Inconel Manufacturer & Supplier in India

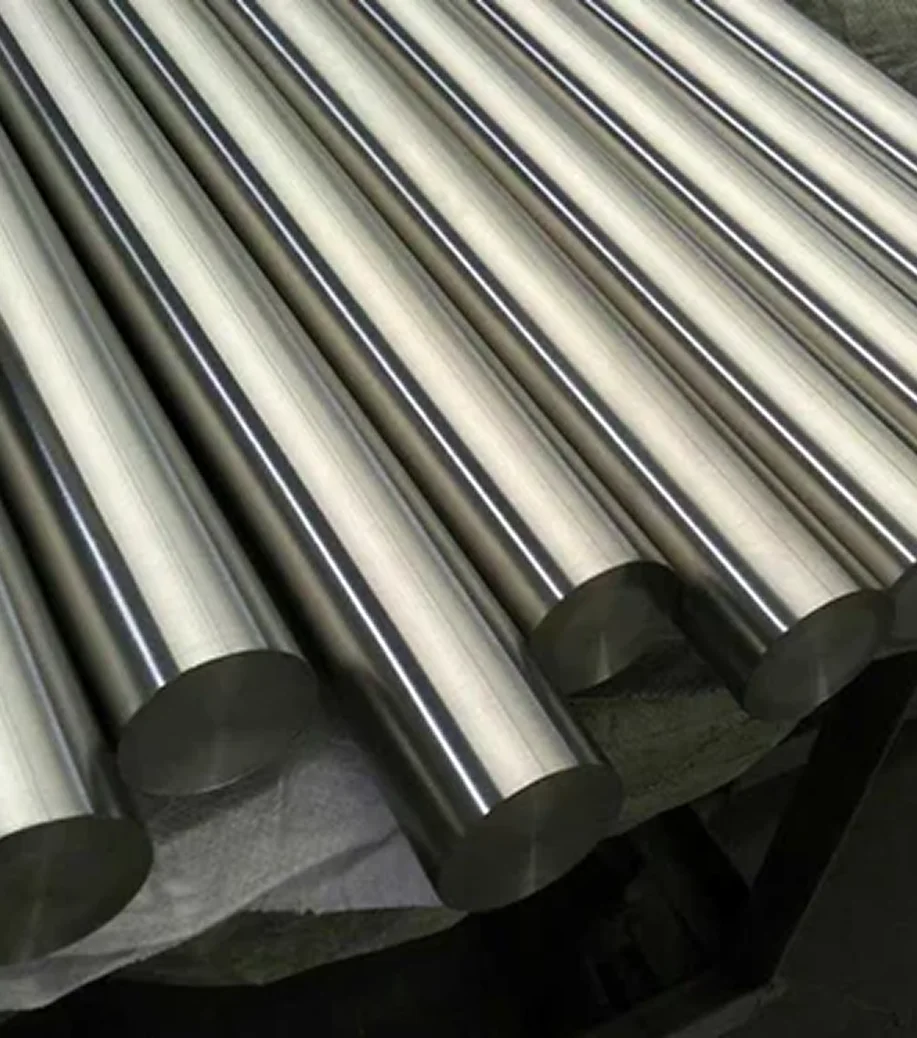

Kalpataru Piping Solutions is a trusted Inconel manufacturer and supplier in India, delivering premium quality Inconel material and components to global clients. As a leading name in the industry, we specialize in a wide range of Inconel products that are known for their durability, corrosion resistance, and performance in high-temperature environments. We supply a comprehensive range of Inconel alloys including Inconel 600, 625, 718, and 825 – available in various forms. Whether you require custom sizes or standard specifications, Kalpataru Piping Solutions offers tailor-made solutions to meet your exact project needs.

Our Inconel material is engineered to perform in demanding applications such as aerospace, chemical processing, marine, power generation, and heat treatment industries. Every product undergoes strict quality testing and complies with international standards to ensure top-tier performance and reliability. As a customer-centric Inconel supplier, we are committed to on-time delivery, competitive pricing, and exceptional service. Kalpataru Piping Solutions has the inventory and infrastructure to deliver high quality products and maintain consistency in the Inconel manufacturing sector.

Contact us today to learn more about our complete range of Inconel alloys and how we can support your project requirements with reliable and efficient solutions.

Types of Inconel Material

What is an Inconel Alloy?

