by kalpataru | Aug 24, 2022 | Blog

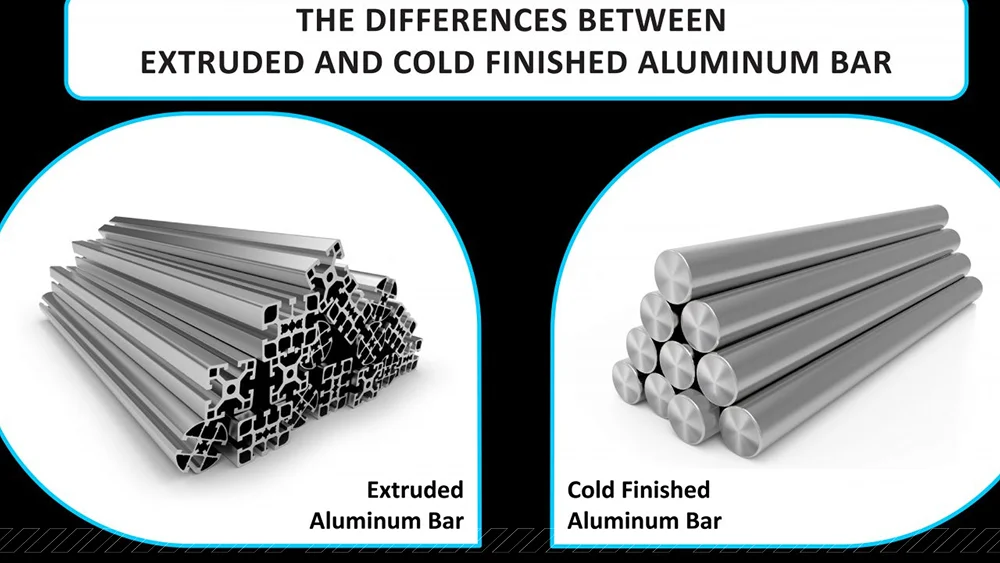

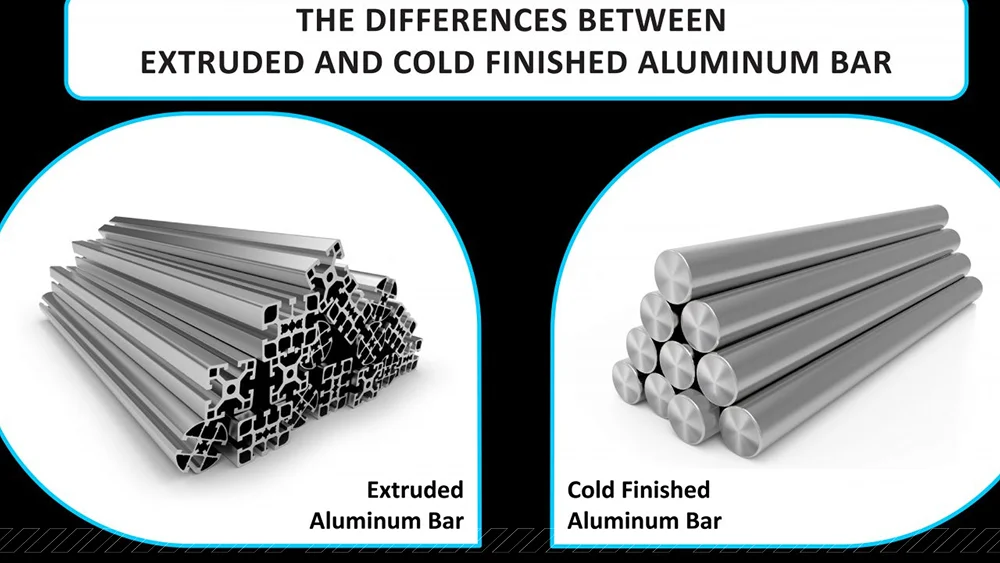

What is Extruded Aluminum?

Extrusion is the technique of driving a material through a die to create a cross-sectional bar, whether it be aluminium or another material. Despite having a number of steps, the method is rather straightforward. The final exterior dimension of the extruded bar must first be produced by a manufacturer or designer using a die.

The finished die is put into an extrusion press where a billet of the desired alloy of aluminium is heated to the necessary temperature, making it malleable. The press then pushes the aluminium through the die, causing a lineal length of regularly formed aluminium to emerge from the other side.

The extruded piece is tension relieved and then cut to the required length after cooling. Now that the metal has undergone post-production processes, it can be heat treated. Less pressure is needed to push the metal through the die since the process occurs at a high temperature, up to 75% of the melting point of aluminium. This indicates that it is quicker than cold forming techniques.

What Is Cold-Finished Aluminum?

Since aluminium is simpler to form at higher temperatures, extrusion is frequently done there as opposed to cold finishing, which is done at ambient temperature. Extremely tight tolerances for the outer diameter are produced by cold finishing. The most typical kind of cold finishing is drawing.

