API 6A Type 6BX 3000 PSI Blind Flanges

Table of Content

- API 6A Type 6BX 3000 PSI Blind Flanges Manufacturer

- API 6A Type 6BX 3000 PSI Blind and Weld Neck Flanges Dimensions

- API 6A Type 6BX 3000 PSI Blind/Weld Neck Flanges Pressure Rating

- API 6A Type 6BX 3000 PSI Blind/Weld Neck Flanges Grades

- API 6A Type 6BX 3000 PSI Blind/Weld Neck Flanges Specification

- Advantages of API 6A Type 6BX 3000 PSI Blind/Weld Neck Flanges

- Applications of API 6A Type 6BX 3000 PSI Blind/Weld Neck Flanges

- FAQS

API 6A TYPE 6B 3000 PSI Blind Flanges| API 6A 3000 PSI Stainless Steel Flange | API 6A 3000 PSI Steel Flange | API 6A 3000 PSI SS Flanges | API 6A Type 6BX 3000 PSI Blind Flanges| API 6A Type 6BX 3000 Flanges | API 6bx Flanges | API 6A Type 6Bx Flanges | API 6A TYPE 6B 3000 PSI Weld Neck Flanges

API 6A Type 6BX 3000 PSI Blind Flanges Manufacturer

As a leading manufacturer of high-pressure steel flanges, Kalpataru Piping specializes in API 6A Type 6BX 3000 PSI Blind Flanges. These forged flanges are essential for sealing the end of a piping system or pressure vessel openings to prevent flow.

The API 6A flange design is crucial for pressure testing the flow of liquids or gases through pipes or vessels. In addition, these API flanges facilitate easy access for maintenance or modifications inside the line. Our range of high-quality API 6BX flanges, available in ASME, ANSI, and DIN standards, is manufactured to meet the highest industry standards in India.

We are exporting API 6A flanges, including API adapter flanges, API blind flanges, and API Series B flanges, at competitive prices. We maintain an accurate stock of API 5L Grade B flanges, ensuring we can supply API flange material at the best price.

Our API 6A blind flanges are suitable for various applications, including pressure classes of 720 psi and 960 psi, following the API specifications with no changes to the ASA B16.5 Standard. These use the 300 lb. and 400 lb. flanges separately. The API 6A Type 6B and 6BX flanges are designed to perform in temperatures ranging from -75° F to 250° F.

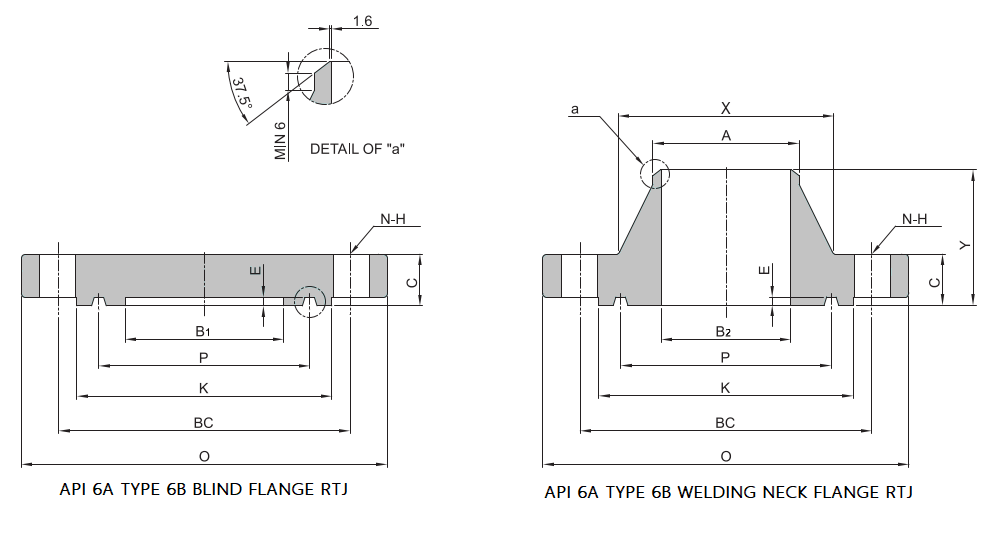

API 6A Type 6BX 3000 PSI Blind and Weld Neck Flanges Dimensions

| Size | B1 | O | C | K | P | E | X | BC | N | H | Y | A | B2 |

Ring Number R or RX |

| 2 1/16″ | 53.2 | 215 | 46.1 | 124 | 95.25 | 7.9 | 104.8 | 165.1 | 8 | 26 | 109.6 | 60.3 | 50.0 | 24 |