Inconel Material Specification

|

Inconel |

Specifications |

|

Inconel Grades |

Alloys 600, 601,625,718, 800, 800H/HT,825 |

|

Size |

15mm NB to 150mm NB (1/2” to 6”), 7″ (193.7mm OD to 20″ 508mm OD) |

|

Form |

Round, Square, Rectangular, Coil, U Tube, |

|

Length |

As per customer’s requirement (Maximum upto 7 meters) |

|

End |

Plain End, Bevelled End |

|

Type |

Seamless / ERW / Welded |

|

OD Range |

1.250″ – 6.000″ (30-150mm) |

Inconel Composition: Key Elements in Alloys

|

Inconel Grade |

C |

Mg |

S |

P |

Cr |

Si |

Mo |

Ni |

Co |

Cu |

Al |

Ti |

Ni |

I |

B |

|

Inconel 600 |

0.15 |

1.00 |

0.015 |

– |

14.0–17.0 |

0.50 |

– |

– |

– |

0.50 |

– |

– |

72.0max |

6.0–10.0 |

– |

|

Inconel 625 |

0.10 |

0.50 |

0.015 |

0.015 |

20.0–23.0 |

0.50 |

8.0–10.0 |

3.15–4.15 |

1.00 |

– |

0.40 |

0.40 |

58.0max |

5.00max |

– |

|

Inconel 718 |

0.08 |

0.35 |

0.015 |

0.015 |

17.0–21.0 |

0.35 |

2.8–3.3 |

4.75–5.5 |

1.00 |

0.2–0.8 |

0.65–1.15 |

0.30 |

50.0–55.0 |

balance |

0.006 |

|

Inconel 800 |

0.10 |

1.5 |

0.015 |

– |

19.0-23.0 |

1.0 |

– |

30.0-35.0 |

– |

– |

0.15-0.60 |

0.15-0.60 |

30.0-35.0 |

39.5 Min |

– |

|

Inconel 825 |

0.05 |

1.0 |

0.03 |

– |

19.5-23.5 |

0.5 |

2.5-3.5 |

38.0-46.0 |

– |

1.5-3.0 |

0.2 Max |

0.6-1.2 |

38.0-46.0 |

22.0 Min |

– |

Inconel Alloy Properties: Mechanical Composition

|

Inconel Grade |

Tensile Strength |

Yield Strength (0.2%Offset) |

Density |

Melting Point |

Elongation |

|

Inconel 600 |

Psi – 95,000 , MPa – 655 |

Psi – 45,000 , MPa – 310 |

8.47 g/cm3 |

1413 °C (2580 °F) |

0.4 |

|

Inconel 625 |

Psi – 135,000 , MPa – 930 |

Psi – 75,000 , MPa – 517 |

8.4 g/cm3 |

1350 °C (2460 °F) |

0.425 |

|

Inconel 718 |

Psi – 135,000 , MPa – 930 |

Psi – 70,000 , MPa – 482 |

8.2 g/cm3 |

1350 °C (2460 °F) |

0.45 |

|

Inconel 800 |

Psi – 85,000, MPa – 586 |

Psi – 35,000, MPa – 241 |

7.94 g/cm³ |

1385–1425 °C (2525–2600 °F) |

0.30 (30%) |

|

Inconel 825 |

Psi – 85,000, MPa – 586 |

Psi – 30,000, MPa – 207 |

8.14 g/cm³ |

1370–1400 °C (2500–2550 °F) |

0.30 (30%) |

Inconel Tensile Strength

|

Physical Properties |

Metric |

English |

|

|

Alloy 600 |

Density |

8.47 g/cc |

0.306 lb/in³ |

|

Alloy 625 |

Density |

8.44 g/cc |

0.305 lb/in³ |

|

Alloy 718 |

Density |

8.19 |

0.296 lb/in3 (8.192 g/cm3) |

|

Alloy 800 |

Density |

7.94 g/cm³ |

0.287 lb/in³ |

|

Alloy 825 |

Density |

8.14 g/cm³ |

0.294 lb/in³ |

Inconel Melting Point

Understand the melting range of different Inconel alloys in both Celsius and Fahrenheit—crucial for high-temperature industrial applications.

|

Inconel Alloy |

Melting Range (°C) |

Melting Range (°F) |

|

Alloy 718 |

1370-1430°C |

2500-2600°F |

|

Alloy 600 |

1354 – 1413 °C |

2470 – 2580 °F |

|

Alloy 625 |

1280 – 1350°C |

2350 – 2460°F |

|

Alloy 800 |

1385 – 1425 °C |

2525 – 2600 °F |

|

Alloy 825 |

1370 – 1400 °C |

2500 – 2550 °F |

Inconel Thermal Conductivity

Inconel alloys offer low thermal conductivity compared to standard metals, making them ideal for high-temperature applications. Their ability to retain strength and resist heat transfer under extreme conditions to be used in aerospace, turbine engines & heat exchangers.

|

Alloy 600 Thermal Conductivity |

Metric: 14.9 W/m-K |

|

Alloy 625 Thermal Conductivity |

Metric: 9.8 W/m-K English: 68 BTU-in/hr-ft²-°F |

Inconel Cost: Factors Affecting Inconel Pricing

The cost of inconel may vary significantly based on multiple factors, as it is a high-performance nickel-chromium alloy designed for extreme environments. Inconel pricing is generally higher compared to standard stainless steels or carbon steels due to its exceptional resistance to heat, corrosion & oxidation.

Overall cost of an Inconel alloy can be calculate by considering below factors, including:

- Grade Selection (e.g., Inconel 600, 625, 718, etc.)

- Product Form (sheet, pipe, bar, fittings, flanges, etc.)

- Size, Thickness & Customization Requirements

- Material Standards & Certifications

- Quantity Ordered & Delivery Timeline

For the most accurate & up-to-date Inconel pricing, please connect with our team to request a quote based on your specific project requirements.