Since aluminium is simpler to form at higher temperatures, extrusion is frequently done there as opposed to cold finishing, which is done at ambient temperature. Extremely tight tolerances for the outer diameter are produced by cold finishing. The most typical kind of cold finishing is drawing.

What is the Difference between Extruded and Cold Finished Aluminum?

Standard aluminium extrusions have the main benefit of being significantly simpler to work with at higher temperatures. An extruded bar often costs less than a cold finished product since this corresponds to faster production rates. Faster production leads to shorter lead times to market.

The tighter dimensional tolerances produced by cold finished production are helpful for using the close-fitting collets present in modern high-speed precision CNC machining machines. Additionally, it enhances the material’s mechanical and physical qualities, boosting machinability and resulting in smaller, quicker-elimination chips during milling.

Extruded and Cold Finished Aluminum are Used in What Applications?

Although extruded aluminium is frequently used in many different applications, it is not appropriate for all of them. The use of the cold finished product as a raw material may result from any requirement for improved properties. Cold polished bar is often used in automotive applications as well as aerospace and defense products that need high strength. In cold finished applications, alloys including 2011, 2024, 6061, and 7075 are employed. Extrusions frequently use the aluminium alloys 1100, 3003, 6061, 6063, and 6101. Probably the most popular is 6061, which is prized for its advantageous characteristics.

Read More :

Different Type of Steel Reinforcement Bars : There are different kinds of steel bars that can be used for building. You should know which one you should choose and why.

Some of the Best Uses of Inconel 600 Round Bars : INCONEL (nickel-chromium-iron) alloy 600 Round bars (UNS N06600/W.Nr. 2.4816) is a technological material that is heat and corrosion resistant. Excellent mechanical properties of the alloy combine high strength with ease of production.

by kalpataru | Aug 24, 2022 | Blog

Introduction

A number of steel bar types are used in concrete buildings. The endurance of the concrete construction is ensured by the use of reinforced steel bars.

Concrete is made with 5 different kinds of steel reinforcement bars.

Hot Rolled Deformed Bars

Cold Rolled Steel Bars

Mild Steel Bars

Twisted Steel Bars

Welded Steel Wire

Hot Rolled Deformed Bars

TMT Bars, which stand for Thermo mechanically treated bars, are another name for hot-rolled deformed bars. Because they have high tensile strength, TMT Bars are often used in RCC (Reinforced Concrete Structure). The ribs on TMT Bars make it possible for cement concrete to stick together better. The best TMT Bars have a tensile strength of 64,000 psi (PSI – Strength of Concrete is measured in pounds per square inch).

Cold Rolled Steel Bars

Even though cold-rolled steel bars are made at room temperature, they look like hot-rolled bars. These bars are made of weak materials and are easy to bend. Cold-rolled bars are almost no longer on the market, but they are still used in some building projects that don’t require a lot of tolerance. It can be stretched up to 60,000 psi.

Mild Steel Bars

This bar is round and has a smooth, flat surface. Mild steel bars are used to make beams and slabs out of RCC. There is a tensile strength of up to 40,000 psi. Mild steel bars are used in small projects with limited funds because they don’t stick well to concrete and aren’t very good.

Twisted Steel Bars

Twisted steel bars are also called “prestressing tendons.” Almost seven different wires have been woven together to make this string. Twisted steel bars have a high tensile strength of 270,000 psi. Most of the time, these are used on scaffold braces to make reinforced cement concrete stronger. It makes sense because of how well it holds together.

Welded Steel Wire

Steel wires are joined together to make weld mesh. A medium amount of tensile strength is made. These are used for fencing, dividing rooms, etc. It is often used in certain parts of buildings because it is easier to find in different diameters and is stronger than a mild steel bar.

It is very important to know that thermomechanically treated (TMT) bars are often used because they have high tensile strength. TMT Bars are strong and also have the right amount of flexibility. Because of this, it offers the best protection possible during any natural disaster, such as an earthquake, flood, etc. TMT Bars have less carbon than other types of steel, which makes them very resistant to corrosion and less likely to wear down over time.

IS Standards say that the Fe 500d grade of TMT Bar is the best mix of strength and flexibility. Because of this, it is highly recommended for building projects.

Read More :

All You Need To Know About Inconel 600 Bars: Inconel 600 is a nickel-chromium composite with great oxidation opposition at higher temperatures, with great obstruction in carburizing and chloride-containing conditions.

