by kalpataru | Apr 2, 2021 | Blog

Steel was really concocted millennia prior, which originates before even the Gregorian Calendar by numerous centuries, yet current steel and its application in development at its most punctual stage were just executed after the Bessemer interaction was presented in 1865.

The innovation has since developed significantly, refining everything from the assembling measures themselves to creating super solid variations of carbon steel and chromium composite steel. Indeed, it’s a continuous interaction as you read this.

Today, development would halt, alongside endless different enterprises like auto, bundling and the tremendous electronic merchandise business, if steel creation endured in any capacity. Remaining consistent with the title however, we are simply going to investigate the part of steel in present day development and why it would for sure go to a jostling stop without the artificial combination. For all your steels needs Kalpataru piping is the place one should go to

Steel is the Single Most Important Metallic Component in Modern Construction

Except if structural specialists can see how to make steel builds and use them in different manners across various kinds of complex developments, they would essentially be unequipped for taking care of their work. In this manner, regardless of whether it is a Masters in Civil Engineering on the web program or a more customary full-time course, any affable designing course will acquaint understudies with the significance, uses, and utilization of steel in development, since it’s that significant.

The development business keeps on being the primary market for steel producers, and it’s not a direct result of the development radiates, bars, bases, and foundations all things considered. Most development hardware is additionally made essentially out of steel amalgams, without which, present-day development can’t continue.

The Future is in Metal, as Steel is Part of the Green Movement Now

Steel is one the most recyclable materials in development, which naturally makes it a piece of the green development, however there’s in reality more to it.

At one time, the manufacturing measures engaged with the steel used to burn-through a ton of energy, as well as delivering contaminated water and smoke into the climate. Today, notwithstanding, steel fabricating is incredibly energy-proficient and the spillover water and emanations are decontaminated to eliminate the poisons from them.

Shockingly, every steel business wasn’t able to take in the additional expenses related to following the green assembling measures at first, because of their foolish need for making quick benefits, rather than building a long haul, feasible industry.

The endeavors of the LEED Green Building Rating System have paid off, however, in light of the fact that green development, made with steel from production lines that train supportable assembling, is significantly more beneficial and for the most part expected by purchasers these days.

As development turns out to be increasingly more subject to steel, as opposed to wood, we can anticipate insignificant dependence on wood later on. This will additionally lessen the need to chop down as numerous trees for amble, and will, thus, make light a major part in easing back deforestation.

A Closer Look at How Exactly Steel is Used in Construction

We previously talked about the significance of steel and why it is so significant in development, and now the time has come to see how precisely is the combination utilized in the business.

Steel Frames and Prefabricated Steel

Have you at any point taken a gander at the One World Trade Center in New York City, or the Willis Tower in Chicago and considered how it could be that these inconceivably tall elevated structures are holding up?

Steel edges and cement is the response to that question, in spite of the fact that it’s just about a hilariously basic one, given the sort of designing wonder and complex executions of the speculations of physical science that were engaged with raising those high rises and holding them back from falling over!

By the by, steel edges and cement are the two fundamental materials which make it workable for the hypotheses of front line structural designing and engineering to be carried out effectively in such activities.

Not to neglect, construction of those steel outlines is the thing that permits them to be pre-built on the ground and afterward introduced as important, which would be much harder to do something else.

On the off chance that you truly need to comprehend the real science behind the cutting edge miracles of man, at that point you should examine design or structural designing, the two of which can be worthwhile profession alternatives. Regardless of whether you have some work at this moment and deficient chance to go for an all day course, you ought to consider getting a Masters in structural designing on the web, in light of the fact that the normal yearly bundle isn’t anything to laugh at! Plus, you will make structures that will stand tall, even long after you are no more.

Steel Buildings

There has been a new flood of fame for unadulterated steel structures, particularly in the modern area, because of their capacity to withstand cruel climate conditions, extraordinary protection, long haul solidness and furthermore in view of the fact that it is so natural to supplant those steel boards that pre-created steel structures are made out of.

These structures can likewise be uniquely designed to suit the particular need which it will serve for the customer. Maybe one of the essential reasons why they are so famous is on the grounds that such a development can be raised in only a couple days or something like that, which saves important time for organizations.