Application of Inconel Alloy

- Chemical Processing

- Marine Industry

- Nuclear Reactors

- Oil & Gas Industry

- Power Generation

- Electronics & Instrumentation

- Automotive Sector

- Aerospace Industry

Frequently Asked Questions About Inconel Alloy

What is Inconel alloy material?

Inconel is consists of nickel-chromium superalloys known for their excellent resistance to heat, corrosion & oxidation to be used for extreme environments.

What are the main applications of Inconel alloy?

Inconel alloy is widely used in aerospace, marine, chemical processing, power generation, oil & gas industries due to its strength & resistance at high temperatures.

Which Inconel grades are available?

Common grades include Inconel 600, 625, 718, 800, and 825. Each grade offers different mechanical and chemical properties for specific applications.

How is Inconel material different from stainless steel?

Comparing with stainless steel, Inconel alloy offers superior strength and corrosion resistance at elevated temperatures and under extreme environmental conditions.

Is Inconel alloy material weldable?

Yes, most Inconel alloys can be welded using appropriate techniques and filler materials, though specialized welding procedures are often recommended.

What forms of Inconel material are available?

We supply Inconel in various forms including sheets, plates, pipes, tubes, fittings, fasteners, flanges & wires.

Can Inconel alloy be customized to specific sizes or standards?

Yes, Inconel materials can be supplied in custom dimensions and according to international standards such as ASTM, ASME, and DIN.

How can I get a quote for Inconel alloy products?

You can contact our sales team with your specific material grade, size, quantity, and delivery location for a quick and competitive quote.

Explorer Other Inconel Products We Offer

- Inconel 600 Perforated Sheets

- Inconel 600 Forged Fittings

- Inconel 600 Olets

- Inconel 600 Fasteners

- Inconel 600 Compression Tube Fittings

- Inconel 600 Pipes & Tubes

- Inconel 600 Flanges

- Inconel 600 Round Bars & Wires

- Inconel 600 Plates & Sheets

- Inconel 600 Buttweld Fittings

- Inconel 600 Instrumentation Valves

- Inconel 600 Filler Wire

- Inconel 600 Long Radius Bends

- Inconel 600 Pipes Spools

- Inconel 600 Shims

- Inconel 600 Wiremesh

Cities We deliver:

Bhopal, Lahore, Milan, Hyderabad, Pune, Vadodara, Pimpri-Chinchwad, Aberdeen, Howrah, Jeddah, Riyadh, Bogota, Petaling Jaya, Dallas, Lagos, Nagpur, Houston, Brisbane, Busan, Karachi, Coimbatore, Seoul, Caracas, Atyrau, Perth, Haryana, Bengaluru, Jaipur, Al Jubail, Kuwait City, Al Khobar, Sydney, Ranchi, Chiyoda, Noida, Chandigarh, Secunderabad, Ahvaz, Port-of-Spain, Singapore, Gurgaon, Rajkot, Rio de Janeiro, Abu Dhabi, Hong Kong, Surat, Sharjah, Hanoi, London, Muscat, Jakarta, Navi Mumbai, Istanbul, Kolkata, Cairo, Mumbai, Santiago, Montreal, Faridabad, Vung Tau, Bangkok, Ankara, Ahmedabad, Granada, Melbourne, Tehran, Visakhapatnam, New Delhi, Los Angeles, Ho Chi Minh City, Edmonton, La Victoria, Baroda, Thane, Nashik, Kuala Lumpur, Moscow, Ernakulam, Courbevoie, Calgary, Geoje-si, Indore, New York, Mexico City, Gimhae-si, Ludhiana, Kanpur, Ulsan, Thiruvananthapuram, Manama, Doha, Chennai, Madrid, Jamshedpur, Algiers, Dammam

Countries We Deliver:

Iran, Venezuela, Saudi Arabia, Slovakia, Romania, Zimbabwe, Spain, Kazakhstan, Canada, Nigeria, Bulgaria, Afghanistan, Thailand, Bangladesh, Poland, United Kingdom, Bahrain, Jordan, Lithuania, Malaysia, France, Nigeria, Japan, Oman, Lebanon, Germany, Croatia, Australia, Puerto Rico, South Korea, Hungary, United States, Bhutan, Mexico, Mexico, Yemen, Singapore, New Zealand, Ecuador, Gabon, Qatar, Denmark, Iran, Netherlands, Norway, Sri Lanka, Belgium, Libya, Kuwait, Pakistan, Gambia, Sweden, Azerbaijan, Argentina, Chile, Ghana, United Arab Emirates, Finland, Nepal, Trinidad andamp; Tobago,Tunisia, Kenya, Peru, Austria, Russia, Ukraine, Italy, Belarus, Bolivia, Serbia, Poland, Mongolia, Turkey, Czech Republic, South Africa, Angola, India, Vietnam, Indonesia, Tibet, Ireland, Costa Rica, Greece, Colombia, Namibia, Iraq, Estonia, Israel, Macau, Philippines, Brazil, Switzerland, Algeria, Morocco, Chile, Portugal, Egypt, Taiwan, China, Hong Kong.