Some of the Best Uses of Inconel 600 Round Bars: INCONEL (nickel-chromium-iron) alloy 600 Round bars (UNS N06600/W.Nr. 2.4816) is a technological material that is heat and corrosion resistant. Excellent mechanical properties of the alloy combine high strength with ease of production.

by kalpataru | Aug 17, 2022 | Blog

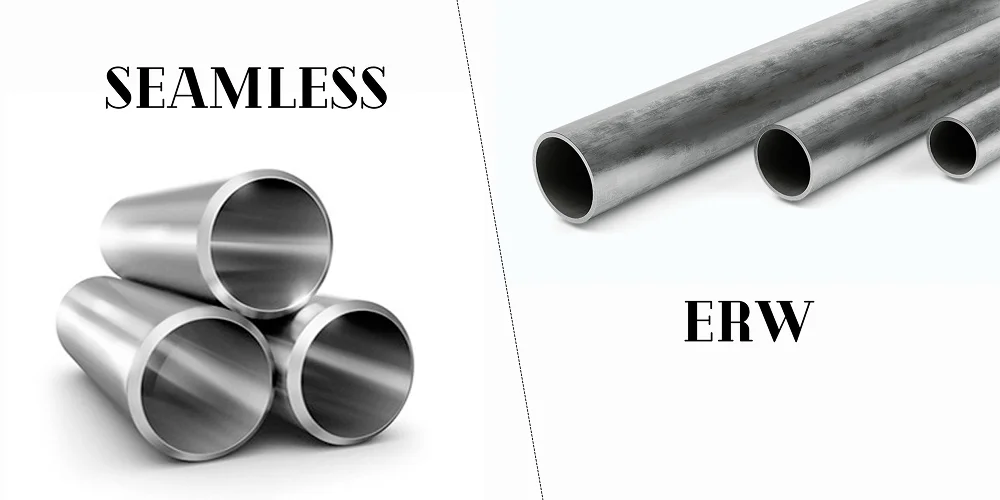

Choosing the right type of stainless steel pipe for your industrial or commercial project, understanding the difference between ERW and seamless pipe is most important. While both pipe types are used for similar functions, they differ in how they are manufactured, their performance & their cost. When comparing ERW pipe vs seamless pipe a few factors like strength, durability & usage in industries. One of the main things to consider is the ERW pipe vs seamless cost, which depends mainly on the manufacturing process and the materials involved. This blog explores these differences in detail to help you make the best choice for your project.

What Are Seamless Pipes?

Seamless pipes are designed for high precision, to offer consistent wall thickness & exact dimensions. They are available in sizes ranging from 1/8 inch to 26 inches in outer diameter (OD). Used in industrial applications where high strength and reliability are essential. They are also essential in transporting oil and gas, as well as in air and hydraulic cylinders, bearings, boilers, automobiles & many more. Made from a solid piece of metal, typically a steel billet. Seamless pipes are created by piercing & elongating the material to form a hollow tube.

What is an ERW pipe?

ERW pipes are longitudinally welded & can be manufactured up to 24 inches OD, using strips or coils of steel. ERW pipes are formed through a process involving the pulling of a steel ribbon through a series of rollers & subsequent fusion via an electric charge. They are used in low to medium pressure applications to transfer oil & water. ERW Steel Pipe commonly comes in a range of sizes, from 2 3/8 inches OD to 24 inches OD, with various length options extending over 100 feet. Surface finishes are available in both bare & coated formats. As a leading ERW Stainless Steel Pipes Manufacturer and exporter, we offer top ERW pipes from India. Contact us for detailed product information or custom requirements.

ERW Pipe vs Seamless Pipe Manufacturing Process

Understanding the ERW & seamless pipe difference with how they are made. The manufacturing process of seamless pipe vs ERW pipe is different & influences their strength, quality & applications.

Seamless pipes are made from solid round steel billets. These billets are first heated & then pierced using a rotary piercer or extrusion process to create a hollow tube. The pipe is then elongated & rolled to achieve the required thickness and diameter. This method does not involve any welding. They mainly offer superior strength & uniformity.

ERW (electric resistance welded) pipes are designed by cold forming steel sheets into cylindrical shapes. The electric current is applied to generate heat through resistance after edges are met together. This heat fuses the edges together to form a weld without using any filler material. Modern high-frequency ERW techniques ensure a strong & smooth weld to use in medium-pressure applications.

Seamless pipes have slight thickness due to the rolling process, while ERW pipes generally maintain a more uniform thickness because they are made from flat steel strips.

Seamless pipes are ideal for applications that require high strength & pressure resistance. ERW pipes are a more cost-effective solution for standard uses. The right choice depends on your project performance needs & overall budget.

Why use seamless pipes instead of ERW pipes?

Seamless pipes feature a smooth finish with low surface roughness. They are used for applications that need precision & high performance. These pipes are manufactured by drawing solid billets into a tube shape. The overall strength of a seamless pipe matches with the strength of the base material to ensure uniformity & reliability under high pressure.

ERW pipes are made by welding steel sheets or coils along a seam. This material may have high strength & the welded seam is typically the weakest point, which can limit the pipe performance under demanding conditions. Because of this, seamless pipes are often preferred in industries where structural integrity and resistance to pressure are critical.

Why Choose Seamless Pipes for the Oil & Gas Industry?