| 2 9/16″ | 65.9 | 245 | 49.3 | 137 | 107.95 | 7.9 | 123.8 | 190.5 | 8 | 29 | 112.7 | 73.0 | 59.7 | 27 |

| 3 1/8″ | 81.8 | 240 | 46.1 | 156 | 123.83 | 7.9 | 127.0 | 190.5 | 8 | 26 | 109.5 | 88.9 | 74.4 | 31 |

| 4 1/16″ | 108.7 | 290 | 52.4 | 181 | 149.23 | 7.9 | 158.8 | 235.0 | 8 | 32 | 122.2 | 114.3 | 98.0 | 37 |

| 5 1/8″ | 131.0 | 350 | 58.8 | 216 | 180.98 | 7.9 | 190.5 | 279.4 | 8 | 35 | 134.9 | 141.3 | 122.9 | 41 |

| 7 1/16″ | 181.0 | 380 | 63.5 | 241 | 211.15 | 7.9 | 235 | 317.5 | 12 | 32 | 147.6 | 168.3 | 147.1 | 45 |

| 9″ | 229.4 | 470 | 71.5 | 308 | 269.88 | 7.9 | 298.5 | 393.7 | 12 | 39 | 169.9 | 219.1 | 189.7 | 49 |

| 11″ | 280.2 | 545 | 77.8 | 362 | 323.85 | 7.9 | 368.3 | 469.9 | 16 | 39 | 192.1 | 273 | 237.2 | 53 |

| 13 5/8 “ | 346.9 | 610 | 87.4 | 419 | 381.00 | 7.9 | 419.1 | 533.4 | 20 | 39 | – | – | – | 57 |

| 16 3/4″ | 426.2 | 705 | 100.1 | 524 | 469.90 | 11.2 | 508.0 | 616.0 | 20 | 45 | – | – | – | 66 |

| 20 3/4″ | 527.8 | 855 | 120.7 | 648 | 584.20 | 12.7 | 622.9 | 749.3 | 20 | 54 | – | – | – | 74 |

API 6A Type 6BX 3000 PSI Blind/Weld Neck Flanges Pressure Rating

| Nominal Size (inches) | Pressure Rating (PSI) | Outside Diameter (inches) | Number of Bolts | Bolt Circle Diameter (inches) | Bolt Hole Diameter (inches) | Minimum Thickness (inches) |

| 1 13/16 | 3000 | 7.06 | 4 | 5.75 | 0.81 | 1.88 |

| 2 1/16 | 3000 | 7.88 | 4 | 6.50 | 0.81 | 2.00 |

| 2 9/16 | 3000 | 8.75 | 4 | 7.38 | 0.81 | 2.25 |

| 3 1/8 | 3000 | 9.75 | 4 | 8.38 | 0.88 | 2.50 |

| 4 1/16 | 3000 | 11.50 | 4 | 9.88 | 0.88 | 2.75 |

| 5 1/8 | 3000 | 13.75 | 4 | 12.00 | 0.88 | 3.13 |

| 7 1/16 | 3000 | 17.75 | 8 | 15.00 | 1.00 | 3.88 |

| 9 | 3000 | 21.75 | 8 | 18.38 | 1.00 | 4.75 |

API 6A Type 6BX 3000 PSI Blind/Weld Neck Flanges Grades

Below is a table detailing the grades available for API 6A Type 6BX 3000 PSI Blind & Weld Neck Flanges, along with their material composition and suitable applications.

