Stainless Steel Flanges

Stainless steel flanges known as SS flanges serve as essential connection components which unite piping systems with pumps and valves and additional equipment. They demonstrate long service life and maximum strength together with corrosion and rust resistance to operate under high pressures with elevated temperatures.

Different grades and standards of these flanges exist to fulfill diverse industrial requirements. The ASTM A182 F304, F304L, F316 & F316L grades represent popular choices because they show exceptional resistance to corrosion. The steel flange finds extensive usage across oil & gas, petrochemicals, water treatment, power plants and food processing industries. The harsh conditions of scrubber systems and acid production and fertilizer plants require special stainless steel flanges constructed from super austenitic stainless steel. The flanges deliver outstanding defense against both rust and chemical deterioration.

Stainless Steel (SS) Flanges Manufacturer in India

Kalpataru Piping Solutions operates as a top stainless steel (SS) flange manufacturer in India and SS flange supplier both within India and throughout worldwide markets. Our company produces high-quality stainless steel flanges in multiple sizes & standards according to worldwide industry standards. We offer various grades of stainless steel like 304 stainless steel flanges, 316 stainless steel flanges & 310 stainless steel flanges etc.

We known as a top stainless steel flange supplier offering various types of flanges including weld neck flanges, slip-on flanges, blind flanges, socket weld flanges, threaded flanges, SS pipe flanges & lap joint flanges to customers worldwide by using premium-grade stainless steels which include ASTM A182 F304, F304L, F316 & F316L. These types of flanges provide durability & extended service life and corrosion resistance to high-demand applications.

The steel flanges are used in multiple industrial applications including oil & gas, petrochemicals, power generation, food processing, water treatment, marine & construction. Our company possesses state-of-the-art production capabilities along with strict quality management measures and skilled technicians to deliver products that fulfill ASME, ANSI, DIN, EN and JIS international requirements.

Kalpataru Piping Solutions functions as your trusted stainless steel (SS) flange manufacturer in India who delivers standard and custom-made solutions at competitive prices with prompt delivery and exceptional customer support.

Stainless Steel Flange Specifications

| Size Range | 1/2 NPS to 40 NPS (15 NB to 1000 NB) |

| Class | 150#, 300#, 400#, 600#, 900#, 1500#, 2500#, PN2.5, PN6, PN10, PN16, PN25, PN40, PN63, PN100 |

| Grades | F-304, 304L, 304H, 304N, 304LN, 316, 316L, 316H, 316Ti, 316N, 316LN, 310, 317, 317L, 321, 321H, 347, 347H, 904L F-51, 53, 55, 60, 68 |

| Specifications | ASTM, ASME, DIN EN |

| Type | SO, WN, SW, BL, THRD, Lap Joint, Orifice Type, Reducing Flanges, Spectacle Blind |

| Face | RF, FF, RTJ, T&G |

SS Flanges Types

As a trusted stainless steel flange manufacturer, we supply high-quality flanges in different types, sizes, and standards

- Stainless Steel Blind Flange

Stainless steel blind flanges operate as solid discs without central bores to create pipe and pressure vessel end seals. This type of flange serves systems that need future growth potential or regular maintenance checks. Blind flanges provide both high pressure resistance & convenient access points for cleaning operations. - Stainless Steel Weld Neck Flange

A stainless steel weld neck flange features a tapered hub extending from the pipe that allows butt welding to the pipe body. The design features of this component enable smooth flow while minimizing stress concentration & effectively operating under high-pressure & high-temperature conditions. The stainless steel weld neck flange serves various applications in the oil & gas sector and power plants. - SS Slip On Flange

The installation of an SS slip on flange requires the pipe to receive the flange component before performing double-sided welding operations. The installation process is straightforward, while the device works best for systems that operate under low pressure. General industries favor this flange because of its affordable price and straightforward alignment process. - Socket Weld Flange

The insertion of pipes into socket weld flanges enables welding before final assembly which creates a round opening that enhances fluid movement. This type of flange provides high-pressure performance together with leak-free operation for small-diameter piping systems. - Stainless Steel Threaded Flange

Stainless steel threaded flanges feature internal threads so they do not need welding for installation. Welding is impractical in low-pressure systems so this type of flange serves as an excellent solution. The flanges find their application in plumbing and industrial piping systems which incorporate externally threaded pipes. - Stainless Steel Plate Flanges

Stainless steel plate flanges feature circular flat shapes with bolt holes which serve to block off pipe sections or connect piping systems. These components offer cost effectiveness together with compatibility for systems under lower pressure conditions. - Stainless Steel Forged Flanges

The stainless steel forged flanges at our facility start from forging high-grade SS material which produces flanges with superior strength and uniformity and reliability. The petrochemical sector together with chemical and marine industries, utilize these components extensively. - Stainless Steel Pipe Flange

A stainless steel pipe flange serves as a connection point between pipes and valves and pumps and other equipment to construct piping systems. The flanges include built-in openings that enable easy inspections and cleaning operations and modifications.