Seamless pipes offer uniform strength throughout the pipe with no welded joints to reduce the risk of failure under high-pressure conditions. Their precise dimensions & smooth surface ensure secure connections with fittings. It is mainly used for leak-proof operations. ERW pipes may have slight variations in wall thickness & rougher edges to use for high-pressure applications. For critical applications like pipelines & drilling systems, seamless pipes provide the durability, consistency needed to maintain operational integrity to avoid cost.

How to identify Stainless Steel Seamless Pipe or ERW?

To identify whether a stainless steel pipe is seamless or ERW is easy. Just only check the stencil marking on the pipe. If you see ASTM A53 Type S then it’s a seamless pipe. If it is marked as Type E then it’s an ERW (electric resistance welded) pipe. This simple step ensures you select the right pipe for your needs. Seamless pipes are flawless and ERW pipes come with unique manufacturing processes to have high strength. Modern ERW pipes are now highly reliable & perfect for many industrial uses.

At Kalpataru Piping Solutions, we are a leading manufacturer and exporter of ERW stainless steel pipes. We offer a wide variety of pipes with different sizes and shapes designed with ISO and OHSAS-certified materials.

ERW Pipe Thickness Chart and Sizes

| DN |

PIPE OUT DIAMETER (OD) |

ERW PIPE THICKNESS CHART |

| | | | | | | | | | | | | | |

| A SERIES |

B SERIES |

SCH5S |

SCH10S |

SCH20S |

LG |

SCH20 |

SCH30 |

STD |

SCH40 |

SCH60 |

XS |

SCH80 |

SCH100 |

SCH120 |

SCH140 |

SCH180 | |

| 324050 |

42.448.360.3 |

384557 |

1.61.61.6 |

2.82.82.8 |

3.23.23.6 |

— |

–3.2 |

— |

— |

3.63.64.0 |

— |

— |

5.05.05.6 |

— |

— |

— |

6.37.18.8 |

| 658090 |

76.188.9101.6 |

7689- |

2.02.02.0 |

3.03.03.0 |

3.64.04.0 |

— |

4.54.54.5 |

— |

— |

5.05.65.6 |

— |

— |

7.18.08.0 |

— |

— |

— |

10.011.012.5 |

| 100125150 |

114.3139.7168.3 |

108133159 |

2.02.92.9 |

3.03.43.4 |

4.05.05.0 |

— |

5.05.05.6 |

— |

— |

5.96.37.1 |

— |

— |

8.810.011.0 |

— |

11.012.514.2 |

— |

14.216.017.5 |

| 200250300 |

219.1273.0323.9 |

219273325 |

2.93.64.0 |

4.04.04.5 |

6.36.36.3 |

— |

6.36.36.3 |

7.18.08.8 |

— |

8.08.810.0 |

10.012.514.2 |

— |

12.516.017.5 |

16.017.522.2 |

17.522.225.0 |

20.025.028.0 |

22.228.032.0 |

| 350400450500550600 |

355.6406.4457.0508.0559610 |

377426478529-630 |

4.04.04.05.05.05.6 |

5.05.05.05.65.66.3 |

— |

8.08.08.08.08.08.0 |

8.08.08.010.0– |

10.010.011.012.5– |

10.010.010.010.010.010.0 |

11.012.514.216.0-17.5 |

16.017.520.020.0– |

13.013.013.013.013.013.0 |

20.022.225.028.030.032.0 |

25.828.530.032.0– |

28.030.036.040.0– |

32.036.040.045.0– |

36.040.045.050.0– |

ASME B36.19 seamless pipe sizes

| NPS(DN) |

ID |

ODIN(MM) |

WTIN(MM) |

WEIGHTLB/FT(KG/M) |

| 1/8(6) |

5S |

0.405(10.3) |

*1 |

… |

| 1/8(6) |

10S |

0.405(10.3) |

0.049(1.24)*1 |

0.19(0.28) |

| 1/8(6) |

40S |

0.405(10.3) |

0.068(1.73) |

0.24(0.37) |

| 1/8(6) |

80S |

0.405(10.3) |

0.095(2.41) |

0.31(0.47) |

| 1/4(8) |

5S |

0.54(13.7) |

*1 |

… |

| 1/4(8) |

10S |

0.54(13.7) |

0.065(1.65)*1 |

0.33(0.49) |

| 1/4(8) |

40S |

0.54(13.7) |