Steel Roofing

Steel material has the very benefit that steel structures have, yet dissimilar to steel structures, which are fundamentally (however not solely) utilized in the business area for warehousing and such, steel rooftops are currently habitually being utilized in private structures too.

They last much more, improve the structure’s protection, and are frequently viewed as a more tasteful decision. All the more critically for those of us that live in storm-inclined states, they are not as simple to blow away and they don’t burst into flames in any event, when hit by lightning or a close-by fierce blaze. As the steel fabricating industry keeps on delivering more grounded, more strong, and harmless to the ecosystem items, the utilization of steel will just increment with time, ultimately supplanting a lot of different materials as of now being utilized in development, to assemble a superior tomorrow for our people in the future.

by kalpataru | Apr 2, 2021 | Blog

A house isn’t just where we invested the greater part of the energy with family, gain experiences and unwind. It’s a huge venture and a potential asset for future assets. It is a spot that you can call your roof, and that is a need on the off chance that there is a danger outside. Yet, for it to be feasible, it must be made of the most strong materials and with the best instruments.

The development business utilizes an assortment of building materials for various parts of a home form. Draftsmen talk with primary architects on the heap bearing abilities of the materials with which they plan, and the most well-known materials are solid, steel, wood, workmanship, and stone. Each has distinctive strength, weight, and toughness, which makes it appropriate for different employments. There are public principles and testing strategies that oversee the utilization of building materials in the development business, so they can be depended on for giving primary honesty. Designers likewise pick materials dependent on cost and style.

Building materials are generally arranged into two sources: normal and synthetic. Materials, for example, stone and wood are normal, and solid, workmanship, and steel are synthetic. However, both should be arranged or treated before they’re utilized in the building. Here is a rundown of building materials that are usually utilized in development.

Practical development likewise mulls over a material’s suitability for the environment in which it is utilized. A few materials hold up well in parched, cool conditions however debase in muggy, hot zones. Debasement and substitution recurrence need to factor into a thing’s by and large eco-invitingness.

Various eco-accommodating structure materials have arisen in the commercial center to lessen the ecological effect of building development and tasks. Yet, recognizing the world’s most eco-accommodating structure materials can be somewhat precarious on the grounds that various individuals have various meanings of supportability.

When hoping to assemble your home, you need to employ the best group to embrace it. Ensure that they have every one of the most recent devices within reach to deliberately deal with the development. A couple of them can be a waterjet slicing machine to correctly cut into solid materials, a protected concrete mixer, few utilities penetrate to a great extent, and an estimating tape and chalk. However, the viewpoint that you need to settle on will be the determination of materials to maintain your home for it to be solid and of worth, some of which are the accompanying.

Concrete

At the point when you need an alternative that gets the job done both strength and cost-viability, cement can be your most ideal decision to build a house. Concrete is a combination of sand and stone that is joined with a blend of concrete and water to shape in molds. This blend can be applied to steel bars and different materials to build dividers safely. Concrete is a material that, when consolidated judiciously with different components, makes for a strong development base and is additionally reasonable. A pre-focused on cement can be a superior alternative for a sturdy home. You can have your dividers and the establishment of your home developed with this material.

Steel

However, the strongest material to withstand any structure is steel. Not Only is steel the most sturdy however it is additionally a naturally protected development material to use in any structure. It doesn’t jeopardize the environment as cutting trees do and it is additionally a material that can be molded and moved in any capacity for quicker development. A steel structure for your home can make it protected in the event that catastrophic events strike. It can likewise be a source to save energy in your home as a steel structure is energy-effective. Its lone con is that it very well maybe a little weighty on your pocket. Kalpataru piping has got your steel needs covered!

Block

Warmed blocks can compensate for a strong structure material for your house. That which used to be an old structure strategy can give your home a steady construction while giving it a vintage look. Block has been embedded into structures before and as we see them remaining to date, this material is intended to be extreme for your home. Nonetheless, they need a solid base to maintain them to make them protected in cruel climate conditions.

