | kg/meter(width 2400mm) |

| 4 | 31.4 | 37.7 | 47.1 | 56.5 | 75.4 |

| 3 | 23.55 | 28.3 | 35.3 | 42.4 | 56.5 |

| 5 | 39.25 | 47.1 | 58.9 | 70.7 | 94.2 |

| 8 | 62.8 | 75.4 | 94.2 | 113 | 150.7 |

| 6 | 47.1 | 56.5 | 70.7 | 84.8 | 113 |

| 10 | 78.5 | 94 | 118 | 141 | 188 |

| 16 | 125.6 | 151 | 188 | 226 | 301 |

| 12 | 94.2 | 113 | 141 | 170 | 226 |

| 22 | 172.7 | 207 | 259 | 311 | 415 |

| 20 | 157 | 188 | 236 | 283 | 377 |

| 25 | 196.25 | 236 | 294 | 353 | 471 |

| 32 | 251.2 | 301 | 377 | 452 | 603 |

| 28 | 219.8 | 264 | 330 | 396 | 528 |

| 36 | 282.6 | 339 | 424 | 509 | 678 |

| 45 | 353.25 | 424 | 530 | 636 | 848 |

| 40 | 314 | 377 | 471 | 565 | 754 |

| 50 | 392.5 | 471 | 589 | 707 | 942 |

| 60 | 471 | 565 | 707 | 848 | 1130 |

| 55 | 431.75 | 518 | 648 | 777 | 1036 |

| 65 | 510 | 612 | 765 | 918 | 1224 |

| 90 | 706.5 | 848 | 1060 | 1272 | 1696 |

| 75 | 588.75 | 707 | 883 | 1060 | 1413 |

| 70 | 549.5 | 659 | 824 | 989 | 1319 |

| 80 | 628 | 754 | 942 | 1130 | 1507 |

| 100 | 785 | 942 | 1178 | 1413 | 1884 |

Physical Properties of Inconel Sheet Metal

Explore key physical properties of Inconel sheet metal, including density and melting range, to ensure optimal performance in high-temperature and corrosion-resistant applications.

| Properties | Alloy 600 | Alloy 601 | Alloy 625 | Nickel alloy 718 |

| Density | 8.4 g/cm³ | 8.1g/cm³ | 8.4 g/cm³ | 8.2 g/cm³ |

| Melting Range,℃ | 1370-1425 ℃ | 1320-1370℃ | 1290-1350℃ | 1260-1340 ℃ |

Size Chart for Inconel Plates & Sheets

View the size chart for Inconel plates and sheets, detailing available dimensions to help you select the right size for your specific engineering or fabrication project.

| SIZE | Inconel Alloy PLATE/ SHEET | SIZE |

| .125″ | Inconel Sheet | 3.18mm |

| .134″ | Inconel Sheet | 3.40mm |

| .156″ | Inconel Sheet | 3.96mm |

| .187″ | Inconel Sheet | 4.75mm |

| .250″ | Inconel Sheet | 6.35mm |

| .312″ | Inconel Sheet | 7.92mm |

| .375″ | Inconel Sheet | 9.53mm |

| .500″ | Inconel Sheet | 12.7mm |

| .625″ | Inconel Sheet | 15.9mm |

| .750″ | Inconel Sheet | 19.1mm |

| .875″ | Inconel Sheet | 22.2mm |

| 1″ | Inconel Sheet | 25.4mm |

| 1.125″ | Inconel Sheet | 28.6mm |

| 1.250″ | Inconel Sheet | 31.8mm |

| 1.500″ | Inconel Sheet | 38.1mm |

| 1.750″ | Inconel Sheet | 44.5mm |

| 2″ | Inconel Sheet | 50.8mm |

| 2.500″ | Inconel Sheet | 63.5mm |

| 3″ | Inconel Sheet | 76.2mm |

Application of Inconel Plates & Sheets

- Chemical processing

- Aerospace

- Nuclear reactors

- Cryogenic storage tanks

- fasteners, springs, mandrels

- Gas turbine engine parts

- Boilers, Calorifiers

- Columns, Dished Ends

- Filters, Flanges

- Heat exchangers, Pipelines

- Pressure vessels, tubing hangers, Valves etc.

Frequently Asked Questions About Inconel Plates & Sheets

What is an Inconel plate?

What is an Inconel sheet?

What is the price of an Inconel plate?

What is the thickness difference between Inconel sheet and plate?

Why is the Inconel sheet not magnetic?

Are Inconel plates suitable for high-temperature applications?

Related Products

- Inconel 600 Pipes & Tubes

- Inconel 600 Flanges

- Inconel 600 Round Bars & Wires

- Inconel 600 Plates & Sheets

- Inconel 600 Buttweld Fittings

- Inconel 625 Pipes & Tubes

- Inconel 625 Flanges

- Inconel 625 Round Bars & Wires

- Inconel 625 Plates & Sheets

- Inconel 625 Buttweld Fittings

- Inconel 600 Shims

- Inconel 625 Shims