0.088(2.24) |

0.43(0.63) |

| 1/4(8) |

80S |

0.54(13.7) |

0.119(3.02) |

0.54(0.8) |

| 3/8(10) |

5S |

0.675(17.1) |

*1 |

… |

| 3/8(10) |

10S |

0.675(17.1) |

0.065(1.65)*1 |

0.42(0.63) |

| 3/8(10) |

40S |

0.675(17.1) |

0.091(2.31) |

0.57(0.84) |

| 3/8(10) |

80S |

0.675(17.1) |

0.126(3.2) |

0.74(1.1) |

| 1/2(15) |

5S |

0.84(21.3) |

0.065(1.65)*1 |

0.54(0.8) |

| 1/2(15) |

10S |

0.84(21.3) |

0.083(2.11)*1 |

0.67(1.0) |

| 1/2(15) |

40S |

0.84(21.3) |

0.109(2.77) |

0.85(1.27) |

| 1/2(15) |

80S |

0.84(21.3) |

0.147(3.73) |

1.09(1.62) |

| 3/4(20) |

5S |

1.05(26.7) |

0.065(1.65)*1 |

0.68(1.02) |

| 3/4(20) |

10S |

1.05(26.7) |

0.083(2.11)*1 |

0.86(1.28) |

| 3/4(20) |

40S |

1.05(26.7) |

0.113(2.87) |

1.13(1.69) |

| 3/4(20) |

80S |

1.05(26.7) |

0.154(3.91) |

1.48(2.2) |

| 1(25) |

5S |

1.315(33.4) |

0.065(1.65)*1 |

0.87(1.29) |

| 1(25) |

10S |

1.315(33.4) |

0.109(2.77)*1 |

1.41(2.09) |

| 1(25) |

40S |

1.315(33.4) |

0.133(3.38) |

1.68(2.5) |

| 1(25) |

80S |

1.315(33.4) |

0.179(4.55) |

2.17(3.24) |

| 1¼(32) |

5S |

1.66(42.2) |

0.065(1.65)*1 |

1.11(1.65) |

| 1¼(32) |

10S |

1.66(42.2) |

0.109(2.77)*1 |

1.81(2.69) |

| 1¼(32) |

40S |

1.66(42.2) |

0.14(3.56) |

2.27(3.39) |

| 1¼(32) |

80S |

1.66(42.2) |

0.191(4.85) |

3.0(4.47) |

| 1½(40) |

5S |

1.9(48.3) |

0.065(1.65)*1 |

1.28(1.9) |

| 1½(40) |

10S |

1.9(48.3) |

0.109(2.77)*1 |

2.09(3.11) |

| 1½(40) |

40S |

1.9(48.3) |

0.145(3.68) |

2.72(4.05) |

| 1½(40) |

80S |

1.9(48.3) |

0.2(5.08) |

3.63(5.41) |

| 2(50) |

5S |

2.375(60.3) |

0.065(1.65)*1 |

1.61(2.39) |

| 2(50) |

10S |

2.375(60.3) |

0.109(2.77)*1 |

2.64(3.93) |

| 2(50) |

40S |

2.375(60.3) |

0.154(3.91) |

3.66(5.44) |

| 2(50) |

80S |

2.375(60.3) |

0.218(5.54) |

5.03(7.48) |

| 2½(65) |

5S |

2.875(73) |

0.083(2.11)*1 |

2.48(3.69) |

| 2½(65) |

10S |

2.875(73) |

0.12(3.05)*1 |

3.53(5.26) |

| 2½(65) |

40S |

2.875(73) |

0.203(5.16) |

5.8(8.63) |

| 2½(65) |

80S |

2.875(73) |

0.276(7.01) |

7.67(11.41) |

| 3(80) |

5S |

3.5(88.9) |

0.083(2.11)*1 |

3.03(4.52) |

| 3(80) |

10S |

3.5(88.9) |

0.12(3.05)*1 |

4.34(6.46) |

| 3(80) |

40S |

3.5(88.9) |

0.216(5.49) |

7.58(11.29) |

| 3(80) |

80S |

3.5(88.9) |

0.3(7.62) |

10.26(15.27) |

| 3½(90) |

5S |

4.0(101.6) |

0.083(2.11)*1 |

3.48(5.18) |

| 3½(90) |

10S |

4.0(101.6) |

0.12(3.05)*1 |

4.98(7.41) |

| 3½(90) |

40S |

4.0(101.6) |

0.226(5.74) |

9.12(13.57) |

| 3½(90) |

80S |

4.0(101.6) |

0.318(8.08) |

12.52(18.64) |

| 4(100) |

5S |

4.5(114.3) |

0.083(2.11)*1 |

3.92(5.84) |

| 4(100) |

10S |

4.5(114.3) |

0.12(3.05)*1 |

5.62(8.37) |

| 4(100) |

40S |

4.5(114.3) |

0.237(6.02) |

10.8(16.08) |

| 4(100) |

80S |

4.5(114.3) |

0.337(8.56) |

15.0(22.32) |

| 5(125) |

5S |

5.563(141.3) |

0.109(2.77)*1 |

6.36(9.46) |

| 5(125) |

10S |

5.563(141.3) |

0.134(3.4)*1 |

7.78(11.56) |

| 5(125) |

40S |

5.563(141.3) |

0.258(6.55) |

14.63(21.77) |

| 5(125) |

80S |

5.563(141.3) |

0.375(9.53) |

20.8(30.97) |

| 6(150) |

5S |

6.625(168.3) |

0.109(2.77)*1 |

7.59(11.31) |

| 6(150) |

10S |

6.625(168.3) |

0.134(3.4)*1 |

9.3(13.83) |

| 6(150) |

40S |

6.625(168.3) |

0.28(7.11) |