Wood

This material is generally utilized inside homes yet less outwardly. It tends to be because of its property of absorbing dampness and inclination to harm with creepy crawlies or fire. In any case, it very well may be a tough material whenever it is absorbed by synthetic compounds that secure it. You can have wood used to build your home by having it kept up and away from hurting substances. It can make for a comfortable-looking home and adds a decent warm inclination. Your unfinished plumbing space can be made of wood to save money on costs. This material is additionally simple to cut and place.

by kalpataru | Mar 24, 2021 | Blog

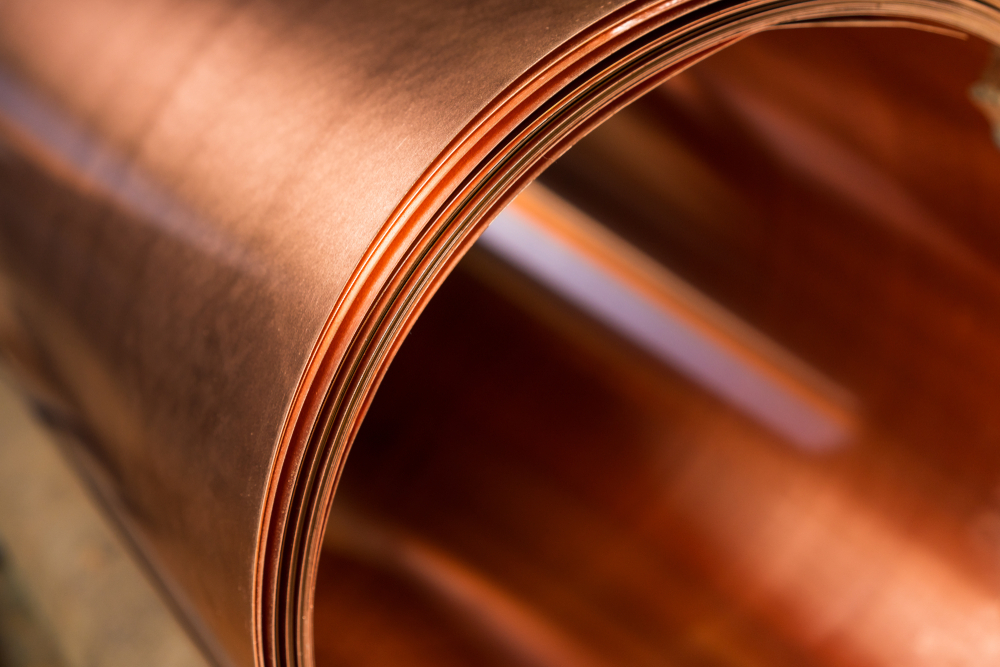

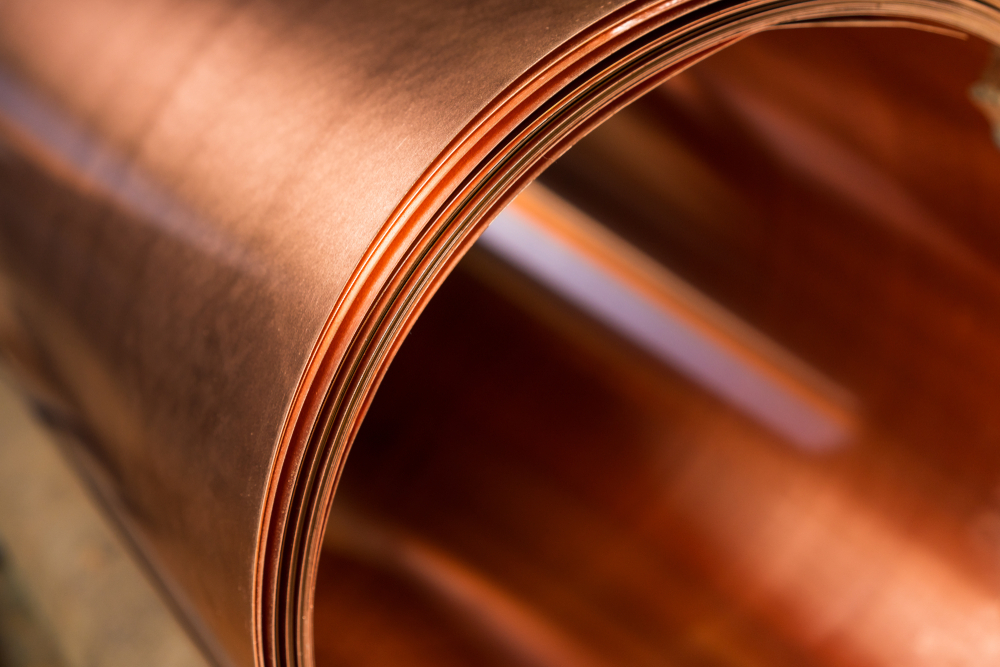

Understanding Copper Alloy

Copper thwarts and sheet metals are accessible in various amalgams, (counting bronze and metal). These distinctive combinations give certain actual properties to copper it doesn’t normally have, however those new properties frequently bring new restrictions too. What makes the compound conversation somewhat simpler is that 99% of the copper sold in the United States is addressed by the three composites recorded beneath.

C11000 – Alloy

QuickShipMetals.com sells copper amalgam C11000, otherwise called Electrolytic-Tough-Pitch. C11000 is 99.9% unadulterated copper, and keeping in mind that it makes a fantastic electrical conveyor, it’s likewise a brilliant material for bar tops, kitchen backsplashes, and it makes an extremely tasteful looking precipitation canal while decorating probably the best glancing rooftops on the planet.

QuickShipMetals additionally offers copper foils produced using a similar C11000 compound, made to ASTM-B152 guidelines – sold in pre-curled rolls.

Thickness

The thickness of copper metal sheeting is recorded underneath in decimals, measure, and ounces. 16-Gauge copper sheeting, for instance, (as per the B. W. G. – Birmingham Gauge Standard) would quantify in at .0647″. A US penny is .059″ thick.

Here’s a correlation of the adaptability of the metal that you can identify with a thing in your regular daily existence. On the off chance that you may have a clinical protection card, copper sheeting with a .010″ thickness will have similar adaptability. A standard Visa is .028″ thick.

Getting down on the check of the metal is another method of deciding thickness. It is critical to remember that with measure, the bigger the number the more slender the material. a 30-Gauge copper sheet is a lot more slender than a 16-measure.

