API 6A Type 6BX 10000 PSI Blind & Weld Neck Flanges

API 6A TYPE 6B 10000 PSI Blind Flanges | API 10000 PSI Blind Flange | API 6A 10000 PSI Stainless Steel Flange | API 6A Type 6BX 10000 PSI Blind Flanges | API 6A Type 6BX 10000 Flanges | API 6A TYPE 6B 10000 PSI Weld Neck Flanges | API 6A 10000 PSI WNRF Flange | API 6A 10000 PSI Weld Neck Flange

API 6A Flanges Manufacturer | API 10000 Blind & Weld Neck Flanges Supplier

Kalpataru Piping Solutions is a top manufacturer and supplier of high-quality API 10000 flanges. The American Petroleum Institute (API) sets standards for API 6A flanges, divided into PSL 1 and PSL 2 levels. PSL 2 flanges undergo stricter testing, ensuring maximum reliability for demanding applications.

Our API 10000 psi flanges meet strict parameters for qualification, temperature, design, and testing. These flanges ensure unmatched quality and safety through rigorous inspections. We serve industries like petroleum, petrochemical, natural gas, and offshore drilling. As a trusted API 6A Type 6BX Flanges manufacturer, we use top-grade materials such as carbon steel, alloy steel, stainless steel, duplex, super duplex stainless steel, Inconel, and Hastelloy. Our API 10000 flanges, heat-treated for strength, have a minimum yield of 75,000 psi, making them ideal for high-pressure applications.

Available in sizes from ½ inch to 24 inches, our API 6A flanges are ring-type joint flanges following API 6A standards. Whether you need API 6A Blind Flanges to close a pipeline or flanges for different pressure levels, we offer reliable, high-quality products at competitive prices. Contact us for your API 10000 flanges needs and experience top-notch manufacturing and services.

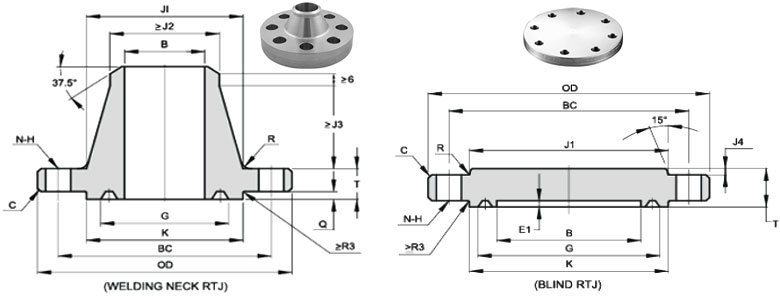

API 6A 10000 PSI Blind and Weld Neck Flanges Dimensions

| Sizes | O.D. | B | E1 | C | Q | K | T | G | J1 | J3 | J2 | J4 | BC | BX | R | N | H |

| 1 13/16″ | 185 | 46.8 | – | 3 | 5.56 | 105 | 42.1 | 77.77 | 88.9 | 48.5 | 65.1 | – | 146.1 | 151 | 10 | 8 | 23 |

| 2 1/16″ | 200 | 53.2 | – | 3 | 5.95 | 111 | 44.1 | 86.23 | 100 | 51.6 | 74.7 | – | 158.8 | 152 | 10 | 8 | 23 |

| 2 9/16″ | 230 | 65.9 | – | 3 | 6.75 | 132 | 51.2 | 102.77 | 120.7 | 57.2 | 92.1 | – | 184.2 | 153 | 10 | 8 | 26 |

| 3 1/16″ | 270 | 78.6 | – | 3 | 7.54 | 152 | 58.4 | 119 | 142.1 | 63.5 | 110.2 | – | 215.9 | 154 | 10 | 8 | 29 |

| 4 1/16″ | 315 | 104 | – | 3 | 8.33 | 185 | 70.3 | 150.62 | 182.6 | 73.1 | 146.1 | – | 258.8 | 155 | 10 | 8 | 32 |

| 5 1/8″ | 360 | 131 | 9.5 | 3 | 9.53 | 221 | 79.4 | 176.66 | 223.8 | 81 | 182.6 | 6.4 | 300 | 169 | 10 | 12 | 32 |

| 7 1/16″ | 480 | 180.2 | 11.1 | 6 | 11.11 | 302 | 103.2 | 241.83 | 301.6 | 95.3 | 254 | 9.7 | 403.2 | 156 | 16 | 12 | 42 |

| 9 “ | 550 | 229.4 | 12.7 | 6 | 12.7 | 359 | 123.9 | 299.06 | 374.7 | 93.7 | 327.1 | 9.7 | 476.3 | 157 | 16 | 16 | 42 |

| 11″ | 655 | 280.2 | 14.3 | 6 | 14.29 | 429 | 141.3 | 357.23 | 450.9 | 103.2 | 400.1 | 14.2 | 565.2 | 158 | 16 | 16 | 48 |

| 13 5/8″ | 770 | 346.9 | 15.9 | 6 | 15.88 | 518 | 168.3 | 432.64 | 552.5 | 114.3 | 495.3 | 17.5 | 673.1 | 159 | 16 | 20 | 51 |