Grades of Stainless Steel Flanges

Different applications and industry needs along with environmental requirements determine which stainless steel flange grade will be appropriate. At Kalpataru Piping Solutions, we provide high-quality SS flanges in the most commonly requested grades, which include:

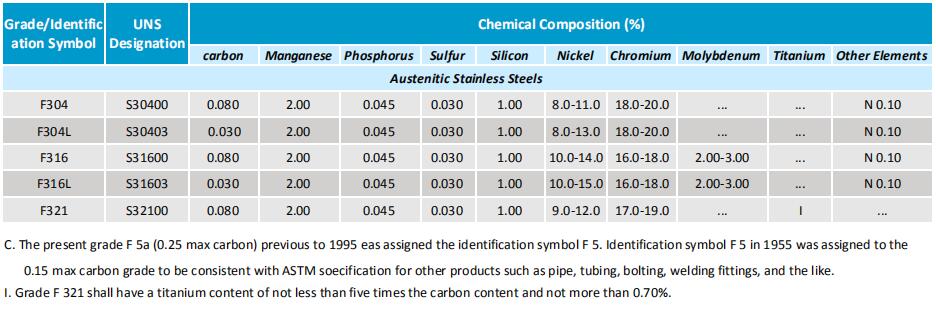

Chemical Composition of SS Flanges

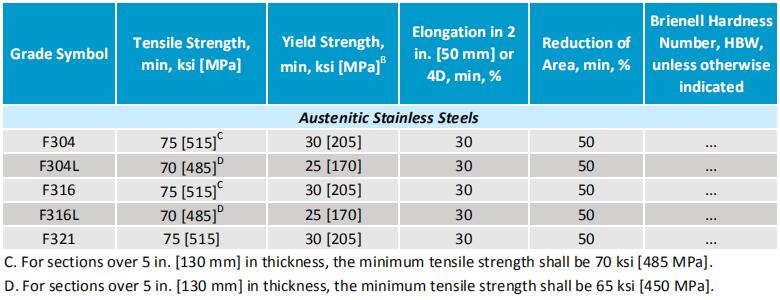

Mechanical Properties of Stainless Steel Flanges

SS Flange Dimensions & Size Chart

| FLANGE NPS | Outside Diameter | Bolt Circle (BC) | Raised Face (R) | Raised Face (RF) | Raised Face Thickness (T) | Flat Face Thickness (T2) | Bolt Hole (B) | No. of Bolt Holes |