Significantly really befuddling, the material business estimates copper thickness in ounces per square foot. 16 oz. a copper sheet is an exceptionally regular size of material copper. The thickness of copper foil sold by QuickShipMetals.com is estimated in millimeters (MIL). The cross-reference table (beneath) will help you convert measure to creeps to ounces.

Temper

Essentially, the Temper of a metal alludes to its hardness. The two limits of Temper are signified as “hard” and “delicate”. While the Copper Development Association has introduced a numbering show H01(soft) to H04(hard), a great many people in the business just allude to temper in determining the level of hardness.

The hardness of the metal decides the application. If you somehow happened to make a pot rack out of a delicate temper copper sheet and decide to hang your grandma’s solid metal griddle on creation, the heaviness of the skillet could disfigure the rack. The primary concern, if your copper project includes supporting any sort of weight, stick to hard temper copper metal sheet like .125″ copper, which is additionally called “copper plate.”

Then again, on the off chance that you are keen on making a copper scratching or just shaping the copper by hand, you would be greatly improved with a milder Temper. Gentler Tempers are simpler to cut too. For beautifying and specialty applications that don’t need supporting a lot of weight, delicate Temper copper foil ought to be your decision.

Finish

In the event that you have at any point strolled in the lower level of an extravagant retail chain and ended up seeing the lovely copper pots hanging in the kitchen office, you have seen an unnatural copper finish. Except if copper is treated with an engineered enamel, it won’t have that profound mirror-like completion. Additionally, if that veneer finish should at any point break (even a little one), air will arrive at the copper and stain the completion decently quickly.

For the most part, the completion of the copper bar and sheet will give a dull reflection. Sometimes, the metal will likewise have a slight waviness to it, despite the fact that it will be extremely smooth. Over the long run, the metal will obscure with openness to air. The oxygen noticeable all around is really eroding the metal. Over various years a greenish patina will frame on the metal. A great many people discover the character acquired by copper through this consumption interaction to be very appealing. Truly, you can really buy copper that has been treated with synthetic compounds which enormously speeds up the consumption interaction.