API 6A Type 6BX 10000 Blind & Weld Neck Flanges Pressure Rating

| NPS | Working Pressure Of API Flanges In (PSI) | Outside Diameter For (O.D.) | No. of (B.H.) Bolt Holes | Diameter Of (B.H.) Bolt Holes | Bolts Length | API Flanges Ring Gasket |

| 1-13/16″ | 10,000 | 7-3/8″ | 8 | 3/4″ | 5-1/4″ | BX-151 |

| 1-13/16″ | 15,000 | 8-3/16″ | 8 | 7/8″ | 6″ | BX-151 |

| 1-13/16″ | 20,000 | 10-1/8″ | 8 | 1″ | 7-3/4″ | BX-151 |

| 2-1/16″ | 2,000 | 6-1/2″ | 8 | 5/8″ | 5/8″ | R-23 |

| 2-1/16″ | 3,000/5,000 | 8-1/2″ | 8 | 7/8″ | 7/8″ | R-24 |

| 2-1/16″ | 10,000 | 7-7/8″ | 8 | 3/4″ | 3/4″ | BX-152 |

| 2-1/16″ | 15,000 | 8-3/4″ | 8 | 7/8″ | 7/8″ | BX-152 |

| 2-1/16″ | 20,000 | 11-5/16″ | 8 | 1-1/8″ | 1-1/8″ | BX-152 |

| 2-9/16″ | 2,000 | 7-1/2″ | 8 | 3/4″ | 5-1/4″ | R-26 |

| 2-9/16″ | 3,000/5,000 | 9-5/8″ | 8 | 1″ | 7″ | R-27 |

| 2-9/16″ | 10,000 | 9-1/8″ | 8 | 7/8″ | 6-1/4″ | BX-153 |

| 2-9/16″ | 15,000 | 10″ | 8 | 1″ | 7″ | BX-153 |

| 2-9/16″ | 20,000 | 12-13/16″ | 8 | 1-1/4″ | 9-1/2″ | BX-153 |

| 3-1/8″ | 2,000 | 8-1/4″ | 8 | 3/4″ | 5-1/2″ | R-31 |

| 3-1/8″ | 3,000 | 9-1/2″ | 8 | 7/8″ | 6-1/4″ | R-31 |

| 3-1/8″ | 5,000 | 10-1/2″ | 8 | 1-1/8″ | 7-3/4″ | R-35 |

| 3-1/16″ | 10,000 | 10-5/8″ | 8 | 1″ | 7-1/4″ | BX-154 |

| 3-1/16″ | 15,000 | 11-5/16″ | 8 | 1-1/8″ | 8″ | BX-154 |

| 3-1/16″ | 20,000 | 14-1/16″ | 8 | 1-3/8″ | 10-3/4″ | BX-154 |

| 4-1/16″ | 2,000 | 10-3/4″ | 8 | 7/8″ | 6-1/4″ | R-37 |

| 4-1/16″ | 3,000 | 11-1/2″ | 8 | 1-1/8″ | 7-1/2″ | R-37 |

| 4-1/16″ | 5,000 | 12-1/4″ | 8 | 1-1/8″ | 8-3/8″ | BX-155 |

| 4-1/16″ | 20,000 | 17-9/16″ | 8 | 1-3/4″ | 12-3/4″ | BX-155 |

| 5-1/8″ | 5,000 | 14-3/4″ | 8 | 1-1/2″ | 10-3/4″ | R-44 |

| 7-1/16″ | 2,000 | 14″ | 12 | 1″ | 7-1/2″ | R-45 |

| 7-1/16″ | 3,000 | 15″ | 12 | 1-1/8″ | 8-1/2″ | R-45 |

| 7-1/16″ | 5,000 | 15-1/2″ | 12 | 1-3/8″ | 11-1/4″ | R-46 |

| 7-1/16″ | 10,000 | 18-7/8″ | 12 | 1-1/2″ | 11-3/4″ | BX-156 |

| 7-1/16″ | 15,000 | 19-7/8″ | 16 | 1-1/2″ | 13″ | BX-156 |

| 7-1/16″ | 20,000 | 24-13/16″ | 16 | 2″ | 17-3/4″ | BX-156 |

| 9″ | 2,000 | 16-1/2″ | 12 | 1-1/8″ | 8-1/2″ | R-49 |

| 9″ | 3,000 | 18-1/2″ | 12 | 1-3/8″ | 9-1/2″ | R-49 |

| 9″ | 5,000″ | 19″ | 12 | 1-5/8″ | 12-1/2″ | R-50 |

| 9″ | 10,000 | 21-3/4″ | 16 | 1-1/2″ | 13-1/4″ | BX-157 |