| 1/2″ | 3.50″ | 2.38″ | 1.38″ | .063″ | .44″ | .38″ | .62″ | 4 |

| 3/4″ | 3.88″ | 2.75″ | 1.69″ | .063″ | .50″ | .44″ | .62″ | 4 |

| 1″ | 4.25″ | 3.12″ | 2.00″ | .063″ | .56″ | .50″ | .62″ | 4 |

| 1-1/4″ | 4.62″ | 3.50″ | 2.50″ | .063″ | .62″ | .56″ | .62″ | 4 |

| 1-1/2″ | 5.00″ | 3.88″ | 2.88″ | .063″ | .68″ | .62″ | .62″ | 4 |

| 2″ | 6.00″ | 4.75″ | 3.62″ | .063″ | .75″ | .69″ | .75″ | 4 |

| 2-1/2″ | 7.00″ | 5.50″ | 4.12″ | .063″ | .88″ | .82″ | .75″ | 4 |

| 3″ | 7.50″ | 6.00″ | 5.00″ | .063″ | .94″ | .88″ | .75″ | 4 |

| 3-1/2″ | 8.50″ | 7.00″ | 5.50″ | .063″ | .94″ | .88″ | .75″ | 8 |

| 4″ | 9.00″ | 7.50″ | 6.19″ | .063″ | .94″ | .88″ | .75″ | 8 |

| 5″ | 10.00″ | 8.50″ | 7.31″ | .063″ | .94″ | .88″ | .88″ | 8 |

| 6″ | 11.00″ | 9.50″ | 8.50″ | .063″ | 1.00″ | .94″ | .88″ | 8 |

| 8″ | 13.50″ | 11.75″ | 10.62″ | .063″ | 1.12″ | 1.06″ | .88″ | 8 |

| 10″ | 16.00″ | 14.25″ | 12.75″ | .063″ | 1.19″ | 1.13″ | 1.00″ | 12 |

| 12″ | 19.00″ | 17.00″ | 15.00″ | .063″ | 1.25″ | 1.19″ | 1.00″ | 12 |

| 14″ | 21.00″ | 18.75″ | 16.25″ | .063″ | 1.38″ | 1.32″ | 1.12″ | 12 |

| 16″ | 23.50″ | 21.25″ | 18.50″ | .063″ | 1.44″ | 1.38″ | 1.12″ | 16 |

| 18″ | 25.00″ | 22.75″ | 21.00″ | .063″ | 1.56″ | 1.50″ | 1.25″ | 16 |

| 20″ | 27.50″ | 25.00″ | 23.00″ | .063″ | 1.69″ | 1.63″ | 1.25″ | 20 |

| 22″ | 29.50″ | 27.25″ | 25.25″ | .063″ | 1.81″ | 1.75″ | 1.38″ | 20 |

| 24″ | 32.00″ | 29.50″ | 27.25″ | .063″ | 1.88″ | 1.82″ | 1.38″ | 20 |

Stainless Steel Flange Weight Chart

| Nominal Pipe Size | “A” (O.D.) | “B” (Thk.) | “C” (RF Dia.) | “D” (B.C.D.) | # Bolt Holes | Dia. of Bolt Holes | Approx. Weight |

| 1/2″ | 3-3/4 | 9/16 | 1-3/8 | 2-5/8 | 4 | 5/8 | 2 |

| 3/4″ | 4-5/8 | 5/8 | 1-11/16 | 3-1/4 | 4 | 3/4 | 3 |

| 1″ | 4-7/8 | 11/16 | 2 | 3-1/2 | 4 | 3/4 | 4 |

| 1-1/4″ | 5-1/4 | 3/4 | 2-1/2 | 3-7/8 | 4 | 3/4 | 6 |

| 1-1/2″ | 6-1/8 | 13/16 | 2-7/8 | 4-1/2 | 4 | 7/8 | 7 |

| 2″ | 6-1/2 | 7/8 | 3-5/8 | 5 | 8 | 3/4 | 8 |

| 2-1/2″ | 7-1/2 | 1 | 4-1/8 | 5-7/8 | 8 | 7/8 | 12 |

| 3″ | 8-1/4 | 1-1/8 | 5 | 6-5/8 | 8 | 7/8 | 16 |

| 3-1/2″ | 9 | 1-3/16 | 5-1/2 | 7-1/4 | 8 | 7/8 | 21 |

| 4″ | 10 | 1-1/4 | 6-3/16 | 7-7/8 | 8 | 7/8 | 28 |

| 5″ | 11 | 1-3/8 | 7-5/16 | 9-1/4 | 8 | 7/8 | 37 |

| 6″ | 12-1/2 | 1-7/16 | 8-1/2 | 10-5/8 | 12 | 7/8 | 48 |

| 8″ | 15 | 1-5/8 | 10-5/8 | 13 | 12 | 1 | 79 |

| 10″ | 17-1/2 | 1-7/8 | 12-3/4 | 15-1/4 | 16 | 1-1/8 | 122 |

| 12″ | 20-1/2 | 2 | 15 | 17-3/4 | 16 | 1-1/4 | 183 |

| 14″ | 23 | 2-1/8 | 16-1/4 | 20-1/4 | 20 | 1-1/4 | 241 |

| 16″ | 25-1/2 | 2-1/4 | 18-1/2 | 22-1/2 | 20 | 1-3/8 | 315 |

| 18″ | 28 | 2-3/8 | 21 | 24-3/4 | 24 | 1-3/8 | 414 |

| 20″ | 30-1/2 | 2-1/2 | 23 | 27 | 24 | 1-3/8 | 515 |

| 24″ | 36 | 2-3/4 | 27-1/4 | 32 | 24 | 1-5/8 | 800 |

SS Flanges Pressure Rating

| ASME/ANSI B 16.36 | Welding Neck Flange, Slip-on Flange, Threaded Flange |

| PRESSURE CLASS | 300, 400, 600, 900, 1500, 2500 |

| ASME/ANSI B 16.5 | Welding Neck Flange, Slip-on Flange, Blind Flange, High Hub Blind Flange, Socket Weld Flange, Lap Joint Flange, Threaded Flange, Ring Type Joint Flange |