Copper for the Kitchen – a more secure, more-effective intends to cook and thaw out…

QuickShipMetals.com offers Copper Heat Diffuser and Defroster Plates produced using C11000 amalgam, otherwise called Electrolytic-Tough-Pitch, second just to silver in warm conduction. C11000 is 99.9% unadulterated copper and keeping in mind that it makes an astounding warmth transmitter, it’s additionally an excellent metal for bar-tops, ledges, tabletops, and kitchen backsplashes.

Professional cooks overall utilize the upsides of copper heat diffuser plates. High, effective warm conductivity converts into an even close ideal conveyance of warmth created by burner burners all through the whole plate surface. The temperature inside the cooking pot or skillet stays as before from the middle to the edge.

This takes your normal home to concoct a full indent in his or her capacity to dominate complex sauces, long stews and the sky’s the limit from there – without searing or singing. Consolidate two copper heat plates with more than two burners, put down your long frying pan and cook an enormous breakfast with supreme warmth control.

Copper’s magnificent warmth move presents an ideal arrangement at the furthest edge of the temperature range – these convenient copper defroster plates defrost food quicker and more secure than some other kitchen surface. Since copper is currently perceived as an enemy of microbial metal.

by kalpataru | Mar 8, 2021 | Blog

What is Hastelloy Steel?

Many nickel-based steel composites display high protection from consumption, and Hastelloy is truly outstanding. As well as remarkable protection from all ways of pitting and breaking, parts produced using Hastelloy metal mixes will, in general, discover great use across a wide scope of substance applications that may somehow or another oxidize the metal. Extra components, for example, molybdenum and chromium balance the profile of a compound that is generally viewed as one of the world’s hardest. Kalpataru Piping has got all your Hastelloy needs covered!

What is a Butt Weld (Buttweld) Fitting?

A buttweld fitting is a weldable Hastelloy C22 pipe fitting that takes into consideration the altar of the course of the stream, to expand, decrease pipe measure or connect assistant gear. Fashioned Steel buttweld fittings are made as per ANSI/ASME B16.9.

Buttweld fittings are accessible as elbows, tees, covers, decreases, and outlets. These fittings are the most well-known sort of welded pipe fitting and are indicated by ostensible pipe size and pipe plan. Buttweld fittings utilize consistent or welded pipe as the beginning material and are framed (through numerous cycles) to get the state of elbows, tees, and reducers, and so forth Similarly as the pipe is sold from Schedule 10 to Schedule 160, butt weld pipe fittings are sold a similar way. Welded butt weld fittings are more normal in hardened steel because of cost advantage. Sch 10 fittings are additionally more normal in hardened steel butt weld fitting.

The erosion-safe Hastelloy combinations are generally utilized by substance preparing enterprises. The requirement for solid execution prompts their acknowledgment and development in the territories of geothermal, sunlight-based energy, oil and gas, and drugs. The advantages of Hastelloy measure hardware incorporate high protection from uniform assault, extraordinarily limited erosion opposition, phenomenal pressure consumption breaking obstruction, and simplicity of welding and creation.

The B-3 combination has extraordinary protection from non-oxidizing acids, for example, hydrochloric corrosive and sulfuric corrosive. The benefits of B-3 compounds over past B-family composites are upgraded warm strength and improved manufacturing qualities. The as of late created Hastelloy Hybrid-BC1 will deal with more grounded non-oxidizing acids than C-type combinations and will endure oxidizing contaminations that B-type amalgams won’t.

The most adaptable of the Hastelloy amalgams are the “C-type” compounds. The C-2000 compound joins remarkable protection from oxidizing media with better obstruction than non-oxidizing conditions and addresses a genuine exhibition get through for substance measure hardware applications.

C-22 combination is especially impervious to pitting and fissure erosion; it has been utilized broadly to ensure against the most destructive FGD frameworks and the most refined drug response vessels.