18.99(28.26) |

| 6(150) |

80S |

6.625(168.3) |

0.432(10.97) |

28.6(42.56) |

| 8(200) |

5S |

8.625(219.1) |

0.109(2.77)*1 |

9.92(14.78) |

| 8(200) |

10S |

8.625(219.1) |

0.148(3.76)*1 |

13.41(19.97) |

| 8(200) |

40S |

8.625(219.1) |

0.322(8.18) |

28.58(42.55) |

| 8(200) |

80S |

8.625(219.1) |

0.5(12.7) |

43.43(64.64) |

| 10(250) |

5S |

10.75(273) |

0.134(3.4)*1 |

15.21(22.61) |

| 10(250) |

10S |

10.75(273) |

0.165(4.19)*1 |

18.67(27.78) |

| 10(250) |

40S |

10.75(273) |

0.365(9.27) |

40.52(60.29) |

| 10(250) |

80S |

10.75(273) |

0.5(12.7)*2 |

54.79(81.53) |

| 12(300) |

5S |

12.75(323.8) |

0.156(3.96)*1 |

21.0(31.24) |

| 12(300) |

10S |

12.75(323.8) |

0.18(4.57)*1 |

24.19(35.98) |

| 12(300) |

40S |

12.75(323.8) |

0.375(9.53)*2 |

49.61(73.86) |

| 12(300) |

80S |

12.75(323.8) |

0.5(12.7)*2 |

65.48(97.44) |

| 14(350) |

5S |

14.0(355.6) |

0.156(3.96)*1 |

23.09(34.34) |

| 14(350) |

10S |

14.0(355.6) |

0.188(4.78)Notes(1),(2) |

27.76(41.36) |

| 14(350) |

40S |

14.0(355.6) |

0.375(9.53)*2 |

54.62(81.33) |

| 14(350) |

80S |

14.0(355.6) |

0.5(12.7)*2 |

72.16(107.4) |

| 16(400) |

5S |

16.0(406.4) |

0.165(4.19)*1 |

27.93(41.56) |

| 16(400) |

10S |

16.0(406.4) |

0.188(4.78)Notes(1),(2) |

31.78(47.34) |

| 16(400) |

40S |

16.0(406.4) |

0.375(9.53)*2 |

62.64(93.27) |

| 16(400) |

80S |

16.0(406.4) |

0.5(12.7)*2 |

82.85(123.31) |

| 18(450) |

5S |

18.0(457) |

0.165(4.19)*1 |

31.46(46.79) |

| 18(450) |

10S |

18.0(457) |

0.188(4.78)Notes(1),(2) |

35.8(53.31) |

| 18(450) |

40S |

18.0(457) |

0.375(9.53)*2 |

70.65(…) |

| 18(450) |

80S |

18.0(457) |

0.5(12.7)*2 |

93.54(…) |

| 20(500) |

5S |

20.0(508) |

0.188(4.78)*1 |

39.82(59.32) |

| 20(500) |

10S |

20.0(508) |

0.218(5.54)Notes(1),(2) |

46.1(68.65) |

| 20(500) |

40S |

20.0(508) |

0.375(9.53)*2 |

78.67(117.15) |

| 20(500) |

80S |

20.0(508) |

0.5(12.7)*2 |

104.23(155.13) |

| 22(550) |

5S |

22.0(559) |

0.188(4.78)*1 |

43.84(65.33) |

| 22(550) |

10S |

22.0(559) |

0.218(5.54)Notes(1),(2) |

50.76(75.62) |

| 22(550) |

40S |

22.0(559) |

… |

… |

| 22(550) |

80S |

22.0(559) |

… |

… |

| 24(600) |

5S |

24.0(610) |

0.218(5.54)*1 |

55.42(82.58) |

| 24(600) |

10S |

24.0(610) |

0.25(6.35)*1 |

63.47(94.53) |

| 24(600) |

40S |

24.0(610) |

0.375(9.53)*2 |

94.71(141.12) |

| 24(600) |

80S |

24.0(610) |

0.5(12.7)*2 |

125.61(187.07) |

| 30(750) |

5S |

30.0(762) |

0.25(6.35)*1 |

79.51(118.34) |

| 30(750) |

10S |

30.0(762) |

0.312(7.92)*1 |

99.02(147.29) |

| 30(750) |

40S |

30.0(762) |

… |

… |

| 30(750) |

80S |

30.0(762) |

… |

… |

ERW Pipe vs Seamless Cost

The cost difference between seamless & ERW pipes arises from their manufacturing processes. Seamless pipes with no weld seam are perfect for high-pressure applications due to their consistent strength & uniform structure. ERW pipes are more cost-effective for less pressure conditions because they are easier to produce & use less material. Seamless pipes have higher cost because they are used in high-pressure & temperature applications. ERW pipes are more affordable to use in applications where extreme pressure resistance is not required.