| PRESSURE CLASS | 150, 300, 400, 600, 900, 1500, 2500 |

| ASME/ANSI B 16.47 | Welding Neck Flange, Blind Flange [Series A & B] |

| PRESSURE CLASS | 75, 150, 300, 400, 600, 900 |

| BS 4504 SEC 3.1 | Welding Neck Flange, Hubbed Slip-on Flange, Hubbed Threaded Flange, Lapped Pipe End Flange, Plate Flange, Loose Plate Flange, Loose Plate With Weld Neck Flange, Blank Flange |

| PRESSURE CLASS | PN 2.5 TO PN 40 |

| BS 4504[PART 1] | Welding Neck Flange, Hubbed Slip-On Hubbed Threaded, Plate Flange, Loose Plate With Weld-On Plate Collar, Blank Flange |

| PRESSURE CLASS | PN 2.5 TO PN 400 |

| BS 1560 BOSS | Welding Neck Flange, Socket Welding Flange, Slip-On Flange, Blind Flange, Screwed Boss Flange, Lapped Flange |

| PRESSURE CLASS | 150, 300, 400, 600, 900, 1500, 2500 |

| BS10 | Welding Neck Flange, Plate Slip-On Flange, Screwed Boss Flange, Slip-On Boss Flange, Blind Flange |

| TABLE | D, E, F, H |

| DIN FLANGES | DIN 2527, 2566, 2573, 2576, 2641, 2642, 2655, 2656, 2627, 2628, 2629, 2631, 2632, 2633, 2634, 2635, 2636, 2637, 2638, 2673 |

| PRESSURE CLASS | PN 6 TO PN 100 |

Frequently Asked Questions on Stainless Steel (SS) Flanges

What is the pressure rating of Stainless Steel flanges?

The pressure ratings of stainless steel flanges extend between Class 150 & 2500 based on the flange type together with its size & material grade. The SS flange size chart provides precise pressure & dimensional data that needs to be considered for accurate measurements.

What are the standard sizes of SS flanges?

Stainless steel flanges exist in dimensions starting from ½ inch and extending to sizes larger than 48 inches. The dimensions of standard ss flanges depend on their type and pressure rating specifications. The ss flange size chart provides the necessary measurements for outside diameter, bolt circle and thickness values for each flange type.

How to calculate SS flange weight?

The calculation of stainless steel flange weight requires the flange dimensions (outer diameter, inner diameter, thickness) together with the flange type & material density information. A stainless steel flange weight chart serves as a quick reference tool by offering pre-calculated weights for standard dimensions.

What is a stainless steel flange?

The stainless steel flange functions as a mechanical joining element between pipes and valves and pumps and other equipment. SS flanges create leak-tight joints that hold pressure while showing strong corrosion defenses when used in industrial operations.

What different types of SS flanges are available?

Common ss flange types include:

- Weld Neck Flanges – For high-pressure, high-temperature applications.

- Slip-On Flanges – Easy to install, used in low-pressure systems.

- Blind Flanges – Used to seal pipe ends or vessels.

- Socket Weld Flanges – Ideal for small-diameter, high-pressure lines.

- Threaded Flanges – Used in low-pressure systems with no welding.

- Lap Joint Flanges – Best for systems that require frequent dismantling.

- Each flange type has its own ss flange dimensions and pressure ratings as per industry requirements.

What is the ASTM standard for stainless steel flanges?

The ASTM A182 standard defines the specifications for stainless steel flanges which should be used for high-temperature applications when manufactured through forging or rolling processes. The industry uses the most popular grades F304, F304L, F316 & F316L for its applications.

What grade is stainless steel flange material?

The standard grades consist of 304 stainless steel flanges, 304L, 316, 316L, 321, 347 & 904L materials. The grades fulfill ASTM A182 requirements & manufacturers according to application requirements for pressure, temperature & corrosion resistance.