Hastelloy Applications

Hastelloy serves a wide range of uses in these industry classes:

Synthetic Process

Petrochemical

Oil and Gas

Drug

Geothermal

Ocean Water

Water Desalination

LNG (Liquefied Natural Gas)

Biomass

Mining

Utilities

Atomic Power

Sun based Power

Hastelloy C22 buttweld fittings are produced using the Hastelloy C22, which has metals including chromium, molybdenum, tungsten, and so on The lightweight fittings produced using this amalgam offer superb protection from a wide range of consumption and are reasonable for opposing both limited and uniform erosion. That is the reason they are utilized in various modern cycles. They likewise offer better and unrivaled weldability. Subsequently, the compound is additionally utilized as filler wires and consumables of weld overlays so their protection from consumption can be improved.

Remarkable Resistance To Corrosion

Hastelloy C22 buttweld fittings and other hardware that are framed from the amalgam are more impervious to erosion than different sorts of Chromium, Nickel, and Molybdenum-based compounds like the Hastelloy C276, C4, and 625.

Protection from Localized Corrosion

The amalgams offer improved protection from a wide range of erosion like fissure consumption, pitting, and breaking brought about by stress consumption. The combination can likewise oppose the watery oxidizing media. Consequently, it can oppose the wet chlorine, nitric corrosive, chloride particles containing oxidizing acids, and other comparative arrangements easily.

Protection from Reducing And Oxidizing Industrial Environments

The Hastelloy tubes and other hardware are likewise productive in mechanical conditions where there are oxidizing and diminishing conditions in the modern cycle streams. Multi-reason plants regularly experience the ill effects of “upset” conditions. In these spots, the amalgam performs quite well and accommodates toughness as it is exceptionally flexible.

Employability In Chemical Processing Industry

At the point when utilized in synthetic handling ventures, the Hastelloy tubes oppose various types of interaction weakening substances effortlessly. These incorporate the solid oxidizing specialists like cupric/ferric chloride, hot and sullied inorganic and natural arrangements, ocean water, saline solution arrangements, formic/acetic acids, and so on

Grain Boundary Precipitation

The composite can oppose the encouraging arrangement in the grain limit weld zone when it is welded. Subsequently, the compounds are exceptionally worthwhile for joining mechanical cycles and conveying fluids and substances starting with one plant then onto the next.

Premium Alloy

Hastelloy is viewed as the most premium of combinations of compounds. Aside from offering upgraded and chief consumption obstruction, likewise offers one-of-a-kind characteristics of opposing warmth.

by kalpataru | Mar 8, 2021 | Blog

Pipe Flanges Information

Pipe Flanges are jutting edges, edges, flanges, or collars used to make an association between two pipes or between a pipe and any sort of fitting or gear part. Pipe flanges are utilized for destroying funneling frameworks, brief or portable establishments, advances between divergent materials, and associations in conditions not helpful for dissolvable solidifying.

Flanges are generally straightforward mechanical connectors that have been utilized effectively for high-pressure funneling applications. They are surely known, dependable, practical, and promptly accessible from a wide scope of providers. Furthermore, the occasion conveying the limit of flanges is critically contrasted with other mechanical connectors. This is a significant component for frameworks that experience pipe-strolling or parallel clasping from temperature and pressing factor varieties (for example profound water pipes). flanges can be intended to meet a wide scope of utilization necessities like high-temperature and consumption opposition.

Activity

Pipe spines have flush or level surfaces that are opposite to the pipe to which they connect. Two of these surfaces are precisely joined through jolts, collars, glues, or welds.

Normally, flanges are joined to pipes by means of welding, brazing, or stringing.

Welding joins materials by dissolving the workpieces and adding filler material. For solid, high pressing factor associations of comparative materials, welding will in general be the best technique for flange association. Most pipe spines are intended to be welded to pipes.

Brazing is utilized to join materials by softening a filler metal which sets to go about as the connector. This strategy doesn’t liquefy the workpieces or actuate warm mutilation, taking into consideration more tight resiliency and clean joints. It additionally can be utilized to associate extremely different materials like metals and metalized ceramics.

Stringing is applied to spines and pipes to permit the associations to be sunk together in a way like nuts or fasteners.