| Grade | Material Composition | Applications |

| AA | Carbon Steel | Suitable for general applications where low-temperature service is required. |

| BB | Low Alloy Steel | Ideal for moderate temperature and pressure conditions, often used in wellheads and manifolds. |

| CC | Corrosion-Resistant Alloy (CRA) | Used in environments where corrosion resistance is critical, such as offshore and subsea operations. |

| DD | Stainless Steel | Suitable for high-temperature and high-pressure environments, commonly used in sour service conditions. |

| EE | Nickel Alloy | Used in extreme temperature and corrosive environments, offering superior resistance to cracking and pitting. |

| FF | Low-Temperature Carbon Steel | Designed for low-temperature applications, ensuring ductility and toughness under cold conditions. |

| HH | High Strength Low Alloy (HSLA) Steel | Ideal for high-pressure and high-stress applications, providing enhanced strength and durability. |

These grades ensure that API 6A Type 6BX 3000 PSI Blind & Weld Neck Flanges can meet diverse operational demands in various industries, including oil and gas, petrochemical, and marine applications.

API 6A Type 6BX 3000 PSI Blind/Weld Neck Flanges Specification

| Specification | Details |

| Standard | API 6A |

| Type | 6BX Blind Flange |

| Pressure Rating | 3000 PSI |

| Material | Carbon Steel, Stainless Steel, Alloy Steel |

| Size Range | 1 13/16″ to 21 1/4″ |

| Connection | Ring-Type Joint (RTJ) |

| Face Finish | Smooth Finish, Serrated Finish |

| Coating | Anti-corrosion Coating, as required |

| Dimensions | As per API 6A |

| Temperature Rating | -50°F to 350°F (depending on material) |

| Usage | Oil and Gas, Petrochemical, Offshore Drilling |

| Testing | Hydrostatic Test, Nondestructive Examination |

| Certification | API Monogram, Material Test Report (MTR) |

| Marking | As per API 6A requirements |

| Customization | Available upon request |

Advantages of API 6A Type 6BX 3000 PSI Blind/Weld Neck Flanges

- Leak Prevention:

These flanges effectively seal pipe or valve ends, preventing fluid or gas leaks and enhancing system safety. - Easy Maintenance:

Blind flanges can be quickly removed for inspection or repairs, ensuring the system remains in optimal condition. - Flexibility:

Available in various materials and configurations, they are adaptable for diverse applications, including oil, gas, petrochemical, and offshore drilling. - Cost-Effective:

More affordable than other flange types, blind flanges offer a cost-effective solution for many industrial uses.

Applications of API 6A Type 6BX 3000 PSI Blind/Weld Neck Flanges

API 6A Type 6BX 3000 PSI blind and weld neck flanges are essential for high-pressure applications across various industries:

- Oil & Gas: They cap off pipelines and valves, facilitating isolation for maintenance, pressure testing, or future expansions.

- Chemical Processing: Similar to oil and gas, blind flanges isolate sections for maintenance, cleaning, or process changes while maintaining system integrity.

- Power Generation: They play a crucial role in isolating sections of piping for maintenance or equipment upgrades within power plants.

- Food & Beverage: Blind flanges ensure hygiene by sealing off sections for cleaning or equipment changes within food and beverage processing facilities.

- Pharmaceutical: Maintaining sterility is paramount. Blind flanges enable isolation for cleaning or equipment maintenance in pharmaceutical production lines.

FAQs

What is the difference between API 6B and 6BX flanges?

API 6A flanges come in 6B and 6BX types. 6B handles up to 5,000 PSI, while 6BX tackles higher pressures (10,000 PSI to 20,000 PSI). The key difference is pressure rating.

What are API spec 6A flanges?

API 6A flanges are high-pressure flanges specifically designed for the oil and gas industry, meeting stricter standards than general-purpose flanges.

What is the pressure rating for API 3000 flange?

API flange designations don’t directly indicate pressure rating. However, API 6A flanges with “3000” in their name (like API 6A Type 6BX 3000 PSI) typically have a pressure rating of 3,000 PSI.

What is API 6A Type 6B?

API 6A Type 6B is a high-pressure flange specifically designed for the oil and gas industry, suitable for applications up to 5,000 PSI.