| 9″ | 15,000 | 25-1/2″ | 16 | 1-7/8″ | 16″ | BX-157 |

| 11″ | 2,000 | 20″ | 16 | 1-1/4″ | 9-1/4″ | R-53 |

| 11″ | 3,000 | 21-1/2″ | 16 | 1-3/8″ | 10″ | R-53 |

| 11″ | 5,000 | 23″ | 12 | 1-7/8″ | 14-1/4″ | R-54 |

| 11″ | 10,000 | 25-3/4″ | 16 | 1-3/4″ | 15-3/8″ | BX-158 |

| 11″ | 15,000 | 32″ | 20 | 2″ | 19-1/2″ | BX-158 |

| 13-5/8″ | 2,000 | 22″ | 20 | 1-1/4″ | 9-1/2″ | R-57 |

| 13-5/8″ | 3,000 | 24″ | 20 | 1-3/8″ | 10-3/4″ | R-57 |

| 13-5/8″ | 5,000 | 26-1/2″ | 16 | 1-5/8″ | 12-3/4″ | BX-160 |

| 13-5/8″ | 10,000 | 30-1/4″ | 20 | 1-7/8″ | 17-3/4″ | BX-159 |

| 13-5/8″ | 15,000 | 34-7/8″ | 20 | 2-1/4″ | 21″ | BX-159 |

| 16-3/4″ | 2,000 | 27″ | 20 | 1-1/2″ | 10-3/4″ | R-65 |

| 16-3/4″ | 3,000 | 27-3/4″ | 20 | 1-5/8″ | 12-1/4″ | R-66 |

| 16-3/4″ | 5,000 | 30-3/8″ | 16 | 1-78″ | 14-3/4″ | BX-162 |

| 16-3/4″ | 10,000 | 34-5/16″ | 24 | 1-7/8″ | 17-3/4″ | BX-162 |

| 18-3/4″ | 5,000 | 35-5/8″ | 20 | 2″ | 18″ | BX-163 |

| 16-3/4″ | 10,000 | 40-15/16″ | 24 | 2-1/4″ | 23″ | BX-164 |

| 20-3/4″ | 3,000 | 33-3/4″ | 20 | 2″ | 15-1/4″ | R-74 |

| 21-1/4″ | 2,000 | 32″ | 24 | 1-5/8″ | 12-1/2″ | R-73 |

| 21-1/4″ | 5,000 | 39″ | 24 | 2″ | 19″ | BX-165 |

| 21-1/4″ | 10,000 | 45″ | 24 | 2-1/2″ | 24-3/4″ | BX-166 |

| 26-3/4″ | 2,000 | 41″ | 20 | 1-3/4″ | 14-1/4″ | BX-167 |

| 21-1/4″ | 3,000 | 43-3/8″ | 24 | 2″ | 17-1/2″ | BX-168 |

API 6A Type 6BX 10000 Blind & Weld Neck Flanges Measurement

- O For Outside Diameter of flange

- T For (Minimum) thread length

- Q For (Minimum) diameter of bolt circle

- Y For Length through hub

- R For Diameter of raised face

- X For Hub Diameter at base

- C For Thickness of flange

FAQs

What is a pressure rating of API 10000 psi flange ?

The pressure rating of an API 10000 psi flange is 10,000 pounds per square inch (psi).

What is an API 6BX flange?

A 6BX flange is a high-pressure ring-type joint (RTJ) flange designed according to API 6A standards which are used for high pressure applications.

What is PSL in API 6A?

PSL in API 6A stands for Product Specification Level, which indicates the level of technical requirements and quality assurance for manufacturing API 6A flanges. There are two levels: PSL 1 (basic quality) and PSL 2 (stricter quality and testing standards).