While the strategy for connection can be a distinctive component, there are different contemplations more imperative to pipe flange determination. Elements a modern purchaser ought to consider first are the spine’s actual details, type, material, and execution, generally reasonable for the application.

Physical Specifications

Most importantly, a flange should fit the pipe or hardware for which it is planned. Actual details for pipe flanges incorporate measurements and configuration shapes.

Flange Dimensions

Actual measurements ought to be determined to estimate flanges effectively.

Outside breadth (OD) is the distance between two contradicting edges of a spine’s face. This can Thickness alludes to the thickness of the joining external edge and does exclude the piece of the flange that holds the pipe.

Jolt circle breadth is the length from the focal point of a jolt opening to the focal point of the restricting opening.

Pipe size is a pipe flange’s related pipe size, for the most part, made by acknowledged principles. It is normally determined by two non-dimensional numbers, ostensible pipe size (NPS) and timetable (SCH).

Ostensible bore size is the inward width of the flange connector. When assembling and requesting any sort of pipe connector, it is essential to coordinate the drag size of the piece with the drag size of the mating pipe.

Flange Faces

Flange appearances can be made to countless custom shapes based plan prerequisites. A few models include:

Level

Raised face (RF)

Ring type joint (RTJ)

O-ring groove

Pipe spines are a significant piece of any handyman’s stockpile of devices. They are utilized to associate areas of pipe to one another, or to different parts or bits of hardware. In the event that you intend to deal with any pipes occupations yourself, odds are you will require a pipe rib for some DIY plumbing occupations around your home or business property in San Jose, CA.

What you probably won’t understand in case you’re new to DIY plumbing is that there are a wide range of sorts of pipe spines available. How would you realize you have the right one for your requirements? Here’s a speedy outpipe of the different sorts of pipe spines and what you should think about them to help you settle on the legitimate choice:

Threaded: Threaded ribs are intended for low-pressure channeling frameworks and are oftentimes utilized in electrified steel pipe or in conditions where it isn’t appropriate to have welding temperature changes of in excess of 260 degrees Celsius, and underneath – 45 degrees Celsius. Try not to utilize threaded ribs for any pipe that could cause serious disintegration, cyclic stacking, or cleft consumption.

Lapped: Lapped ribs don’t come into contact with the media, and the material of the pipe spine can’t be equivalent to that of the pipe. All things considered, there should be a stub end or welding ring to make it appropriate for destructive medium pipe pipes.

Socket weld: Socket weld spines are most appropriate for more modest, high-pressure funneling. They are utilized in comparative conditions as slip-on spines, yet have an interior pocket plan that makes better liquid stream and a smoother bore. They additionally have the advantage of altogether more prominent strength than twofold welded slip-on spines when they are inside welded.

Slip-on: Speaking of slip-on ribs, these ribs are useful in light of the fact that they are not difficult to adjust and for the most part come in at a lower cost than a portion of different alternatives on this rundown. They’re bound to be utilized in low-pressure conditions, for example, non-sanitizing packed air and low-pressure water flow.

Welding neck: Welding neck spines are known for a higher strength and firmness. They are regularly utilized in conditions that have an enormous temperature pressure change range or in high-temperature, high-pressure conditions, however they can likewise be valuable for low-temperature pipe pipes.

Blind: Blind spine is most generally utilized for fixing pipe closes. Dazzle pipe spine will for the most part be introduced toward the finish of a header or in an area where there are probably going to be extra future connections.

by kalpataru | Feb 26, 2021 | Blog

Perhaps the best metal utilized in both the mechanical and modern areas is the Nickel 200. It is professed to be financially unadulterated nickel that has around 99.6 percent fashioned nickel that has incredible consumption obstruction and great mechanical properties. It has the properties of Nickel 200 that make its items in pretty much every area of the world profoundly popular.