Frequently Asked Questions on ERW Pipe vs Seamless Pipe

Which is better, seamless or ERW pipe?

Seamless pipes are typically considered better for high-pressure applications. Since these pipes don’t have a weld seam to have a uniform structure with no weak points to provide superior strength & pressure resistance. ERW pipes have a welded seam to use in high corrosive environments.

What is the price difference between ERW and seamless pipes?

Seamless pipes generally cost around 30% more than ERW pipes. The price difference increases for larger diameter pipes. ERW pipes are made by welding steel strips together to make it more affordable as seamless pipes which have more complex manufacturing processes.

When to use a seamless pipe?

Seamless pipes are used in high-pressure applications as they have high strength & resistance to corrosion to transfer fluids such as natural gas & air in industries like oil and gas, power generation & pharma.

What is the ERW pipe used for?

ERW pipes are commonly used in construction, automotive & agricultural applications. ERW pipes are used for medium-pressure applications.

by kalpataru | Aug 10, 2022 | Blog

Introduction

INCONEL (nickel-chromium-iron) alloy 600 Round bars (UNS N06600/W.Nr. 2.4816) is a technological material that is heat and corrosion resistant. Excellent mechanical properties of the alloy combine high strength with ease of production.

An Inconel fastener, often known as a fastening, is a piece of hardware that mechanically connects or fastens two or more things. Inconel round bars are often used to create non-permanent connections, which may be disassembled and rebuilt without causing damage to the connecting components. For their weight, Inconel 600 round bars are very robust. Round Inconel 600 bars have a melting point of 1413 degrees Celsius and a density of 8.47 grammes per centimetre (2580 degrees Fahrenheit).

- Cylindrical Inconel 600 bar characteristics

In Inconel 600 round bars, you can find nickel 72.0, chromium 14.0–17.0, iron 6.00–10.00, carbon 0.15, manganese 1.00, sulphur 0.015, silicon 0.50, and copper 0.50. It also exhibits tensile strengths of 95,000 Psi and 655 MPa as well as yield strengths of 45,000 Psi and 310 MPa.

- Round Inconel 600 Bars’ features

Inconel 600 round bars were extremely powerful and have great corrosion resistance. The presence of sulfuric and hydrochloric acids is advantageous for this material. Amazing Mechanical Capabilities at High Temperatures The resistance to stress corrosion cracking is good.

- Application of Round Inconel 600 Bars

Round Inconel 600 bars are applied throughout a wide range of industries. They execute their jobs in an environment where they must be able to handle the extreme pressure and do well under stress. Some of the industries that use these round bars are trains, petrochemicals, pulp and paper, oil and gas, and pulp and paper. Based on nickel, Inconel 600 is an alloy. Round bars have been utilised in a wide variety of applications, including the heaters, stills, bubble towers, and condensers used in the processing of fatty acids; the same evaporator tubes, tube sheets, and flaking trays used in the production of sodium sulphide; and the machinery used to handle biogenic acid in the manufacturing of paper pulp.

Read More :

Monel or Inconel? Which Alloy Is Best for You? : Inconel is a nickel-chromium alloy with iron and molybdenum that comprises 50-72 per cent nickel and 14-21 per cent chromium.

Inconel vs Hastelloy: Inconel is a corrosion-resistant, oxidation-resistant alloy that performs well in high-temperature, high-pressure conditions, Hastelloy is a nickel-molybdenum alloy with a high melting point. It is available in a variety of grades, the bulk of which are nickel chromium molybdenum alloys.

by kalpataru | Jul 5, 2022 | Blog

In order to comply with the government’s COP26 commitments, the Ministry of Steel has requested the stakeholders to develop a time-bound action plan to cut emissions in the steel industry. A government report states that whereas the iron and steel sector generally generates 8 percent of the world’s yearly carbon dioxide (CO2) emissions, it makes up 12 percent of the total CO2 emissions in India. The COP26 climate change summit’s accords require the Indian steel industry to considerably decrease its emissions.

Prime Minister Narendra Modi said at the COP26 global climate summit in November 2021 that India will reach its goal of having net zero emissions by the year 2070.

In a recent meeting, Steel Minister Ram Chandra Prasad Singh “urged the stakeholders to develop a time-bound action plan and work together to reduce emissions from the steel industry in line with the commitments made by the Government at COP26.”

In addition, the current situation, the next steps for promoting the switch to green steel, the various strategies and technologies that the steel industry can use to produce green steel, and the levels of technological readiness were discussed.

At the meeting, participants also discussed using green hydrogen to produce iron and carbon capture, utilization, and storage (CCUS) technologies to reduce emissions.

“Reputable academic institutions, research laboratories, and steel companies have submitted joint collaborative R&D project proposals for the development of new alternative processes and technologies to address the sector’s challenges…(and) The ministry will provide financial assistance under the R&D Scheme for the Financial Year 2022-23.

Read More :

How does India intend to decarbonize the steel sector? : As one of the most significant materials for engineering and construction, steel is used in many aspects of our life. Steel is one of the most important components of modern society.

ISMC (Indian Standard Medium Channel) Weight chart: Mild steel channels are U-shaped steel structures that can be described by the size and thickness of their sides. Mild steel channels have two parts: the flange at the bottom and the web at the top. The flange is the horizontal part at the bottom, and the web is the vertical part at the top.

by kalpataru | Jul 5, 2022 | Blog

Introduction

As one of the most significant materials for engineering and construction, steel is used in many aspects of our life. Steel is one of the most important components of modern society. The steel sector is currently one of the three industries that produce the most carbon dioxide. Therefore, steel businesses across the globe face an increasing decarbonization challenge to decrease their environmental and economic carbon footprint.

Currently, India is the world’s second-largest steel producer. India plans to treble its steel production by 2030, according to its National Steel Policy from 2017. Multiple analyses indicate that by 2050, the amount of steel utilized could increase by a factor of several. In order to meet expanding domestic and international demand, India’s steel production will significantly increase during the next few decades.

The majority of carbon emissions from steel factories may be readily extracted from their process- and off-gas. Thus, they are suitable candidates for carbon capture. This collected carbon can be sold back into the market, allowing manufacturers to maintain low costs while making significant progress toward global net-zero targets, or it can be stored for the long term. Captured CO2 from steel mills can be used as a raw material. For instance, it can be used with water and steel slag to produce construction materials. Tata Steel will establish India’s first carbon capture plant for blast furnaces in 2021. This facility will catch and reuse 5 tonnes of CO2 per day.

Use of Syngas

Syngas is typically produced by converting coal to gas, and their primary usage is to generate power. Using the syngas may be more efficient than directly burning the original fuel. Syngas can be utilized to produce an effective reducing gas that can be used to produce DRI. This method is utilized by the JSPL steel factory located in Angul, Odisha.

Use of Green Hydrogen

Hydrogen-based green steel production can make India less reliant on coal imports and more self-reliant. Investing in blast furnaces now will ensure that imported coal will be required until at least the middle of the century, if not longer. By replacing coal with hydrogen produced from renewable energy (dubbed “Green Hydrogen”), the majority of carbon could be eliminated from the industrial sector. If coal were replaced with hydrogen at the current price, steel prices would increase. This disparity is anticipated to narrow over the next few years, and it may perhaps disappear by 2030. On the one hand, carbon and carbon-emission pricing could increase the cost of utilizing coal, while on the other hand, the costs of renewable electricity, hydrogen, and steel production using hydrogen-based processes will decline. With Reliance and Adani entering the green hydrogen industry, India might become a leader in the production of green steel.

Use of Solar Power

To achieve the temperatures required for conventional steel production, a great deal of fossil fuel energy is employed. In India’s major steel-producing states, such as Odisha and Chhattisgarh, where there is abundant sunlight, solar energy can replace fossil fuels. Currently, solar electricity is the cheapest form of energy in India.

Through Adopting Energy Efficiency Measures

The steel business is subject to global competition, therefore producing steel using less energy can be a competitive benefit in addition to reducing energy use. Process industries can save expenses by utilizing energy more efficiently, and energy-saving solutions can be advantageous for a company. Utilizing more efficient technology, recovering energy throughout the manufacturing process, enhancing the efficiency of energy conversion, and ensuring that operational methods are as efficient as possible are ways to improve energy efficiency.

Through Recycling Steel Scrap

Reusing steel reduces the amount of ore that must be extracted. Additionally, it conserves energy and reduces greenhouse gas emissions. Steel can be recycled as often as necessary without losing its useful properties. This transforms a resource that cannot be utilized repeatedly into one that can. Recycling steel uses around half the energy required to produce new steel, resulting in fewer carbon emissions.

All of the above must be included in India’s carbon emission reduction plan. The PHD Chamber of Commerce and Industry is committed to assisting stakeholders and the Central and State Governments in their efforts to decarbonize business and industry. Minerals & Metals Committee and Power, Renewable & Alternate Energy Committee of PHDCCI have been working to prioritize policy reforms and promote sustainable development goals in order to achieve the ambitious decarbonization & RE target and assist the government in constructing an Atmanirbhar & Green Bharat.

Read More :

ISMC (Indian Standard Medium Channel) Weight chart: Mild steel channels are U-shaped steel structures that can be described by the size and thickness of their sides. Mild steel channels have two parts: the flange at the bottom and the web at the top. The flange is the horizontal part at the bottom, and the web is the vertical part at the top.

Production-linked incentive: Steel PLI application deadline is likely to be extended, again: As a result, instead of 2023-24 as proposed in the scheme guideline announced in October, the release of incentives under the scheme would begin in 2024-25.