One of the items that have high electrical and warm conductivity with low fume pressing factor and gas content is nickel 200 pipes. These pipes are significantly utilized in the territories where less destructive metal is required. These pipes are typically round in frame and can be normal or sliced long as indicated by the determinations of the clients. They are essentially utilized in warmth treatment, machining, machining and extension, and so forth. Kalpataru Piping Solutions is one of the leading suppliers of nickel 200 pipes

Since they are incredibly adaptable, these pipes can be applied to an assortment of ventures. Aviation, the engine business, medication, development and plan, manures, atomic force, the vehicle, and transport industry, siphons and valves, the synthetic business, the oil business, and numerous others are a portion of the areas wherein these pipes can be utilized.

As a result of its phenomenal properties, you can utilize consistent tubing much of the time. It has high electrical conductivity, fantastic dry fluorine opposition, and very solid electrical, warm and magnetostrictive properties, valuable for burning pop, protection from erosion, and protection from a few unique synthetic compounds that diminish it. You presently know why they have a particularly expansive reach subsequent to learning every one of these favorable circumstances of Nickel 200 pipes.

Nickel 200 is an unadulterated nickel combination of 99.6 percent and is probably the hardest metal in nature. Incredible mechanical properties and high warm and electrical conductivity are displayed. What’s more, the useful properties of Nickel 200 and its synthetic construction simplify it to deliver and exceptionally impervious to destructive conditions.

Advantages of Nickel 200 pipes

One of the items that have high electrical and warm conductivity with low fume pressing factor and gas content is nickel 200 pipes. Such pipes are utilized basically in zones where less destructive metal is required. These pipes are ordinarily round in frame and can be ordinary or sliced long as per the determinations of the clients. They are significantly utilized in warm medicines, machining, development and machining, and so on.

Extraordinary mechanical qualities

Low gas content

Low pressing factor of fume

Attractive properties

High conductivity of warmth and power

Utilizations of Nickel 200 Pipes

There are a few distinctive modern utilizations of nickel compound 200 pipes, some of which incorporate Electronic components, Electronic parts, Wires for segments of warming, Connections/terminals of batteries, Chemical assembling, Aircraft parts, Manufacturing of food, and Processing Synthetic Fiber.

Nickel 200 Pipes are broadly used to ship liquids and gases in numerous modern applications. These pipes are consistently accessible and fit as a fiddle that makes it effective to deal with the pressing factor of the fluid. Nickel 200 bars and nickel 200 flanges are broadly utilized in applications that require exact external breadths. These cylinders are accessible in numerous shapes like square, round, and rectangular. These items are accessible in numerous kinds like Seamless, created, welded, ERW, and so on according to the business requests. Nickel 200 Pipes has industrially unadulterated fashioned materials that offer great substance, mechanical highlights, and consumption obstruction. These pipes can be formed with uncommon gear.

A few Advantages of Nickel 200 Pipes and Tubes:

Nickel 200 Pipes offer amazing protection from the forceful environments containing acidic salts at different temperatures. Nickel 200 bars have incredible warm and electrical conductivity. These pipes have a low fume pressing factor and gas content that makes them appropriate for some enterprises. Nickel 200 Pipes have extraordinary toughness, weldability, attractive and magnetostrictive highlights. These cylinders offer magnificent mechanical strength and resistivity in any diminishing, oxidizing, and antagonistic conditions. In chloride-containing conditions, Nickel 200 Pipes are exceptionally impervious to hole and stress erosion. These highlights make these pipes an ideal answer for the applications that handle engineered strands, acidic soluble bases, and food preparation. These pipes and cylinders have broad properties like higher malleability, simple fabricability, great completion, and cost viability.

Employments of Nickel 200 Pipes and Tubes dependent on highlights:

Nickel 200 Pipes are especially valuable in the primary enterprises where fantastic erosion obstruction is required. Nickel 200 bars proficiently work in clinical applications where exact external measurements are prime contemplations. The external measurement of cylinders makes it simple to demonstrate the amount it can hold. These pipes are additionally utilized in the delivery drums, electronic enterprises, where uncommon conductivity highlights are required. Because of higher mechanical strength and great malleability, Nickel 200 pipes are entirely found a way into applications like aviation, compound gear, rocket engines, safeguard, rocket parts, and some more. These cylinders are appropriate for channeling frameworks utilized related to the salts. Nickel 200 bars show a higher resistivity to any acidic media and this makes them the totally dependable item in the food preparing industry.